Im doing a metal finish on a Mig-15 and was wondering how you get the Tin Foil to stick on the model, and how do you get it to form to compound curves?

Please keep in mind that Im a Tread Head and I dont do many Planes, but I needed a change in pace.

Thanks in advance

General Aircraft

This forum is for general aircraft modelling discussions.

This forum is for general aircraft modelling discussions.

Hosted by Jim Starkweather

Help with Tin Foil

wolfpack6

Joined: August 07, 2004

KitMaker: 179 posts

AeroScale: 80 posts

Posted: Tuesday, March 08, 2005 - 01:42 AM UTC

procrazzy

Joined: November 28, 2004

KitMaker: 359 posts

AeroScale: 0 posts

Posted: Tuesday, March 08, 2005 - 04:36 AM UTC

I have heard the somethng called 'alclad' is purposley desined for metal finishs. I have never used it myself but i am sue some other fourm members have used it.

cheers

Philip

cheers

Philip

Posted: Tuesday, March 08, 2005 - 08:47 AM UTC

There was a great article about this in FSM, I'll see if I can find it and give you the date. This is not really the easiest way to replicate a bare metal finish,as Philip suggests Alclad II is a much easier way, although it requires an airbrush.

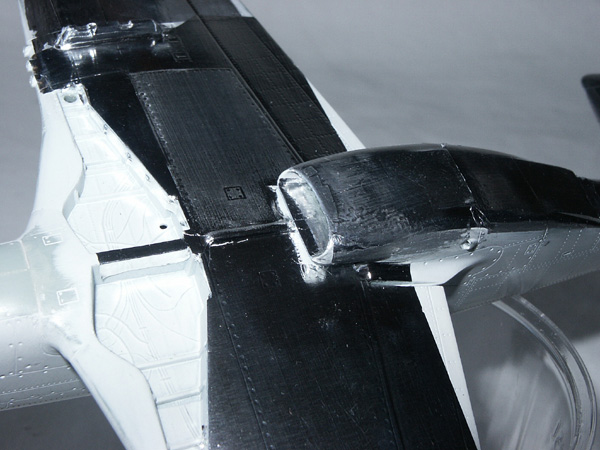

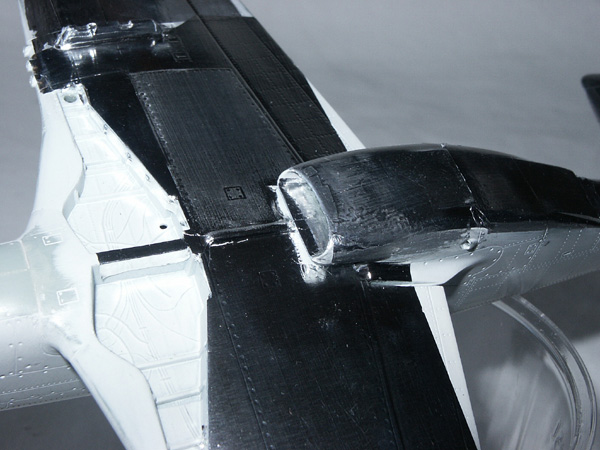

Here is a pic of my attempt at this method

Use the cheapest (therefore thinnest) aluminium kitchen foil cut a pieceand apply Microscale Micro Metal Adhesive, let it dry. Carefully apply the foil to the model and carefully burnish it from the inside out. It will conform surprisingly well to compound curves but sometims you will have to slit it. To elliminate overlap apply to panels. You will need a sharp blade to cut it in situ, a dull one will tear it. If you must overlap then use fine emery paper to thin the edge. If you miss a piece or have to cover od sticky out bits simply do them seperately. The biggest proplem I found was the brush marks in the glue showed up in the foil, I intent to get a roller to apply it in future.

Mal

Here is a pic of my attempt at this method

Use the cheapest (therefore thinnest) aluminium kitchen foil cut a pieceand apply Microscale Micro Metal Adhesive, let it dry. Carefully apply the foil to the model and carefully burnish it from the inside out. It will conform surprisingly well to compound curves but sometims you will have to slit it. To elliminate overlap apply to panels. You will need a sharp blade to cut it in situ, a dull one will tear it. If you must overlap then use fine emery paper to thin the edge. If you miss a piece or have to cover od sticky out bits simply do them seperately. The biggest proplem I found was the brush marks in the glue showed up in the foil, I intent to get a roller to apply it in future.

Mal

wolfpack6

Joined: August 07, 2004

KitMaker: 179 posts

AeroScale: 80 posts

Posted: Tuesday, March 08, 2005 - 10:59 PM UTC

Thanks Guys, this should help.

Ill keep you posted!

Ill keep you posted!

rv1963

Joined: December 07, 2004

KitMaker: 1,888 posts

AeroScale: 39 posts

Posted: Wednesday, March 09, 2005 - 01:15 AM UTC

If you are going to use foil why not try bare metal foil all the car guys use it to put the chrome trim around the windows of their cars and it already has adheasive on it, never tryed it on an airplane but it works on cars.

Probuilder

Joined: January 10, 2005

KitMaker: 193 posts

AeroScale: 0 posts

Posted: Wednesday, March 09, 2005 - 03:51 AM UTC

I have tried Both methods and Bare metal foil is a step above aluminum for but the best results seem to come from Alclad and Model Masters Metilizers. They give a consistent finish. you can go old school and get some Rub-n-Buff from hobby lobby, it's like a paste you rub on and then polish to a hi/med/lo shine depending on what you are going for.

Bender

Joined: October 20, 2002

KitMaker: 323 posts

AeroScale: 0 posts

Posted: Monday, March 14, 2005 - 06:22 AM UTC

Quoted Text

Use the cheapest (therefore thinnest) aluminium kitchen foil cut a pieceand apply Microscale Micro Metal Adhesive, let it dry. Carefully apply the foil to the model and carefully burnish it from the inside out. It will conform surprisingly well to compound curves but sometims you will have to slit it. To elliminate overlap apply to panels. You will need a sharp blade to cut it in situ, a dull one will tear it. If you must overlap then use fine emery paper to thin the edge. If you miss a piece or have to cover od sticky out bits simply do them seperately. The biggest proplem I found was the brush marks in the glue showed up in the foil, I intent to get a roller to apply it in future.

Mal

hey mal, not sure how long you were waiting, but from my experimenting on my P-51, it kinda looks as if you were letting the foil adheasive dry too long, I applied the foil to the kit after just a min or so of glue drying and it smoothed pertty well for the most part, I had a couple of problem areas, but maybe give it a try again and dont let the glue dry so much. you may get some "oozing" but it cleans right up with a damp paper towl or rag

Posted: Monday, March 14, 2005 - 09:28 AM UTC

Thanks bender, that may be the answer I'm looking for. I followed the instructions and they work, sort of like contact adhesive, but I can now see how applying the foil before the adhesive dries will help elliminate brush marks. If I get a chance I'll give it a try, maybe that mustang will get finished after all

Thanks again

Mal

Thanks again

Mal

|