Just thought I would share some progress pics of the project I have just started - the 1/48 scale Blue Max Sopwith 7F-1 Snipe (there is plenty of history around on this aircraft so I won't go into it here). I plan to build this as a 4SQN Australian Flying Corps aircraft (yes I am feeling a little patriotic after building all that German stuff!) The kit is limited run, and is one of three Snipe kits in this scale (the others being the CSM resin offering and the Hi-Tech kit, also limited run). Being a Blue Max kit (ie nice fine details but nothing really fits), I am in for a fun time.

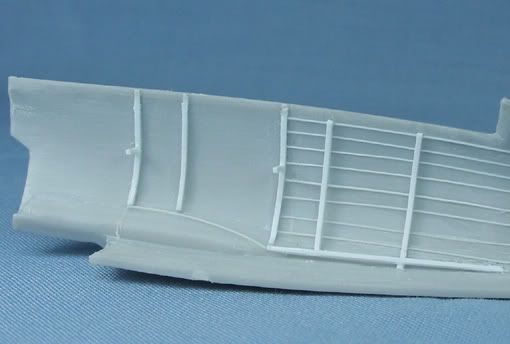

I have not done too much to date, however, I started with the upper fuselage decking. Dry-fitting revealed that it sat too high and was too wide, so I sanded the deck until it sat properly at the right height. Looking at photos and drawings in the datafile, it quickly became ovious to me that Blue Max got the shape of the cockpit opening rather wrong. The opening needed to be extended forward, noting the assymetry between sides (the required adjustments are marked in blue - of note, taking a look at sprue shots, Hi-Tech got the cockpit opening wrong as well, and I am not so sure on the CSM shape).

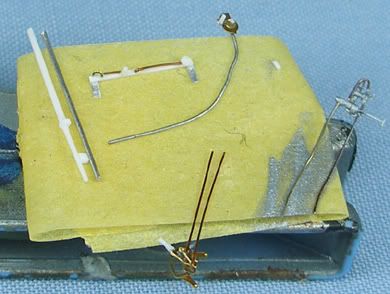

I thusly modified the kit cockpit opening and thinned the thick plastic to a more realistic thickness. Whilst I was on the decking, I made a few more corrections. The hand hold behind the cockpit is moulded as a round dimple, where photos clearly show a smaller rectangular opening with rounded ends. I filled the dimple then cut a new handhold. I also added the panel lines where the plywood section of the decking finishes and the metal part starts. Other additions included the windshield stand, bulkhead behind the cockpit opening, and the raised lip around the bottom sides of the decking (a feature prominent in photos).

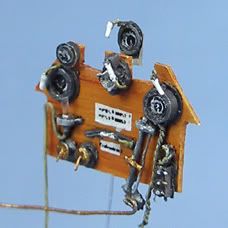

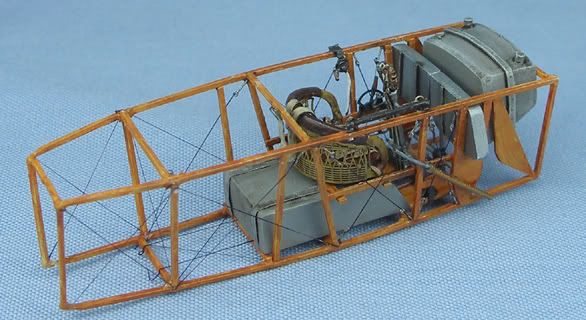

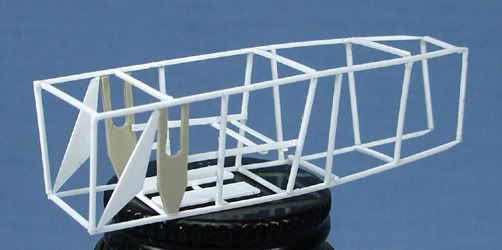

Next I moved to the cockpit itself. The enlarged cockpit opening, plus the "open" centre wing section, meant that I couldn't get away with anything too simple. The kit cockpit is simple and predominantly white metal, and it quickly became apparent to me that it wouldn't fit. A such, I decided to largely scratch build the cockpit. After thinning out the sides a little, I built up the cockpit framing from strip and sheet styrene (plus some heat stretched styrene for the stringers), making sure to check that it fit. I did have to taper the frame towards the lower part of the cockpit due to the indents for the wing attachments, however, when in place with the decking on it is surprisingly difficult to tell that it is tapered.

Here it is all closed up to make sure it fits (no doubt something will happen as I built it up that will take it all out of level!!)

Next I will tackle some painting and cockpit detailing.

All comments and feedack welcome.

BC