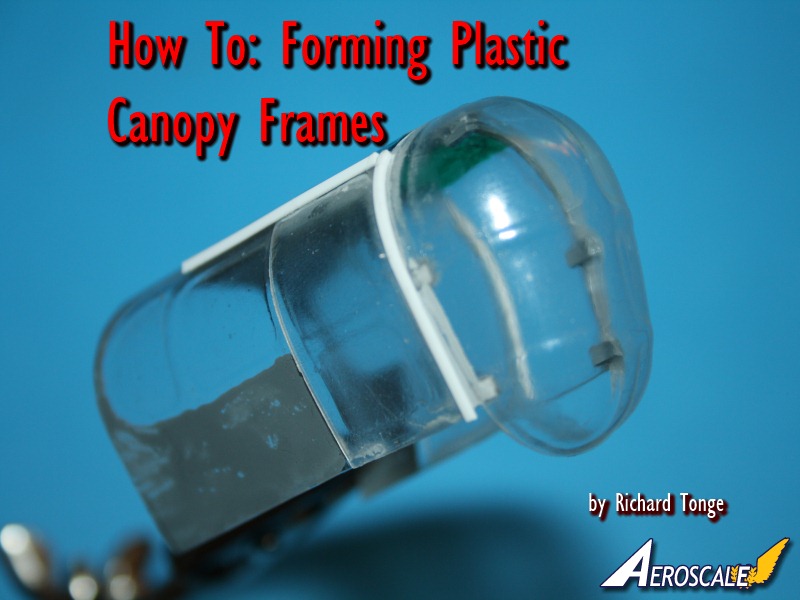

1⁄1How To: Forming plastic canopy frames

5

Comments

the problem

I am building a resin S-51 helicopter model which has a large vac-formed greenhouse canopy. I needed to bend some .030 X .030 plastic strip to replicate the exterior door framework which was not included on the kit canopy. The problem I was presented with was how to bend it when the canopy is much thinner and weaker than the plastic strip. Even heat forming would melt the canopy before the strip bent properly.the solution

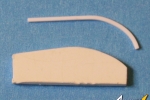

I solved this problem by making a template to bend the strip over without damaging the canopy.Step 1: I used my contour gauge ( available at most hardware stores) to copy the canopy profile.

Step 2: Transfer profile to a sheet of 1/8th styrene using a marker.

Step 3: Score along the inside of the marker line and snap off the profile.

Step 4: Sand the profile edge to shape.

The kit instructions called for the .030" sq styrene to be cut to 1" long, I prefer to cut to length after forming to shape.

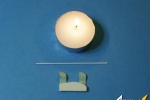

Step 5 : Using a tea light candle, heat the styrene ( caution: do not overheat). When the styrene goes soft place it on profile jig and tape until it cools (caution: when heating the styrene, do not pull or twist the part).

Step 6 : Trim the part to length.

Step 7 : Attach your newly made parts to your canopy.

equipment needed

Contour gauge;Tea light, small candle or other heat source;

1/8th inch thick styrene sheet stock;

Masking Tape;

.030" X .030" square strip;

Sanding supplies;

Knife.

conclusion

This technique is useful for making any kind of bent strips which must exactly fit your model, whether inside or outside. You can add extra detail with confidence that it will fit where you want it to.Comments

Nice one Richard , I used a similar method for forming parts of the frame on my SSW build .

Terri

JAN 04, 2014 - 06:25 AM

Hello...

Yes, it's a nice technic...! I'll take notes about it...

Thanks

Diego

JAN 05, 2014 - 05:22 AM

Richard, nicely done. Your method is much better then my glue and tape method.

Joel

JAN 06, 2014 - 06:38 AM

Joel , give it try . In stead of using a candle , tape the part to mould and dip it in hot water for a few seconds ...and let cool . Remove tape and part and walla !

Terri

JAN 06, 2014 - 03:44 PM

Copyright ©2021 by Richard Tonge. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2014-01-04 05:08:28. Unique Reads: 8713