I would really love some feedback to see where I stand.

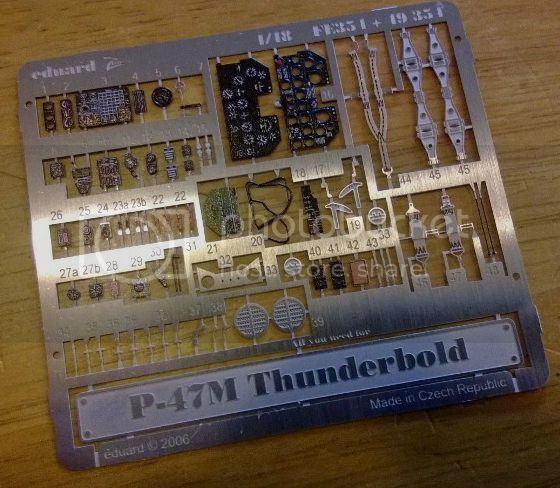

Areas where I feel I need a lot of help in are dealing with photo-etched parts. One this model I tried my hand at these ones made by eduard:

I live in Australia and it seems very difficult to obtain photo-etched parts locally. It also takes a long time to order them from overseas and this can really kill a lot of the momentum in a build.

But with regards to attaching photo-etched parts to models, I would really like to gain some insight into what is the correct type of adhesive to use. I read up that modelling glue is a no-no and a lot of people use regular super-glue. I personally didn't have much luck with the super-glue, so i'm very interested to learn how the veterans do it.

I also had a bit of trouble bending some of the photo-etched parts. Some of the seat-belt parts can be mighty tricky. is it just a matter of being very patient with tweezers, or am I missing something?

Thanks for reading my build. Sorry for weighting it wight a lot of questions at the end.

Dinuka