Another update with loads of pictures too.

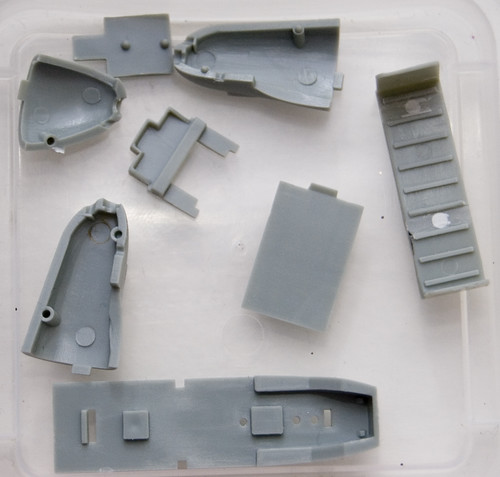

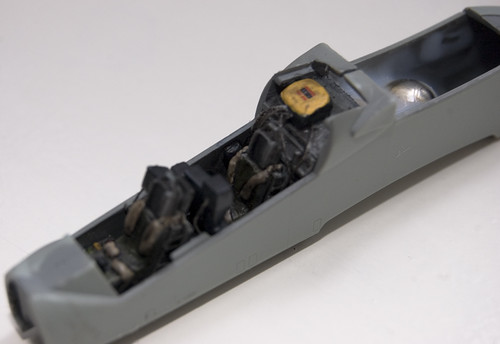

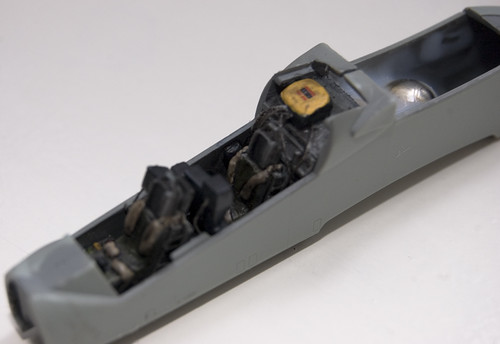

So I've closed up the fuselage halves and thankfully the seams on the tub aren't that bad but I've realized the Bronco is going to have lots of sub assemblies so there will be seams aplenty soon enough.

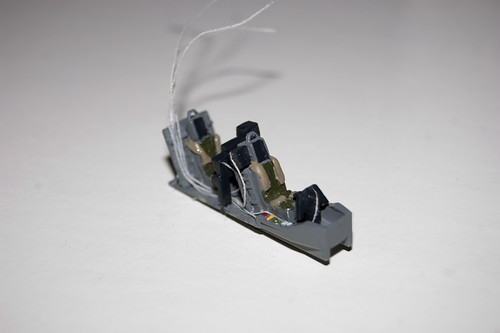

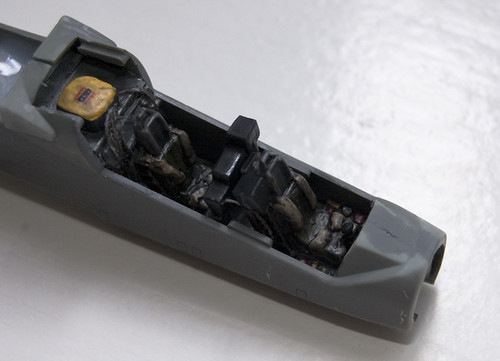

You can see what I was trying to do with the thread here; I made a 'fuse box' of sorts out of green putty with the idea of feeding the threads into it. I don't think the effect was really pulled off very well. In fact once I started weathering the cockpit the thread stained, as you can see, which I didn't really want. I'm just hoping that once the canopy is on it'll all come together.

The weathering was done with a Citadel wash, Babab Black in this case, and then a matt coat followed. The shelf the fuse box is sitting on is a piece of evergreen; Academy provided nothing for this area and there would've been a hole into the fuselage visible through the canopy. I still need to block up the back of it.

So that's the cockpit, certainly not the best I've done but it'll do I think. I might add some brake lines to the landing gears later in the build so if anyone has any suggestions for a good, and easily attainable, material for brake lines then let me know.

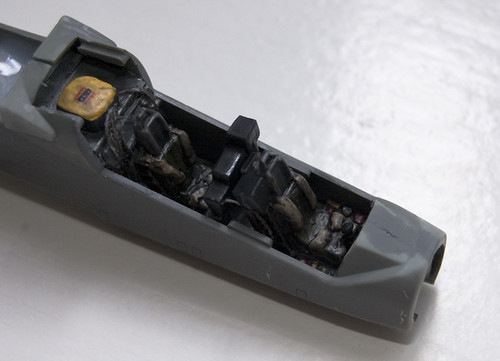

Weight is going to be a big issue for this build, I can tell. Academy suggests about 8g for the nose but there's absolutely no room in there. So I've added to two fishing weights immediately behind the cockpit and I'm hoping this will place weight just forward, or on, the main landing gear. I might be able to squeeze some one cent coins into the tail booms just behind the props to add in more weight.

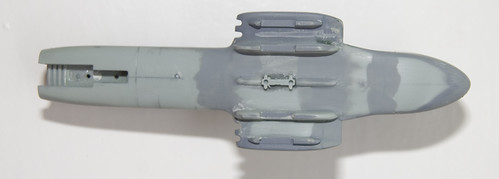

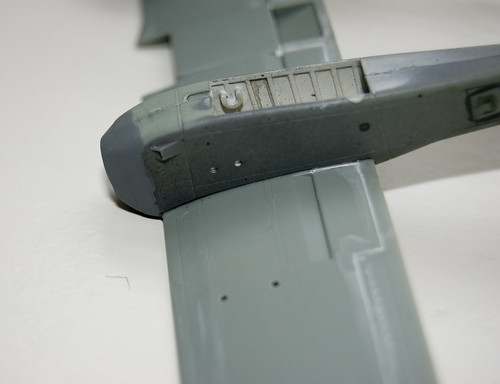

You can see a few seams here on the underside of the fuselage tub. The indented area accepts the weapons station which will create more work as its fit isn't great. The fit of the nose to the fuselage also isn't great.

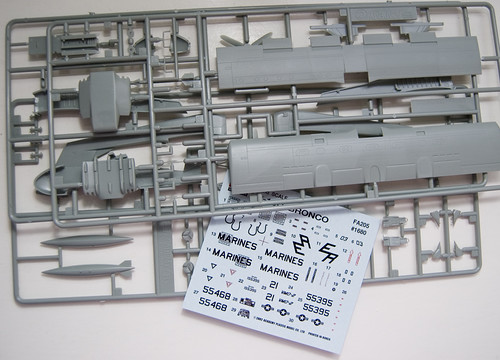

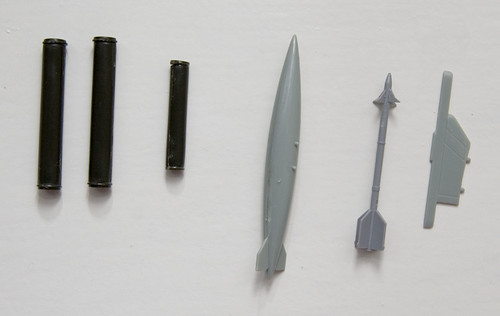

And here is the weapons station; the grooves in the front accept the OV-10's guns which are M60 machine guns. I thought I read somewhere that some OV-10D's had their M60's upgraded to 30mm cannons but I'm not sure. I'll be leaving the guns off until late in the build to make sure I don't damage them.

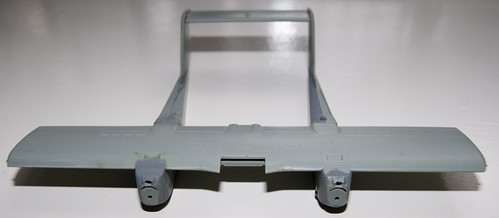

The OV-10 has long 40 foot wing and the kit wing comes in two pieces that need to be joined together with four small holes drilled out first for the wing pylons. The middle gap at the back of the wing slots over the fuselage tub while the other two gaps accept the tail booms. As far as sub assemblies go first I'll need to add the weapon station to the fuselage tub and clean that up. Then I'll add the wing to the top of the fuselage tub and clean that up. The tail booms will be assembled, and cleaned up, then attached to the wing and, again, cleaned up. Lots of seams and gaps to look forward too.

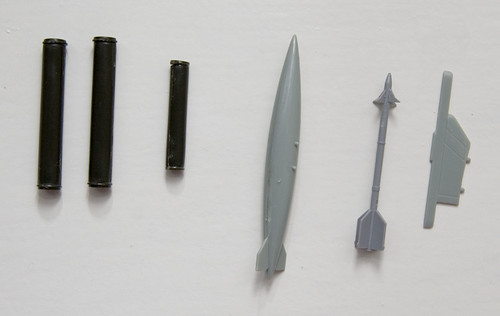

Finally the weapons loadout for the Bronco. Moving from left to right there are two LAU-10 rocket pods, an LAU-68 rocket pod, a 150 gallon fuel tank, an AIM-9L Sidewinder and a wing pylon launch rail for the Sidewinder. I took the loadout information from the

Desert Storm website I mentioned earlier in the build blog.

The three rocket pods came from the old Italeri NATO weapons set, two of which I bought recently from eBay. The Sidewinder came from a Hasegawa weapon set and the fuel tank plus the wing pylon are from the kit.

So the next big job is to get the sub assemblies built and start joining everything together, then the Bronco can really start taking shape. There's a lot work involved but it's worth it for a Bronco in my opinion, great looking aircraft.

Now, let me ask everyone one last question. Considering the amount of gaps and seams I'll be facing what is everyone's favoured method for dealing with them?