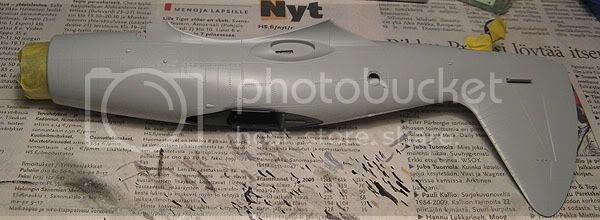

So, it's Trumpeter's 1:48 scale Westland Wyvern S.4 (late) kit, enhanced using Eduard's interior PE set, Pavla's resin ejection seat and the occasional self-made improvement.

First, what you've seen already if you watched the campaign thread. Not that much so I'll just go through them briefly here again.

Pin ejector marks filled, cockpit sidewall PE parts attached. In retrospect, the time used filling and sanding those marks was pretty much wasted, as none of them are visible on the finished model.

Cockpit construction underway, seat being dryfitted. Unpainted PE parts glued in place.

More ejector marks to be filled under the landing flaps and one idiotically placed in each main gear well (circled). The latter were filled with milliput because the area would have been almost impossible fill and then sand using regular putty.

One of the mistakes repeated from the 1:72 scale kit, the prop blades were of the broader type used on the prototype. Shown in the pic after sanding to a more accurate shape.

And now on to the newer stuff.

The gunsight is all PE (well, apart from the acetate sheet glass, of course). Eduard's instruction point out to use a film part for the glass, but there's none provided, as the instruments are pre-painted on the parts, and someone must have forgotten the gunsight. So I used some left-over film from my parts box. The length of the glass is pure guesswork though. I hope I got it about right. The control stick received a piece of wire, replacing the flat PE part.

Because Eduard had somehow decided on a dark grey cockpit interior color for the prepainted PE parts, I went for the easier (and inaccurate) way of just coping with that and painting the rest to more or less match the color of the PE. I settled for Xtracrylics' extra dark sea grey, which was a pretty good match for the prepainted color. A better match than the photos suggest, they look more different in the pics for some reason.

The main gear well just screamed for some detailing, so I added some wiring following photos of the prototype I found (let's hope they didn't differ much in the production version...

), keeping it down to reasonable level as the wheel well isn't that hugely visible in the finished model with the inner gear doors closed (the instructions inaccurately point them to be assembled open, another error carried over from the smaller scale kit).

), keeping it down to reasonable level as the wheel well isn't that hugely visible in the finished model with the inner gear doors closed (the instructions inaccurately point them to be assembled open, another error carried over from the smaller scale kit).

After putting the wings together, I'm wondering how to attach the outer folding sections sturdily... On the 1:72 version the two small spars and butt joints of the wings themselves were strong enough, but I doubt they'll be enough this time in 1:48... Of course, I first thought about gluing styrene sheet to the insides of the wing halves to get more gluing surface, but it turned out only one side are of the same thickness.

Also using those blanking plates might have been a bad choice, as leaving them off would have made it possible to install proper supports inside the wing. Well, I think I'll think of something. Suggestions are also welcome of course.

Also using those blanking plates might have been a bad choice, as leaving them off would have made it possible to install proper supports inside the wing. Well, I think I'll think of something. Suggestions are also welcome of course.

Those lovely contra-rotating props! This time Trumpeter included a gimmicky option of having the propellers rotate in opposite directions like on the real McCoy. Or actually the geared system seemed to be the primary option, with the simple non-rotating option seemingly just thrown in at the last moment, consisting of simply replacing the back part of the inner prop assembly with a simple plastic part that was just supposed to be glued on.

While the geared props actually worked surprisingly well, I didn't want to use that option because the assembly didn't fit in tightly enough, resulting in slightly drooping appareance, and also because it was impossible to be fitted in place after painting.

Because I didn't want that and still be able to move the propellers if I wanted to, I had to get creative. In the end it wasn't that hard to pull off, but I really would have appreciated a simple solution with rubber grommets to have been included in the kit like so many manufacturers already do.

The outer prop was easy, the hexagonal metal axel fitting snugly in place with a bit of super glue. Then I just had to install grommets left over from some Hasegawa kit in the other prop and inside the engine cowling. The first was easy, just leaving off an unseen plastic part left a hole where I could drop in a grommet inserted inside a piece of styrene tubing cut open. A piece of styrene sheet glued over the opening held the grommet inside.

The engine cowling was next. As the two parts going between the cowling halves were to be used with the gear system, they were moulded in a different kind of plastic like the gears themselves (ABS? Who knows?), apparently to be able to withstand the spinning of the props without melting or deforming, they couldn't be glued with regular styrene cement (I doubt CA would stick either), I cut a donut shape from styrene sheet to hold a grommet inside a piece of styrene tube in place without glue.

(note the styrene sheet now covering the hole behind the rear prop, holding the grommet inside)

According to the numbers in the pic:

1) As I wanted to be able to install the props after painting, I cut off the front portion of that gear-associated part that also acts as the back plate of the rear spinner when using the gears. Now it just holds the grommet in place.

2) Another grommet is installed in gear housing, centered by a styrene donut shape and some more sliced tubing.

3) The rear spinner back part of the gearless option was used.

That's it for this time. Hope you didn't fall asleep as. Sorry for that, I probably should have started this thread a bit earlier.