#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Wednesday, October 02, 2013 - 06:58 PM UTC

OK, any ideas how to get out of this mess? The kit took a bit of heat damage. I'm thinking about strapping the bing to something stiff and then using hot water or steam to soften the part and straighten it. Any luck with that?

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Virginia, United States

Joined: December 13, 2002

KitMaker: 1,434 posts

AeroScale: 403 posts

Posted: Wednesday, October 02, 2013 - 07:08 PM UTC

The boiling pot should fix it. just use a hard surface for cooling as it may warp again. A few years ago, I had DML JU88 I got at a yard sale that was warped like that in the wings and my GF at the time teased me for cooking the wings in my stock pot to get a bad warp out of them. She kept asking when the chicken soup would be ready. HTH

Steve Manchur

US Navy Damage Controlman 1st Class (DC1)

Proud Veteran

STRONG LIKE AXE, HUNG LIKE MAUL!

Fair winds and following seas.

TCS and DBF

Merlin

Senior Editor

Senior Editor

#017

United Kingdom

Joined: June 11, 2003

KitMaker: 17,582 posts

AeroScale: 12,795 posts

Posted: Wednesday, October 02, 2013 - 07:16 PM UTC

Hi Mark

Yep, I'd try hot water too, or a hair-dryer on full as an alternative. Are the wing top halves straight? If so, they'll also help take out some of the warp once you get rid of the worst of it. It also might be worth adding a "spar" from scrap rod or a piece of balsa to hold everything to shape.

All the best

Rowan

BEWARE OF THE FEW...

As I grow older, I regret to say that a detestable habit of thinking seems to be getting a hold of me. - H. Rider Haggard

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Thursday, October 03, 2013 - 08:00 AM UTC

Thanks, Right now my plan includes a hair drier, cold water, a stiff stick and a new metal spar. Could be interesting....

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Joel_W

Associate Editor

Associate EditorNew York, United States

Joined: December 04, 2010

KitMaker: 11,666 posts

AeroScale: 7,410 posts

Posted: Thursday, October 03, 2013 - 10:46 AM UTC

Mark, trying to fix the warp issue could very well cause twisting in the repair process. I would approach the repair issue by first deciding on a flat stiff surface to tape the wing to that is water & heat resistant. Start off taping the flat, unwarped portion to the flat surface working your way up to the warp. Not necessarily the other side unless the wing is supposed to be flat all the way across. Then using hot water, a heat gun, or hair dryer, start to heat the warped end. As it becomes pliable, tape it a little at a time, then repeat till you have the whole wing taped. Then Gently heat again. I would let it air cool, not dunking it in cold water, which will make the plastic even more brittle, and it could crack.

Whatever little warpage is left can be removed using a wing spare as Rowan suggested.

Good luck, and let us know how it turns out.

Joel

On my Workbench:

Monogram 1/24 scale 427 Shelby Cobra

Just Completed:

Beemax 1/24 scale BMW M3 E30 1992 Evolution II

Alberta, Canada

Joined: January 19, 2008

KitMaker: 6,743 posts

AeroScale: 6,151 posts

Posted: Thursday, October 03, 2013 - 11:38 AM UTC

Take a box that will kit the wing . Cut a hole on both ends . Take a solid ruler or something that will work the same . Fasten the wing to this with rubber bands . End of the wings and the middle place box lid on and blow hot air into the box with a hair drier for a few minutes , hit the cool button and do the same . remove the box lid and let cool a bit more . You might have to try this a few times but it will take the wrap out .

Terri

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Thursday, October 03, 2013 - 12:06 PM UTC

Hi Terri, long time no see.

Good idea, thanks for suggesting using a ruler. I have a couple of steel scales around that might just help.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Joel_W

Associate Editor

Associate EditorNew York, United States

Joined: December 04, 2010

KitMaker: 11,666 posts

AeroScale: 7,410 posts

Posted: Monday, October 07, 2013 - 01:41 AM UTC

Mark, have you tried to straighten the wing yet?

Joel

On my Workbench:

Monogram 1/24 scale 427 Shelby Cobra

Just Completed:

Beemax 1/24 scale BMW M3 E30 1992 Evolution II

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Monday, October 07, 2013 - 02:26 AM UTC

Yes, I've tried a couple of things. It's not fully solved, but I'm making progress. I'll try and post pictures tonight.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

#084

Quebec, Canada

Joined: September 14, 2005

KitMaker: 2,485 posts

AeroScale: 95 posts

Posted: Monday, October 07, 2013 - 04:29 AM UTC

Clamp your part between 2 pieces of rigid wood and soak in

very hot water....almost boiling water...allow to cool...

should resolve the problem.

Cheers,

Joe

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Monday, October 07, 2013 - 06:17 PM UTC

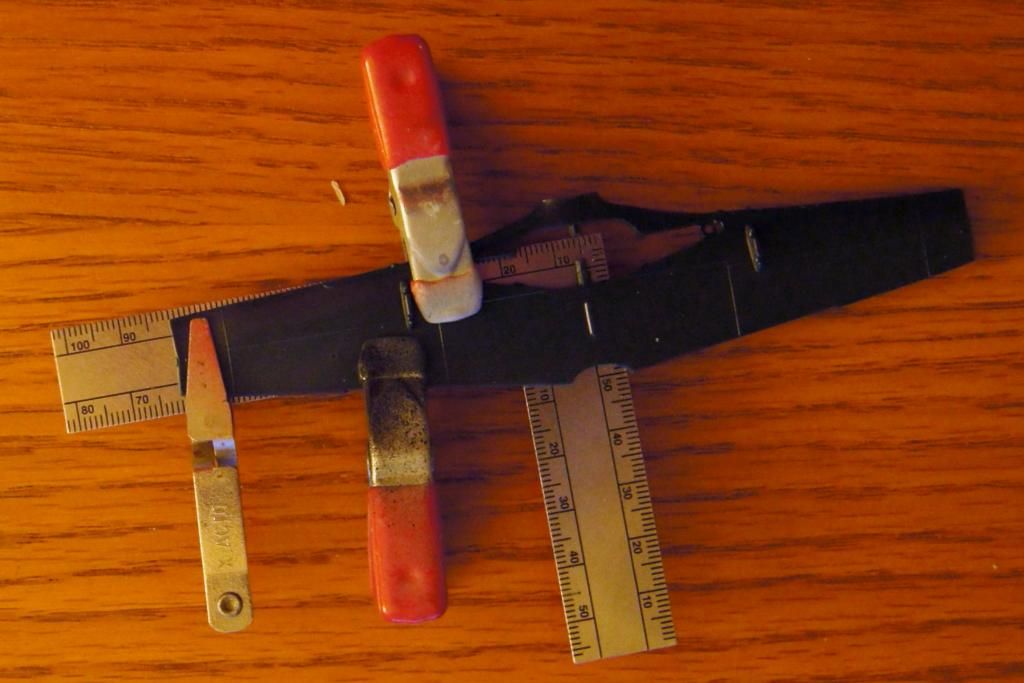

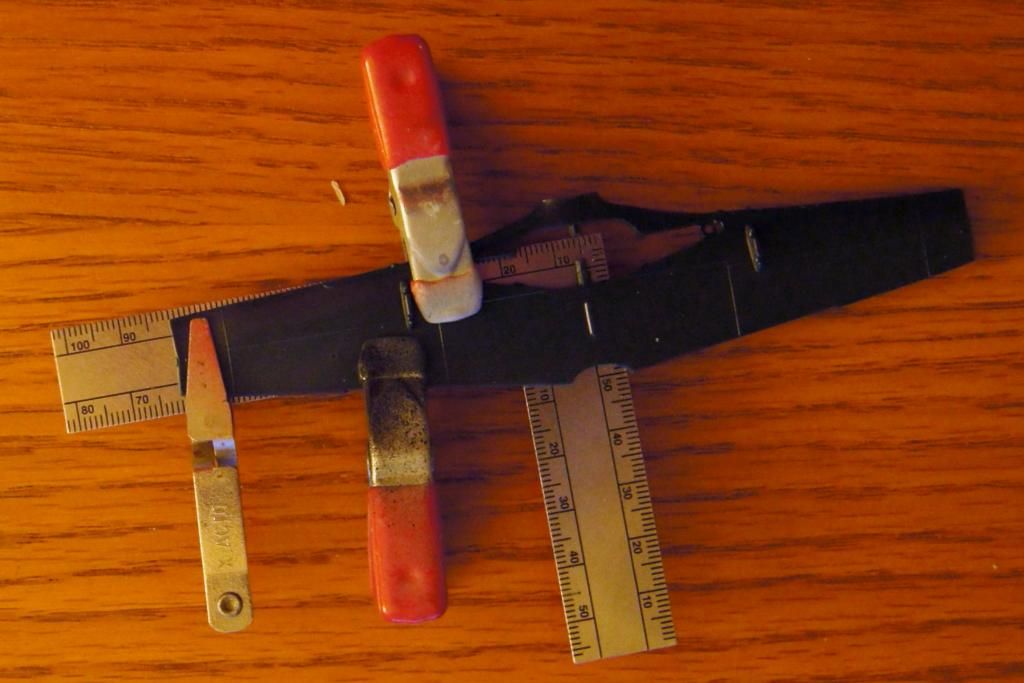

Well, my first try was to clamp the wing to a scale and heat it with my hair drier.

Starting here:

it took a little bit of the warp out:

but it's clearly not fixed;

Second pass was into a cup of hot 130-140 F water.

I've started trying to superglue a steel dowell in place to pull the last of the warp out.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

British Columbia, Canada

Joined: September 03, 2009

KitMaker: 6,965 posts

AeroScale: 6,247 posts

Posted: Monday, October 07, 2013 - 06:19 PM UTC

The water needs to be hotter. Try it with water that's just been boiling, then bend it against the warp (gently) before clamping it straight to cool.

When once you have tasted flight you will walk the Earth with your eyes turned skyward.

For there you have been, and there you will always long to return.

-Leonardo Da Vinci

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Monday, October 07, 2013 - 06:28 PM UTC

I'm hesitating on the boiling water, melted a car trying that trick a few years ago (like the Johnson Administration).

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Croatia Hrvatska

Joined: November 06, 2009

KitMaker: 624 posts

AeroScale: 609 posts

Posted: Monday, October 07, 2013 - 08:48 PM UTC

Mark,

Sorry if I am late, but drop a look

here.

All the best,

Entoni

"When everything else fails, read the instructions"

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Tuesday, October 08, 2013 - 02:26 AM UTC

Thanks, I'll have to look at it tonight (Content filtering at work)

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

British Columbia, Canada

Joined: September 03, 2009

KitMaker: 6,965 posts

AeroScale: 6,247 posts

Posted: Tuesday, October 08, 2013 - 04:24 AM UTC

Quoted Text

I'm hesitating on the boiling water, melted a car trying that trick a few years ago (like the Johnson Administration).

Yes, it can't be actually boiling, but cooled for about 20 or 30 seconds. Dip in the wingtip for 5 - 10 seconds or so and then try bending it. Be ready to clamp it flat right away if the bending is successful. To be really extra-certain, have a pot full of ice water standing by to dip it in to cool it quickly.

When once you have tasted flight you will walk the Earth with your eyes turned skyward.

For there you have been, and there you will always long to return.

-Leonardo Da Vinci

Merlin

Senior Editor

Senior Editor

#017

United Kingdom

Joined: June 11, 2003

KitMaker: 17,582 posts

AeroScale: 12,795 posts

Posted: Tuesday, October 08, 2013 - 08:22 AM UTC

Hi Mark

If you don't like the idea of actual boiling water, try the steam from a kettle. It gives an extra element of control. Tape the part to a level surface first - and, obviously,

be careful - it's still at boiling point, so you can scald your fingers...

All the best

Rowan

BEWARE OF THE FEW...

As I grow older, I regret to say that a detestable habit of thinking seems to be getting a hold of me. - H. Rider Haggard

#435

Nelson, New Zealand

Joined: February 14, 2013

KitMaker: 480 posts

AeroScale: 478 posts

Posted: Tuesday, October 08, 2013 - 12:37 PM UTC

Quoted Text

If you don't like the idea of actual boiling water, try the steam from a kettle.

The best way, Rowan. That is a technique I use when scratch-building a wing and need to curve the plastic. For 'washout' of wingtips or even a length of wing, a la Harry Woodman.

Wear

oven gloves and tape the plastic to a thick board and allow the steam, which is super-heated water, and slowly work the board across a steam kettle or upside-down over a pot of boiling water. It cools quickly.

It may pay to have a friend with you if this is your first attempt to avoid scalding yourself, but it really is a simpler process than most as we are familiar with steam and can have a good idea of what it can do.

Cheers

Karl

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Tuesday, October 08, 2013 - 01:49 PM UTC

On another project tonight, but I'm looking forward to the challenge.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Joel_W

Associate Editor

Associate EditorNew York, United States

Joined: December 04, 2010

KitMaker: 11,666 posts

AeroScale: 7,410 posts

Posted: Sunday, October 20, 2013 - 03:59 AM UTC

Mark, just curious how the warp fix went, and what process you decided to use.

Joel

On my Workbench:

Monogram 1/24 scale 427 Shelby Cobra

Just Completed:

Beemax 1/24 scale BMW M3 E30 1992 Evolution II

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Sunday, October 20, 2013 - 04:18 AM UTC

Today's the day I try the steam and clamp method.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Sunday, October 20, 2013 - 06:20 PM UTC

Well, that didn't work. It doesn't look any less warped, and the piece of wire I was hoping to reinforce the unbend popped off. I asume the super glue failed.

I took one of the backer boards I used, and make some holes in it to clear the underwing pylons. I'll try it again tomorrow.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

Joel_W

Associate Editor

Associate EditorNew York, United States

Joined: December 04, 2010

KitMaker: 11,666 posts

AeroScale: 7,410 posts

Posted: Monday, October 21, 2013 - 06:12 AM UTC

Mark, sorry to hear that. Enough steam should eventually soften the plastic enough for it to relax, so that the warp is gone. Perhaps more intense steam (closer to the source) for a longer period of time will do the trick.

Joel

On my Workbench:

Monogram 1/24 scale 427 Shelby Cobra

Just Completed:

Beemax 1/24 scale BMW M3 E30 1992 Evolution II

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Monday, October 21, 2013 - 06:18 AM UTC

First next step is more steam, I've already pocketed one of the blocks to clear the pylons. I may not have gotten the plastic hot, let alone hot enough.

Final step may be to make some kerf cuts along the back side of the wing and bend the remaining plastic into contact with the upper wing.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E

#439

Washington, United States

Joined: November 05, 2005

KitMaker: 4,950 posts

AeroScale: 3,192 posts

Posted: Wednesday, October 23, 2013 - 06:29 PM UTC

Well, no joy. 3 passes across the steam out of the tea kettle, into the clamp, and the warp is no better, if not worse.

Next up; kerf cuts into the bottom of the wing and try to glue it to the upper wing.

Hanger Queens in Waiting:

Monogram 1/72 F8F-1

Corsair the Sky Pirate - 1/72 Ace A-7D

Century Series - Airfix 1/72 F-105G

Anti Shipping - Academy 1/72 PBJ-1D

Academy 1/72 F-84E