Yes I have had some success with using kitchen foil. I have mainly been defeated by not being able to get a smooth coat of adhesive on it. The actual process is pretty easy. You will need to use Microscale Micro Metal Foil Adhesive and the cheapest, therefore thinnest, kitchen foil you can find. Follow the directions on the bottle of adhesive and give it a go. Having just re-read them I might try thinning the adhesive, to avoid the brush marks I get.

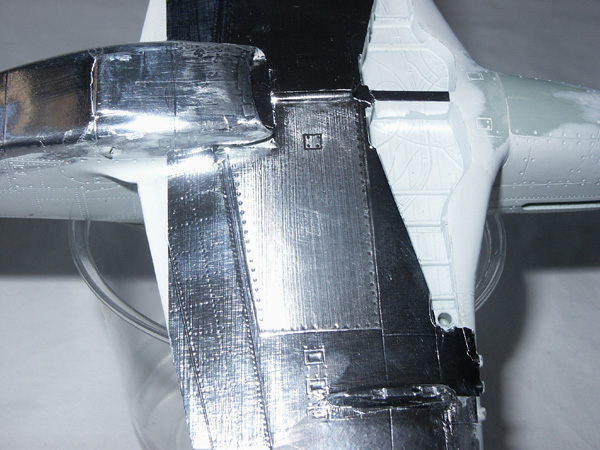

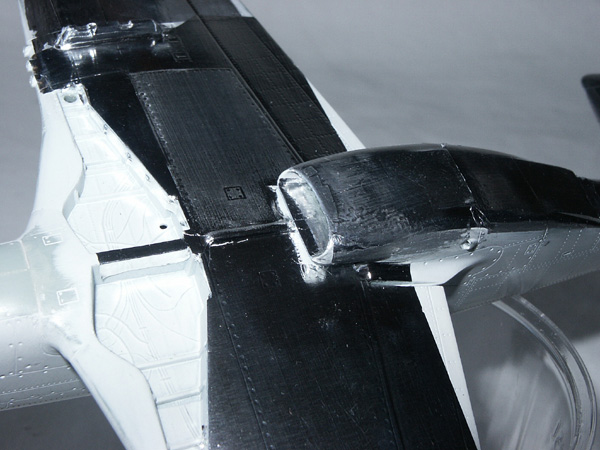

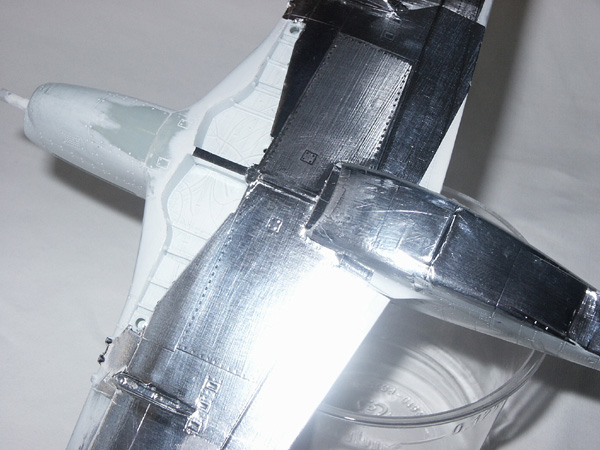

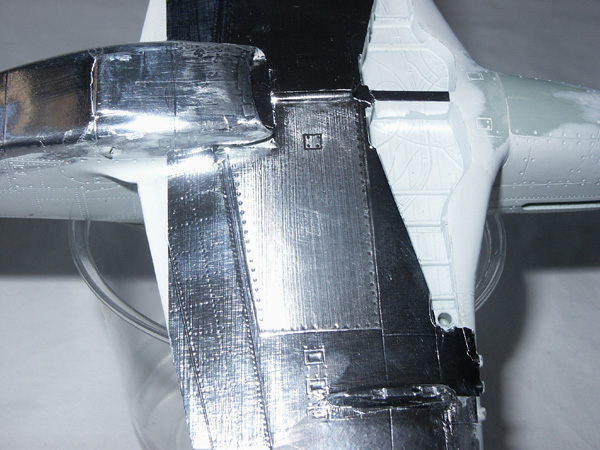

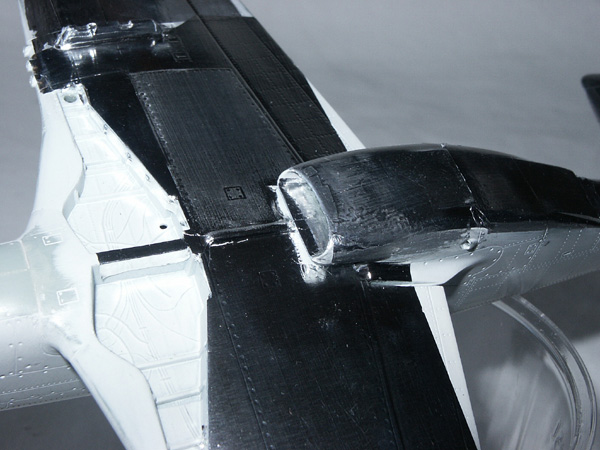

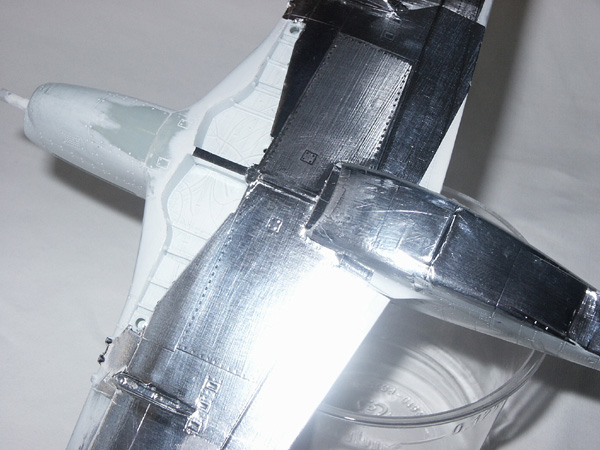

I have been experimenting on an Arii P-51, you need to have a flawless finish to the model. Although the instructions state that it works best on an unpainted surface, I primed my model, as usual, with white auto plastic primer. This showed up any imperfections, I then polished the surface. Here are a couple of pics, I had no problem foiling around the intake lip and I almost managed to foil the wheel bays. Couldn't quite get the foil to stretch that far, so removed it. I didn't worry about the edge of the foil, I just sanded it with 1000 grit emery, to thin it. My idea is to sand panels, in different directions, using 12000 grit emery, to replicate panels laid with the grain running in different directions. It works

but is spoiled by the brush marks in the Adhesive.

Hope this helps

Mal