Hi Bob, Drabslab, Michael, Richard, Roy, et.al.,

Thank you for checking out this build. I am annoyed that I took the following photos back on the 9th, took them on a 3-week training trip to post, and then forgot about them. Three weeks late - hope this is worth the wait.

First, to answer some questions.

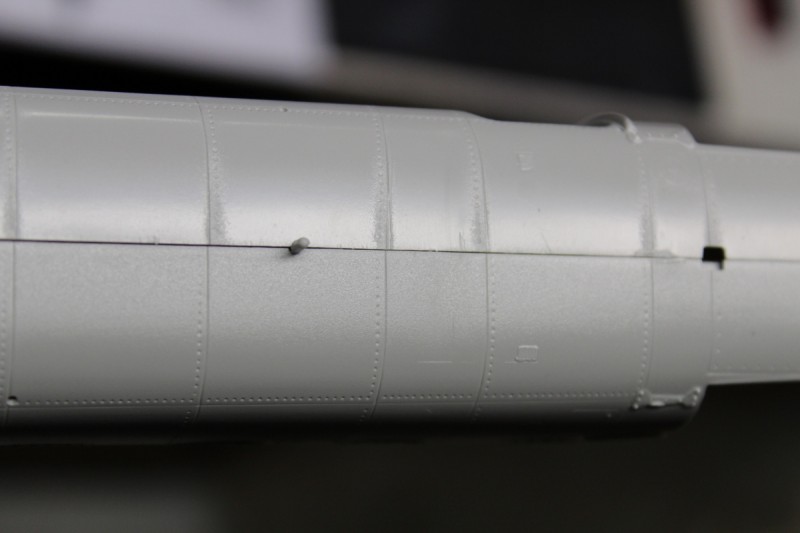

Drabslab - I do not know about the panel lines on the real thing.

Michael -

I assume this is the same model tooling as in years gone by so alignment and texturing of the molds may be getting a little long in the tooth? I do not know. I recall Italeri makes a 1/72 H-21 but otherwise the only other 1/48 H-21s I know of are the ancient Aurora model and the ones by Fonderie Miniature or Special Hobby.

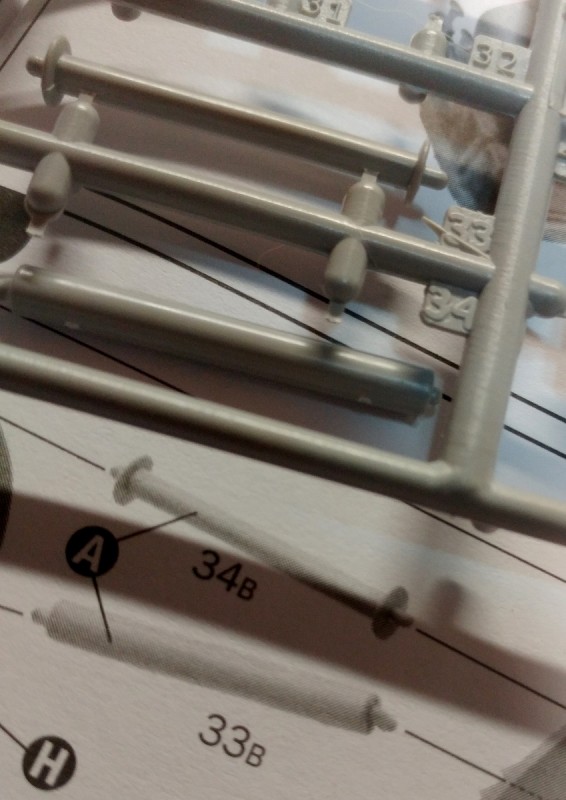

Roy - Fit might be tricky closing the fuselage. The fuselage interior lacks substantial alignment lines and troughs for the bulkheads, and that might make closing the fuselage challenging. But my main complaint is that the instruction sheet has some vague instructions, and some of the parts lack distinct attachment parts.

So now, some model updates!

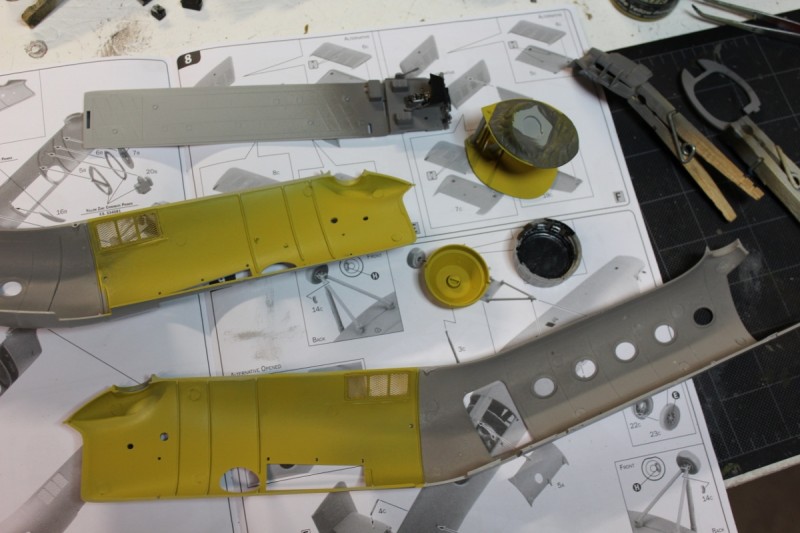

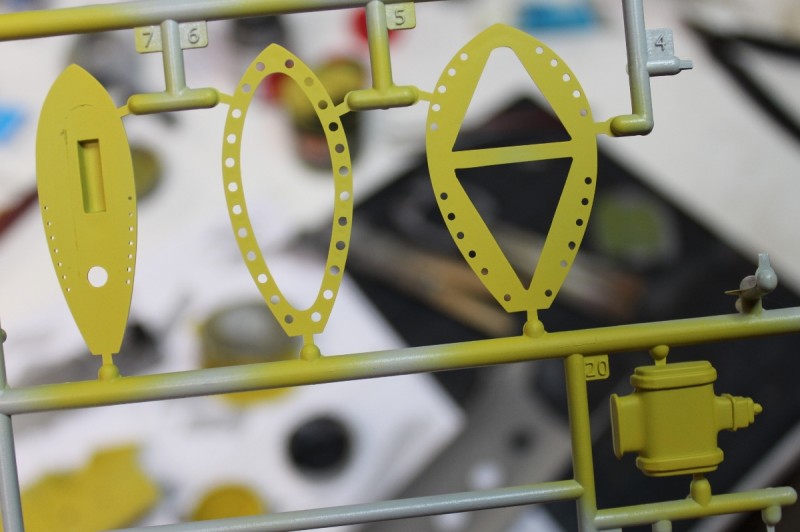

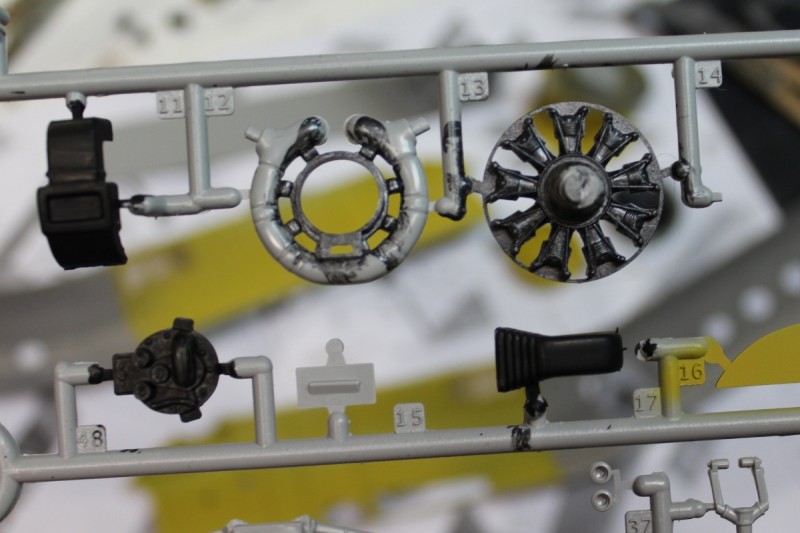

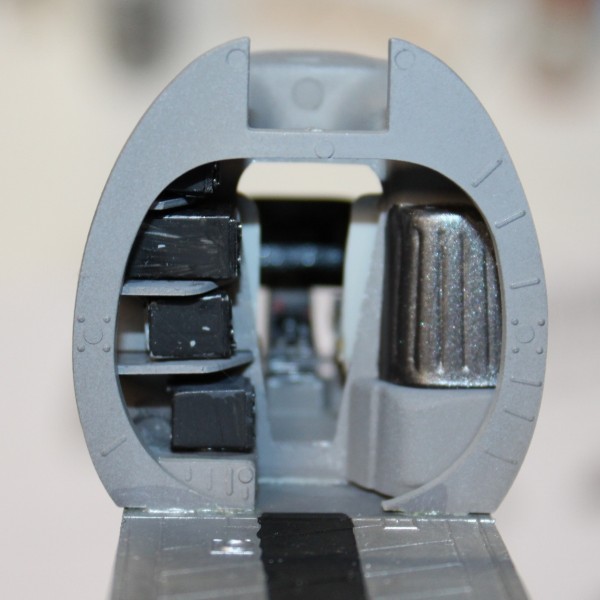

First, the powerplant. It is well rendered and has a separate manifold ring with separate exhaust outlets.

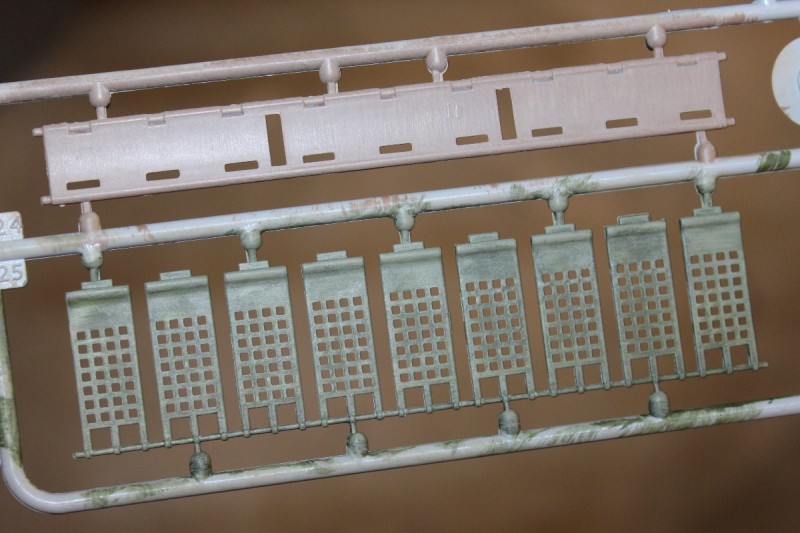

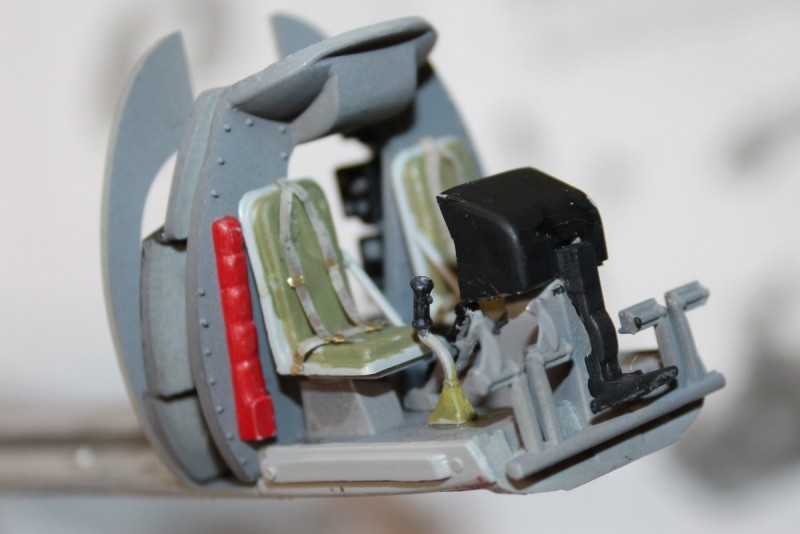

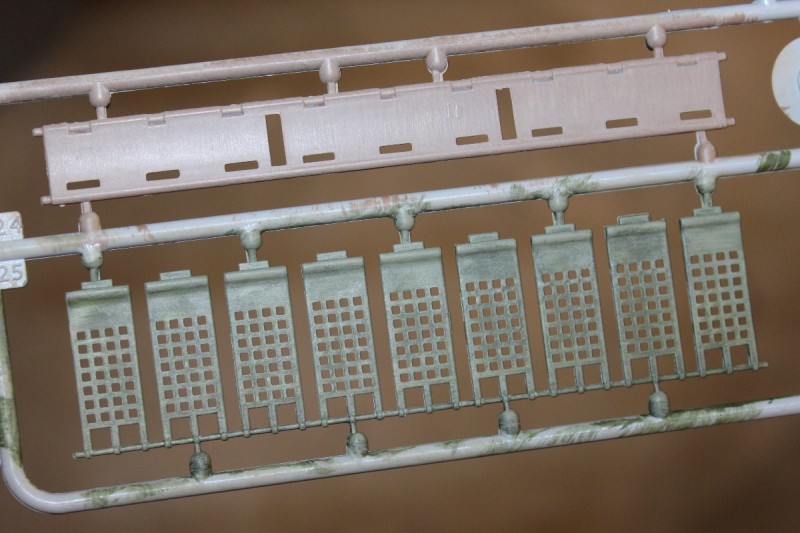

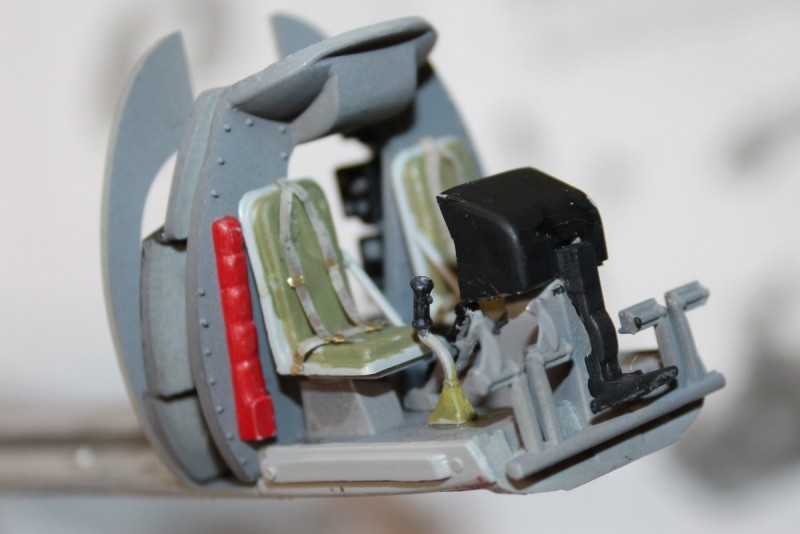

The seating for passengers:

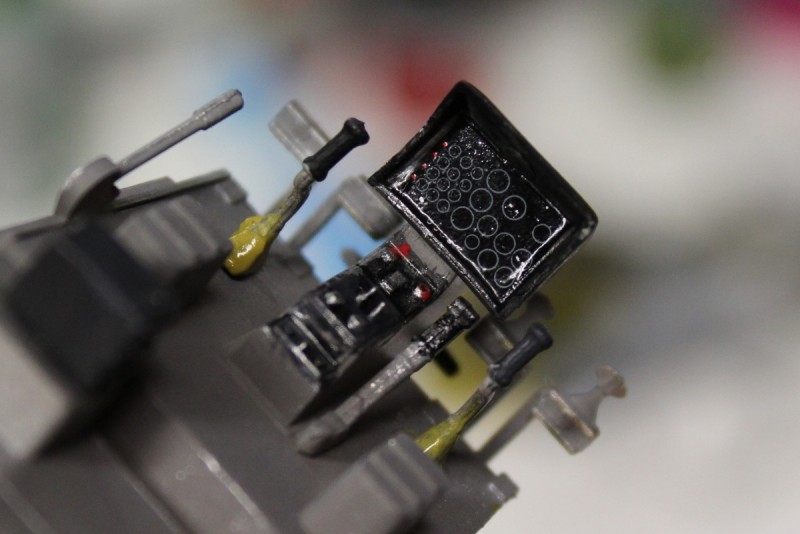

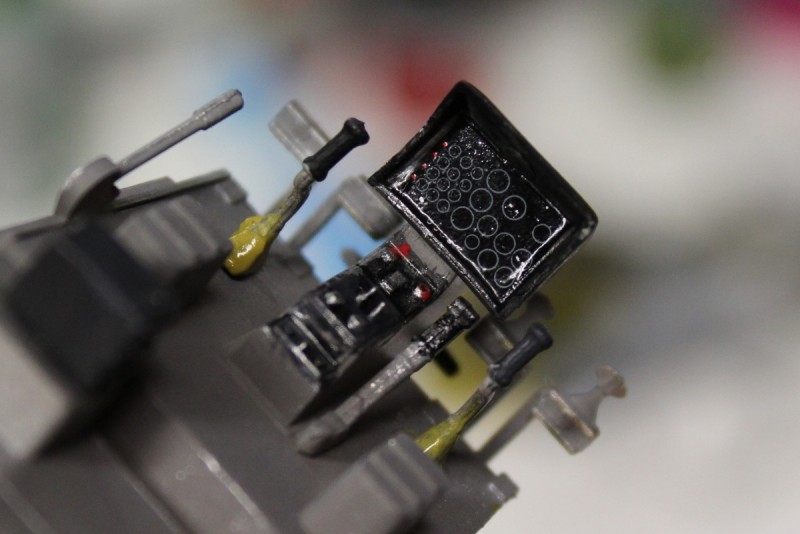

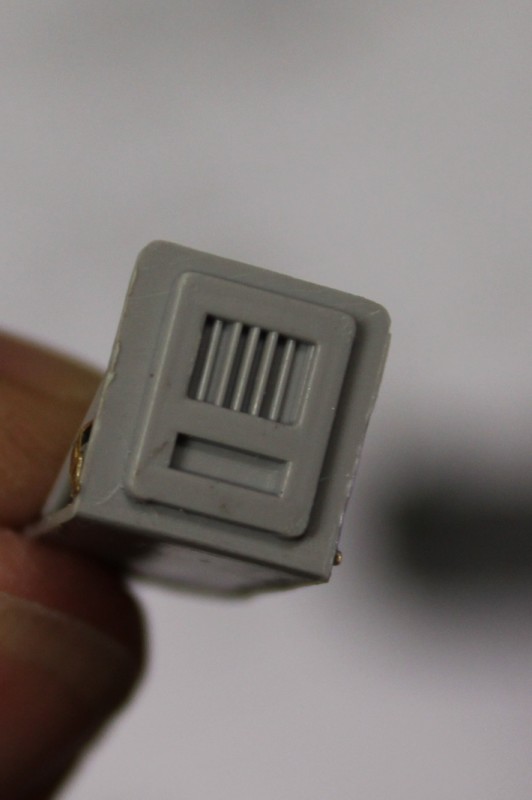

Italeri handles the instrument panel with a decal, a common method. But the bezels are so faint, as are the dial details.

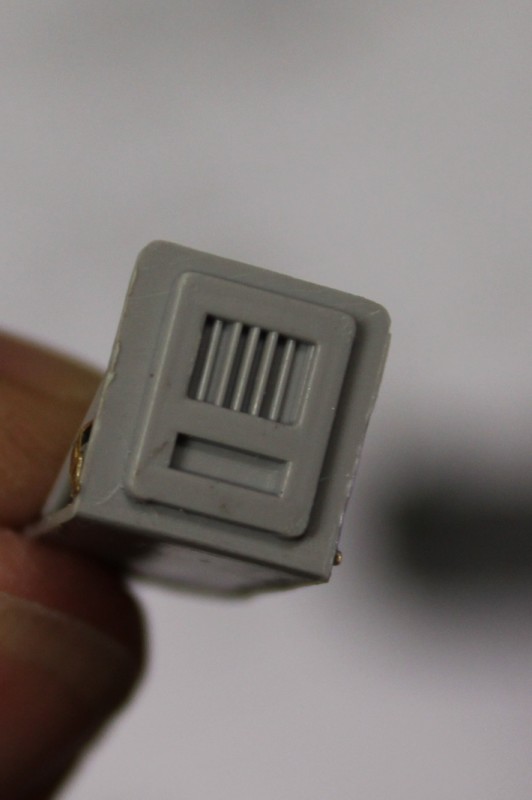

One of you helo experts may be able to tell me why the seat of the seat is so detailed?

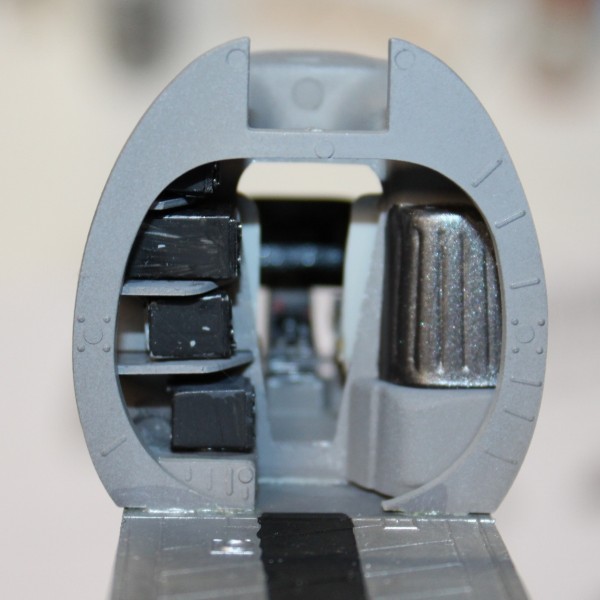

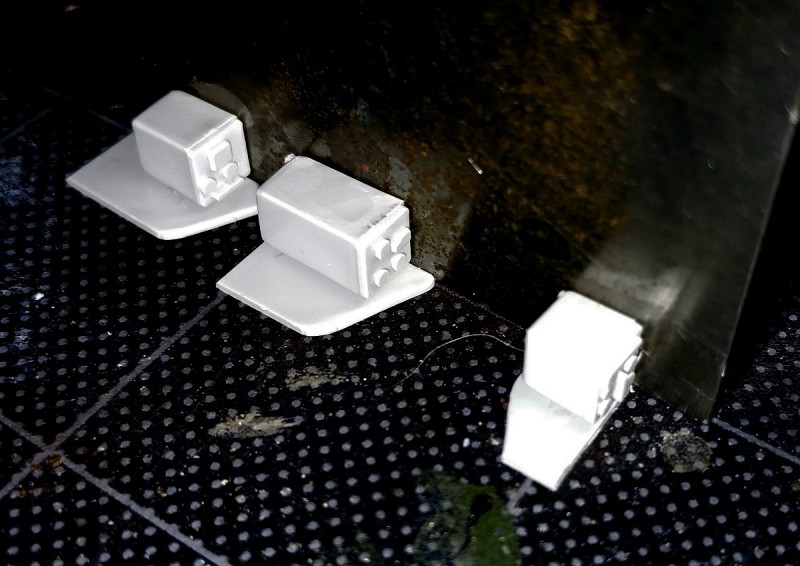

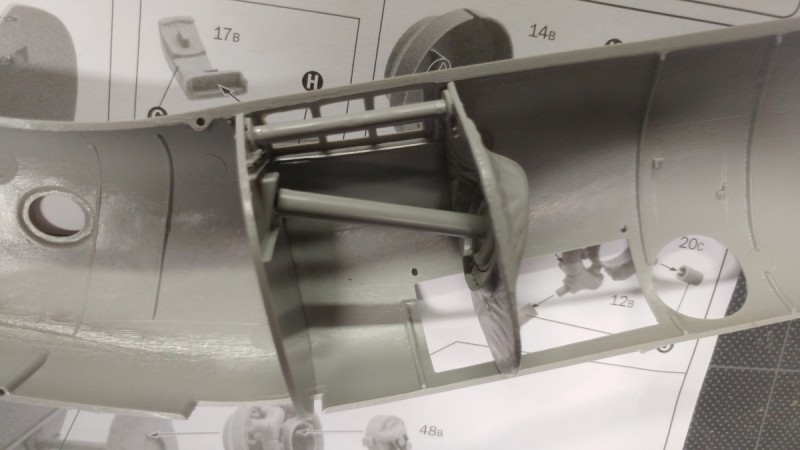

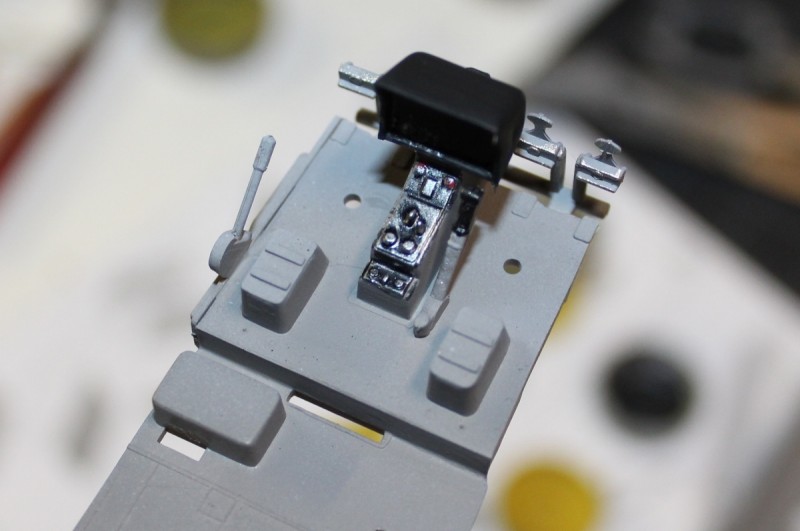

Assembly of the comm stack is interesting. Four radios set upon three shelves and a lump molded on the floor. The shelves are separate pieces and fit between bulkheads - slots behind the pilot and ridges fore the passenger /cargo area. Each radio fits onto its shelf via a protrusion under the radios. There is nothing to indicate alignment. I put a lot of effort into lining up the radios on the shelves, only to find out that they did not fit well against the cockpit bulkhead. So I plucked them off, joined the shelves to both bulkheads, and reinstalled the radios.

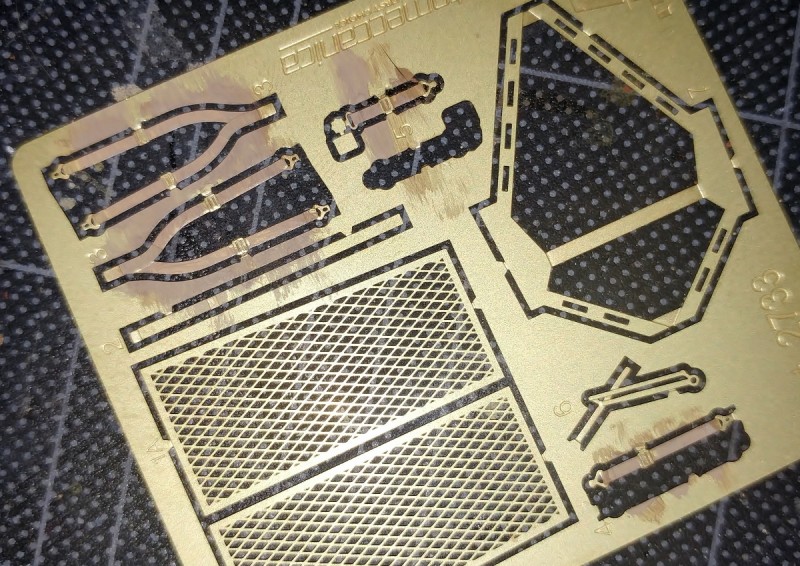

There is a piece of P/E that is shown to be involved with the assembly, but I can not figure where it is supposed to be attached.

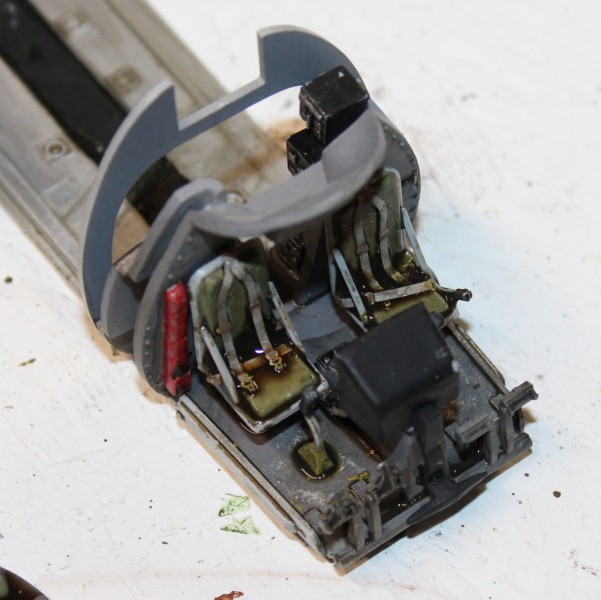

The cockpit is assembled.

Yes, your see that correctly. The forward bulkhead

does slope forward. To prove it, I put the assembly next to a reference photo in the instructions.

Yes, Italeri's instructions are a mixed bag. I'll comment more during the build if need be.

I apologies for the delay in posting this update and hope you check back for the next one.

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

---(1200x912).jpg)

---(1200x587).jpg)

---(596x1200).jpg)

---(968x1200).jpg)

.jpg)