Hey Ralph,

The Phantom is looking great, nice work. Iíve built a few Phantoms over the years and pick up a few tips that Iíd like to share.

First, those nasty intakes. Only real solution is to get resin intake covers, or work from the inside before closing up the fuselage. What I did was cut the intakes inners from the fuselage, then install the outer sections and putty and sand. Them replaced the cut section using evergreen plastic card.

Exhaust nozzles, what I did first was to sand off the back side of the blades and screens. This gave it the look as if it went completely through. And for the nozzle details I used .005 brass metal sheet cut to size and glued in. you can also use those aluminum pop cans which work great. I also scribed the outer detail feathers, it gave a look as if it wasnít just a molded on bumps.

Ejection seats, resin ones are worth it, but if your using figures then go with the kit supplied one and spice them up. As to the hoses, well I do know where they go on US Air Force and Navy/Marine Phantoms, but I canít say for sure on yours and Iíd hate to give the wrong info. Here are a few site that may help youÖ

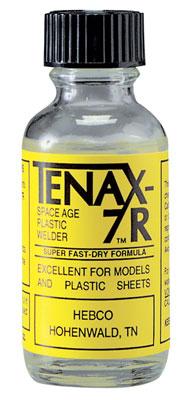

Ejection site 1 Ejection site 2 Ejection site 3 Ejection site 4 Ejection site 5 Panel scribingÖwhat a job right! Anyhow it looks great, what are you using to scribe with. I too had my fair share of scribing, when Iím finished Iíll go over it with 1000 grit and light swipe across the line with Ten-X to smooth out the line and to clean them out.

As for the rest of the detail, it all looks good and can't wait for the next update.

Joe