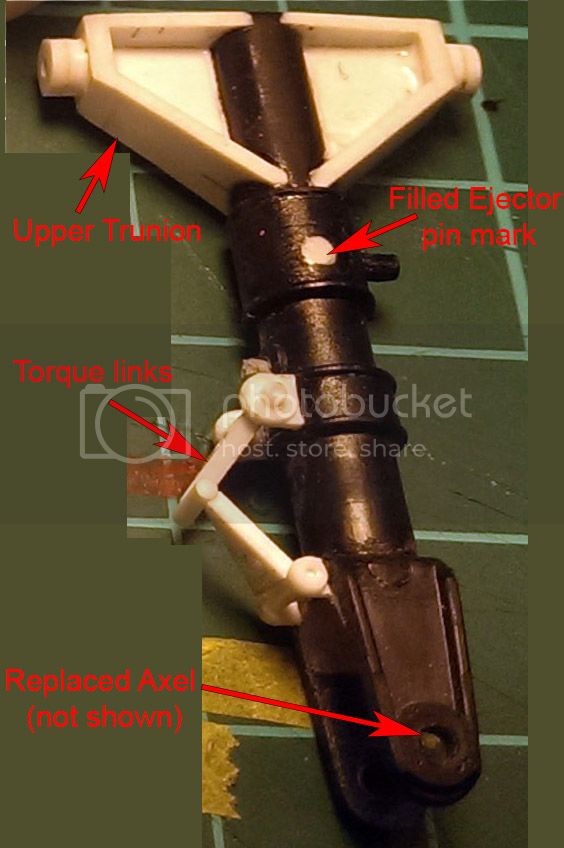

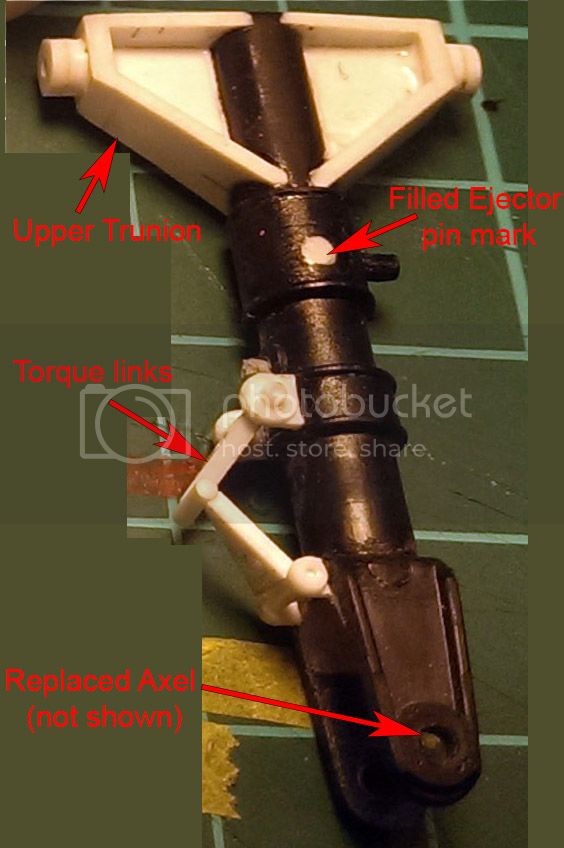

I have rebuilt the main gear as they were pretty malnourished. I rebuilt the upper trunnion, filled the ejector pin marks with discs of punched styrene, rebuilt the torque links and replaced the axel with brass rod to make fitment of the wheels easier along with stronger.

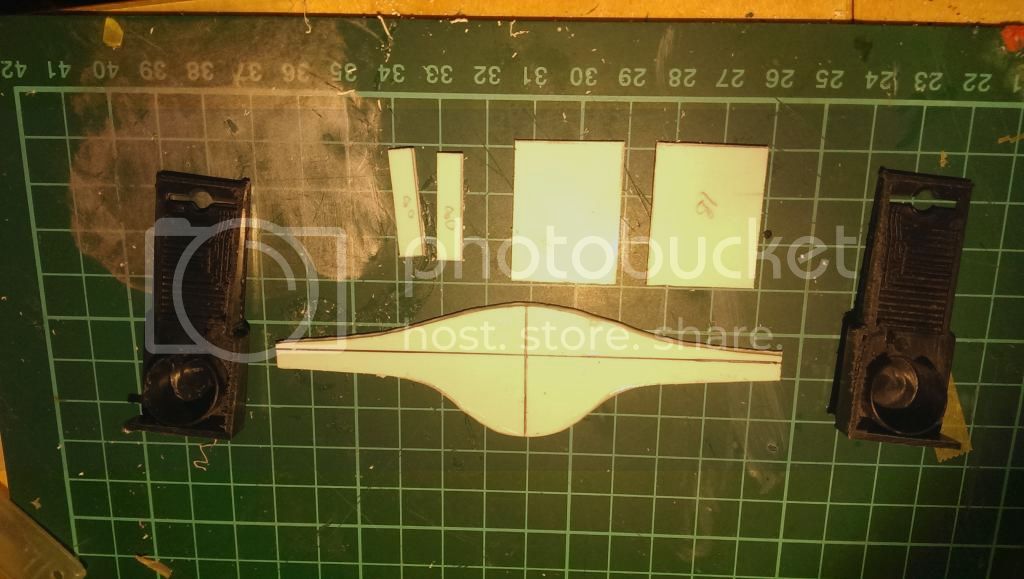

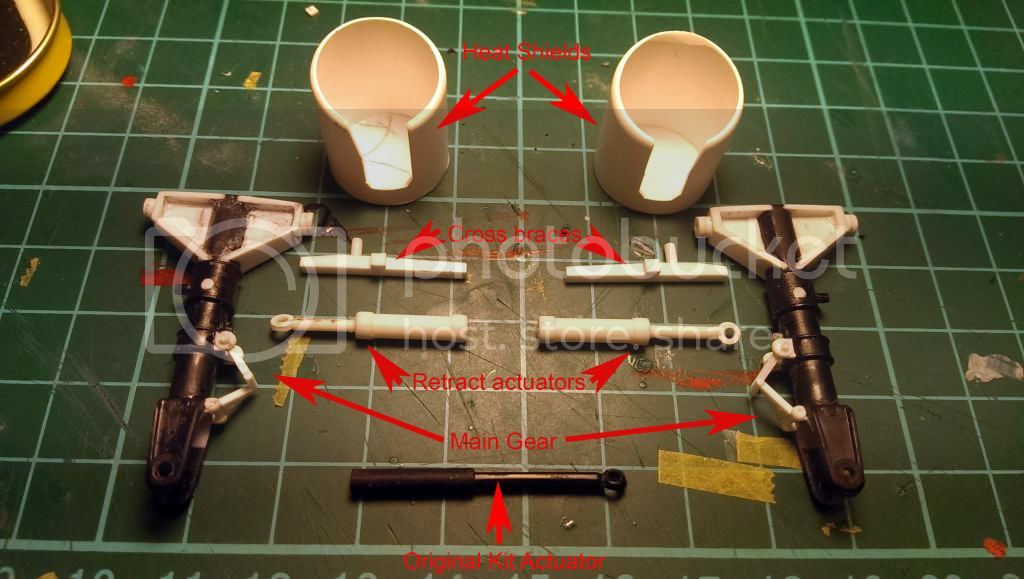

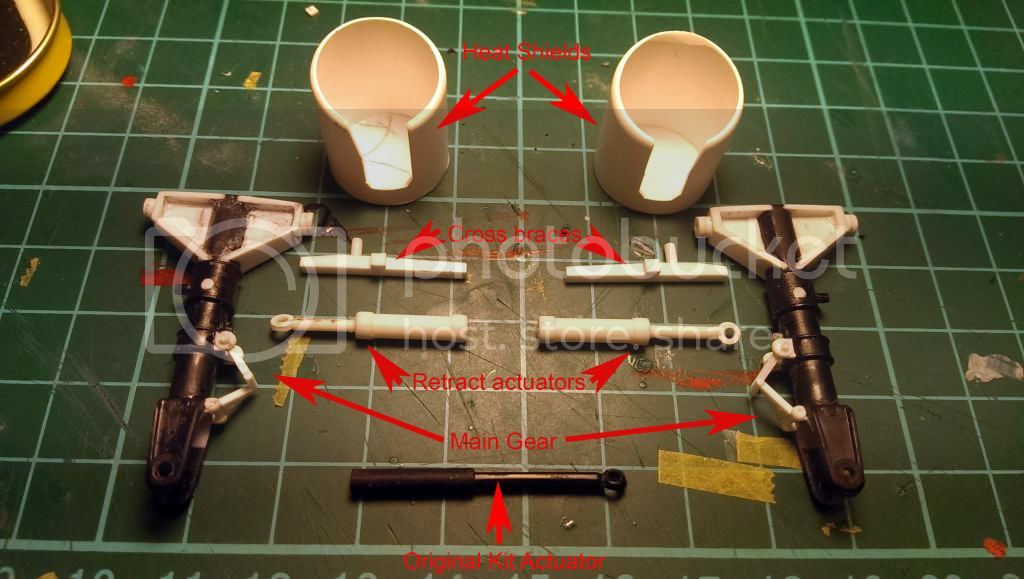

This is all the parts I have built so far for the undercarriage.

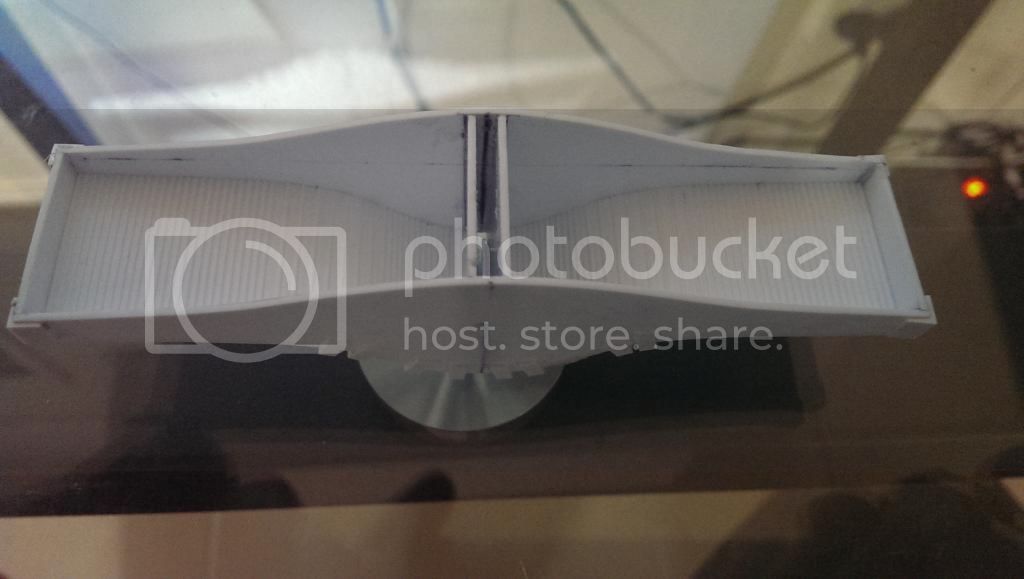

Here is the wheel well and heat shields offered up to the MWW as a test fit (I know that one is in backwards :wasntme:/>/>/>/>/> ).

I have started to plumb the wheel well using thick wire to re-produce the ECS ducting that runs along the front. The "Heat Wrap" is made from Tamiya tape, and the clamps are created with Milo tin foil.

This is what it looks like all together so far.

and with the old wheel well beside it..

I still have to finish plumbing the wheel well, and finish detailing the gear legs, but I've made a good dent in all that I want to do.

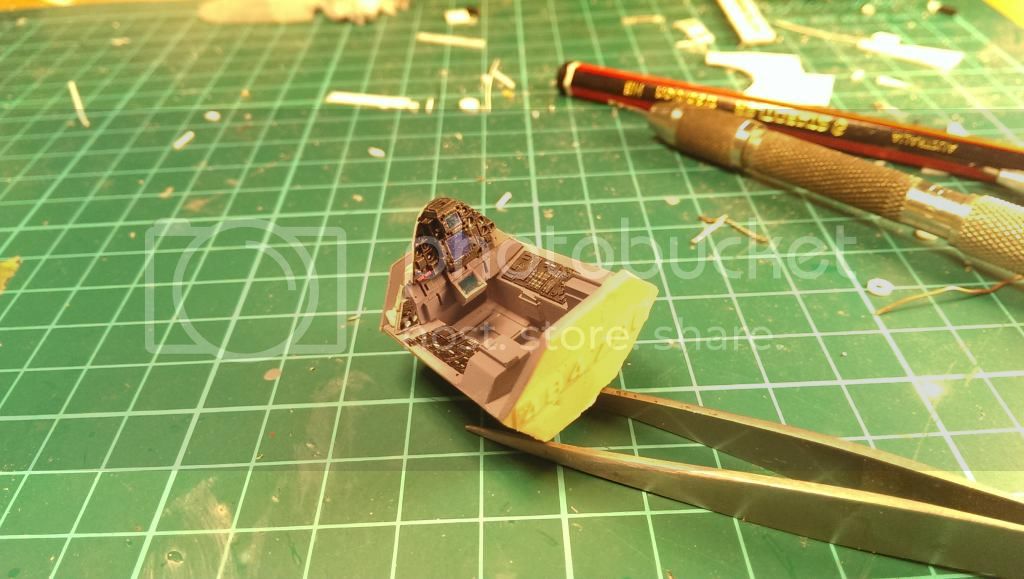

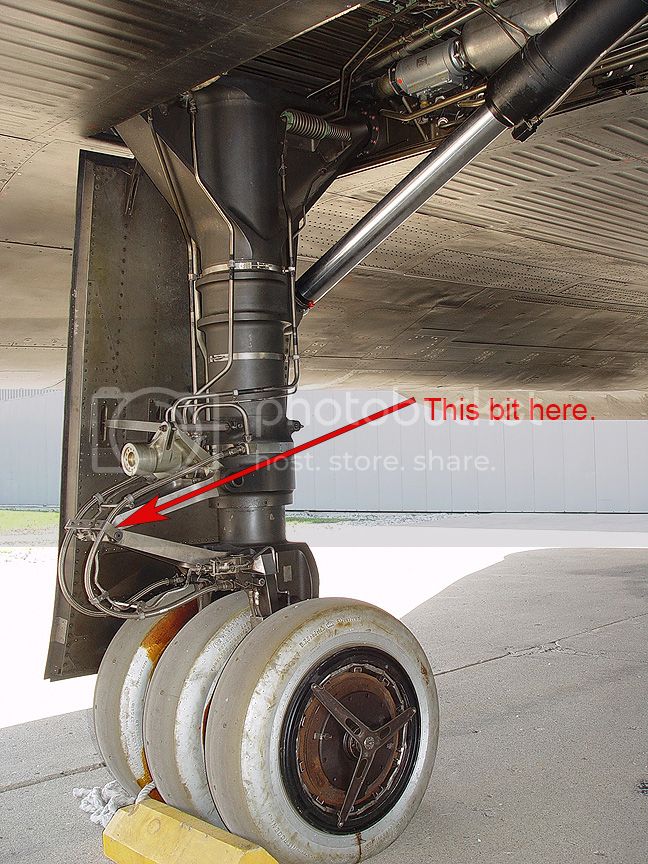

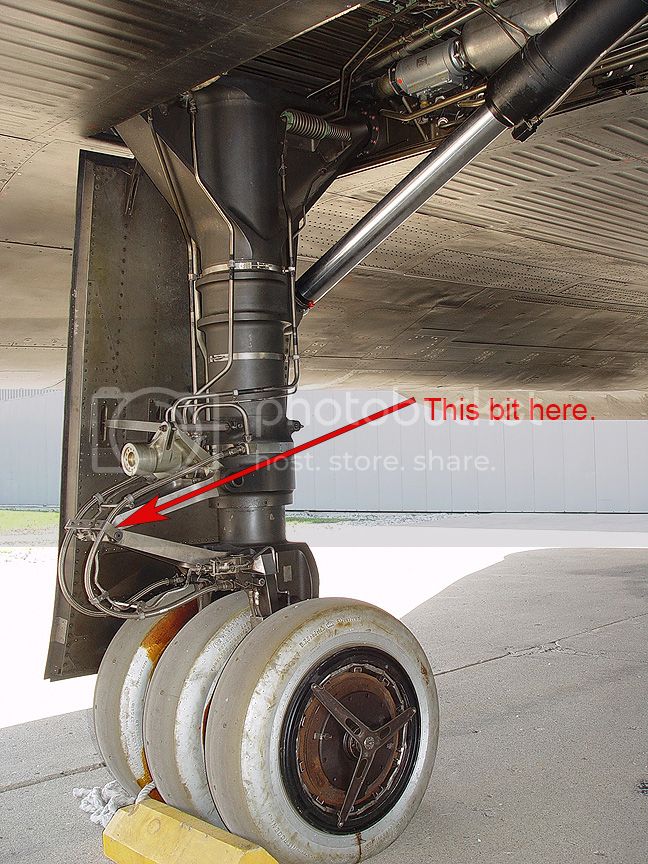

I've painted the main gear and started plumbing them. One thing I noticed on the scissor links, at the front there was a bracket that held the braided hydraulic lines shown here.

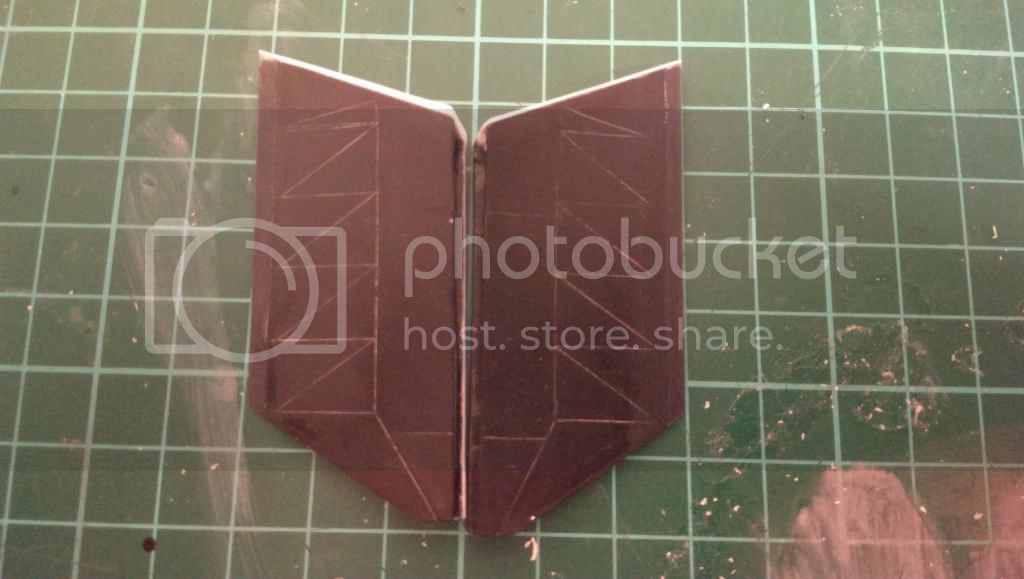

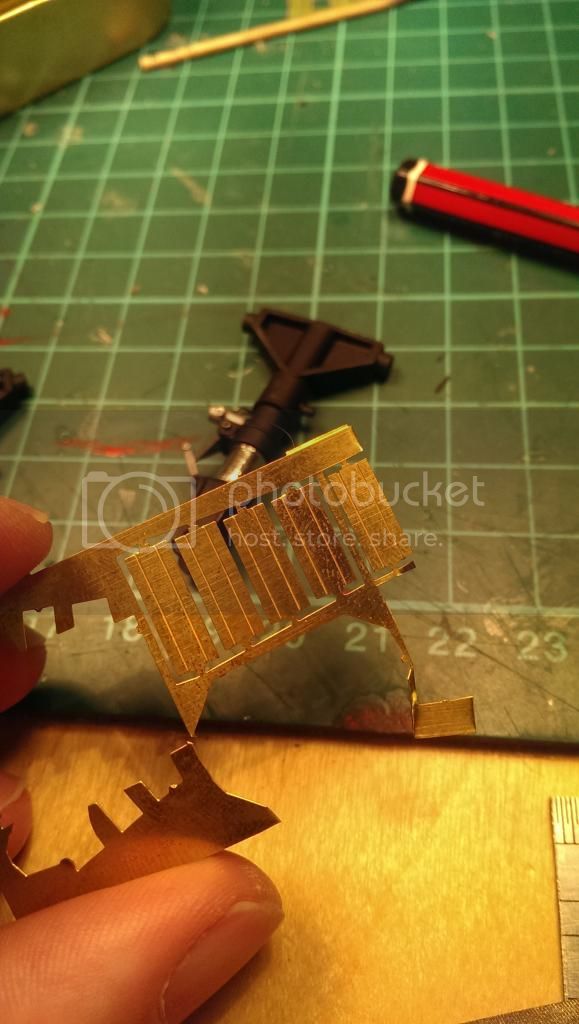

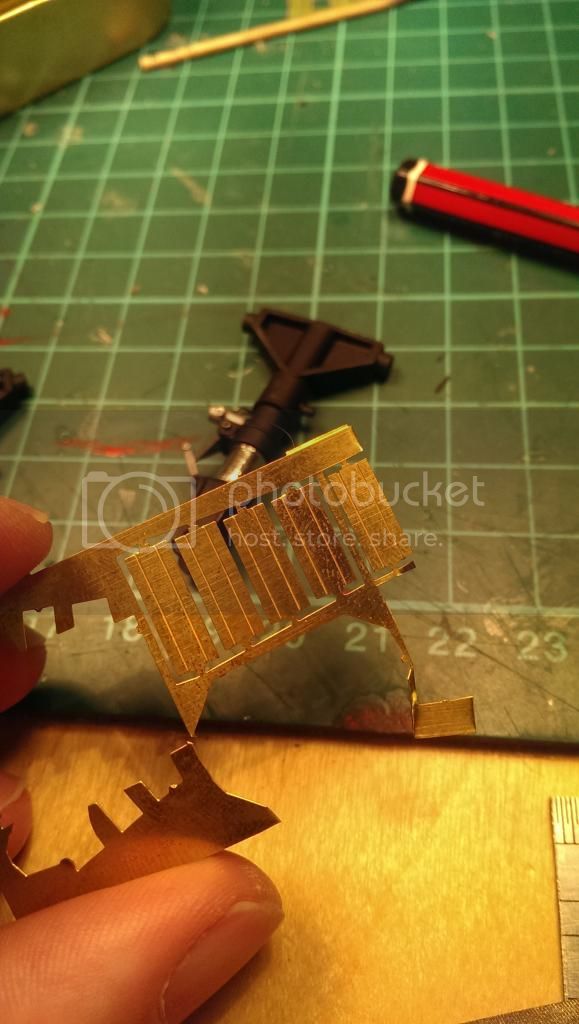

My first thought was to create them out of plasticard. The problem with this was that they were extremely fragile and any movement of the lines or gear would cause them to break off, not to mention that they looked rubbish. I thought that brass etch would be a much better solution. SO after a bit of looking around in the old spares box I found some leftover brass from some Flightpath F-111 ladders.

The outer part of the rung was the right width, it just needed to be trimmed to the correct length and bent to shape.

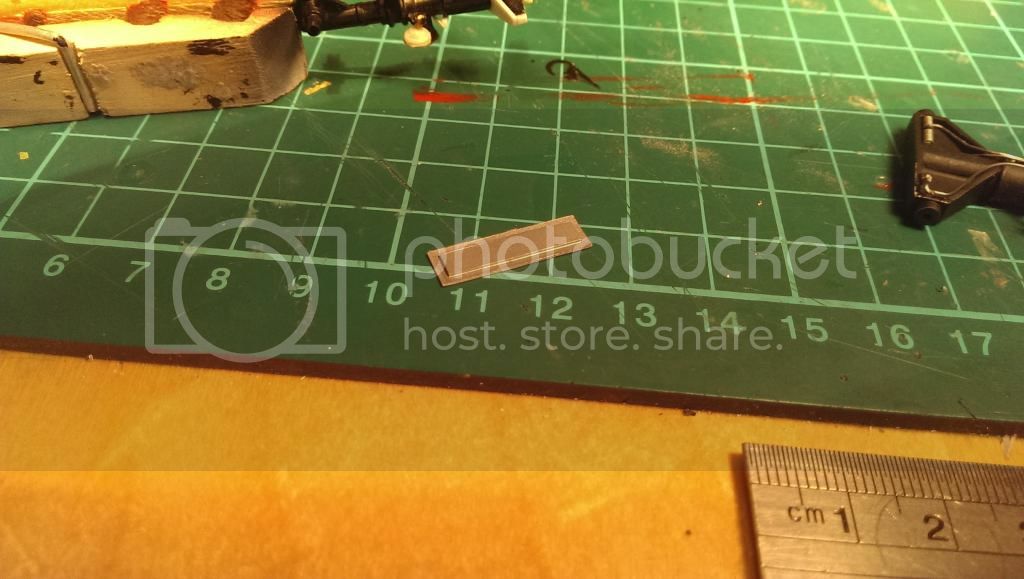

This is the end result...

I'm very happy with them and I believe they will be much stronger (not to mention better looking).

During this time I also built up and added the door connection, Hydraulic.... um... things

/> as seen here along with the finished bracket.