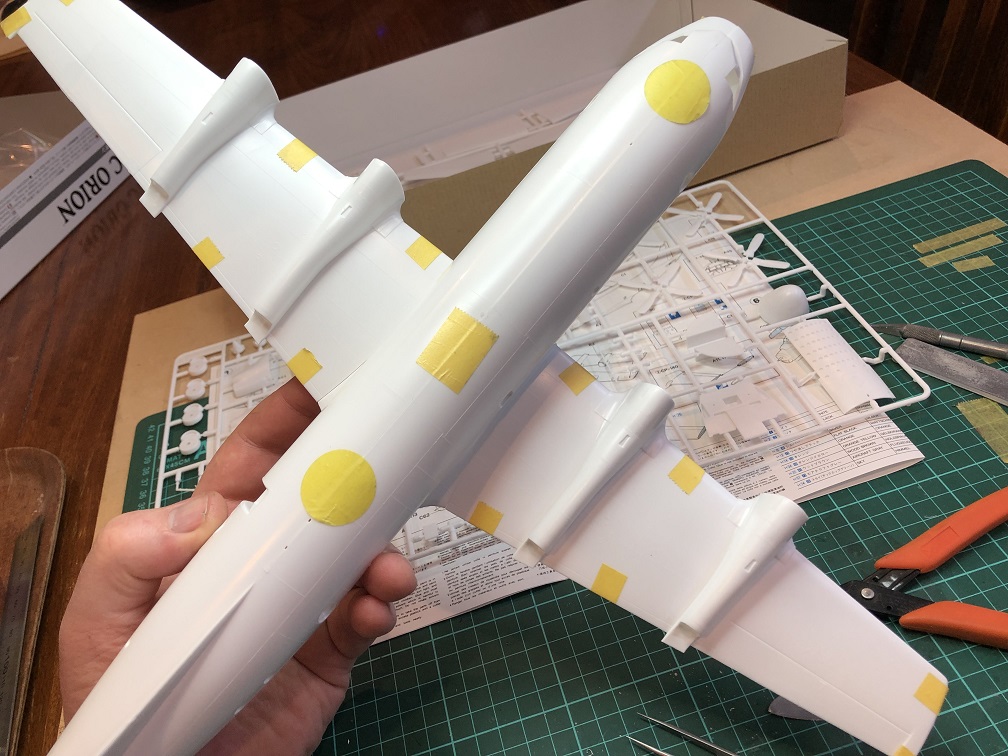

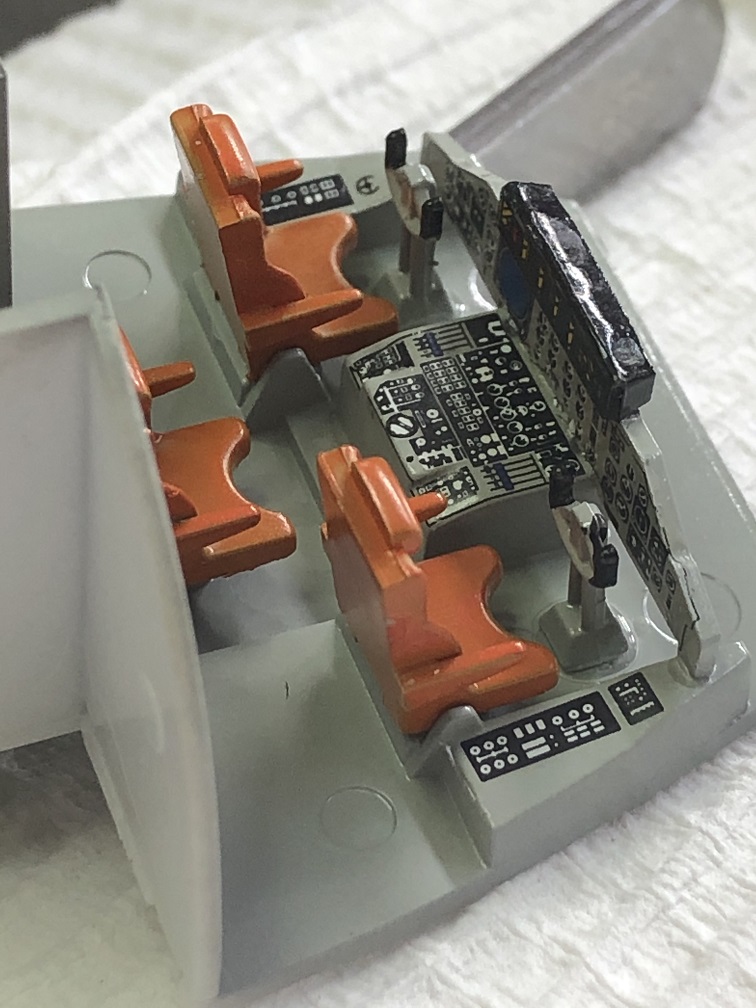

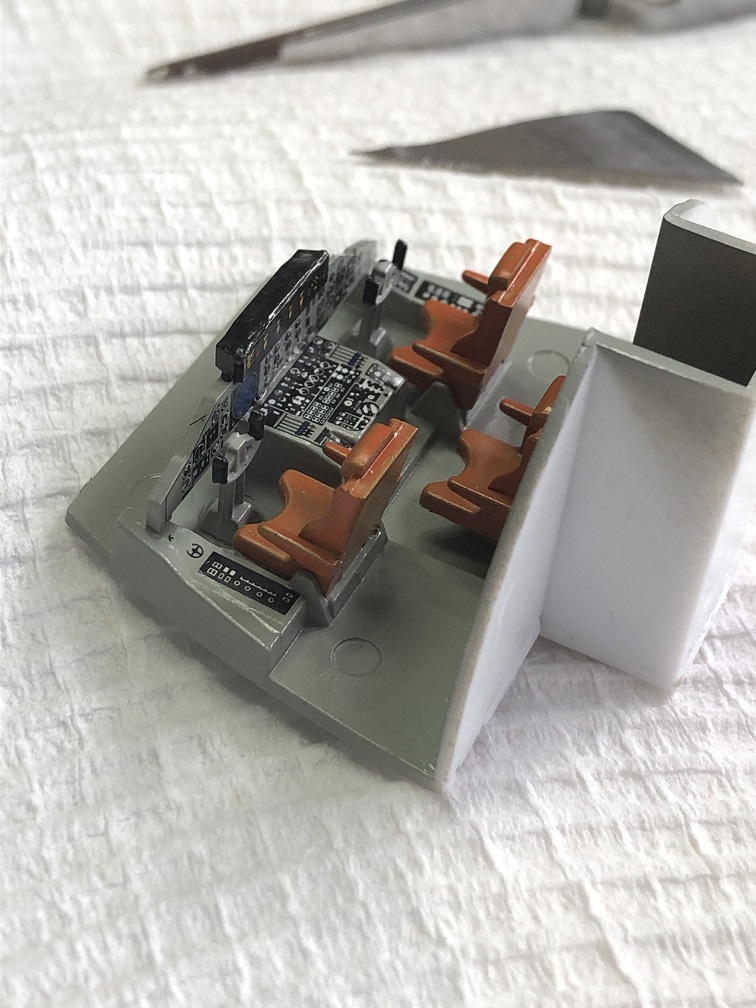

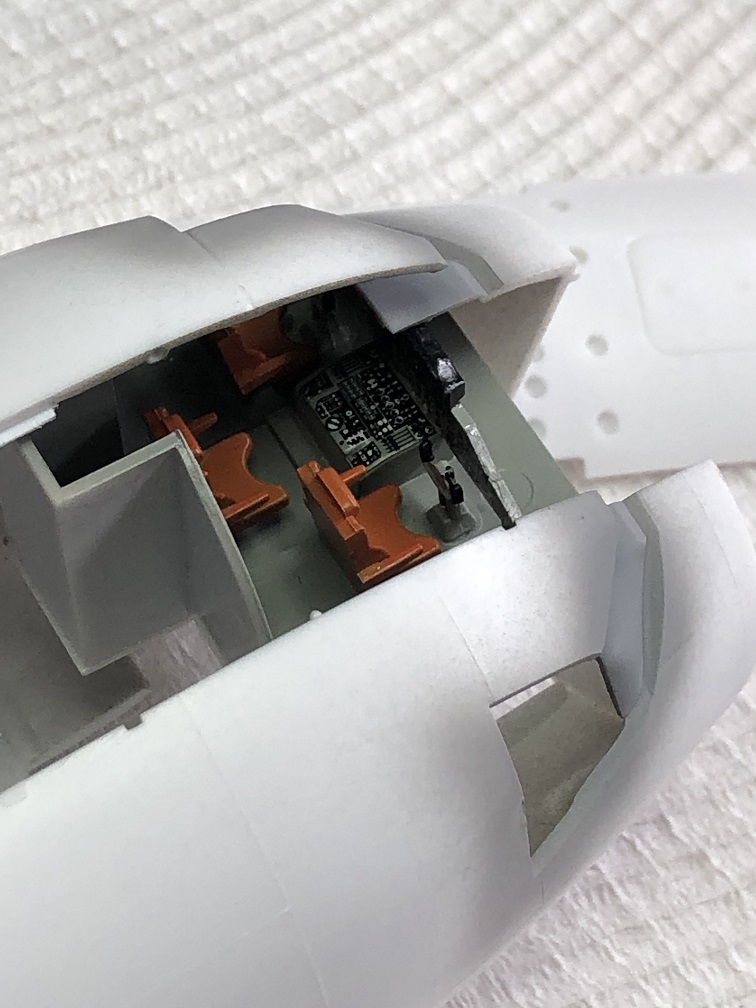

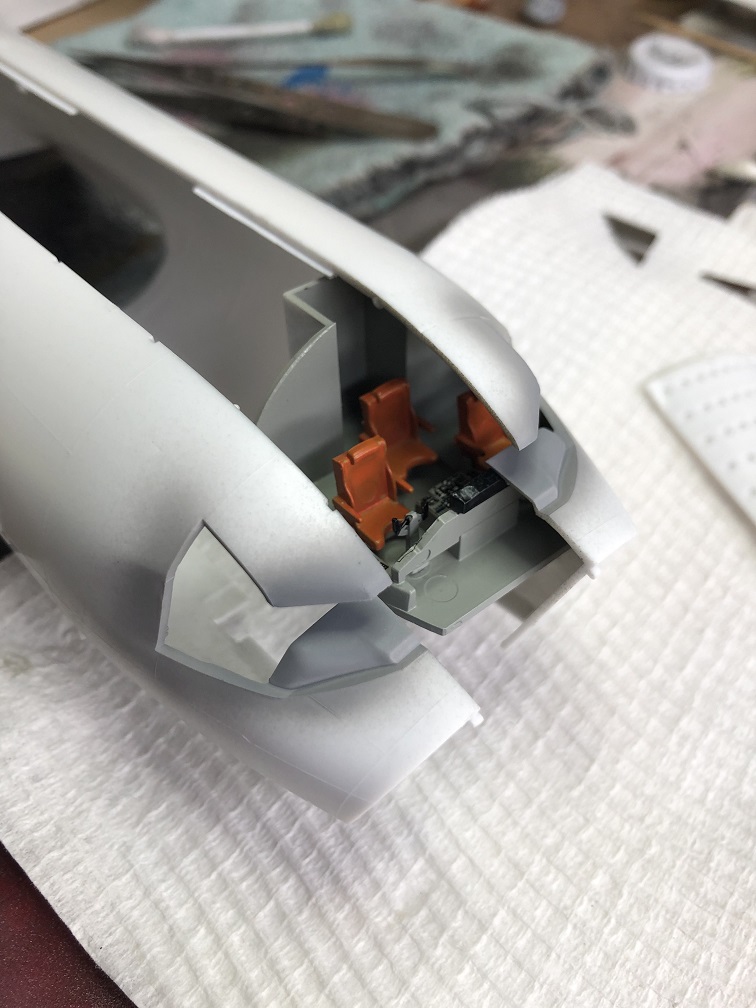

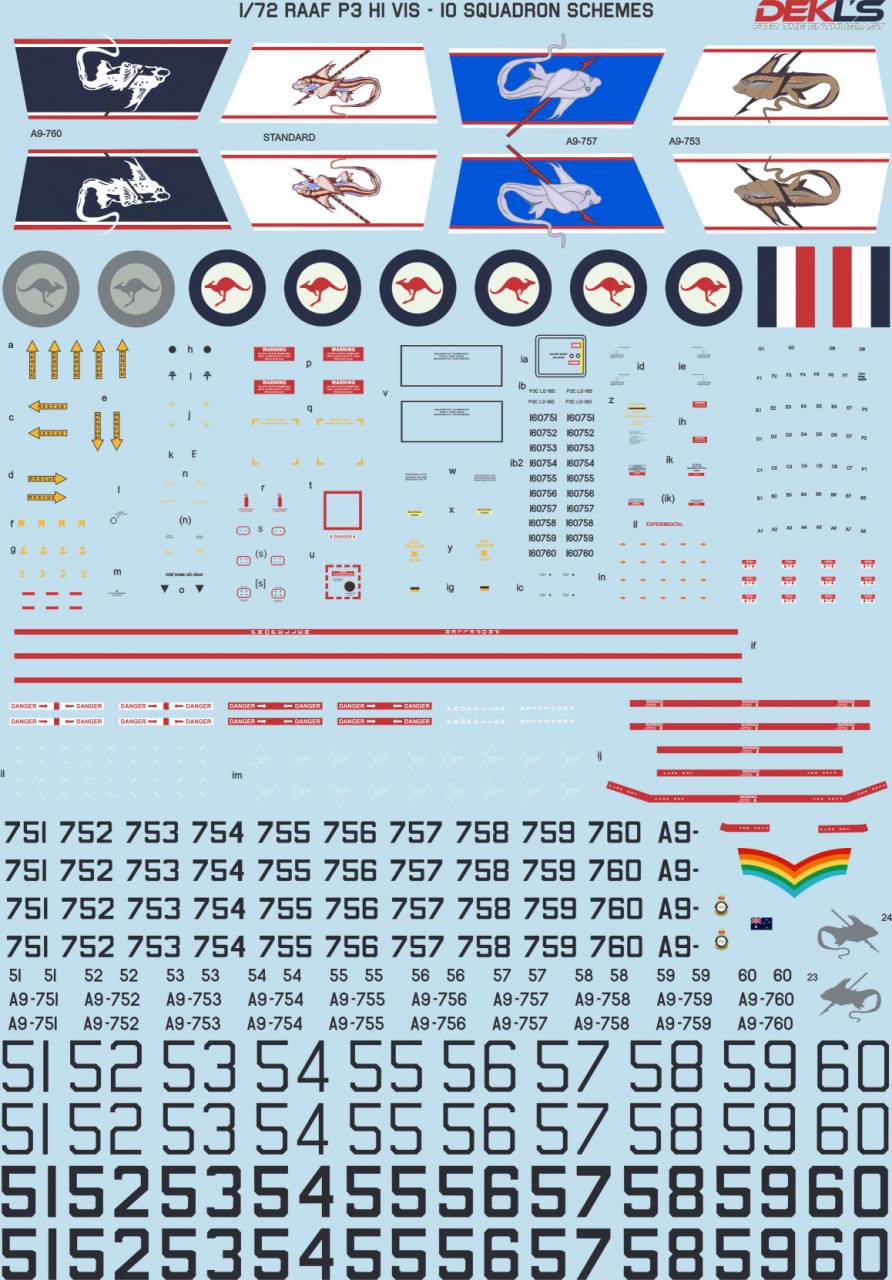

One of my best friends is an RAAF Squadron Leader, and in his early years in the service was an electronics engineer on the P-3C. He has asked me to build one of the aircraft that he worked on, Serial A9-757 from 10 Squadron RAAF.

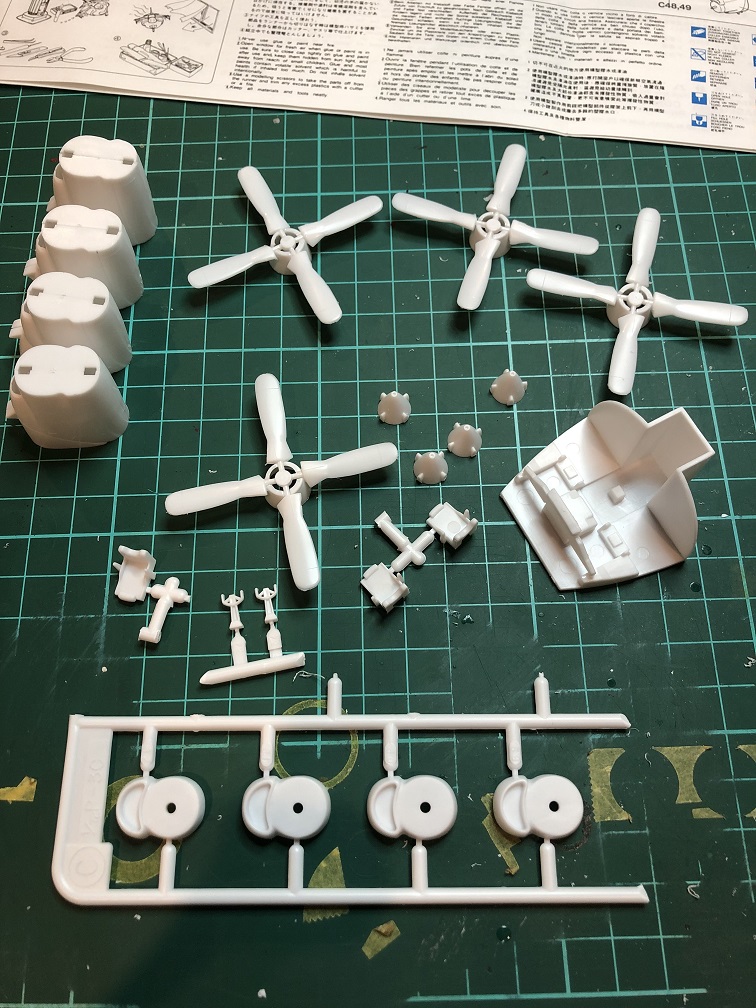

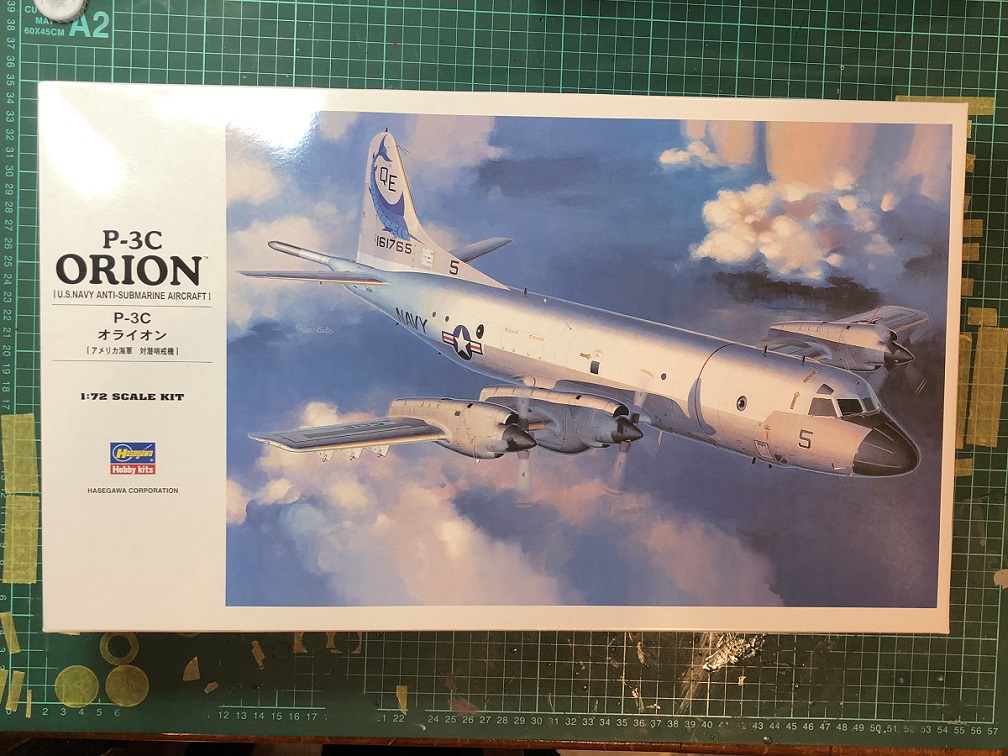

He picked up the kit and gave it to me, and I have ordered the decal set from a local supplier.

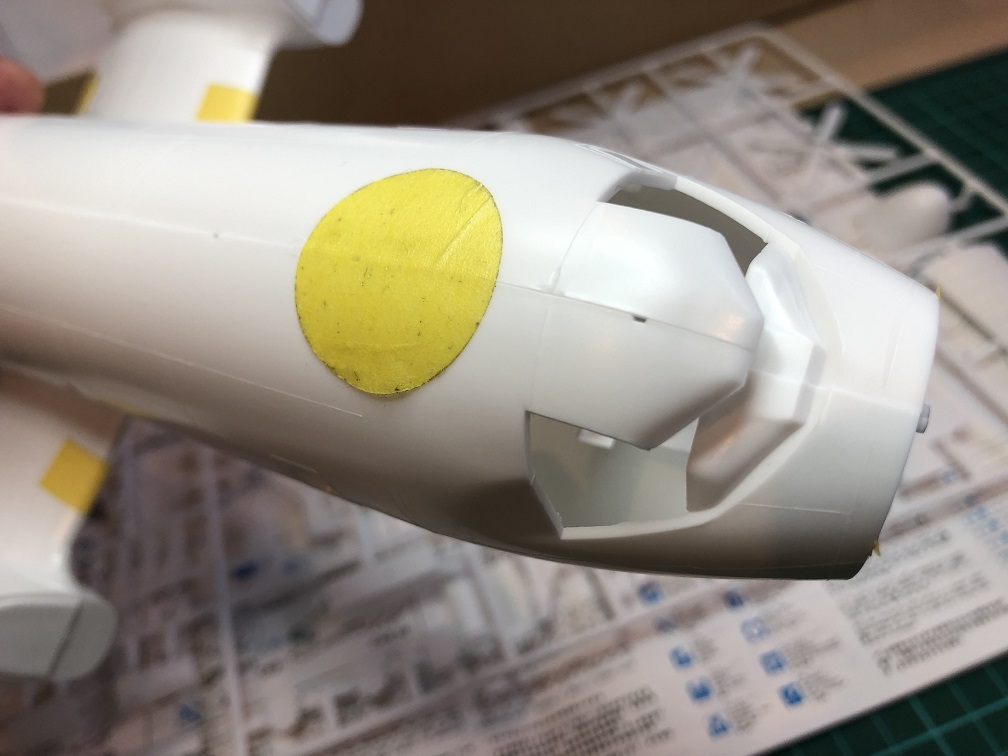

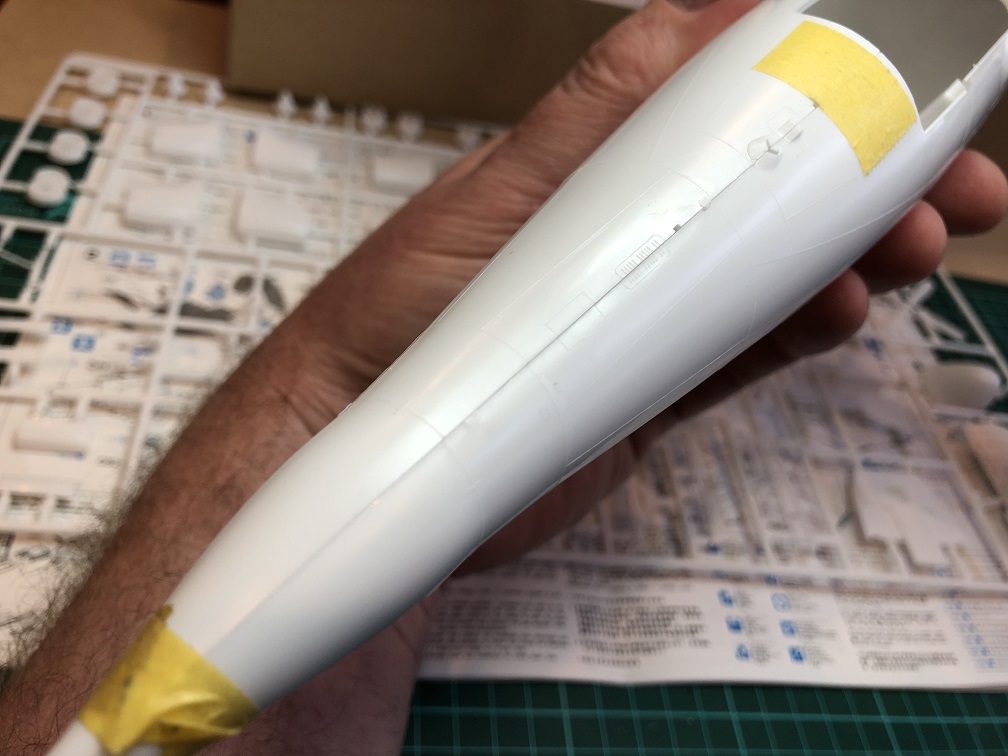

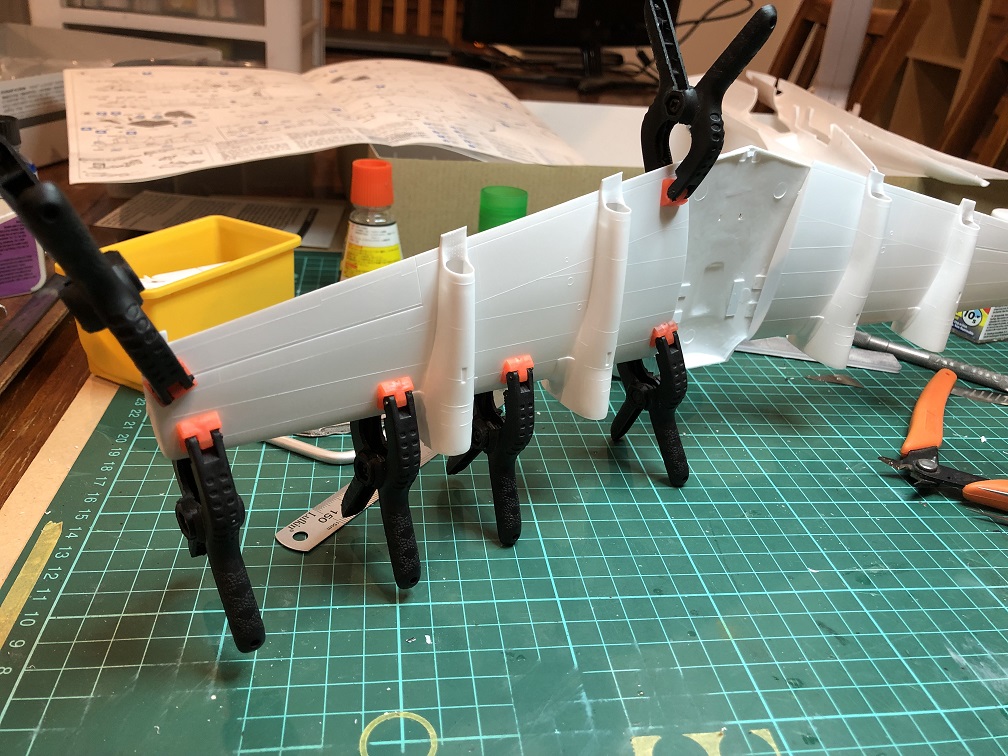

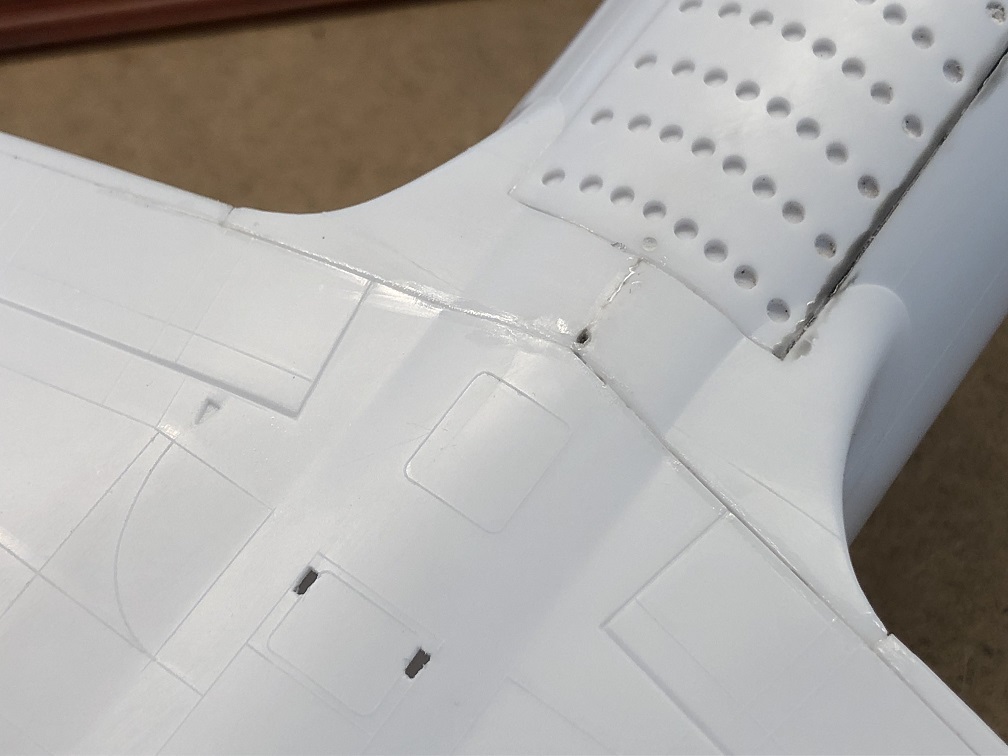

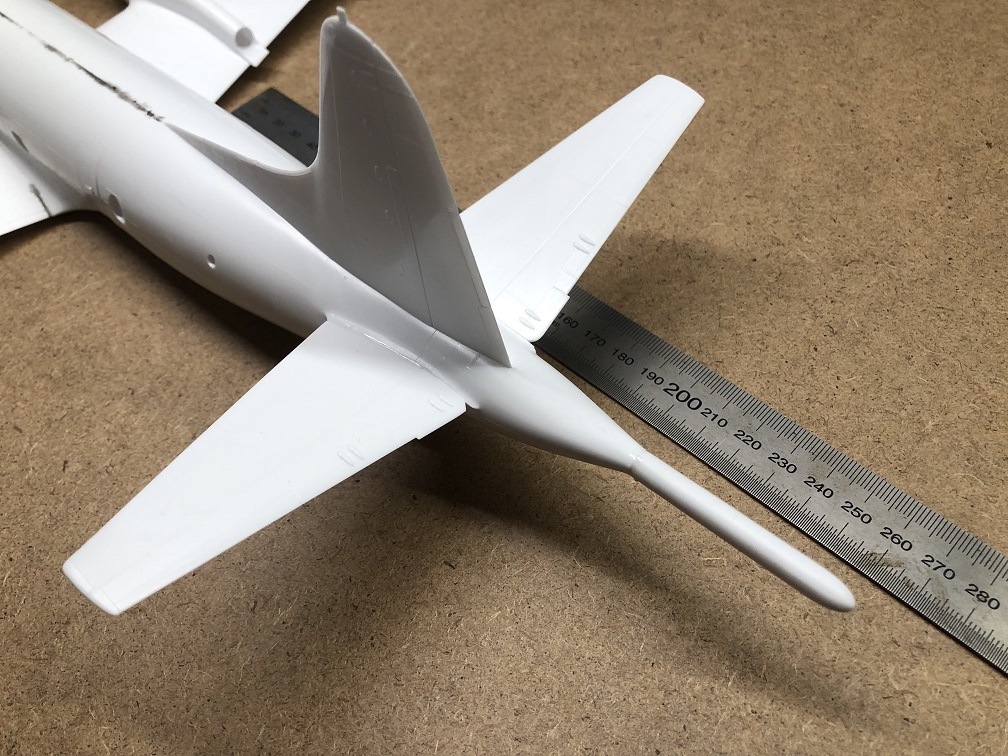

I will post up progress as I make my way through this build, which is a bit outside my comfort zone of single engine WWII fighters and old Chevy cars

He also worked on F/A-18A Hornets, and is moving to the USA on a 3 year contract to look after the EA-18G Growlers, and has asked me to build one of each of those as well

Cheers, D