1⁄72

Friday, March 06, 2020 - 08:57 AM UTC

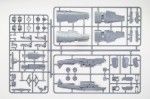

The first test sprues and test build of the 1/72 scale Bristol Beaufort is featured on this weeks Airfix Workbench

”Since it was first announced at the beginning of the year, the new 1/72nd scale Bristol Beaufort Mk.I tooling has been receiving plenty of attention from Workbench readers and the wider modelling community. An aircraft which is perhaps not quite as well known as other WWII types, our decision to produce this new kit has resulted in many people brushing up on their Beaufort research and looking a little deeper into the service history of this distinctive aeroplane. An aircraft which started development as an intended evolution of the company’s successful Blenheim design, the Beaufort would turn out to be a very different looking aircraft and one which had the distinction of being the only monoplane produced for the Royal Air Force which was designed from the outset as a torpedo bomber and reconnaissance platform.

Although not enjoying the same popular recognition as either the earlier Blenheim or later Beaufighter, the Beaufort was a rugged and highly effective aircraft, one which was required to perform a particularly demanding role and one which would make a significant contribution to the Allied war effort during WWII. It also happens to be one of the more interesting aviation types of the Second World War and one we are looking forward to welcoming into the Airfix range later in the year.

As our new Beaufort has created so much interest since its announcement at the beginning of January, we are delighted to already be in a position to bring Workbench readers a major update from the project and a selection of exclusive images which are being published for the first time. With grateful thanks to the projects designer Matt, we have been given access to the first test frames from the Beaufort tooling, along with the first full test build from these initial parts. Although we are happy to show them at this very early stage, please do remember that they show kit components which are still in development and may be subject to many changes before the kit is released for production.

Representing a crucial stage in the development of any new model tooling project, the arrival of the first test frames must be a time of great excitement for the Airfix team, though undoubtedly mixed with a little apprehension. The first opportunity the kits designer will have to assess the fruits of many weeks hard labour, these test frames represent the first physical samples from his newly designed model tooling and the start of an intensive period of assessment and report creation.

On the day new test frames are delivered at the Airfix office, a large box containing around ten complete component sets arrive from the manufacturing plant, with the honour of opening the box usually reserved for the designer responsible for the project. Once a basic initial inspection of the contents has taken place, the serious business of review can begin in earnest, something which calls upon every ounce of the designer’s experience and a period of activity which requires intense concentration. Every aspect of the kits design has to be assessed, from surface detail to checking for sink marks and from the general fit and finish, to checking overall tolerances.

Once this detailed component inspection has taken place and a review report started, the next stage is to continue this assessment through a test build, where the actual fit of components can be checked. Usually, at least two full builds will be completed, one to assess the actual fit accuracy of the individual parts, with the other used to check construction order, working closely with our illustrator Richard, as he puts the finishing to the new model’s instruction leaflet.

For the modeller, the sight of these early development images offer a fascinating insight into the work the Airfix designers do in ensuring their new kits are as accurate and enjoyable to build as they can be. This next selection of images are not computer renders, but the first time actual plastic components are constructed to build an Airfix Beaufort. Though still subject to change, they show that this much anticipated model project is advancing nicely.

Even though great care is taken during every stage of the design process to ensure any new kit is as detailed and accurate as it possibly could be and accepting the fact that our design team have an incredible wealth of experience to call upon, at this first test frames stage, their assessment typically results in as many as 50 or 60 improvement recommendations being fed back to the manufacturing plant. All these alterations will have to be completed before the next set of component frames can be assessed, where this entire process will be repeated once more.

In most cases, this process of inspection, assessment and improvement takes place three or four times during the development of a new kit, before the designer is happy to release his latest modelling masterpiece for production and the enjoyment of thousands of modellers all over the world.

Even though great care is taken during every stage of the design process to ensure any new kit is as detailed and accurate as it possibly could be and accepting the fact that our design team have an incredible wealth of experience to call upon, at this first test frames stage, their assessment typically results in as many as 50 or 60 improvement recommendations being fed back to the manufacturing plant. All these alterations will have to be completed before the next set of component frames can be assessed, where this entire process will be repeated once more.

In most cases, this process of inspection, assessment and improvement takes place three or four times during the development of a new kit, before the designer is happy to release his latest modelling masterpiece for production and the enjoyment of thousands of modellers all over the world.”

Airfix

A04021 - Bristol Beaufort Mk.1 – 1/72

Please remember, when contacting retailers or manufacturers, to mention that you saw their products highlighted here – on Aeroscale.

Although not enjoying the same popular recognition as either the earlier Blenheim or later Beaufighter, the Beaufort was a rugged and highly effective aircraft, one which was required to perform a particularly demanding role and one which would make a significant contribution to the Allied war effort during WWII. It also happens to be one of the more interesting aviation types of the Second World War and one we are looking forward to welcoming into the Airfix range later in the year.

As our new Beaufort has created so much interest since its announcement at the beginning of January, we are delighted to already be in a position to bring Workbench readers a major update from the project and a selection of exclusive images which are being published for the first time. With grateful thanks to the projects designer Matt, we have been given access to the first test frames from the Beaufort tooling, along with the first full test build from these initial parts. Although we are happy to show them at this very early stage, please do remember that they show kit components which are still in development and may be subject to many changes before the kit is released for production.

Representing a crucial stage in the development of any new model tooling project, the arrival of the first test frames must be a time of great excitement for the Airfix team, though undoubtedly mixed with a little apprehension. The first opportunity the kits designer will have to assess the fruits of many weeks hard labour, these test frames represent the first physical samples from his newly designed model tooling and the start of an intensive period of assessment and report creation.

On the day new test frames are delivered at the Airfix office, a large box containing around ten complete component sets arrive from the manufacturing plant, with the honour of opening the box usually reserved for the designer responsible for the project. Once a basic initial inspection of the contents has taken place, the serious business of review can begin in earnest, something which calls upon every ounce of the designer’s experience and a period of activity which requires intense concentration. Every aspect of the kits design has to be assessed, from surface detail to checking for sink marks and from the general fit and finish, to checking overall tolerances.

Once this detailed component inspection has taken place and a review report started, the next stage is to continue this assessment through a test build, where the actual fit of components can be checked. Usually, at least two full builds will be completed, one to assess the actual fit accuracy of the individual parts, with the other used to check construction order, working closely with our illustrator Richard, as he puts the finishing to the new model’s instruction leaflet.

For the modeller, the sight of these early development images offer a fascinating insight into the work the Airfix designers do in ensuring their new kits are as accurate and enjoyable to build as they can be. This next selection of images are not computer renders, but the first time actual plastic components are constructed to build an Airfix Beaufort. Though still subject to change, they show that this much anticipated model project is advancing nicely.

Even though great care is taken during every stage of the design process to ensure any new kit is as detailed and accurate as it possibly could be and accepting the fact that our design team have an incredible wealth of experience to call upon, at this first test frames stage, their assessment typically results in as many as 50 or 60 improvement recommendations being fed back to the manufacturing plant. All these alterations will have to be completed before the next set of component frames can be assessed, where this entire process will be repeated once more.

In most cases, this process of inspection, assessment and improvement takes place three or four times during the development of a new kit, before the designer is happy to release his latest modelling masterpiece for production and the enjoyment of thousands of modellers all over the world.

Even though great care is taken during every stage of the design process to ensure any new kit is as detailed and accurate as it possibly could be and accepting the fact that our design team have an incredible wealth of experience to call upon, at this first test frames stage, their assessment typically results in as many as 50 or 60 improvement recommendations being fed back to the manufacturing plant. All these alterations will have to be completed before the next set of component frames can be assessed, where this entire process will be repeated once more.

In most cases, this process of inspection, assessment and improvement takes place three or four times during the development of a new kit, before the designer is happy to release his latest modelling masterpiece for production and the enjoyment of thousands of modellers all over the world.”

Airfix

A04021 - Bristol Beaufort Mk.1 – 1/72

Please remember, when contacting retailers or manufacturers, to mention that you saw their products highlighted here – on Aeroscale.

Click Star to Rate

Only 1 reader has rated this.

THIS STORY HAS BEEN READ 2,012 TIMES.

| Airfix Reviews | MORE |

| MiG-17F by Andy Brazier | |

| B-25 Mitchell Mk.II by Frederick Boucher | of 3 ratings, 100% found this helpful | |

| Spitfire FR Mk. XIV by Rowan Baylis | of 1 ratings, 100% found this helpful | |

| Bristol Blenheim Mk.1F by Kevin Brant | of 2 ratings, 100% found this helpful | |

| Phantom FG.1 by Andy Brazier | |

| Supermarine Walrus Mk.I by Kevin Brant | |

| Junkers Ju 87B-1 by Rowan Baylis | of 1 ratings, 100% found this helpful | |

| Curtiss P-40B Warhawk by Rowan Baylis | of 1 ratings, 100% found this helpful | |

| Boulton Paul Defiant by Adam Rehorn | |

| Gloster Meteor F.8 by Andy Brazier | of 1 ratings, 100% found this helpful | |

| Hawker Hurricane Mk. I by Rowan Baylis | |

| Red Arrows Folland Gnat T.1 by Rowan Baylis | |

| F-80C Shooting Star by Frederick Boucher | of 1 ratings, 100% found this helpful | |

| Harrier GR.1 by Andy Brazier | |

| Hawker Typhoon 1B by Mal Mayfield | |

Comments