I had high hopes for this bird, especially having 2 other Roden kits, and the reputation Roden have acquired. I have to say my first impressions aren't good. I have found the kit to be covered in flash; parts misaligned when moulded, and the detail very soft in lots of cases. Locating pins and holes are so misformed or shallow as to be of no use.

This going to be a real FUN build

First up, the obligatory box and bits shots:

Here's a pic of a sprue of parts, and Rodens little joke to it's buyers...those wonderfully pronounced ejector pin marks which leave both a mix of extra plastic and recesses, in the most awkward of places. Just look at the size of those rigging wires too. Filligree this is NOT! I think this is is worst moulded kit I have seen since I returned to the hobby....

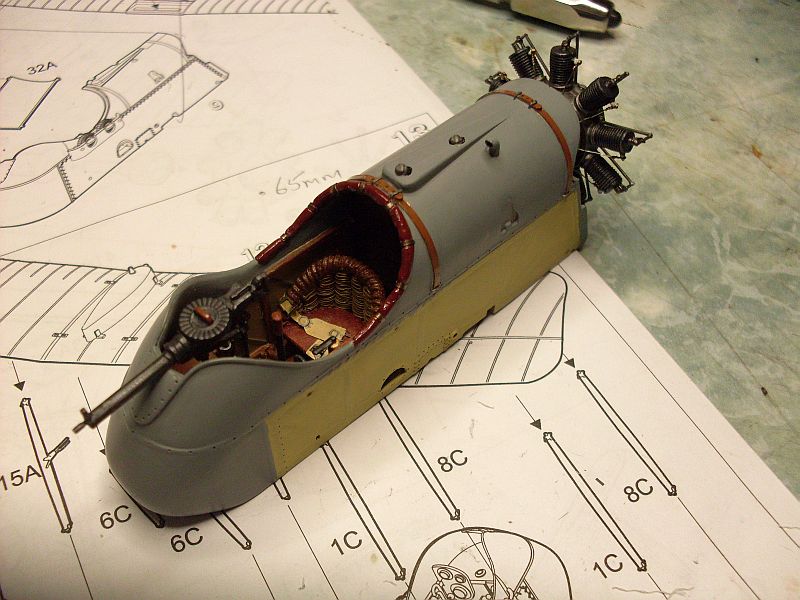

I did some serious cleaning up of the nacelle parts, and I have also had to run the nacelle halves (the joins) over a piece of wet 'n day paper to even up the joining faces, as these too were dire.

Notice I have also opened up the holes on the rear nacelle, over the fuel tanks where the cabane struts later attach. I can't understand why Roden moulded these with no opening.

I now have to work a way of wrinking the external canvas too. The pics I have of the DH-2 show the canvas to be everything from taught to wrinkled to hell and back. I think a few wrinkles will add character. Extra detaling will be added to the interior, such as cabling, and the new cross brace wires. The padded area behind the pilots head is aldo badly moulded, and I'll replace this with 2 part epoxy putty.

The horribly moulded bucket seat will be replaced with a handmade wicker one. Never tried it before, so that will be fun.

......lets see if we can make a silk purse from a sows ear

Jim