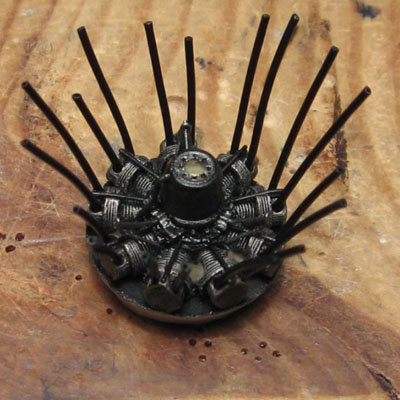

As I got the engine components done, I started painting on them.

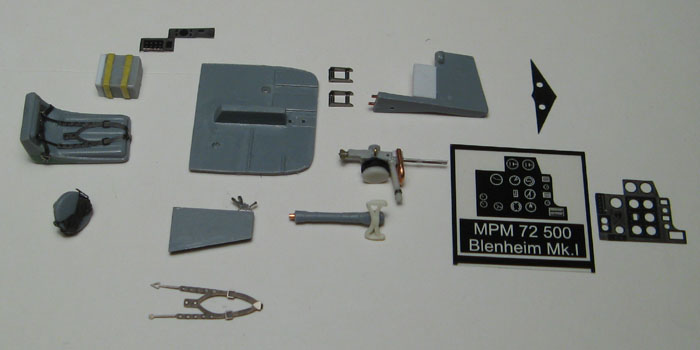

Here's the parts for one engine (excluding parts going to the exterior of the cowling):

The 18 black tubes are the exhaust pipes that will go between the engine cylinders and the exhaust collector ring. That's cord from a broken computer mouse with the wires inside removed. The idea is that they should line up correctly when just glued to the holes drilled at a slight outward angle in the engine cylinders and trimmed to the right length.

The two air intake pipes are steel tubing from some electrical parts, annealed over a lighter flame to ease bending to the right shape. The resulting scorched color looked so nice I decided no to paint the pipes at all.

The three triangular exhaust collector ring supports were quite tricky to make, even though I made the decision to make them from two pieces of brass wire instead of the realistic three. That turned out to be a good choice, as even these simplified ones were quite tedious and hard to make, individually dryfit and trim to the right length. Now I have them all marked so I'll know which one goes to which engine and which place.

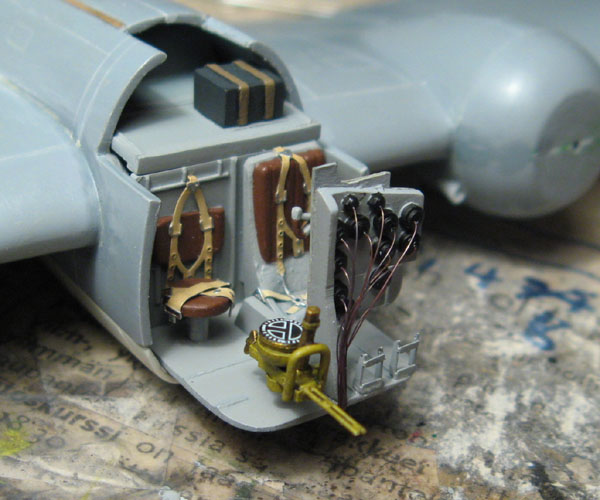

The engines received a black primer coat and the insides of the cowlings a light grey, some mr. surfacer 1000, which happens to be quite similar to the light grey interior paint on the real thing.

Obviously, the black from a spray can didn't cover all the nooks and crannies of the engines, so I finished the priming with my airbrush to avoid filling up all the lovely details.

And now for something completely different...

A blast from the past.

For drybrushing the engines, I dug out some humbrol enamels, as they dry slower and their metallics' smaller pigment size is better suited for this smaller scale.

That smell of paint and mineral spirits was quite nostalgic. The drawback: I have to wait around the usual six hourse before I can continue with the details.

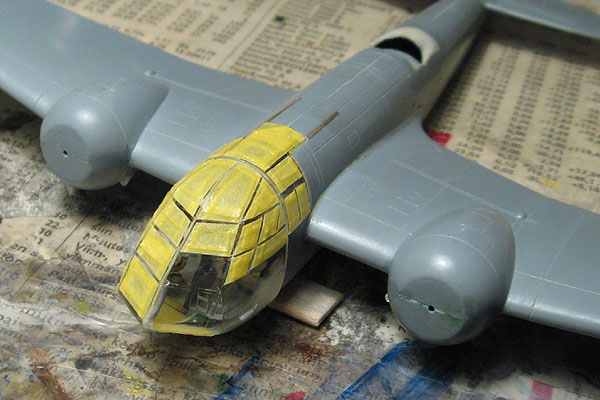

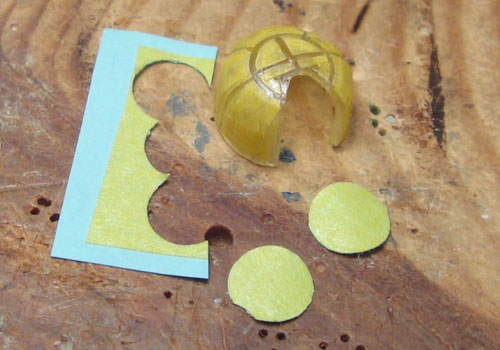

This was another small victory. I managed to get the cockpit glazing to fit without steps in the seam with the fuselage. The only was to sand the gluing surfaces going down in the middle of the glazing, quite a daunting task at first, but it wasn't that tricky in the end. The main concern was to keep the meeting edges straight, take care not to scratch the parts and keep from sanding too much.

With the glazing fitting nicely, I glued a strip of styrene to the bottom edge of the fuselage opening to help gluing on the glazing straight and to reinforce the seam.

Next I'll go back to the engines.

My next update should be just around the corner.