The kit is the Vintage Fighters Series P-47D Thunderbolt in 1/24th scale, and it has been covered in a couple of build logs here and in other forums, but I am going to run another detailed build log here as I am going to be using a few weathering techniques and products to try to show a fairly "war-weary" subject.

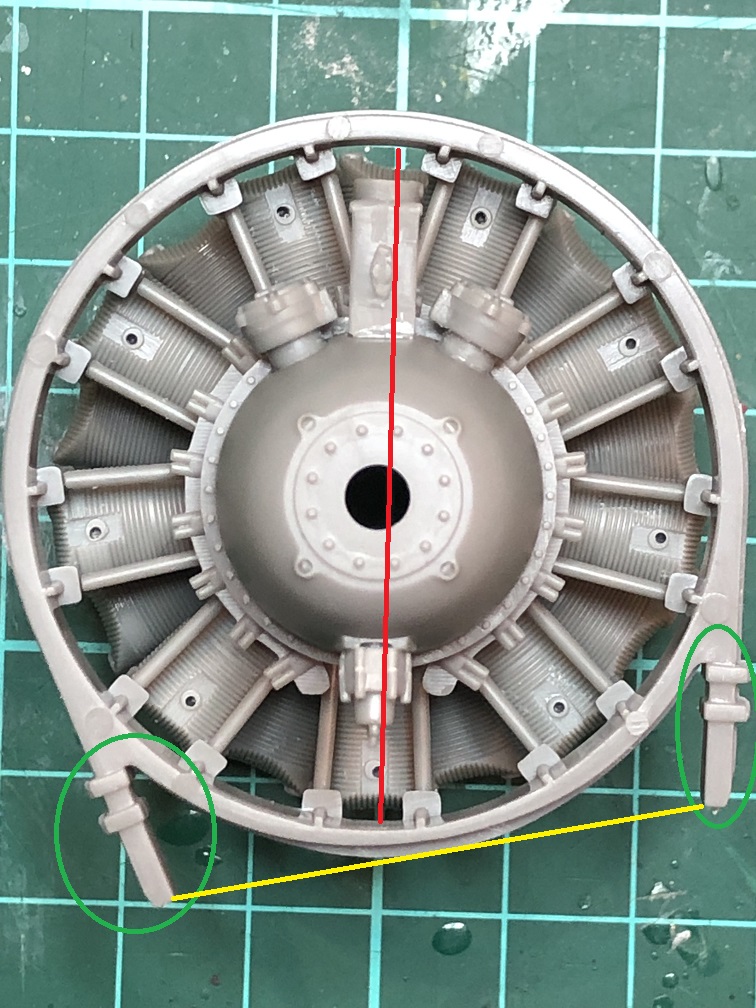

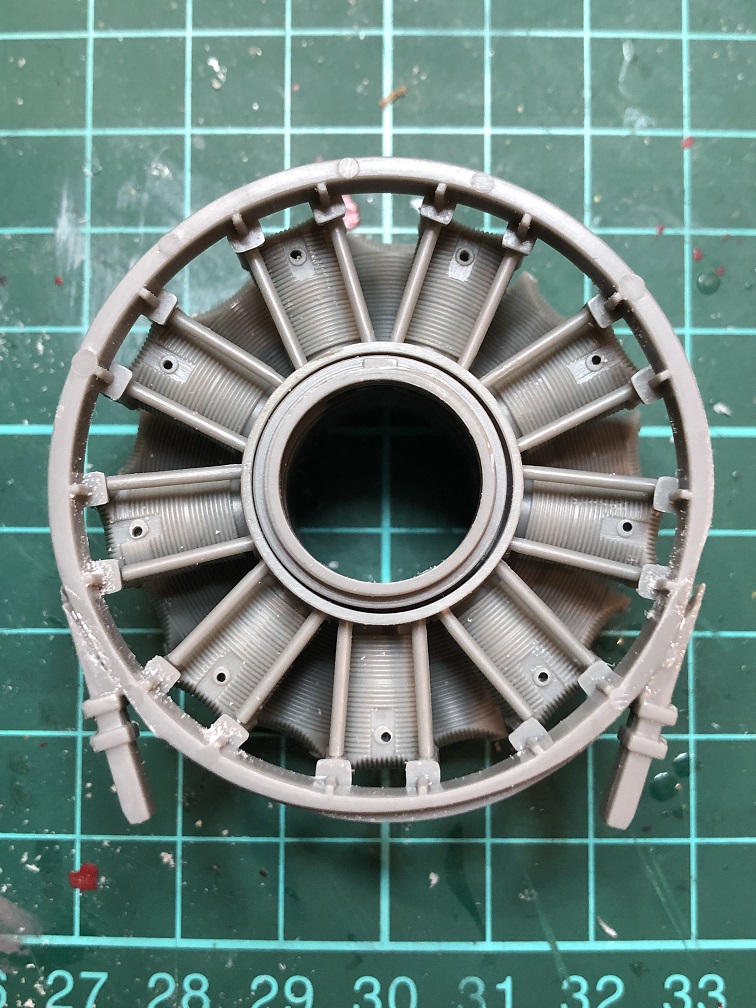

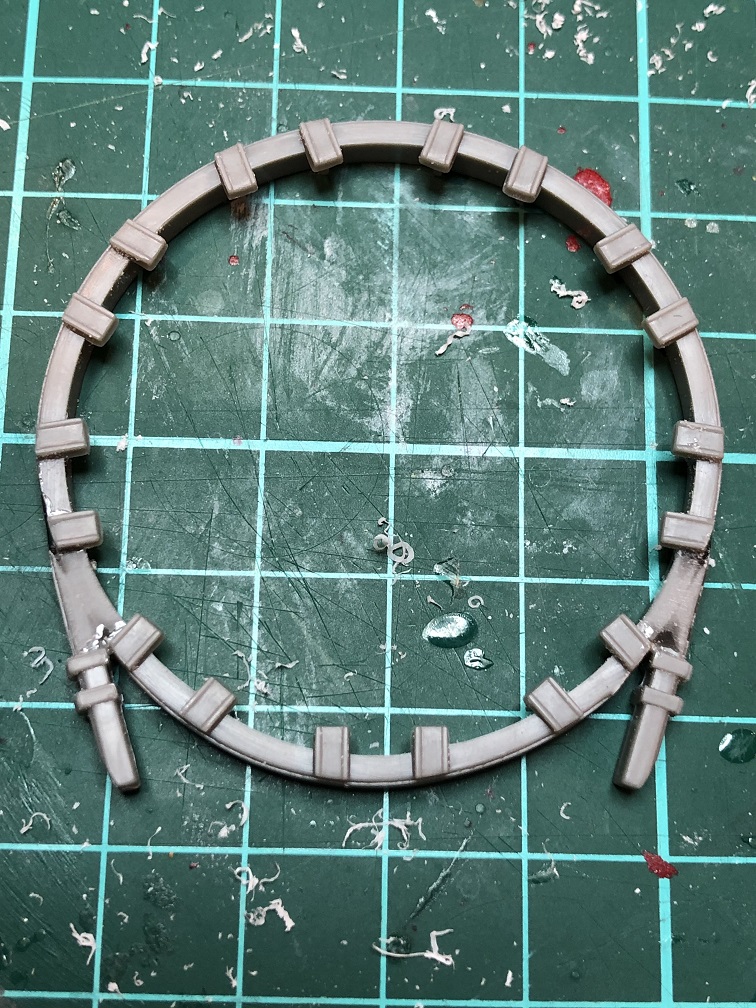

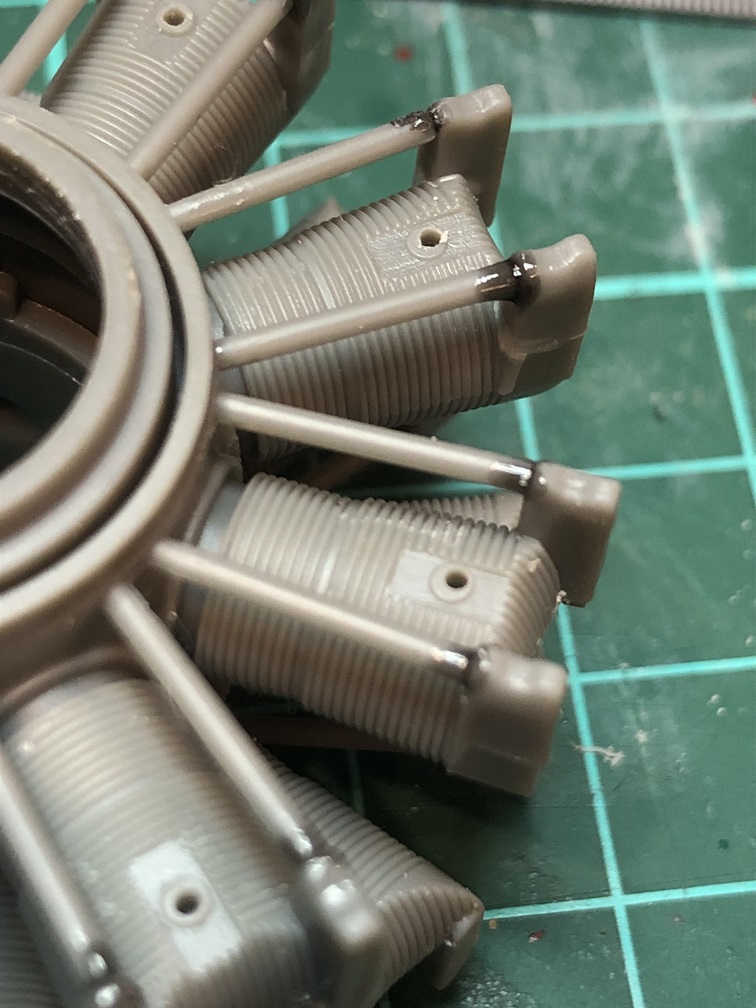

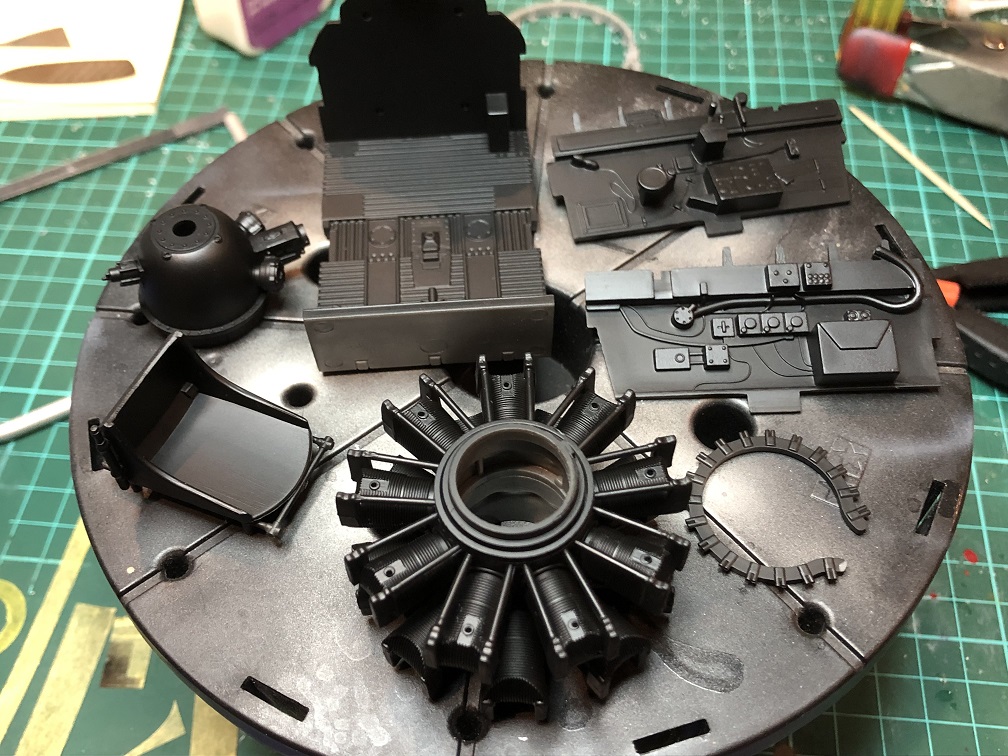

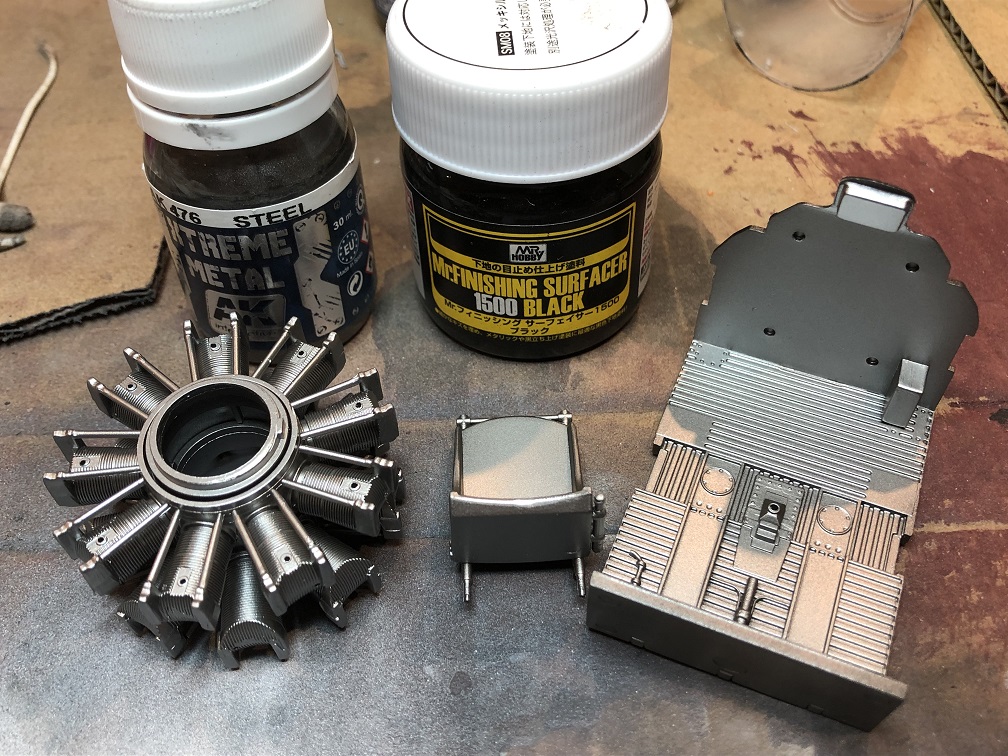

Here are a couple of shots I took back in 2009 when I tinkered with a few of the sub-assemblies. There is a 1/72 Revell P-47D sitting amongst the 1/24 parts to get a concept of the scale.

I started a build log back then, but it has been severely "Photobucketed" and I'm not going back to try to fix it as the scope of the build has changed.

As always, I welcome any and all comments, critique, suggestions and advice. I'm here to learn on every kit I start, and I hope that others will benefit from my rambling builds and commentary!

Cheers, D