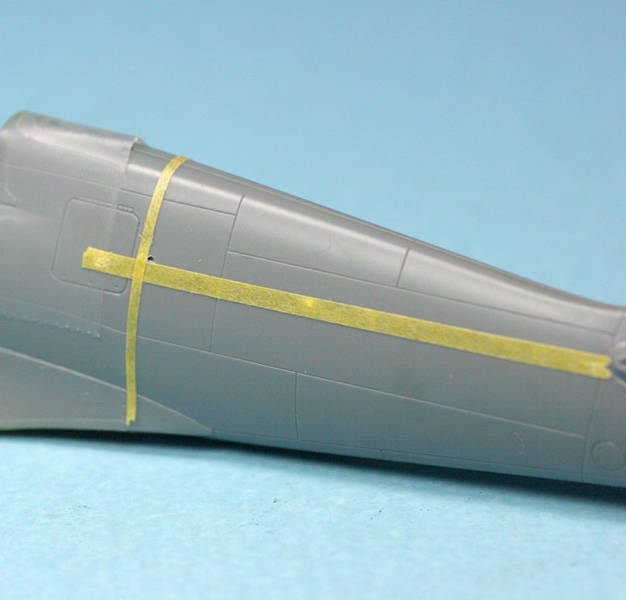

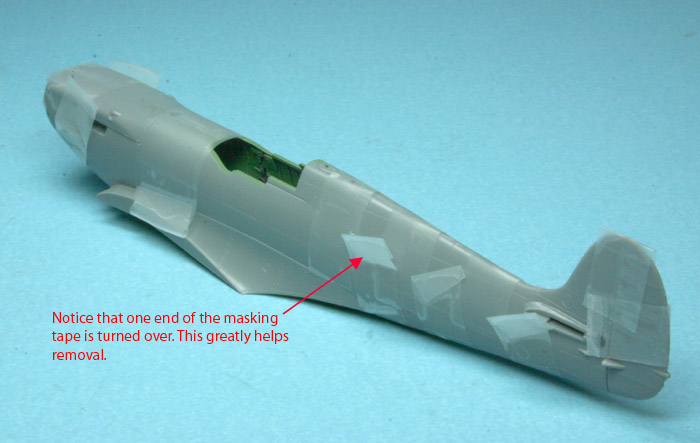

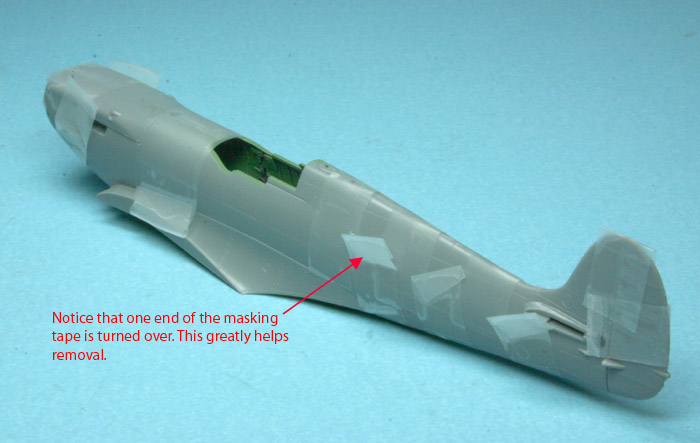

Next I joined the fuselage halves. First of all, as with everything, test fit. Check that everything fits as it should, if not find out why and fix the problem. The fuselage on this model presented no problems. Hold the halves together and us liquid glue applied with a small paint brush. Work along the fuselage and as you go squeeze the halves together so that the molten plastic oozes out as small beads. Tape along the fuselage, as you go, to keep things as they should be. A tip when doing this is to turn over a little of one end of the tape (the end which is placed last). Doing this will make the removale of the tape far, far easier (trust me

) Don't apply tape before gluing as the glue can run under it and spread.

When the joint is dry, I usually leave thigs over night, remove the tape. You will see the benefit of turning over the end, or you will be cursing if you didn't

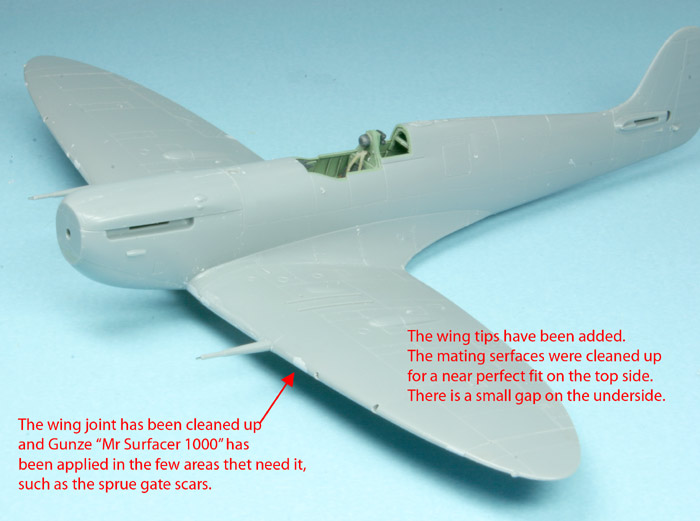

The plastic that has oosed out of the joints will act as filler for them and just requires sanding away. Be careful not to loose the cross section of the fuselage by over zealous sanding. I scraped the dried beads off first, using the edge of a scalpel blade then, carfully sanded, using a fine and extra fine grit foam sanding sticks. After I had gone over the entire seam there were a couple of places that required more work. This was mainly due to the scars from cutting the pieces off the sprue tree. I brushed on Gunze "Mr Surfacer 1000", let it dry and sanded smooth, job done

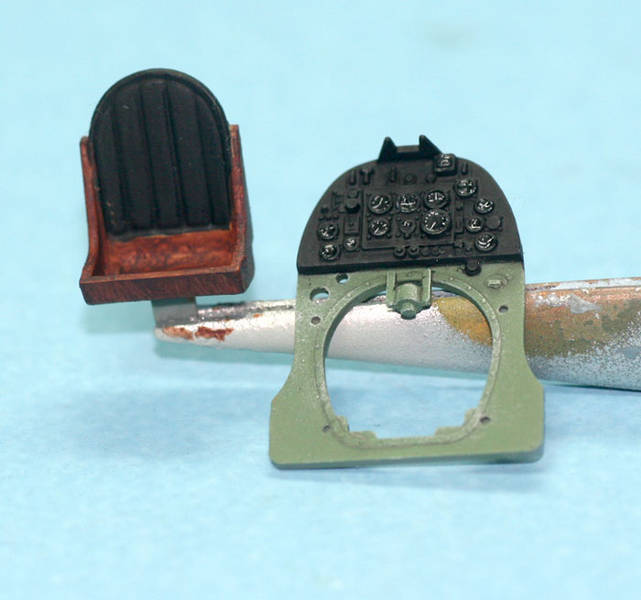

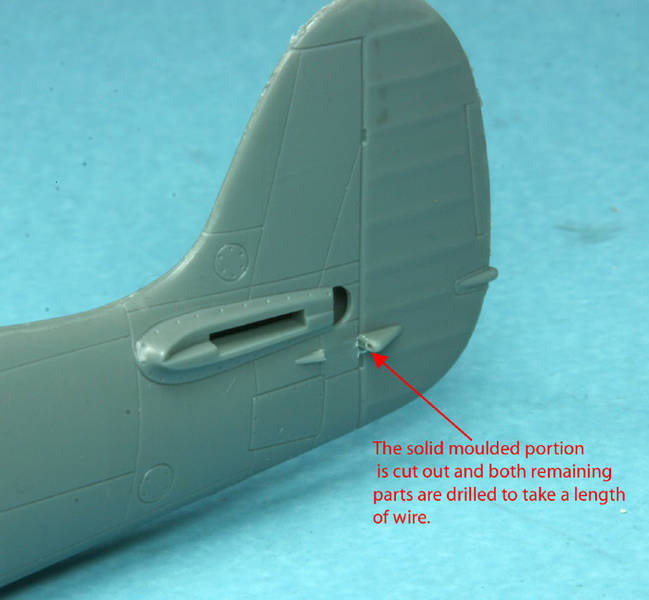

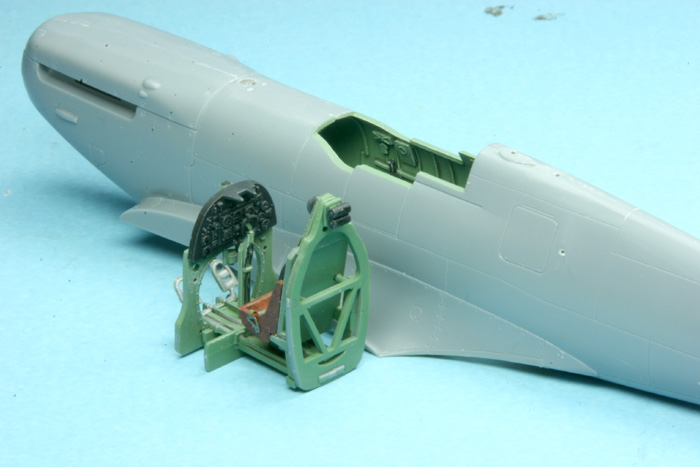

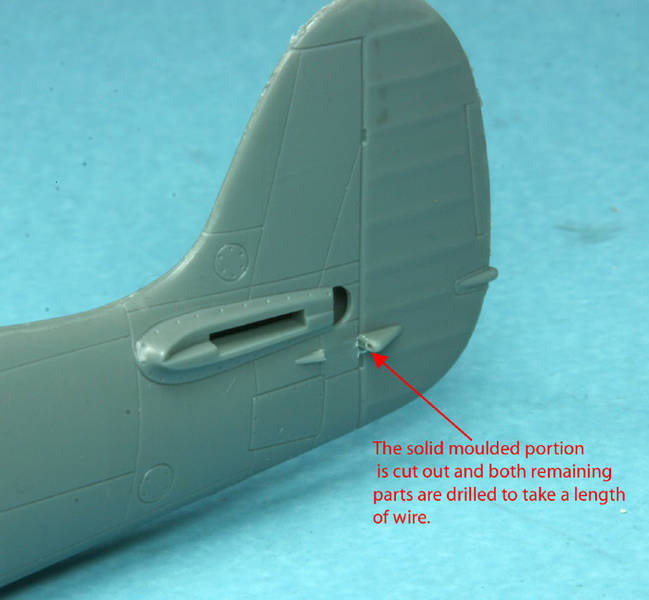

While waiting for the fuselage halves to dry I started fitting the cockpit interior tigether. I also cut away the solid plastic fillet between the fuselage and rudder, on the port side and drilled a hole in each of the remaining parts, to except a short piece of wire. This is a nice easy update. To drill the holes first of all mark the start position with a pointed tool, such as a compass needle. (trust me

)

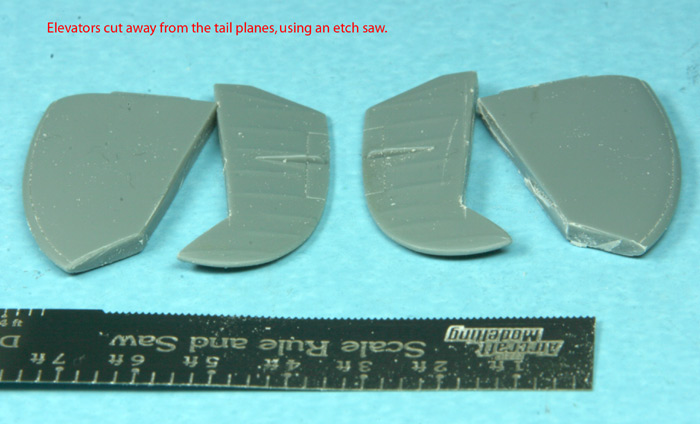

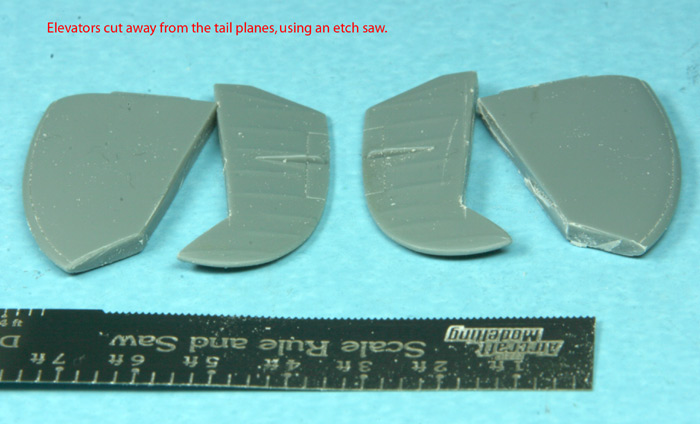

That wasn't all I did while waiting for the fuselage halves to dry. I like to show drooped Elevators on most of my Spitfire Models and this is an easy way to do it. First of all cut the elevetors away from the tail planes.

Next replace the hinge slots which would have been lost when cutting, use the edge of a flat file. Glue a thin piece of styrene strip to horn balance and a thicker piece, about 40 thou', to the long edge of the elevator. Using a triangular file cut a slot into the mating face of the tail plane. The edge of the opening needs to be nice and thin. You don't have to file until the outer edge is thin, you can just tilt the file to either side to thin it, otherwise you will go to deep (trust me

).

The dropped elevators aren't finished yet and, as yet, I have done nothing else to them. So a good time to skip to another post.

Mal