A visit to Eduard

17

Comments

Visit of the company

Jan Zdiarsky then allowed us to visit the Eduard facilities and he was kind enough to answer each of our questions. Regarding future products, there was little to see because when we started our tour around 3:00 PM, the plant was already getting empty. It seems as if there is more activity in the morning. From the 80 people who work there we saw only a fraction. Good thing is that we walked through empty corridors and taking pictures was very easy.The first place we stopped by was Jan's office. There we saw a young lady (which Steffen found very to his taste he told me) working on the next Eduard Newsletter. I know many modellers are waiting for each installment with great expectations and it is always very commented in the modelling forums, especially when there are some hints about future projects. Jan is the PR man of Eduard and in his office is located the photo studio he uses to shoot pictures of the model kits which are presented on the Eduard website.

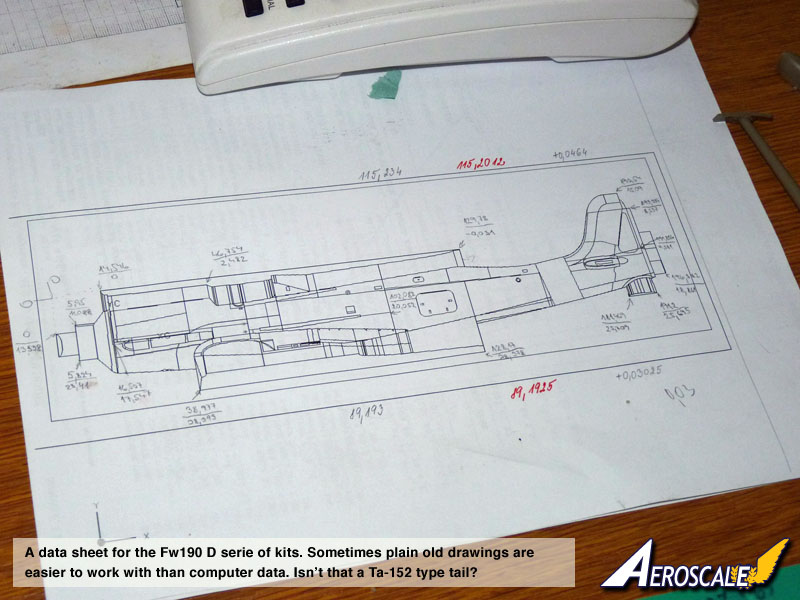

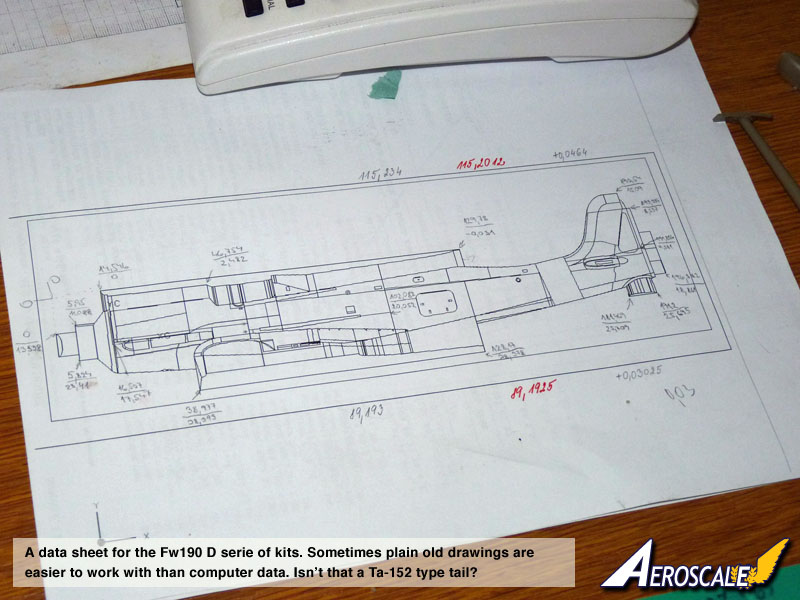

Eduard is a single company which is split in many departments, each one having it's own office. The first we saw was the one dedicated to plastic model kit design. In the rather big room were several computers and fortunately one was running with some data from the new Albatros D.II Oeffag 253. It was not work in progress for the plastic parts of the kit which have now been finalized, but 3D animations were tested in order to make a presentation movie of the model for it's official launch. This is a first for Eduard and I'm already looking forward to see how it will look like. Elsewhere in the room some resin masters of the Fw190 D were still laying around while some Spitfire references displayed on a third desk made it obvious on what subject the designers were working there.

Next, we spent some time in the Photo-Etched office were the products are designed using computers as well. Sometimes we hear people complain that Eduard produce PE parts which are impossible to use because they are too complex or too small and that the Czech manufacturer probably never test fit it's own products. Well this is of course not true and we actually saw one employee test building one of the new PE reference prior to giving the green light for production.

The third department we visited was the Brassin one. This is a new product by Eduard which is a mix of resin and photo-etched parts. The designers of the Brassin line are also working with computers to produce the masters but the castings are done with more traditional techniques in a separate room located at the same place. The PE parts which accompany the resin bits are also designed by the Brassin team and not the PE department like one would have thought. In boxes, we could see many parts that were destined to be included in the new kit of the Su-22/Su-17M-3 "Fitter" which should be available by the time you read this report. Brassin sets are usually cast in numbers reaching from 400 to 1000 pieces. Interesting news is that the team is working on an 1:32 scale engine for the Bf109 E serie of kits.

Before going downstairs, Jan Zdirasky presented to us the person who was responsible for the now famous "wrong Bf109 E-4 canopy". Obviously he wasn't fired and the people at Eduard took the whole story with philosophy. After all, more than 20 people saw the canopy before the kit went into production said Jan and nobody noticed the problem. "Errare humanum est" (error is human) and Eduard have corrected the canopy part in the meantime so everything is fine again. Not every company would have done this.

The various production machines are located either on the ground floor (photo-etch printing) or the basement (plastic injection, milling machines and photo-etch bath-tubs). We weren't allowed to take pictures of the new PE printing machines because Eduard have implemented their own technology into them and they don't want to share their secrets with the whole model kit industry. The Czech manufacturer is currently the leader of photo-etch production and wants to remain it in the future. We had the opportunity to see the printing process of PE parts live and I can say that the process is quite tedious and time consuming.

If on the first floor we found the head of the Eduard Company, in the basement is it's heart. Indeed, the milling machines, injection machines and PE production are all located there, for practical reasons for sure. Unfortunately the plastic injection machines weren't working so we only saw the metal molds in place and some sprues piling up in big containers. Some milling machine were working though and we could watch them grinding resin and metal blocks. In a small workshop we could see the metal molds for the new Albatros, as well as some inserts for the forthcoming MiG-21 kit. I tried to manipulate one half mold of the Albatros and I can tell you that it is very heavy indeed. It is better not to let it fall on your feet! Unfortunately the PE production line wasn't working neither when we were there.

Once our visit in the basement was finished, we went upstairs to see the storage room. We were surprised by its relatively small size but bigger parcels were also stored in corridors. The racks were nevertheless impressive, especially those carrying all the catalogue of photo-etched references which is quite large to say the least. Initial run for a PE fret is about 300 ex. but of course when the stock level is low, orders are given to resume production for that particular item. For plastic model kits it is the same only that the production number varies greatly depending on the subject: 1500, 3000, 5000 ex. The metal molds now allow Eduard to re-launch the production of one kit if necessary so if a kit is sold-out, chances are high to see it re-issued again, except for Limited Editions of course.

Credits

Many thanks to M. Vladimir Šulc and M. Jan Zdiarsky from Eduard for having allowed us to visit the Eduard company and for having devoted some of their precious time for us. Thanks also to all the people who have worked there and who were very friendly. Many thanks as well to Steffen Arndt for having been my GPS system during the trip (must think of buying an update…) and for having shared his photos of which some found their way into this feature.Comments

I use a lot of there components and it is very interesting to see there factory Thanks guys.And I envy you for being able to go.

Build On,

Justin

P.s. Nice darts!

JUN 12, 2010 - 04:47 PM

Like Justin I am very envious and jealous of you guys. The report is great and the photo's fascinating.

Thanks for sharing your visit with us J-L (and Steffen)

JUN 12, 2010 - 05:18 PM

Excellent feature Jean-Luc.

A very interesting and informative read. I would love to visit a model factory, just to see how it all comes together.

Andy

JUN 13, 2010 - 12:16 AM

Hi all,

Thank you for your kind comments. I can imagine a lot of people would have liked to make the trip with us...

I don't really know why Eduard have dropped the Phantom. Maybe the risk is too big with the Chinese manufacturers on the same market segment? Modern stuff is not my speciality so maybe Steffen has a better answer to give.

The Spitfire Mk.IX was already announced just before Tamiya put their model on the market. I'm sure the people at Eduard would have preferred to have the exclusivity but if they manage to do a nice but much cheaper model than the Tamiya one (without an engine for example but with a detailed PE cockpit), it will sell nevertheless. Same for the Bf109s. I'm sure they will sell as well as the Fw190 series. Good is that Eduard always do very attractive boxings.

fact is that Eduard is no longer a short run manufacturer which can afford it to design kits that will only sell in the 1000 or 2000 ex. range. They have to choose subjects with much more potential.

Jean-Luc

JUN 13, 2010 - 12:49 AM

Thanks for sharing that Santa-Luc and Steffan, of course I'm not jealous at all I'm hoping that Eduards Spit will be as accurate but cheaper than Tamiya's with a nice Brassin interior, and I'll have a million I'm also hoping that they do a 1/32 Mk1 and MkV, and Hurricane and Whirlwind and...............Keep it up Eduard ,you're doing brilliantley

JUN 14, 2010 - 08:35 AM

Hi all,

I'm a little bit surprised that there was no reaction for this picture...

I have received confirmation that Eduard will indeed produce a Fw190 D fuselage with Ta 152 style tail for a forthcoming Limited Edition...

Jean-Luc

I have received confirmation that Eduard will indeed produce a Fw190 D fuselage with Ta 152 style tail for a forthcoming Limited Edition...

Jean-Luc

I have received confirmation that Eduard will indeed produce a Fw190 D fuselage with Ta 152 style tail for a forthcoming Limited Edition...

Jean-Luc

I have received confirmation that Eduard will indeed produce a Fw190 D fuselage with Ta 152 style tail for a forthcoming Limited Edition...

Jean-Luc JUN 15, 2010 - 05:04 AM

Jean - Luc! You are the man! Its a great piece. I am speechless. Most impressive bit of journalism!

JUN 15, 2010 - 07:07 AM

Hi Jean-Luc

I noticed the photo and it's great to hear that Eduard have decided to go ahead with Ta 152 tail for a special edition. There are a couple of interesting schemes shown in Jerry Crandall's book. I wonder if Eduard will also do a a gyro gunsight? A late-style drop tank would be a very useful addition too - much better than my hasty home-made effort.

All the best

Rowan

JUN 15, 2010 - 07:23 AM

The very last picture of your story illustrates that even in the manufacturing process, it is a very hands on effort to deliver the goods to the modeler.

Thanks for sharing your trip with us!

JUN 16, 2010 - 06:11 AM

Copyright ©2021 by Jean-Luc Formery. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2010-06-12 00:00:00. Unique Reads: 23966