1⁄48How to: Making Movable Landing Gear

5

Comments

Making Landing Gear Magic

The movable landing gears add another dimension to the appearance of a finished airplane model and I will try to do it with my current build – the new GR.9 Harrier from Eduard. It is still a work-in-progress build and it will take me quite some time to finalize it, but the landing gears are ready and they can be displayed up or down. In order to make them movable, I used magnets and hinges.(Photo 1)

You Will Need

- Several small powerful Neodynium magnets;

- Contour gauge;

- Superglue or Epoxy;

- Varying thicknesses of wire and metal rod;

- Scrap plastic sheet and sprue of various lengths.

Detailed Steps

It comes to miniature neodymium magnets that measure only 1 mm in thickness. They can be found in the specialized metallurgic stores and they vary from contact surface, to shape and size. This 1/48 scale Harrier will have to transform from a typical “parked” display to a complete “flying” display and there will be a third display in a moment of “VTOL”. For this, there are over a dozen magnets in total used in the model to make all that is require to move/turn/rotate in order to reach for the maximum realism in all these three different display settings. The landing gears received 4 small cylindrical magnets, each with a radius of 3 mm and just 1 mm thick, which help keep the doors of the landing gears always closed, but in the same time, the doors can open temporarily to permit lowering and retracting of the landing gears.(Photo 2, Photo 3)

Each of these small Neodymium magnets provides a force of attraction of 0.24 kg to iron surfaces and respectively it was enough to keep the gear bay doors closed.

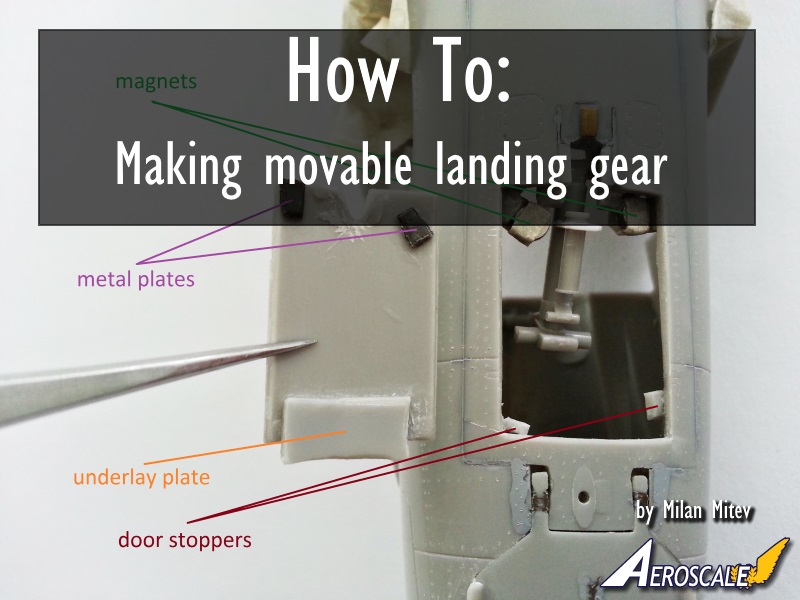

Let`s see an in-depth overview of their function. First, the magnets are attached to small plastic rods made out of stock plastic leftovers, via CA glue. For the main landing gears – two magnets were needed for each landing gear to get the doors close snugly, correctly and with enough force of attraction. The location of the magnets is from the fuselage side and is such that the pylons of the landing gears can freely move back and forth without being stopped by the magnets. At the opposite sides of the magnets are actually located the edges of the doors, while the doors themselves needed sawing and cutting from the underbelly fuselage part. Then, the one side of the door received a big “notch”, an underlay plate, which acts as a pivot point and is overlapped by the edge of the fuselage. Thus, one side of a door stays exactly on its place and flush with the fuselage thanks to this modification, while the other side of the door is held on place by the force of a magnet. From the opposite sides of the magnets – I glued two small metal plates with CA glue, which make a direct contact with the neodymium magnets. This gives an imaginary force in that area of nearly 0.5 kg. The doors for the main landing gears always stay closed in all the different display modes, so the doors of each main landing gear are glued together as one big piece, and respectively moved at once. Let`s see the “doors” closing setup for the rear main wheel bay:

(Photo 4, Photo 5, Photo 6, Photo 7)

How the landing gears are lowered and retracted? This journey started by tracing the proper contours of the space needed inside the fuselage so the landing gears can retract impeccably. For the rear landing gear – it was easy, but for the nose landing gears – a lot of modifications on the cockpit tub were needed. Here are a couple of moments from the tracing process:

(Photo 8, Photo 9)

In order to make them movable, I used simple hinge mechanisms with metal rods, which indeed are the stronger types of wires that I usually use for wiring, plumbing and scratchbuilding. The rods enter through small long holes on a separate part, which respectively is glued firmly to the landing gear pylons. The rods are glued to the fuselage. A lot of trials, test fits, and modifications of the plastic material are required to get the impeccable movement, i.e. the little bay door behind the nose landing gear is glued permanently to the pylon and moves along with the pylon. But in the end – the motion of the landing gears became just about real and the benefits are unparalleled.

(Photo 10, Photo 11)

Improvement and painting. The painting of the landing gear was easy and quick, because they are white and the airframe that I`m making has almost perfectly clean landing gears, but upon painting I added a few wires and other elements to the landing gears. I used thin wires, of which only the white ones are glued prior to the painting. I painted other wires in black separately and put them off aside to dry good. In the meantime, the landing gears received their main colors – Tamiya metalizer for the oleos, Revell white acrylic for the pylons and a mixture of white/black acrylic coats for the tires. The dry painted parts were protected with a thin coat of Aqua Gloss lacquer and the black wires were glued. Then, the parts received a delicate weathering with Tamiya smoke X-19 and Marabu black by using mostly pin-washing effects. A few small details were picked out with contrasting red, black and rusty paint, some light overall buffing with pigments, a couple of drybrushed scratches with oil paints, and the movable landing gears for the Harrier are ready.

(Photo 12, Photo 13, Photo 14)

Of course, they will be lowered only when the Harrier is displayed on the ground or in a VTOL mode. The small underwing landing gears required a completely different approach so I prefer to leave them as a surprise during the display of the finished model. Thanks.

Comments

Very nice idea. those magnets are super. I hoe you continue this article because I really wonder how this w

ill look when finished.

MAR 28, 2017 - 12:28 AM

10x! I finished it a few months ago - here is the full build video - LINK Enjoy!

MAR 28, 2017 - 03:22 PM

whats the name of the magnets you've used? i'm thinking about getting them for detachable weapons.

your model is amazing.

MAR 30, 2017 - 12:51 AM

Hi and thanks too. They are neodymium magnets and Pramiz is the name of the company where i found them.

MAR 31, 2017 - 04:53 PM

Copyright ©2021 by Milan Mitev. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2017-03-26 16:44:37. Unique Reads: 10640