I'm back again. I have actually started another build, stretching a Revell BO 105 into a 105CBS.

Here we go ...

1:32 MBB BO105CBS Build

Hereís a how I built an MBB BO 105CBS from a couple of Revell 1:32 scale kits. This would work just as well for any of the 1:72 or 1:48 kits around, I just like Ďem big.

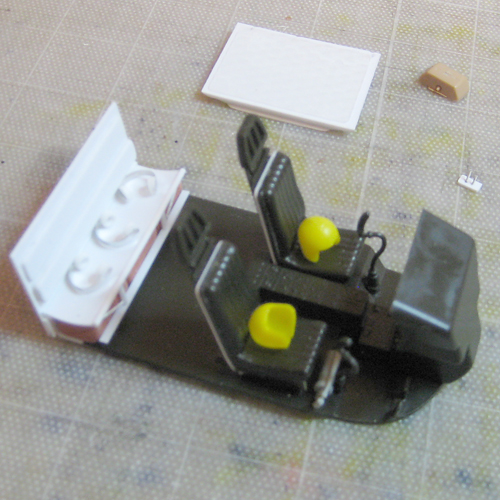

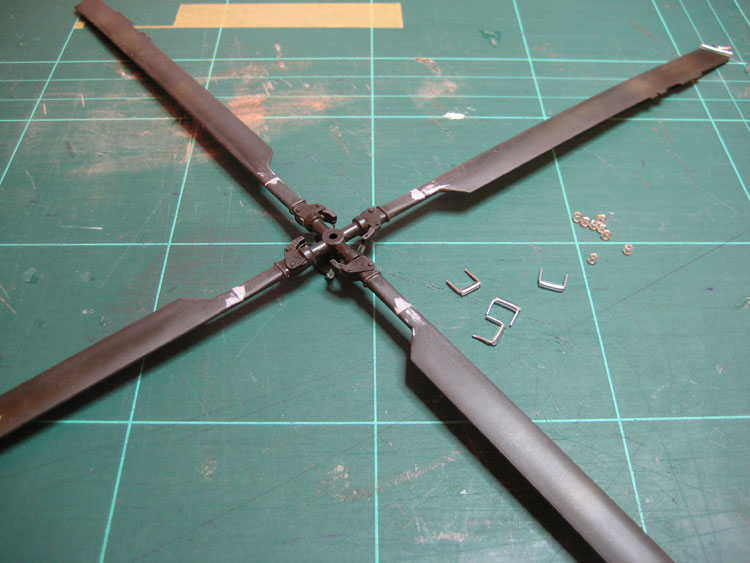

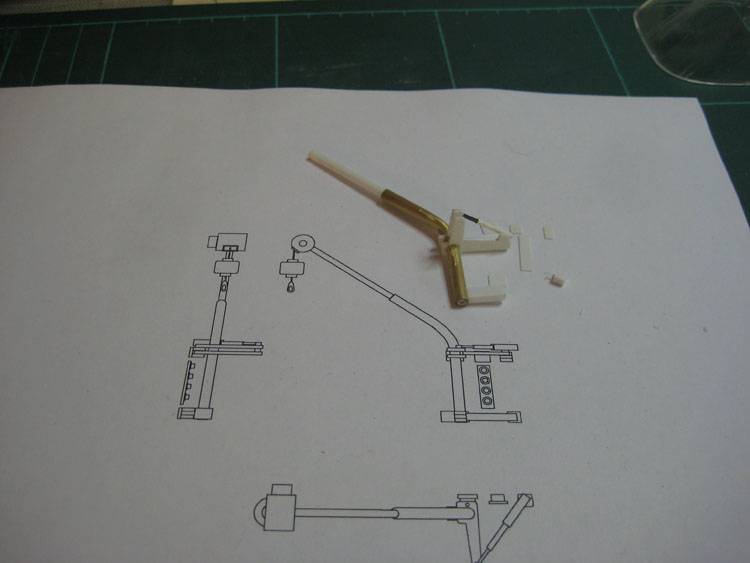

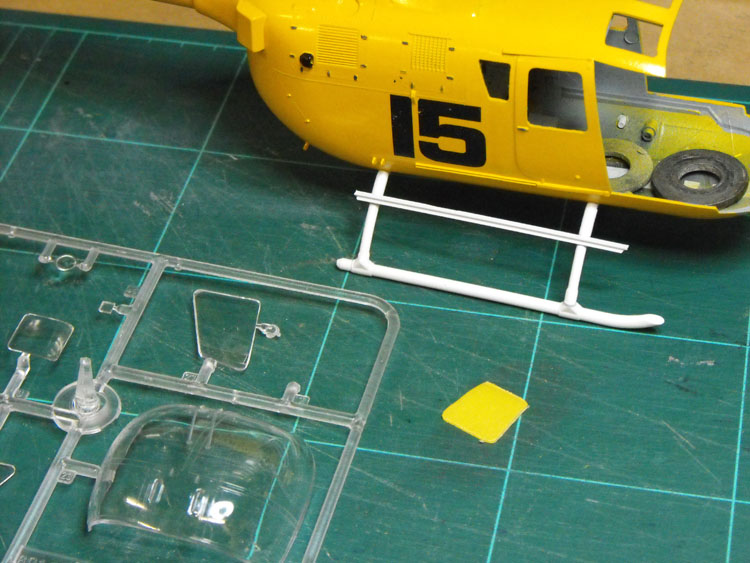

All the Revell and Italeri 1:32 BO 105 kits are for the standard short fuselage version. The donor kits for this bash were the Revell ADAC triple-pack that has the 105, a BK 117 and a n EC 135, and the standalone Revell BO 105 PAH anti-tanker. The 105CBS version has an additional 8 inches length in the cabin. This was done so it could take the larger American rescue litters. There are some detail differences, which I will cover later, and a few additions to make the particular subject I am modelling here. This project is a BO 105CBS, c/n: S-615, VH-NSL, that was operated by the National Safety Council Australia (Victorian Division) (NSCA) in the mid 1980s. It was not ever used in the rescue role, so the internal fitout was quite basic, just the rear seats, no stretchers, no medical gear. It was, however, fitted with an external rescue winch.

Stretching the Fuselage

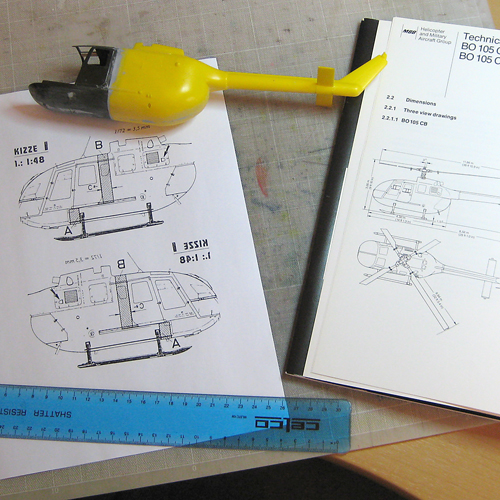

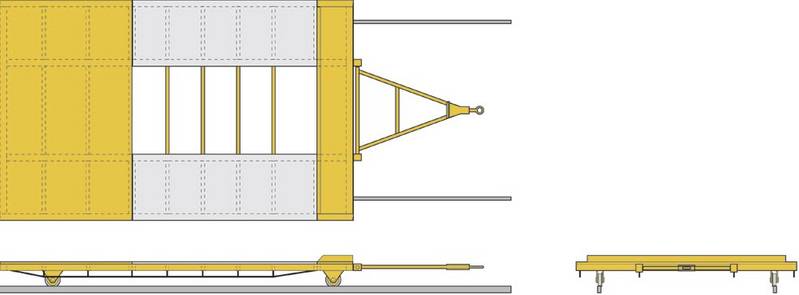

This looks to be a fairly easy excersize as far as fuselage stretches go, but it is my first attempt, so letís see what happens! You need to add about 7.8mm to the fuselage length and the fuselage is constant in section where the stretch occurs. This extension was done on the full size chopper in the simplest way possible. The extension below the floor was made ahead of the landing gear, so the landing gear attachments stayed standard. Above the floor the extension was made at the rear end of the cabin, again changing as little as possible. An extra rear window was added in the extension and this third window is the easiest way to pick the difference between the stretched and standard airframes.

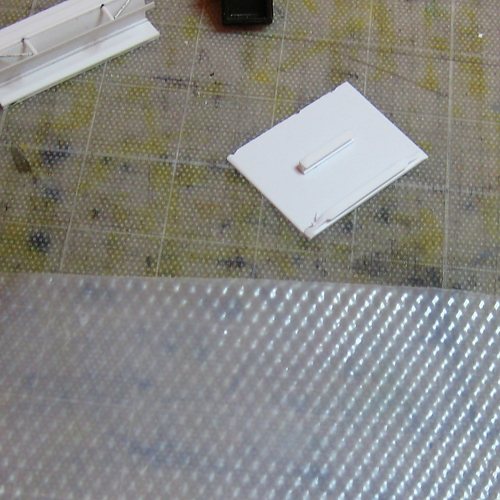

You could probably do this stretch with an insert made from plastic card, but that sounds like too much work!

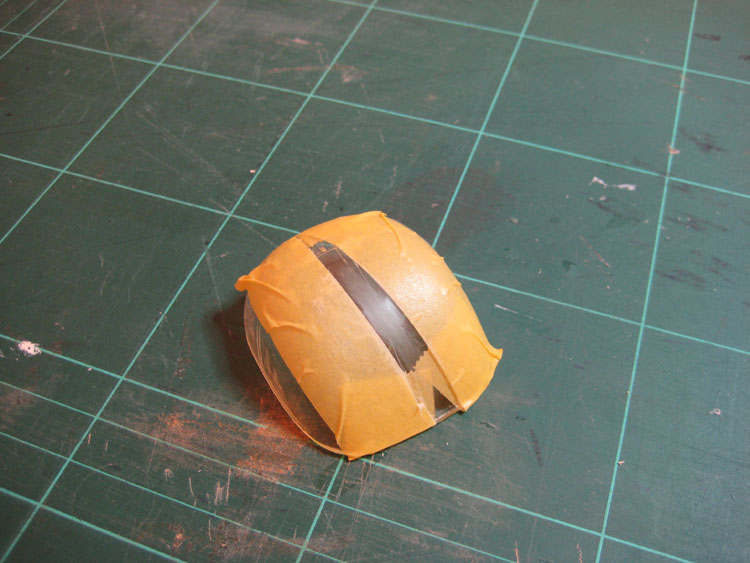

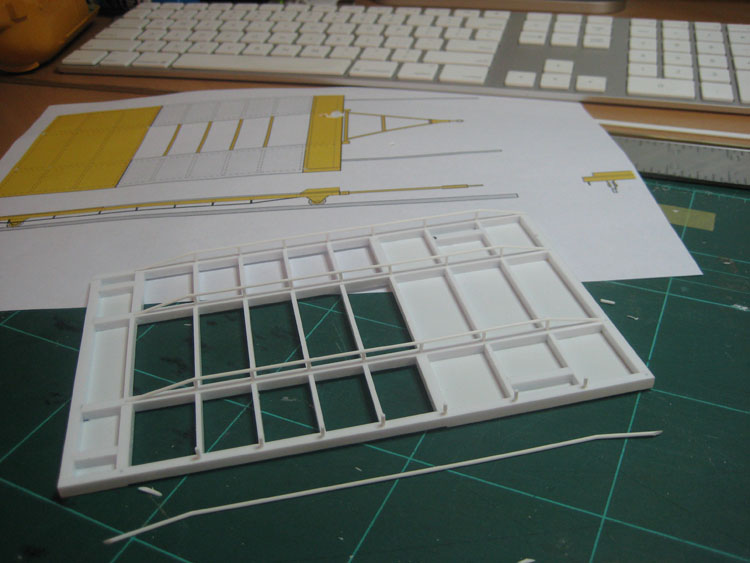

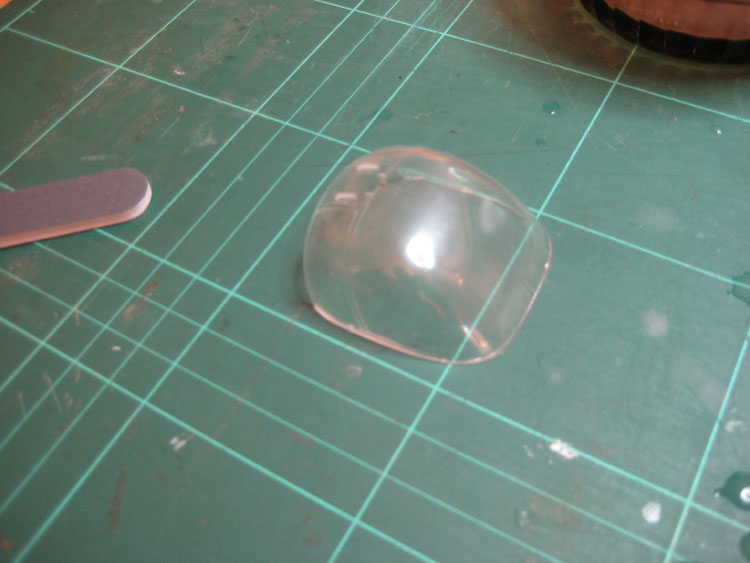

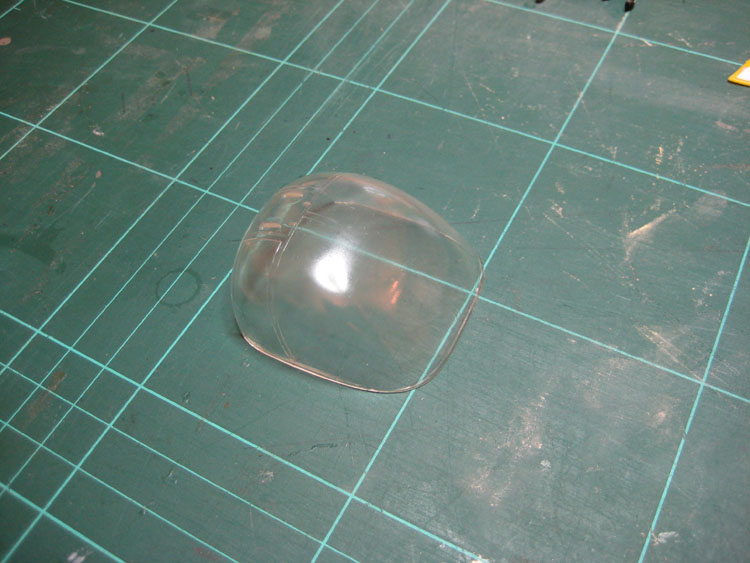

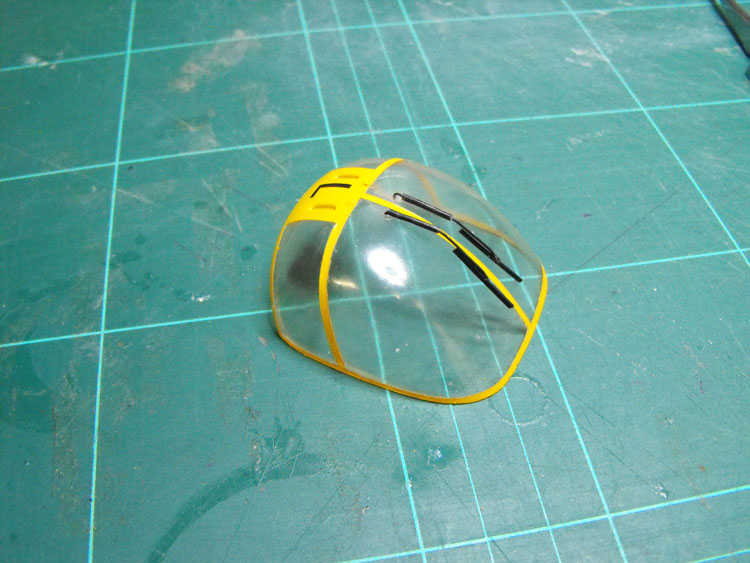

With the large, single piece, nose transparency, it is possible to finish the fuselage first and then slide the interior in afterward. This is a huge advantage as you donít need to finalise the interior first-up and you can also do the meaty work on the fuselage, even the painting, without fear of damaging a delicate interior. For this reason, and because it was my first stretch, I tackled the fuselage first. As per the instructions, I drilled out the holes for the ďgrab-handleĒ antennae on the tail boom.

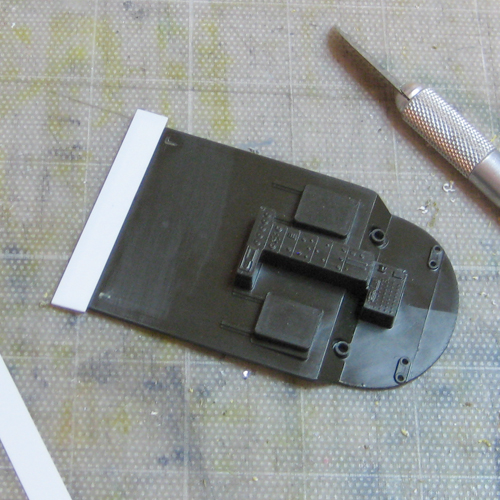

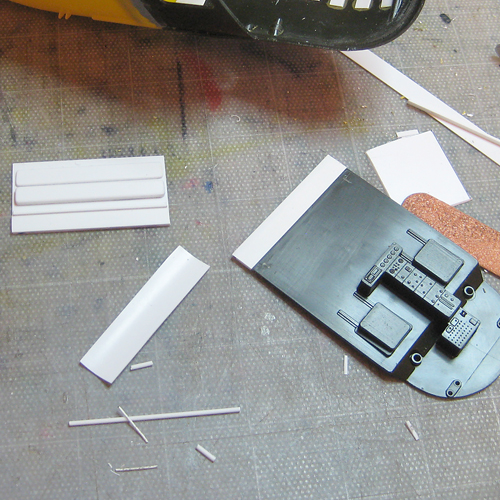

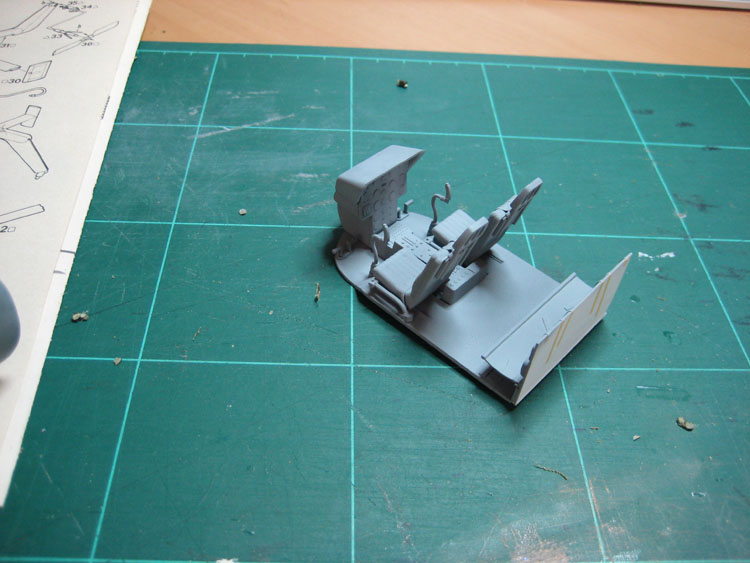

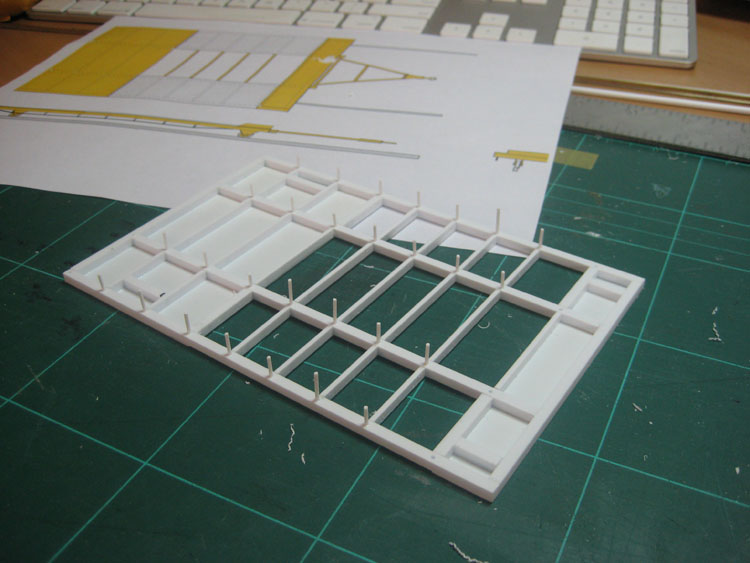

The gearbox bulkhead and floor can go in and I also glued in the rear cabin bulkhead. The PAH rear bulkhead had some nice quilted detail, but a hole at the bottom, so I doubled it up with a spare bulkhead to blank off the hole and give even more stiffness. As an extra precaution I added some plastic card to the fuselage join to make it all good and solid for when I started cutting. I did this to both fuselages.

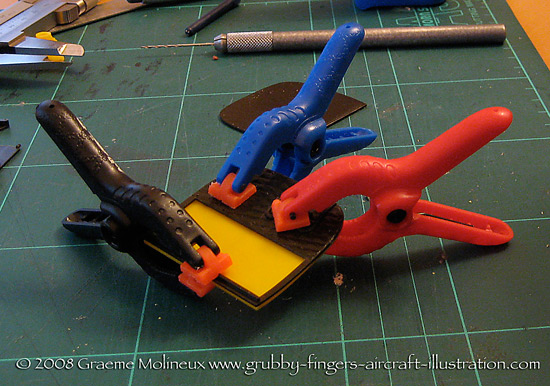

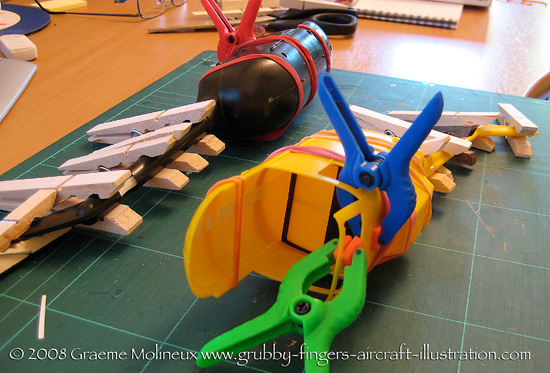

The fuselage halves are now glued together, clamped up and left to cure.

Now comes the interesting part - the cut-and-shut. Deep breath and away we go ...

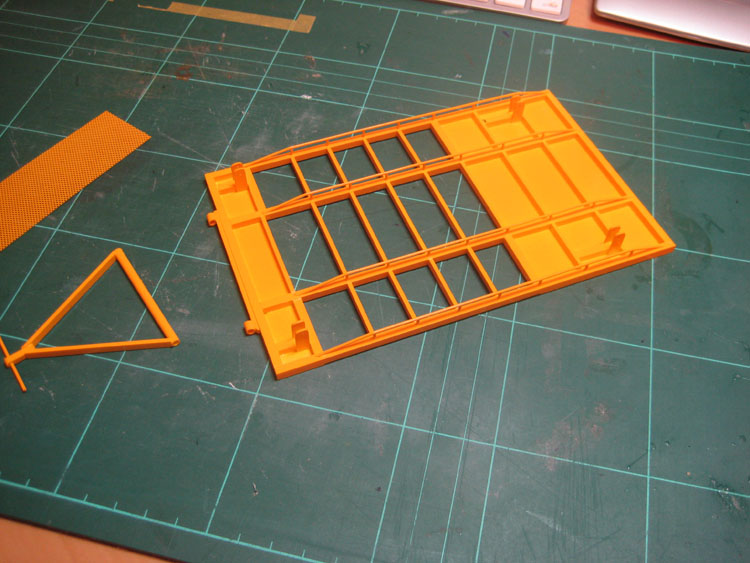

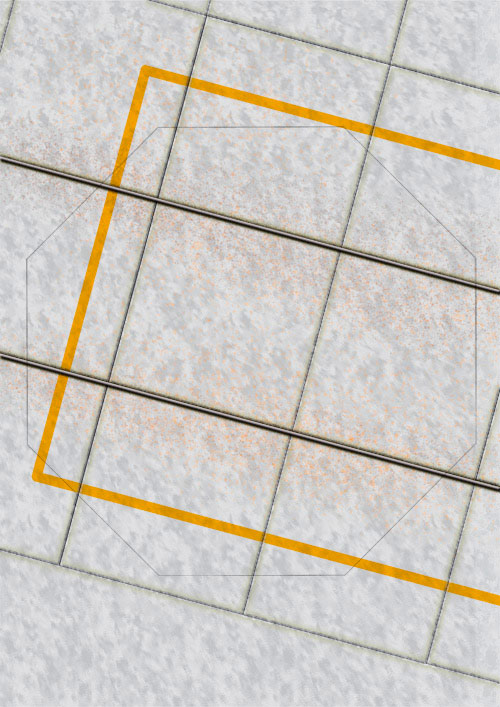

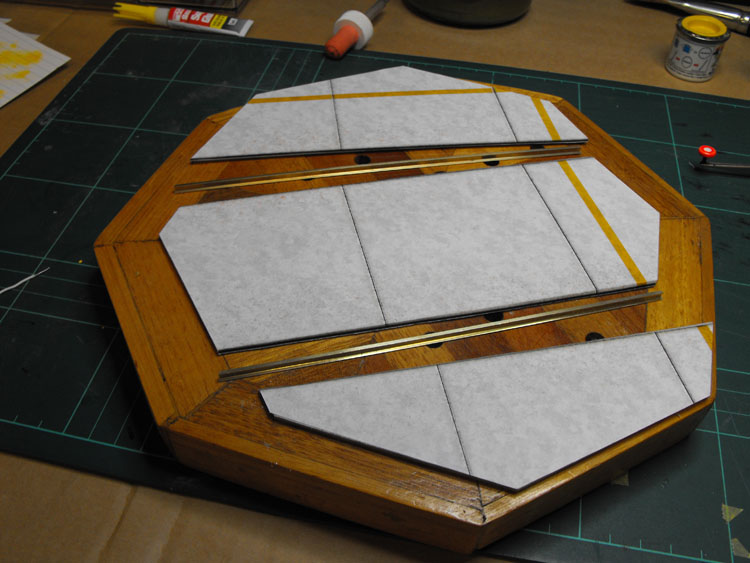

With my two fuselages assembled and thoroughly cured I set about marking up the cut. I decided to simplify the stretch even further. Rather than cut and shut two sections, as per the original, above and below the floor, I made a single cut right through one section of the fuselage and re-drilled the front landing skid mounting holes. This way I am just trying to butt two cylinders together rather than trying to align several loose pieces. Iíll keep the rear cabin doors shut to ease the process further.

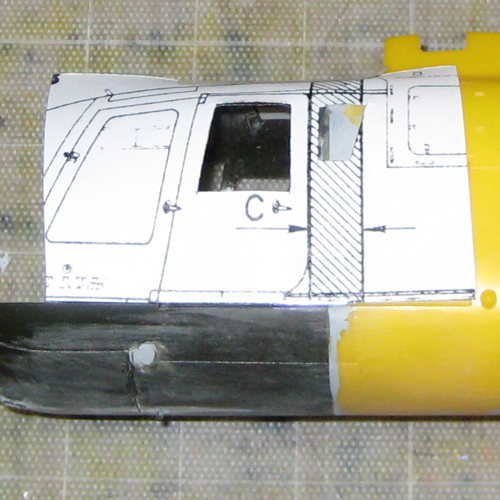

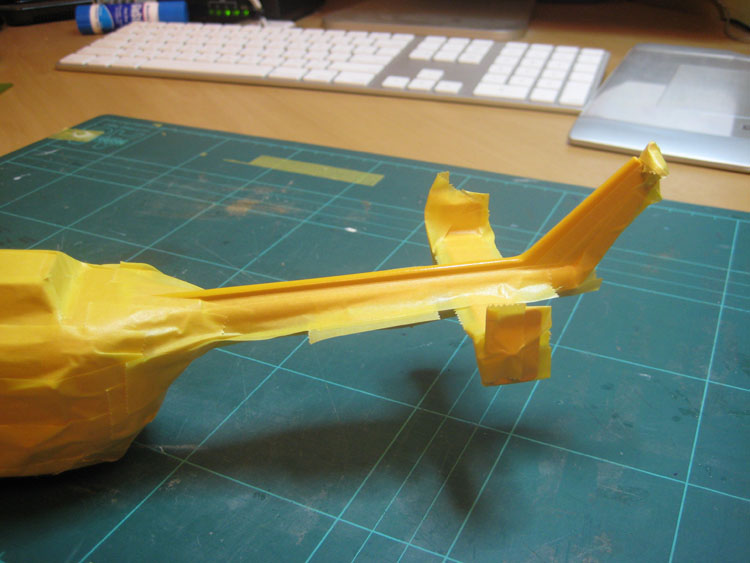

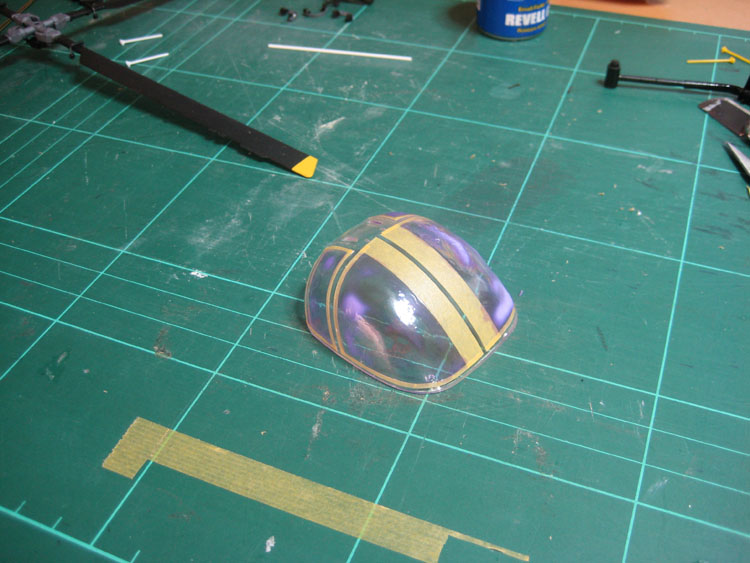

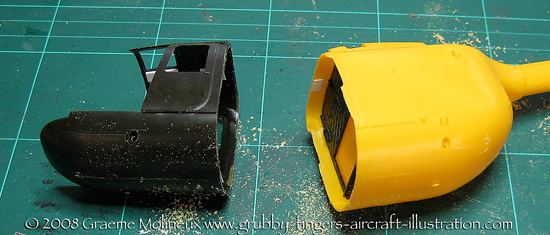

I ran masking tape next to the line to act as a cutting guide and to protect the bits I was going to keep. And I cut ...

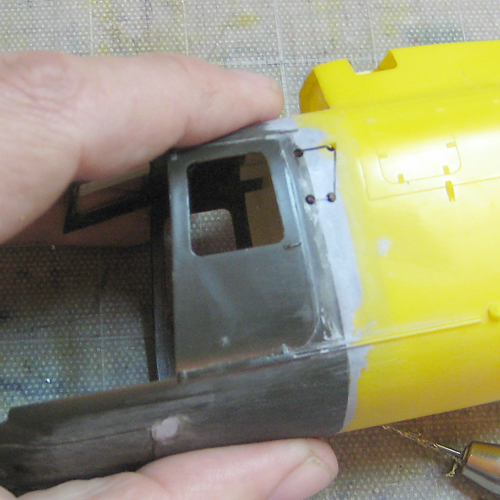

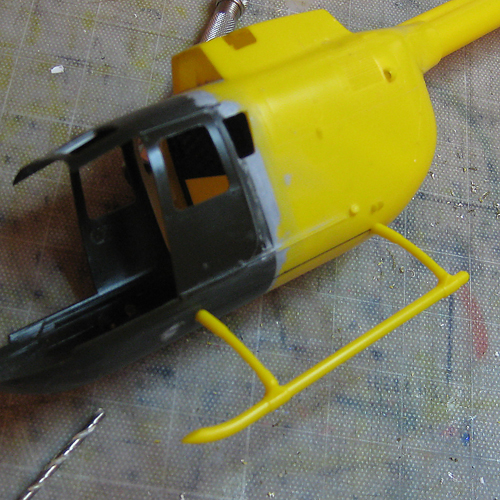

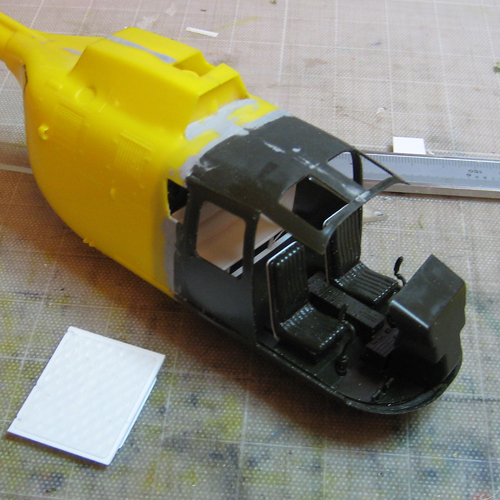

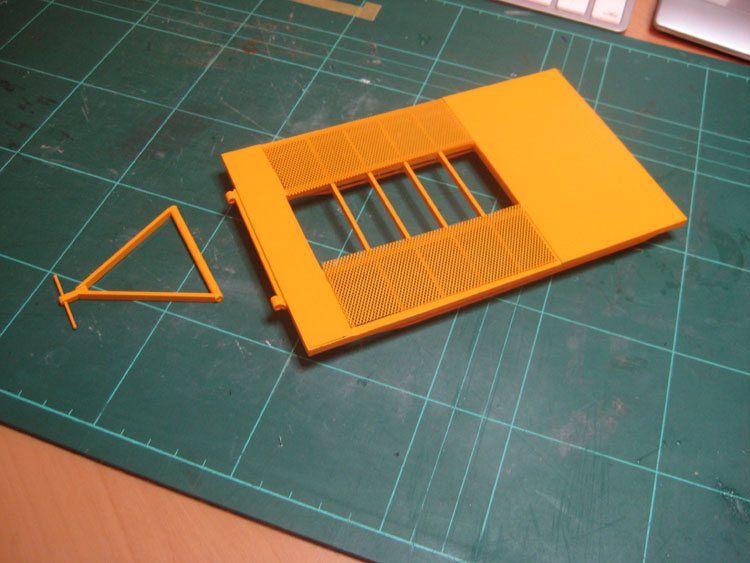

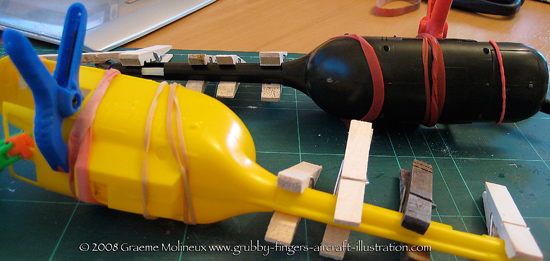

Once the cutting was finished I started breathing again. You can see the overlap between the fuselage sections. The green fuselage was cut immediately in front of the engine nacelle, and the yellow was cut 8mm forward of that line.

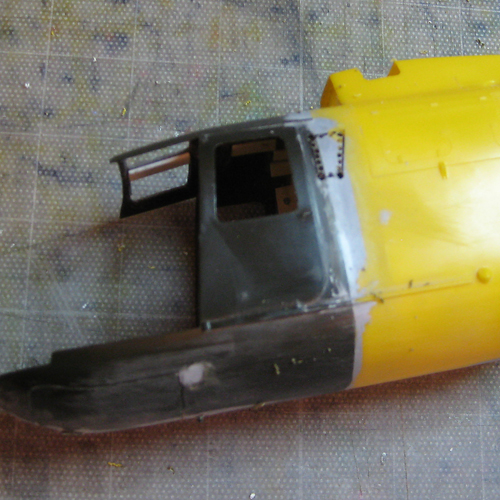

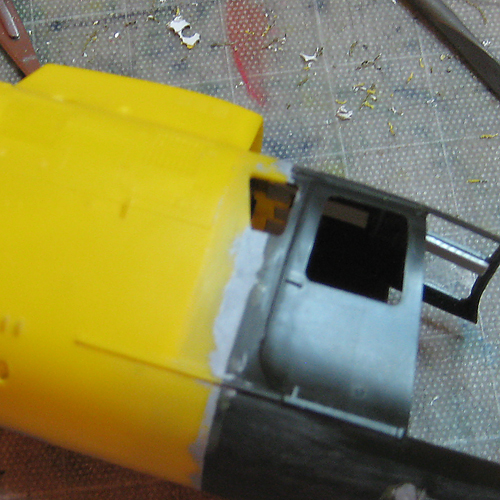

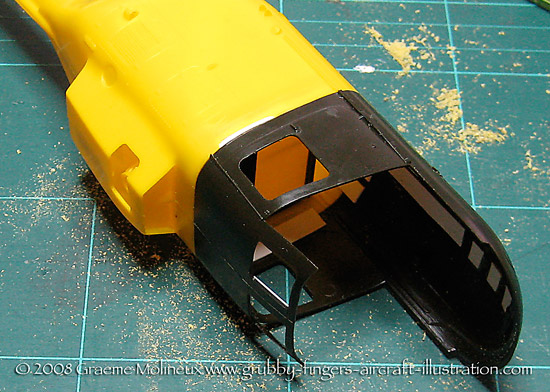

Now the front and rear sections are brought together and glued. I added some thin plastic strip to strengthen the join and cover the hole from what was left of the door window on the yellow section. I also sanded down what was left of the main side doors on the rear section as it was raised.

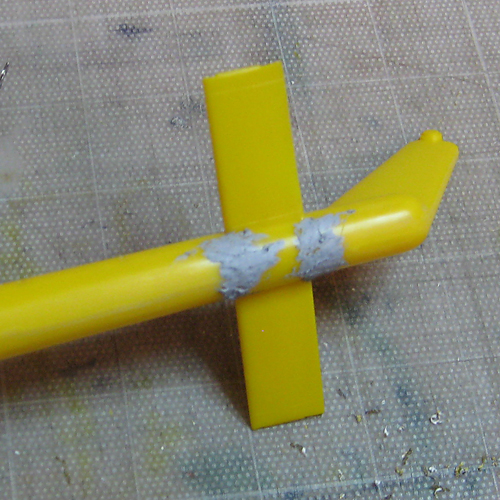

Next steps will be bogging up the join, attaching the tailplane and cleaning it all up. I'll probably start on the interior in the mean time too.