Boeing produced 4 different models of the "Next Generation" 737s; the -600, -700, -800, and -900, distinguished by differing fuselage lengths. The -600, -700 and -800 were designed as replacements for the -500, -300 and -400 respectively, and were of similar length and passenger capacity. The -900 has no prior 737 analogue, and is closer in concept to the 757. Revell's -800 kit makes an excellent starting point for conversions to the other 3 versions.

Since the -900 is longer than the -800, there is no getting around the fact that you will need to add extra material to the fuselage. Some people use extender plugs and wrap them in plastic card, but I've found that using two kits can be made to work, since the second kit can be used to make a short fuselage, thus getting two different airplanes for the price of two identical ones. A bargain any way you cut it!

In this exercise, we'll be making a -600 and a -900 from two -800s. Let's call them kit A and kit B.

Cut kit A as follows:

Long nose, short centre section, long tail.

Cut kit B as follows:

Short nose, long centre section, short tail.

Now mix the components up:

For the -900, use nose A, centre section B and tail A. Adjust the length to the proper -900 length by trimming the sections.

For the -600, use nose B, centre section A and tail B. Once again trim to adjust the correct length.

Use sections of the sprue as internal splints to keep the kit from going banana-shaped. The cuts have to be placed carefully to ensure that each kit has suffucient fuselage length available. Cutting templates for all versions of the 737 NG are available for download from the Draw Decal website.

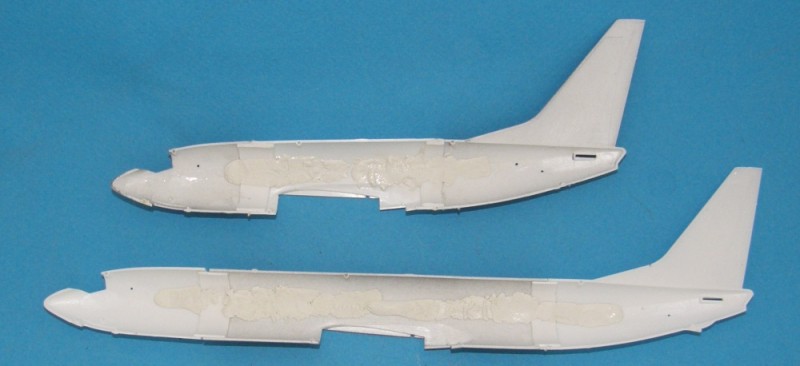

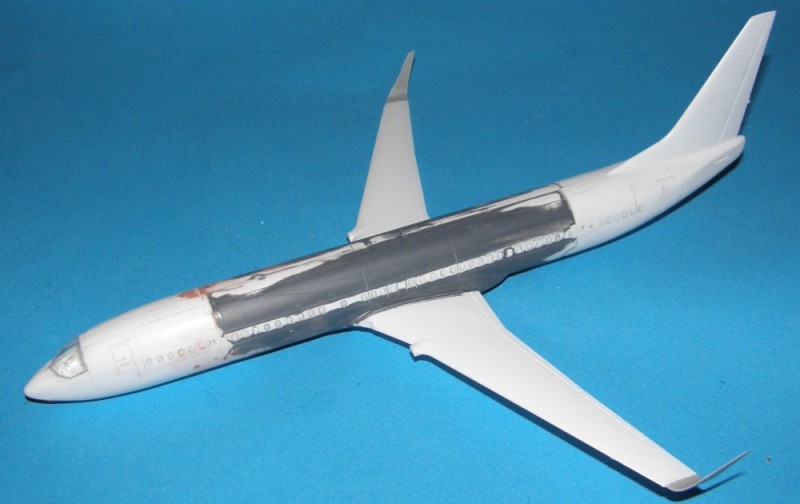

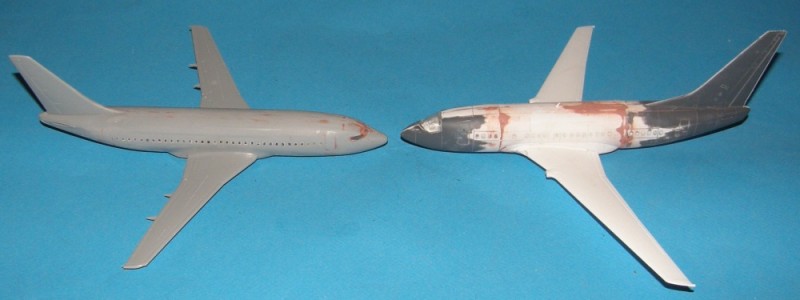

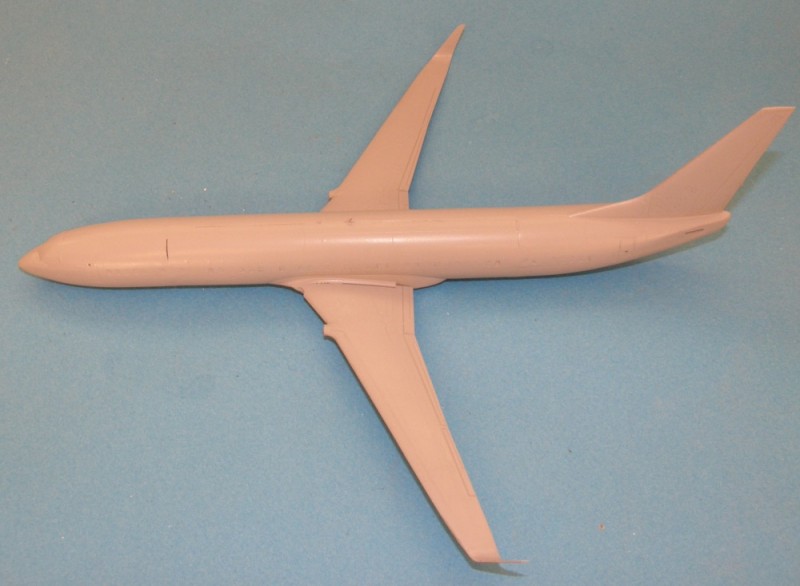

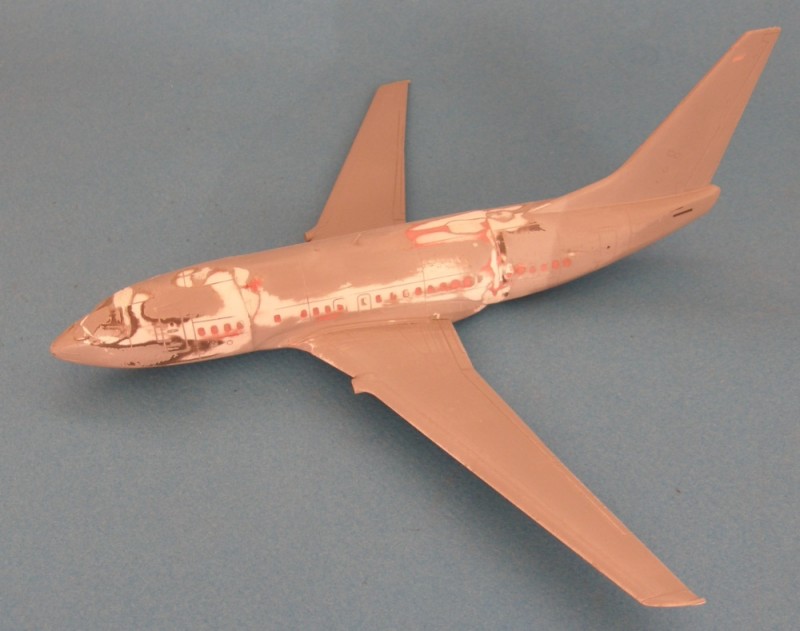

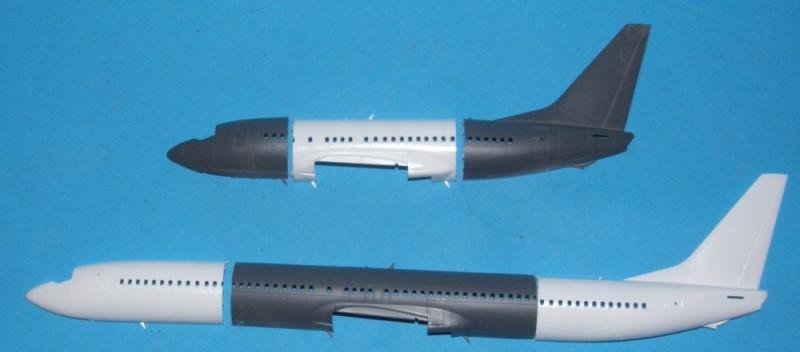

These pictures illustrate the process. Kit A is white and kit B is grey.

The cuts are marked with tape. In each case the cut will be made on the side of the tape nearest the wings

The cuts are made

And the parts are swapped around.

Left as-is, the -900's fuselage will be too long, so the nose and tail parts must be trimmed shorter. The offcuts from the trimming may be used as tabs to strengthen the joins. The tail bumper on the -600 must be removed, and the forward emergency exit filled in.