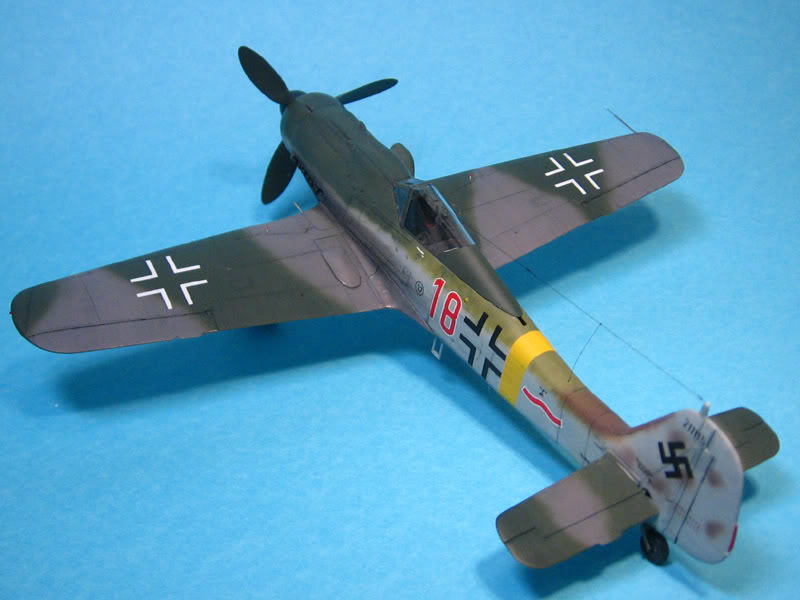

I started working on the kit on Saturday the 3rd. Here's some in-progress pics.

To make it possible to attach the cowl mg's after painting, I glued pieces of styrene sheet inside the upper cowling to form a shelf for the parts. The kit included copper tubing for mg's and cannon barrels but I'm replacing all of them with brass tubing and hypodermic needles. Brass tubing and needles make nicer mg's than just one piece of tubing and the needles I'm using are more in-scale than the thickish copper tubing supplied in the kit (they would look good for 30mm barrels, though). The harder material is also a bonus.

Here the fuselage halves have been glued together and the supercharger intake is held in place with a clothes peg. The only after-market parts I added were PE seatbelts from eduard. Only the lap belts have been glued in at this point, as the shoulder belts attach to the PE parts glued behind cockpit. (The later dragon-issued version has belts included in the PE fret, but no pilot figure like this kit). Visible in pic are the styrene shims I added to the wings and a spreader made from sprue glued inside the fuselage to get rid of the seams that would otherwise occur. I chose this method since the upper-wing to fuselage seam is not the most robust one in the world, the upper-wings are quite thin.

This is the PE "shelf" that goes behind the cockpit and where the antenna wire attaches. The part has been annealed with a lighter to make bending easier. I wished they made the parts from brass, as steel is not the most user-friendly material, especially with smaller parts. But robust it is, that's for sure. (The kit included two frets, one of "regular", and one thicker. The latter required side cutters and force to cut through the fret.)

The main landing gear legs, as well as anti-sway braces for the bomb rack and exhausts are white metal castings in this kits (re-produced in plastic by later issuers of the kit). The good thing about these is that you don't need to paint the oleo struts. I polished them by rubbing them with the side of a needle, then brushed on two coats of future to protect the shiny surface against possible oxidation.

The propeller blades were separate with no pins or other means to attach them to spinner at the same angle. Eduard's Fw-190 A8 has the same wider bladed props that go unused, and are a single piece, so I used them. The only modification needed was to cut away a pin in the middle of the trimaster spinner base plate. The new prop was a drop-fit to the spinner.

This part was the one I didn't like that much. The brace that goes inside the canopy. Not only does it have several parts that need to be glued to each other at an angle, they are photo-etched, requiring super glue. Taking measures from the canopy, attaching the partially completed brace to a piece of cardboard and marking the place of the front plate I was able to get the angle right. Dryfitting the completed assembly inside the canopy while the glue dried ensured the finished part would actually fit.

After struggling with bending a thick and narrow PE part made of steel, and getting this fixed to 2 other PE parts at a certain angle, painting, addind a warning text decal and attaching a support wire was a breeze.

The airframe is here masked and ready for priming. Since the canopy is going to be overall RLM 83 and fits very well, I decided to paint it separately. It also made it easier to mask the cockpit opening.

There, it's primed and ready for painting.