1⁄48PC-6 Amphibian

3

Comments

history

First flown in 1959, the Pilatus Porter has been a quiet success for the Swiss aircraft industry. The first Turbo Porter was produced in 1961. The Porter has primarily been used by military services, but as they became surplus during the 1990s, several have been sold out of the service into civilian hands.Floatplane conversions had been attempted during the Porter's military service but these did not suit the Porter's military taskings. Civilian conversions have been more successful.

the kit

I reviewed this kit on Aeroscale earlier this year. It's a good kit but not one which will fall together.building

Step 1:The cockpit control panel is made up of 4 parts and a decal for the instruments. I used a photo from the Pilatus web page to model the current layout of the instrument panel.

Step 2/3/4:

Trim off front door hinges to get frames to fit door openings and glue in all transparent parts.

Step 5/6:

Layout and drill all holes as marked.

Step 9/10 :

Assemble the cockpit interior walls and paint the interior Aircraft Grey.

Step 11:

Elevators are assembled at this step. Ejector pin marks needed to be removed before 3B & 9B were glued together.

Step 12 :

In my in box review i missed the very fine location points which must be be drilled in order for the seats to be assembled! Drill 12 X 1mm holes for the seat frames.

Step 13/14/15/17 :

The frames for the seats are very fine moldings and it would have been better if these had been PE parts. A lot of time was spent building the seats and if you leave the doors open it would have been worthwhile but once the doors are closed nothing will be seen. If I was to build this step again I would cut styrene blocks to the correct height and glue them to the floor the same as the pilots' seats.

Step 16/18 :

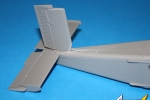

Port and Starboard flaps and wing tips are assembled in this step. Two parts (13C) should be glued on but only one is supplied. The clear lamp covers were left off until after painting.

Step 20 :

Cockpit floor is glued into fuselage after ejector pin marks have been removed from cockpit walls.

The rudder and elevator assemblies are glued to fuselage

The sliding door tracks and doors are glued to fuselage. There is a gap around the doors that will need to be filled with a thin styrene strip ( this seal frame can be seen in photos of the model).

Step 21:

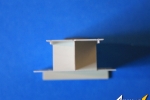

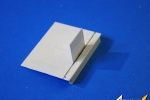

Fuselage underside panel is glued on and then the float frame mounts are glued on using the float frames as a guide for location. Wings and struts are next to be glued.

Step 22:

Propeller blades are assembled to the hub with the pitch setting at the neutral position (Turbine stopped).

Step 24:

Nose is assembled. The locating pin sink holes will need to be filled. Roden moulded a mismatch between the nose halves. The pictures clearly show that one side is considerably thicker than the other. This needs to be addressed before the halves can be glued together. I left off the exhausts and prop assembly until after painting the model.

Step 25:

Nose is glued onto fuselage along with antennas. The marker light is left off until after painting.

The dorsal fin halves 1L/2L are glued together but will not fit on the tail as shown. I had to cut back the tail until it fit tightly.

Step 26:

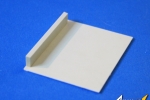

Float wheel frames 4K/6K are assembled along with the wheels which are left off until after painting.

Step 27/28 :

Float halves are cleaned up of flash and glued together then rudders and nose wheels are glued on. I glued a 1 oz(28g) fishing weight into the nose of each float to keep the model from tipping back onto its tail.

Step 28 :

I assembled the float struts using a jig I made with styrene sheet drilled to the spacing copied from the aircraft fuselage. Once fuselage and floats had joins had dried it was time for the paint shop.

Painting:

All clear parts were masked with Micro Mask. The paint guide does not show the black anti-glare panel. Don't forget to apply it.

I used automotive spray paints for this build. First I sprayed the and model with grey primer and allowed it to cure for 48hrs. Next, three top coats of bright white went on with 24 hours drying time between each coat. I finished the painting with 2 coats of automotive high gloss clear once more allowing 24 hours drying time between coats.

The propeller blade backs were painted a very dark grey and the fronts of the blades had white stripes painted on (the paint guide shows stripes on both sides of prop which is not correct).

Decals:

There are few decals for this kit. I cut the fuselage stripes into three parts per side to make them easier to handle. I found that the decals will stretch easily and when they make contact with the kit. They tend to stick down right away even on the high gloss surface!

The decals were allowed to dry for 24hrs and then a top coat of gloss clear was sprayed onto seal everything. I found that these decals are a vast improvement over early Roden efforts.

conclusion

I Love these floatplanes! The decals worked well and are much improved over Roden's earlier decal standard. The seating assembly is very tedious and the sliding doors need a sub frame added to fill the gap. This kit provides only one decal option. Despite these little negatives, I enjoyed building it. I recommend this kit to all but novice builders. Tragically, the aircraft portrayed in this kit recently crashed in Costa Rica. I wish to dedicate this build to the young lives lost in this horrible accident.Comments

Thanks for sharing. I usually stay with 1/72, but this one is sure tempting.

MAY 11, 2013 - 05:59 AM

Well done Richard. A sweet looking model.

What's with all the drilling and hand fitting of parts? Not a beginners project.

I must be spoiled. Lol

Winter

MAY 11, 2013 - 02:01 PM

Copyright ©2021 by Richard Tonge. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2013-05-11 12:46:16. Unique Reads: 8446