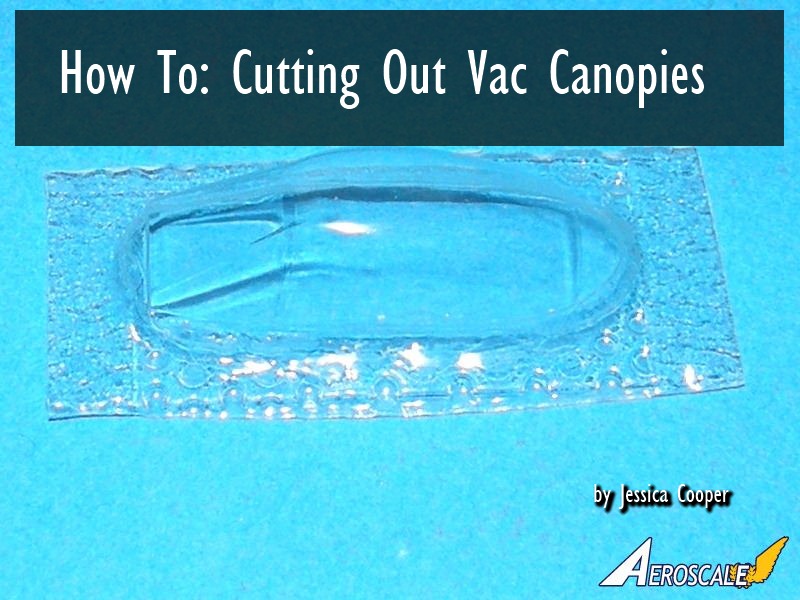

How To: Cutting out vac canopies

11

Comments

the dreaded vac canopy

Many modellers are wary of using vacuformed canopies due to their fragility. It is so very easy to slip up and ruin your canopy (and the chances seemingly tend to increase when there's only one in the kit). As a result, many people stay away from vac canopies. Doing a vac canopy calls for a bit of care and patience, but not nearly as much as people may fear.tools and equipment needed

You will need the following:- 1. A fine point sharpie marker

- 2. A razor knife with a brand new blade

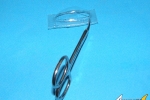

- 3. A pair of fine tip cuticle scissors

- 4. Tweezers

- 5. A coarse sanding stick

- 6. Epoxy putty

getting to work

First, mark around the edges of the canopy with your marker.Run the tip of your blade along the marked line with just enough pressure so it scores the plastic, but doesn't cut through. Take this step slowly and carefully. Two or three shallow passes are better than one heavy one. Cut in stages instead of making one complete circuit around the canopy.

Then cut the scrap backing plastic with the cuticle scissors until the cuts go just to the edge of the canopy but not into the frame. Be very careful with this step. In the case of this Venom canopy, I've used the Sharpie marker to illustrate where the cuts should go. In highly curved areas make the cuts closer together.

The scored line along the canopy base makes the plastic weaker there. Now take one of the cut segments and carefully bend it down and towards the centre of the canopy. You'll have to bend it back and forth a few times before it snaps off but eventually it will snap off.

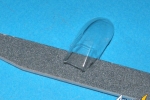

Repeat this step until you've snapped off all of the waste plastic from your canopy. Avoid the temptation to rush! Now your canopy is free of its base, but the edges are quite rough. You'll need to carefully sand the edges of the canopy using a sanding stick until it's all smoothed off.

The sanding stick may be used along the edges in order to properly shape the canopy to fit the model. Work slowly and carefully. Remember that it's easier to remove material than add it. If you must add material, add it to the fuselage rather than to the canopy. A nice trick here is to roll a rope of epoxy putty around the cockpit opening and squish the canopy into it while it's soft (Use a little water to make sure the putty won't stick to the canopy). Sculpt the putty to shape then remove the canopy. Once the putty hardens you can paint it, then glue the canopy into place.

Now you have your canopy ready to glue (you may wish to repeat the score and bend steps to open it if it was moulded shut and you want to display it open). Since vac canopies are not made from styrene, regular model cement will not affect it. Glues of choice are epoxy, superglue (non-fogging is best) Krystal Kleer or white glue (PVA. White glue is very good for filling small gaps without damaging the canopy or the model. Apply a blob, then smooth it into place with a wet fingertip). Once the canopy is glued in place, it will be fairly robust, but you should obviously avoid crushing it.

To mask, you can use thin strips of masking tape to outline the canopy panes and then fill in with other small pieces of tape. If Eduard or other manufacturers make pre-cut masks they may be used. Another way is to place a piece of masking tape on the canopy, trace the outline of the glazing on the tape with a pencil, remove it and cut to shape before placing the freshly-cut mask back on the canopy.

conclusion

Doing a vac canopy need not be as intimidating as it appears. Work slowly and carefully to achieve best results. I would put a vac canopy on at the same time I'd do an injection one. Usually the windscreen goes on before painting so the frames get the same paint as the fuselage. If I'm displaying the canopy open, I'll mask and paint it at the same time I do the fuselage but I'll install it last after decalling and weathering.Comments

Fill the canopy with Plaster of Paris it will support the canopy and stop any flexing that might cause cracks to form. If a knife blade cuts through the plastic it will cut into the plaster and not deflect. Same if you need to drill any holes for machine guns etc.

JAN 25, 2014 - 04:12 AM

That sounds like a good idea. I think you would have to use a release agent, though.

JAN 25, 2014 - 04:21 AM

You can also use silly putty or blue-tack to achieve the same re-enforcement under the canopy without the need to worry about getting it back out later. This is especially useful if you want to cut the canopy open.

JAN 25, 2014 - 05:22 AM

That sounds like a good idea. I think you would have to use a release agent, though.[/quote]

Never had any problem removing the plaster plug, it usually drops out very easily. You can file down the plaster afterwards and if you have one of those double moldings with a spare canopy back to back you can separate them by cutting through with a razor saw.

The problem with Silly Putty and Blutac is putting it in not taking it out. Some canopies are very thin and fragile and forcing in putty can cause cracks and/or white stress marks. Also it is not hard and when if you press hard with a knife or other tool the plastic can still flex and crack.

JAN 25, 2014 - 06:15 AM

Which is why I stress how important it is not to press hard. Multiple light scoring passes with a brand new blade are far preferable to one hard cut.

JAN 25, 2014 - 07:17 AM

Well no plaster or silly putty, just a new blade and a lot of patience ( and a sharpie) and I have successfully cut out my first vac canopy. And I only stabbed myself once( I guess I should add a bandaid to my list of tools)! But it worked fine and the blood washed right off!

Actually the method worked perfectly I stabbed myself because of my own clumsiness.

JAN 25, 2014 - 03:55 PM

Jessica

Thanks for putting the article together,

I'm not quite so frightened of Vac Form canopies now I know what to do.

Chris

JAN 26, 2014 - 07:23 PM

Thanks, Jessica. I enjoyed your article, especially the idea of using epoxy putty to form a bed for the canopy. Cheers

FEB 01, 2014 - 12:54 PM

Good article! I found it looking for tips prior to working with my first vac canopy. I ruined the canopy of a 1/48 JAS-39 Gripen by trying to "gently" polish it with a Dremel. Derp...

I would add the following observations:

- If you have the original canopy, it can be very useful as a form to provide strength to the vac while working with it. It will probably nest inside well.

- Use the sharpest scissors you can get your hands on. Cheap scissors are a no-go for this job.

- Removing the excess "base": Do test cuts. Nibble away at it until you can really tell how the plastic will react (does it crack easily).

- The importance of scoring the plastic cannot be understated. This will prevent cracks from "racing" into areas you don't want them to. Same principle as drilling a small hole in a car's windshield to stop a crack from spreading.

- If you use a razor saw, remember that it generates heat. Factor a tiny bit of melt into where you decide to make your cut. Don't get too close the the canopy's frame. Draw the saw towards you, don't try to move in both directions.

- Finally, go slow and have patience. If in doubt, don't cut, sand.

I took my time, worked methodically, and was pleasantly surprised with the results. I won't hesitate to use vac canopies in the future.

MAY 30, 2018 - 03:40 AM

Copyright ©2021 by Jessica Cooper. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2014-01-25 00:14:09. Unique Reads: 12334