I picked up a MONOGRAM F-80 kit for change. Just now got around to looking at it with the intention of maybe building it for some relaxation.

The wing bottom is one peice and warped almost to the point of looking like a bow.

I thought that I had read in a post some years back that boiling water was used to take out warps.

If anyone has a tip on how to do this please help me out.

Bob

General Aircraft

This forum is for general aircraft modelling discussions.

This forum is for general aircraft modelling discussions.

Hosted by Jim Starkweather

MONOGRAM F-80 WARPED WING QUESTION

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, September 22, 2019 - 01:18 PM UTC

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Sunday, September 22, 2019 - 03:09 PM UTC

You can dip the wing briefly in water that has been briefly brought to the boiling point, then turn the heat off before the dipping-- but wear gloves and be careful. Another technique is to play a hair dryer back and forth over the part and carfully bend it back into shape. I have a folding travel hair dryer on my workbench just for this purpose and to assist with difficult decals (Roden's for example) the travel types are usually smaller, putting heat into a smaller area. But-- have you tried to see if the parts will straighten out by placing the top wings on and using a rubber band to see if that works first?

VR, Russ

VR, Russ

Naseby

Joined: October 15, 2010

KitMaker: 825 posts

AeroScale: 476 posts

Posted: Sunday, September 22, 2019 - 06:13 PM UTC

Glue a spar in the wing. Using the hot treatment is a huge risk. I

messed up an Avenger wing this way in the past.

messed up an Avenger wing this way in the past.

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, September 22, 2019 - 06:57 PM UTC

@ Naseby: I tried cutting out a spar, but the wing is so thin that my efforts were not good.

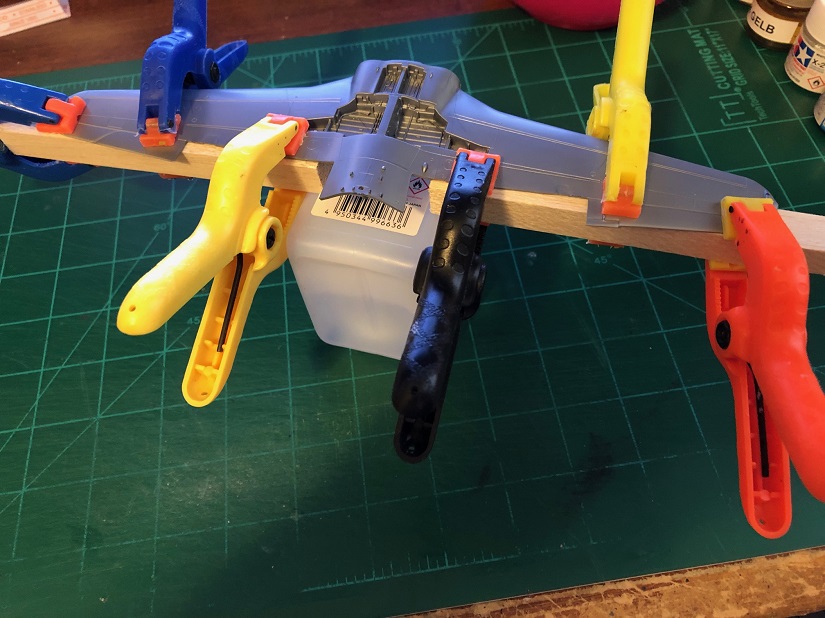

@ Russ: I have clamped 1/2" x 1/2" wood to the wing and thought that I would try the hot water method.

@ Russ: I have clamped 1/2" x 1/2" wood to the wing and thought that I would try the hot water method.

magnusf

Joined: May 02, 2006

KitMaker: 1,953 posts

AeroScale: 1,902 posts

Posted: Sunday, September 22, 2019 - 07:34 PM UTC

Give it a try but I think the chances for a good-as-new-result are slim  . I had a minor warp on a wing once that curled up like a piece of bacon in a hot frying pan when trying to straighten it using hot water...

. I had a minor warp on a wing once that curled up like a piece of bacon in a hot frying pan when trying to straighten it using hot water...

Sorry for being pessimistic!

Magnus

. I had a minor warp on a wing once that curled up like a piece of bacon in a hot frying pan when trying to straighten it using hot water...

. I had a minor warp on a wing once that curled up like a piece of bacon in a hot frying pan when trying to straighten it using hot water...Sorry for being pessimistic!

Magnus

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, September 22, 2019 - 07:54 PM UTC

Magnus, thank you for your input. I will try the hot water and it will be no loss if the wing does not weather the effort. It only cost $1.26 USD. So this could be a test kit.

Bob

Bob

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Monday, September 23, 2019 - 02:16 AM UTC

Bob, I'd try the boiling water trick as a last resort. I usually grab the hair dryer tick first. You've got the right idea with the board, but some wood will warp as well in hot water-- I use a foot long aluminum ruler, depending on the part. I forgot to mention that. Getting an entire wing into a pot of near boiling water is a trick in itself-- use a pair of kitchen tongs-- I also forgot to mention that.

VR, Russ

VR, Russ

M4A1Sherman

Joined: May 02, 2013

KitMaker: 4,403 posts

AeroScale: 254 posts

Posted: Monday, September 23, 2019 - 03:43 AM UTC

Quoted Text

Bob, I'd try the boiling water trick as a last resort. I usually grab the hair dryer tick first. You've got the right idea with the board, but some wood will warp as well in hot water-- I use a foot long aluminum ruler, depending on the part. I forgot to mention that. Getting an entire wing into a pot of near boiling water is a trick in itself-- use a pair of kitchen tongs-- I also forgot to mention that.

VR, Russ

AGREE-

Hi, Russ!

M4A1Sherman

Joined: May 02, 2013

KitMaker: 4,403 posts

AeroScale: 254 posts

Posted: Monday, September 23, 2019 - 04:42 AM UTC

Hi, All-

Interestingly enough, I bought one of those when they first came out, back in the late 1970s. My Lower Wing was warped, but not very badly. My cure was to use the old, slow-drying TESTORS (tube) Cement- This was the old "recipe" stuff before they changed the formula to comply with the ofttimes ridiculous EPA/CPA/FBI/CIA/AFLCIO/ICCMC/SWAK/EVOO and IOU regulations.

HOWZZAT fer "Alphabet Soup"???

I glued the Upper Wing halves to the Lower Wing and clamped them all together, using a half-dozen of the old-style wooden clothespins with the metal springs in them. I slipped a washcloth between the surfaces of the Upper and Lower Wings and the clothespins in order to protect the surfaces from being marred. I then very carefully slipped two 6-inch steel rules in-between the clothespins and the washcloth, making sure that the steel rules were placed in positions in support of the Lower Wing, and lining up with the Upper Wing halves. These steel rules were added to give me a little bit of extra rigidity...

After setting the Wing assembly aside to dry overnight, I went on to other things. (Namely, my second MONOGRAM 1/48 B-17G) The following morning, I saw that this "method" worked in straightening out the "wing-warp" of my F-80. "Old school", yes. But it worked...

As I said in the beginning of this post, my Lower Wing wasn't very badly warped, so it stands to reason that the Lower Wing conformed to the "strength" of the two Upper Wing parts AND the "stiffening-help" of the two steel rules. Not quite as drastic or as dangerous(?) as the boiling water-trick, but this method was still quite effective in giving me a properly-straightened Wing assembly, without ruining the dihedral-angle of the Wing...

(Note: dihedral- the angle of which the wings of an aircraft are vertically inclined- Websters Collegiate Dictionary)- NOT being a smart-aleck; some of the newer modelers may not be familiar with the term "dihedral", that's all...

I'm not saying that this method will work in the case of this particular F-80 kit, but it might work in other cases. I've used this little "trick" several times subsequently, with good results...

VR, Dennis

Interestingly enough, I bought one of those when they first came out, back in the late 1970s. My Lower Wing was warped, but not very badly. My cure was to use the old, slow-drying TESTORS (tube) Cement- This was the old "recipe" stuff before they changed the formula to comply with the ofttimes ridiculous EPA/CPA/FBI/CIA/AFLCIO/ICCMC/SWAK/EVOO and IOU regulations.

HOWZZAT fer "Alphabet Soup"???

I glued the Upper Wing halves to the Lower Wing and clamped them all together, using a half-dozen of the old-style wooden clothespins with the metal springs in them. I slipped a washcloth between the surfaces of the Upper and Lower Wings and the clothespins in order to protect the surfaces from being marred. I then very carefully slipped two 6-inch steel rules in-between the clothespins and the washcloth, making sure that the steel rules were placed in positions in support of the Lower Wing, and lining up with the Upper Wing halves. These steel rules were added to give me a little bit of extra rigidity...

After setting the Wing assembly aside to dry overnight, I went on to other things. (Namely, my second MONOGRAM 1/48 B-17G) The following morning, I saw that this "method" worked in straightening out the "wing-warp" of my F-80. "Old school", yes. But it worked...

As I said in the beginning of this post, my Lower Wing wasn't very badly warped, so it stands to reason that the Lower Wing conformed to the "strength" of the two Upper Wing parts AND the "stiffening-help" of the two steel rules. Not quite as drastic or as dangerous(?) as the boiling water-trick, but this method was still quite effective in giving me a properly-straightened Wing assembly, without ruining the dihedral-angle of the Wing...

(Note: dihedral- the angle of which the wings of an aircraft are vertically inclined- Websters Collegiate Dictionary)- NOT being a smart-aleck; some of the newer modelers may not be familiar with the term "dihedral", that's all...

I'm not saying that this method will work in the case of this particular F-80 kit, but it might work in other cases. I've used this little "trick" several times subsequently, with good results...

VR, Dennis

Jessie_C

Joined: September 03, 2009

KitMaker: 6,965 posts

AeroScale: 6,247 posts

Posted: Monday, September 23, 2019 - 08:38 AM UTC

Quoted Text

@ Naseby: I tried cutting out a spar, but the wing is so thin that my efforts were not good.

@ Russ: I have clamped 1/2" x 1/2" wood to the wing and thought that I would try the hot water method.

Clamping it to wood will probably work. Clamp first, then pour the just-boiled water over.

Have you thought about a very thin metal spar? Maybe a bit of piano wire from the RC section of the hobby shop?

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Monday, September 23, 2019 - 09:17 AM UTC

M4A1Sherman

Joined: May 02, 2013

KitMaker: 4,403 posts

AeroScale: 254 posts

Posted: Monday, September 23, 2019 - 10:39 AM UTC

Hi, Bob!

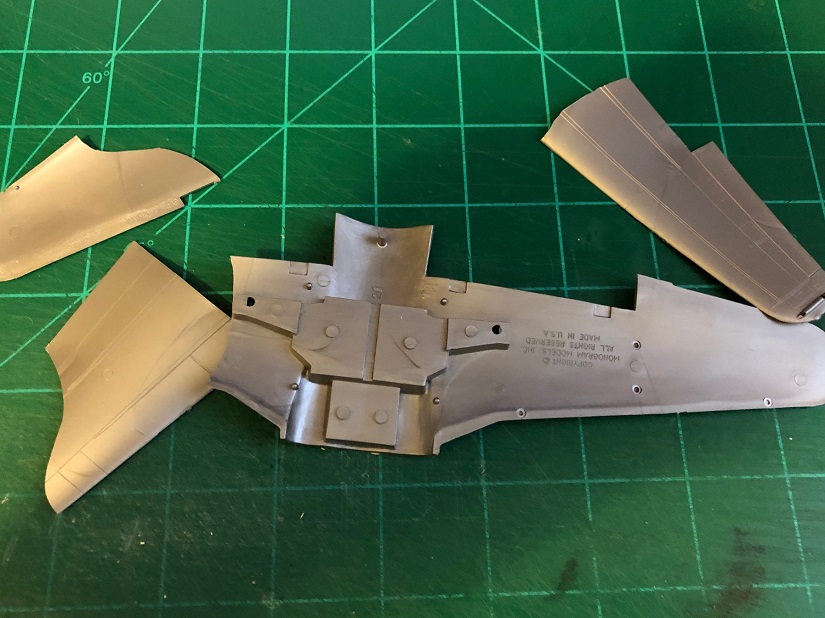

Wowww... That's a shame...

Maybe SOMEDAY some enterprising model manufacturer will take matters in-hand and produce a DECENT 1/48 P/F-80A or C. The old MONOGRAM kit is ACTUALLY BETTER than the much newer HOBBY BOSS offerings. Hold onto the parts, though- You never know when you might come across another one of the MONOGRAM F-80 kits "for cheap", or even a partial "parts kit" with a good Lower Wing. Check Ebay, too...

Wowww... That's a shame...

Maybe SOMEDAY some enterprising model manufacturer will take matters in-hand and produce a DECENT 1/48 P/F-80A or C. The old MONOGRAM kit is ACTUALLY BETTER than the much newer HOBBY BOSS offerings. Hold onto the parts, though- You never know when you might come across another one of the MONOGRAM F-80 kits "for cheap", or even a partial "parts kit" with a good Lower Wing. Check Ebay, too...

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Monday, September 23, 2019 - 11:26 AM UTC

Quoted Text

Hi, Bob!

Wowww... That's a shame...

Maybe SOMEDAY some enterprising model manufacturer will take matters in-hand and produce a DECENT 1/48 P/F-80A or C. The old MONOGRAM kit is ACTUALLY BETTER than the much newer HOBBY BOSS offerings. Hold onto the parts, though- You never know when you might come across another one of the MONOGRAM F-80 kits "for cheap", or even a partial "parts kit" with a good Lower Wing. Check Ebay, too...

I was thinking the same thing. So I will just shelve it for now.

Jessie_C

Joined: September 03, 2009

KitMaker: 6,965 posts

AeroScale: 6,247 posts

Posted: Monday, September 23, 2019 - 03:27 PM UTC

Okay, that looks actually repairable. All you need is some sheet plastic to back the cracks and that same piece of wood. As a bonus, I'll bet that the warp would come out a lot flatter

M4A1Sherman

Joined: May 02, 2013

KitMaker: 4,403 posts

AeroScale: 254 posts

Posted: Monday, September 23, 2019 - 08:34 PM UTC

Hi, All!

I think Jessie may have something there; it wouldn't hurt to try what she says...

I think Jessie may have something there; it wouldn't hurt to try what she says...

Bravo1102

Joined: December 08, 2003

KitMaker: 2,864 posts

AeroScale: 64 posts

Posted: Monday, September 23, 2019 - 10:01 PM UTC

Jessie is right. An armor builder like me found it easier to fix a major warp in a wing after it snapped into several pieces. That was some very brittle Russian plastic too. Can't tell to look at the built kit.

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Tuesday, September 24, 2019 - 04:10 AM UTC

Well that's a real bummer.... maybe gentle heat from a hair dryer would have worked better? I think you should still try and repair it. One thing I notice frequently in old silver molded Monogram plastic kits is a lot of "swirls" in the plastic... I wonder if the wing broke along one of those "swirl" lines? I've read somewhere those are caused by differences in temperature of the plastic as it's injected into the molds, and can cause weak spots.

VR, Russ

VR, Russ

Bigrip74

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Tuesday, September 24, 2019 - 04:22 AM UTC

I had offered the kit and Jesse has shown interest. So it should be mailed out in a couple of weeks.

Bob

Bob

|