That Monty Python quote couldn't be more fitting here, as I can't remember when I last built a jet, let alone a modern one. Must have been several years since I even worked on a jet.

But here we go again, back to the 'future'.

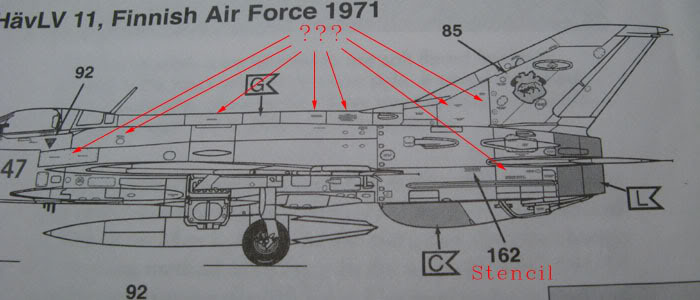

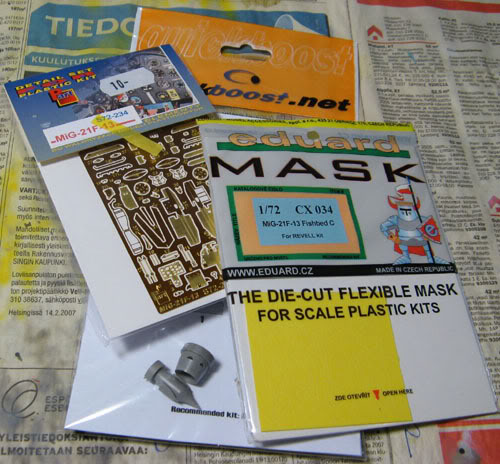

As my entry to the Mark Sharpe memorial campaign, I'll be building Revell's new (well, it's a couple of years old now) Mig-21F-13 in 1:72 scale.

I couldn't resist adding some aftermarket parts, I got a PE set by Part and Quickboost's nose ring and exhaust cone.

It's been in progress for about two weeks now, here's what I've done so far.

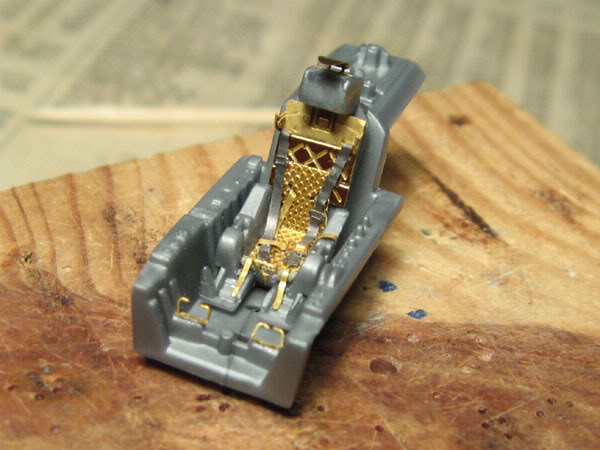

The cockpit tub didn't get much PE, just the straps to the rudder pedals. The ejection seat has some of the parts in place and is being dryfitted to the tub. The locator hole for the seat was enlarged a bit to allow the seat to sit snuggly without clamping when adding the seat later in the build.

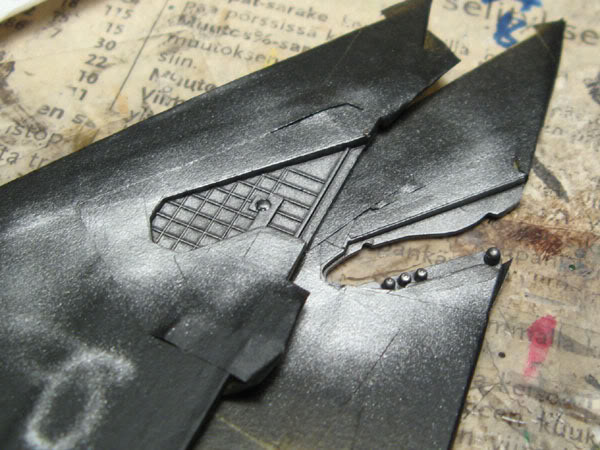

Here's the landing gear doors assembled and the first attempt to fill the incorrect recessed details in the tires with Mr. Surfacer. All the tires had strange, quite heavy side detail, while my references showed the tires being smooth. The recesses were too heavy for mr. surfacer, it would have required many application to fill the holes. I opted for milliput.

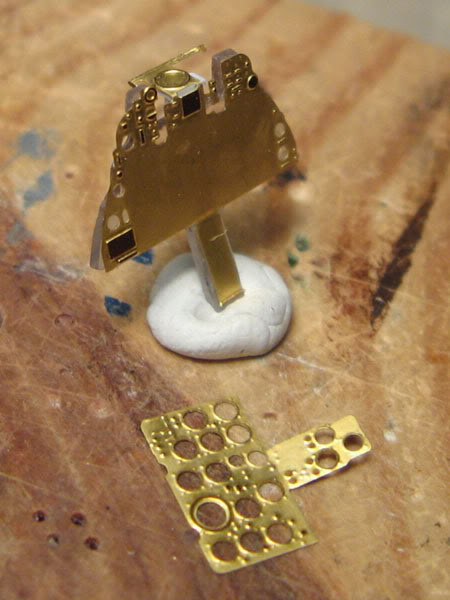

Here's the wheels after applying Milliput to fill the side details, with the wheel hub PE parts already cut from the fret.

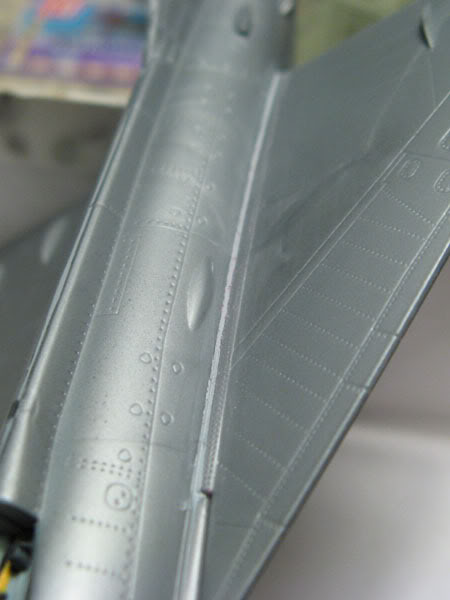

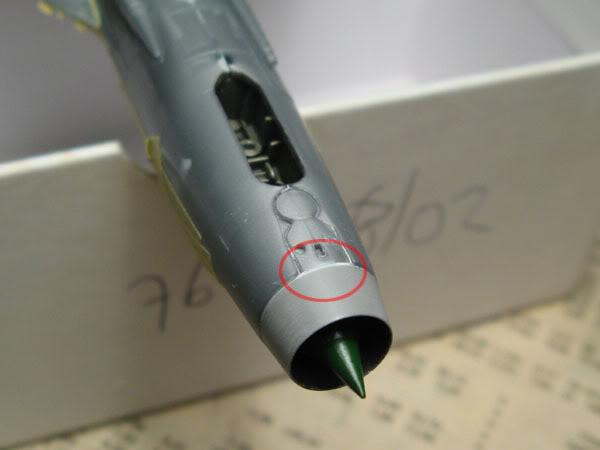

While the plastic parts seem to be mostly well moulded, the prominent locators and shelves for the cockpit and front landing gear bay in the fuselage halves resulted in some minor sink marks in the outside. Not a big issue, a single application of mr. surfacer and sanding took care of them.

There's the cockpit tub with the seat dryfitted again, this time the seat being finished.

The reference photos I managed to find indicated the Part seatbelts being somewhat incorrect (at least for the version this is), but I didn't bother and proceeced with the PE provided. Since I lost one of the shoulder belts, I replaced both with left-over parts from some eduard PE set, since the parts were a bit wider than Part's belts, this way it's not that noticable.