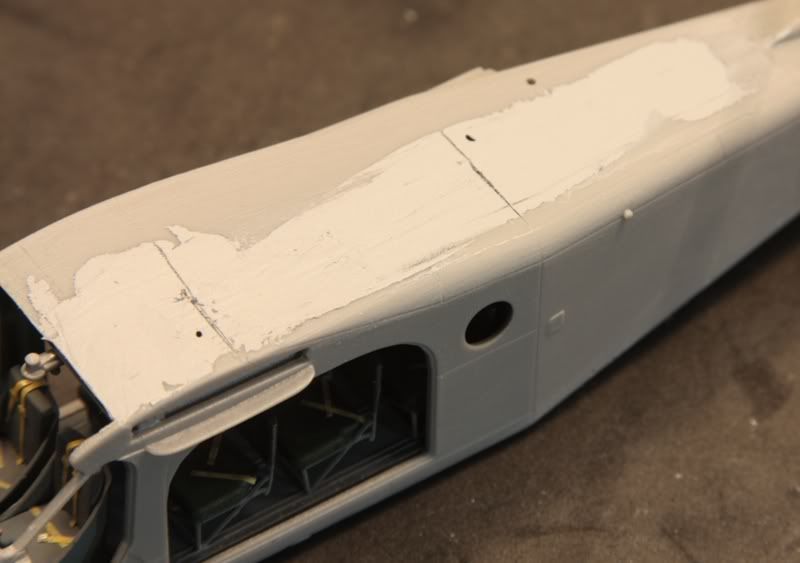

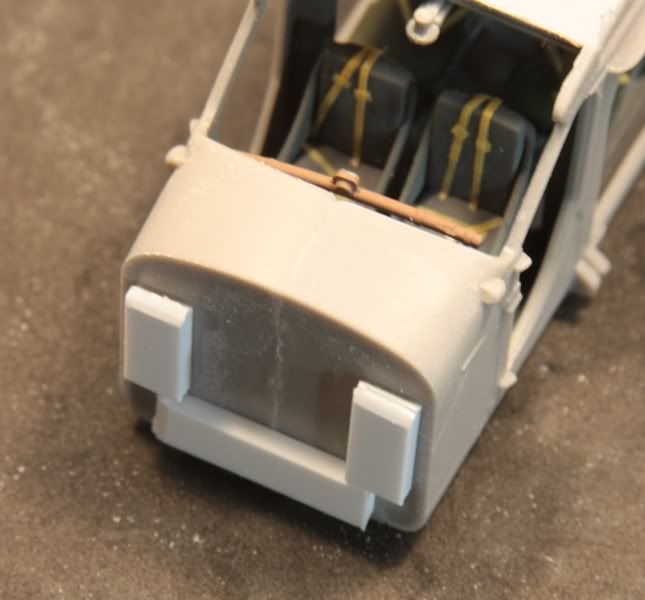

Lots of progress and some minor setbacks. Once my hangover subsided, I made some decent progress on this thing. I began by dressing the puttied areas on the nose. In doing so, I figured it would be easier to remove the molded on scoop on the top of the cowling and replace it later. It was molded with one half on one side of the cowl, and the other half on the opposite side. Not an easy seam to dress by any means.

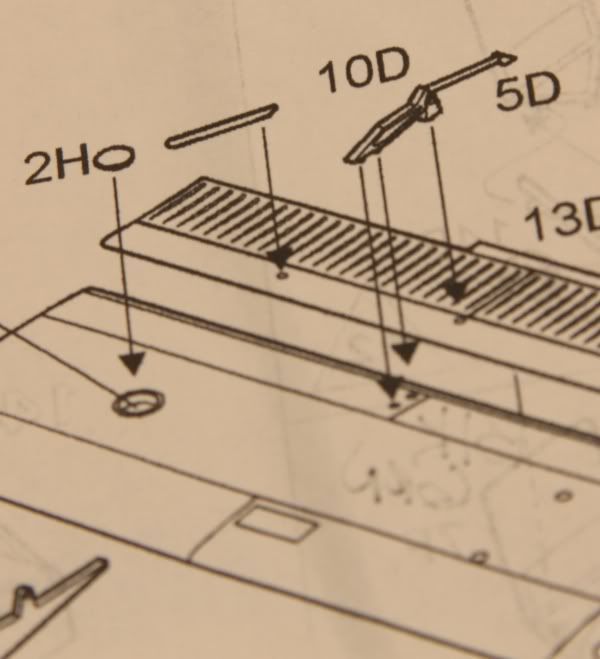

Moving on to the bottom, I discovered the same problem with the details down there...

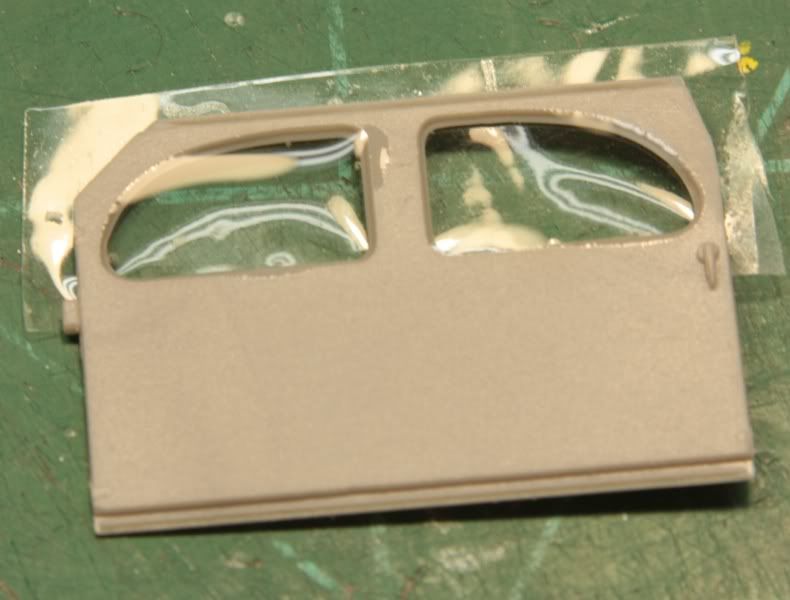

I treated this area the same and sanded off everything, then smoothed out the plastic. I used my punch set and made the disc from some scrap .010 sheet, and added the strips with .020 half round pieces. The detail in front of this was cut from the same scrap .010 sheet then had the corners rounded off a bit. The scoop is a piece of triangular stock cut to length. All of this is a little larger than what was molded on the kit, but should look the part once painted.

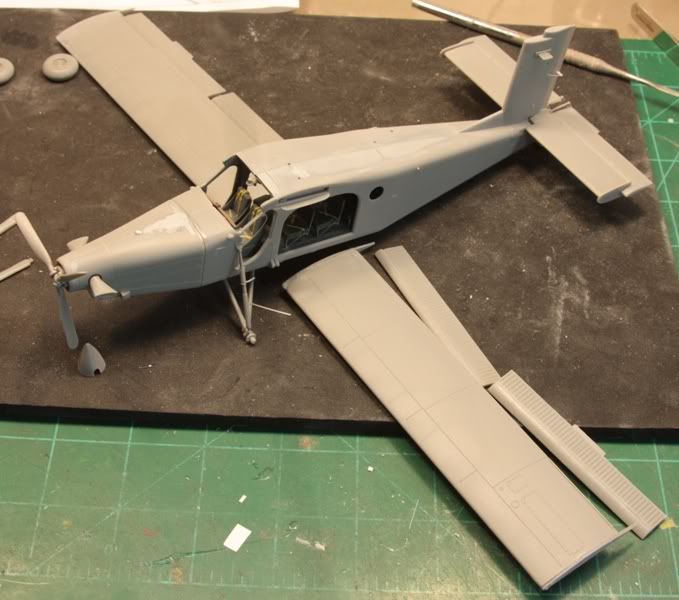

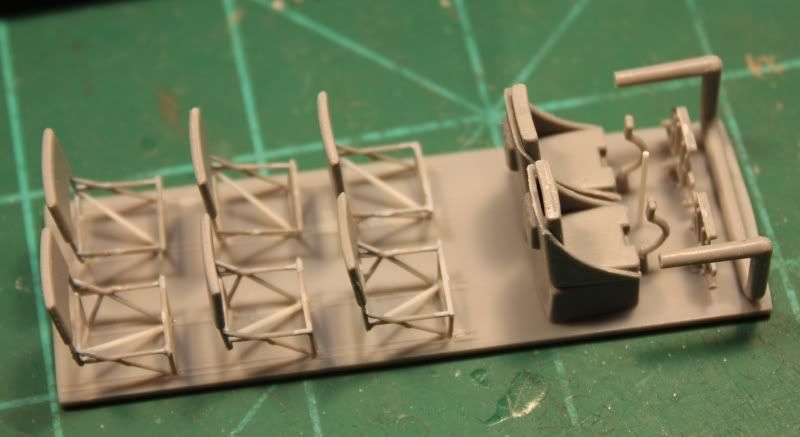

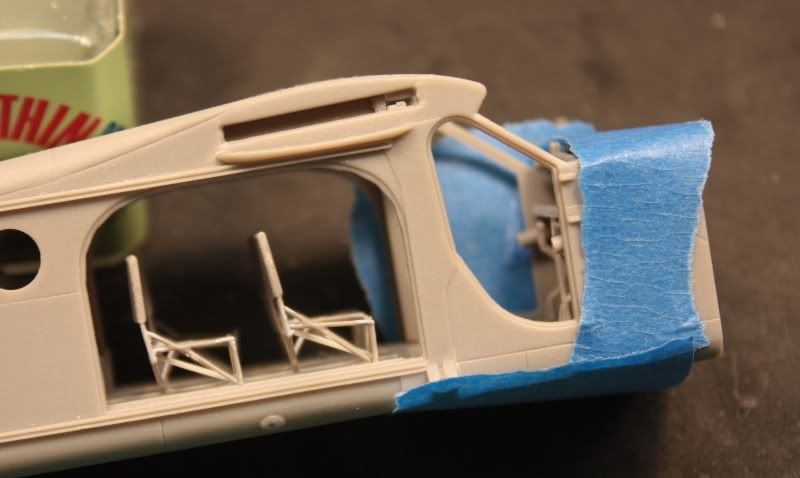

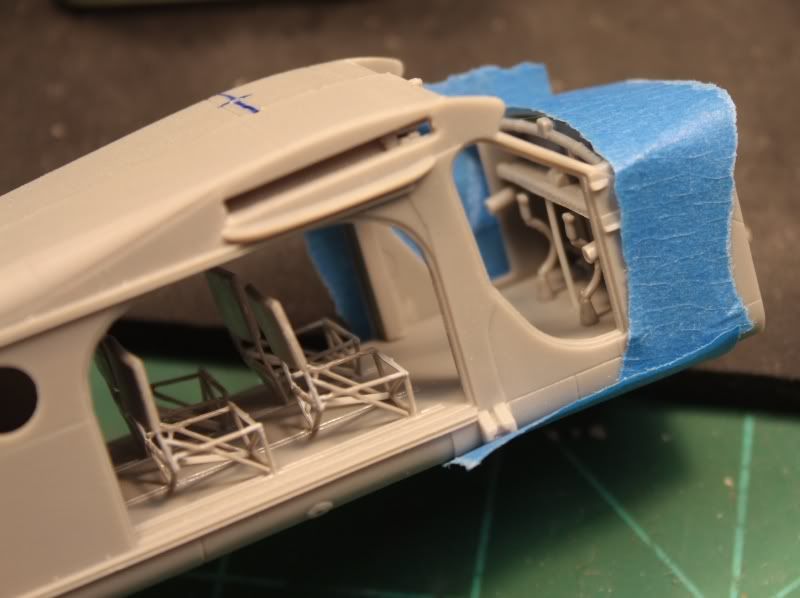

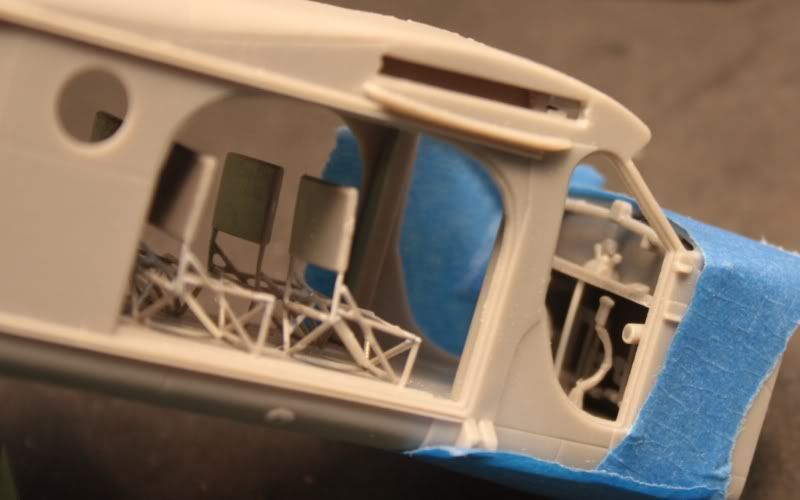

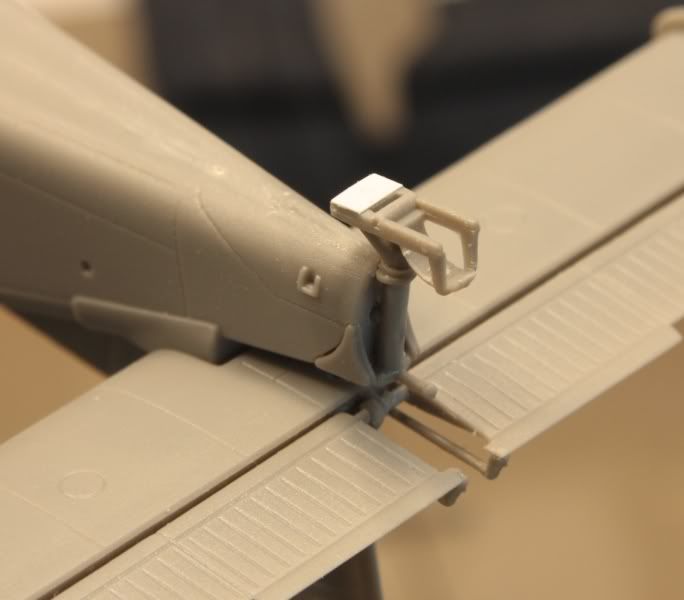

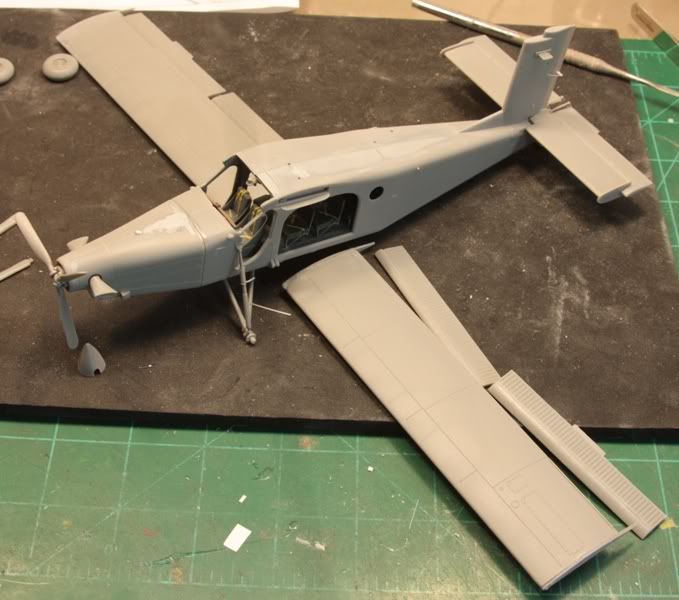

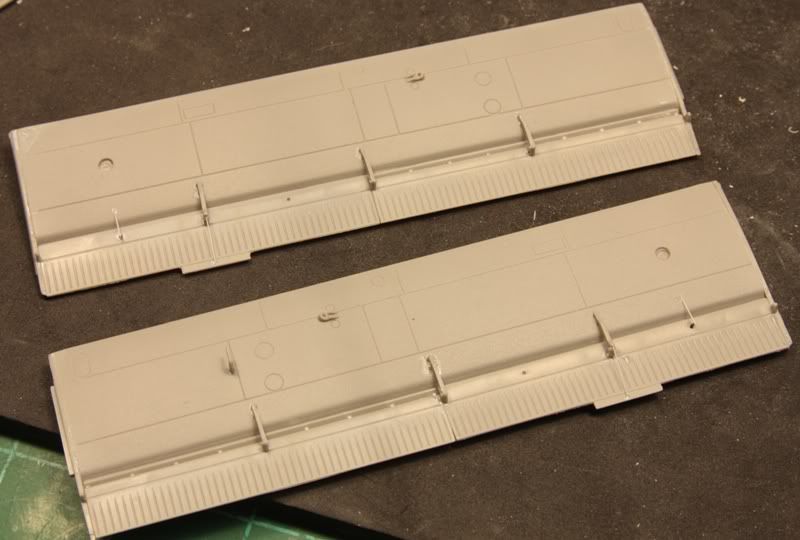

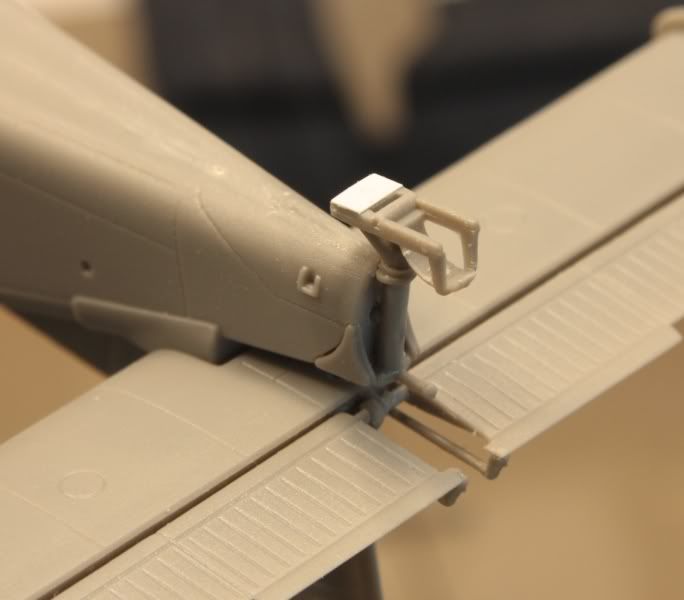

I added the spindly landing gear. This reminds me of the Fiesler Storch. I was pleasantly surprised at how well everything fit. I didn't have to cut, sand or otherwise tweak anything to get the pieces to line up and fit.

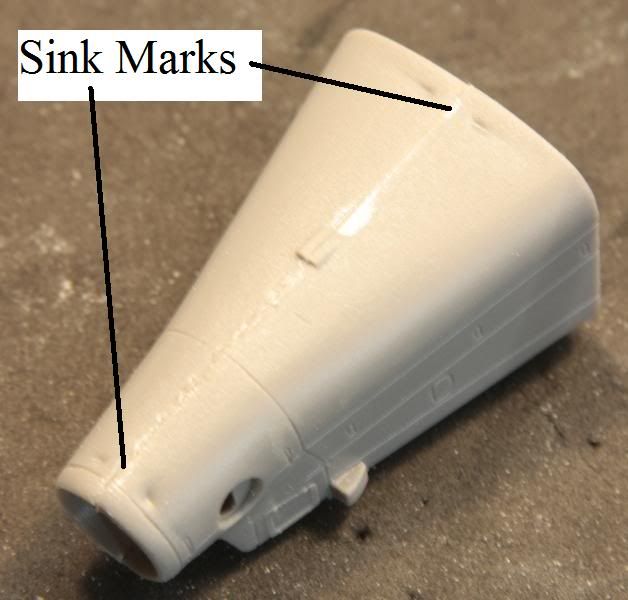

I also added the tail wheel. No problem adding this piece either...but there was a small sink mark on the bottom that I cut some .005 sheet to cover rather than putty it.

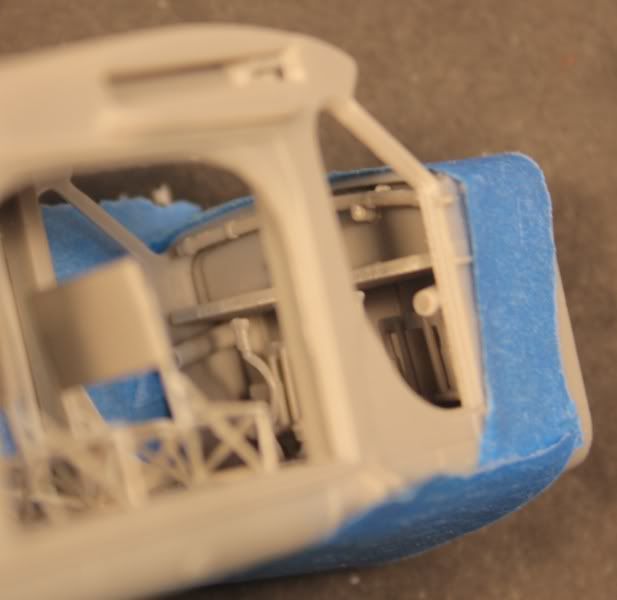

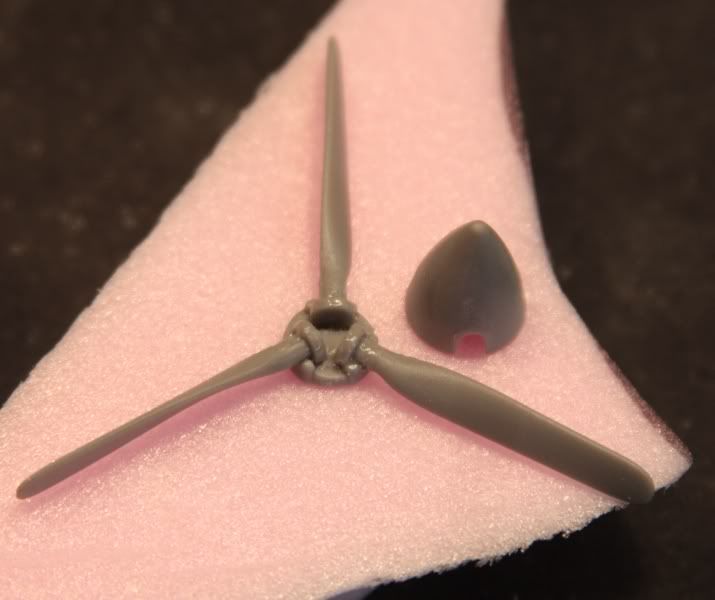

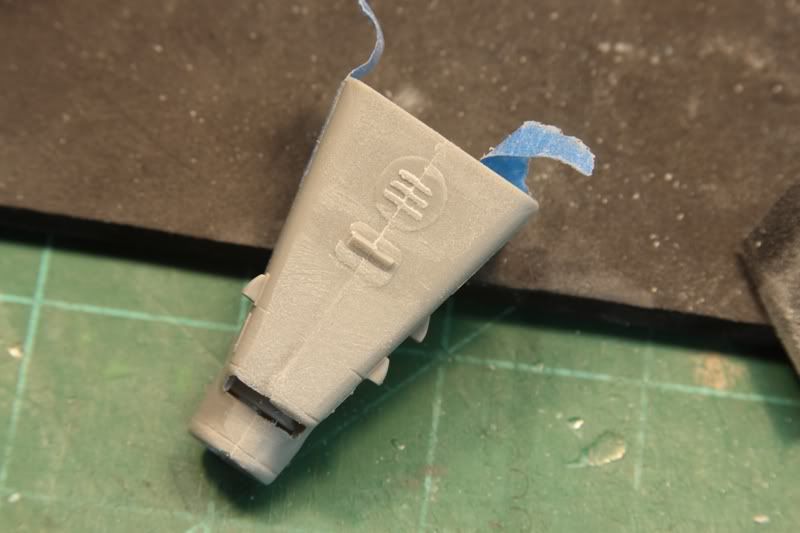

I assembled the exhausts and about lost my cool. They are really small, have no locating pins/tabs and were hard to hold onto. I had to scrape the exhaust openings a bit to make them look like the gases had some place to escape as they were molded almost completely closed. Once assembled and dry, I was able to dress the small seams with the back of a #11 blade, and some fine sandpaper.

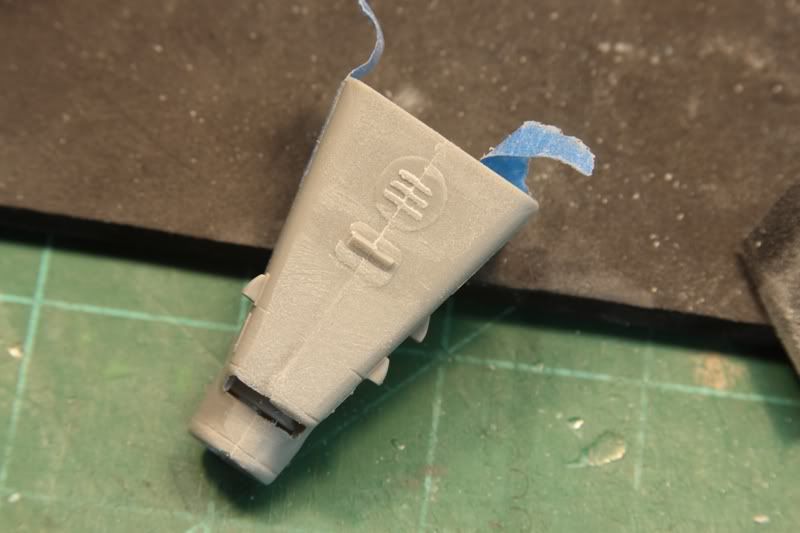

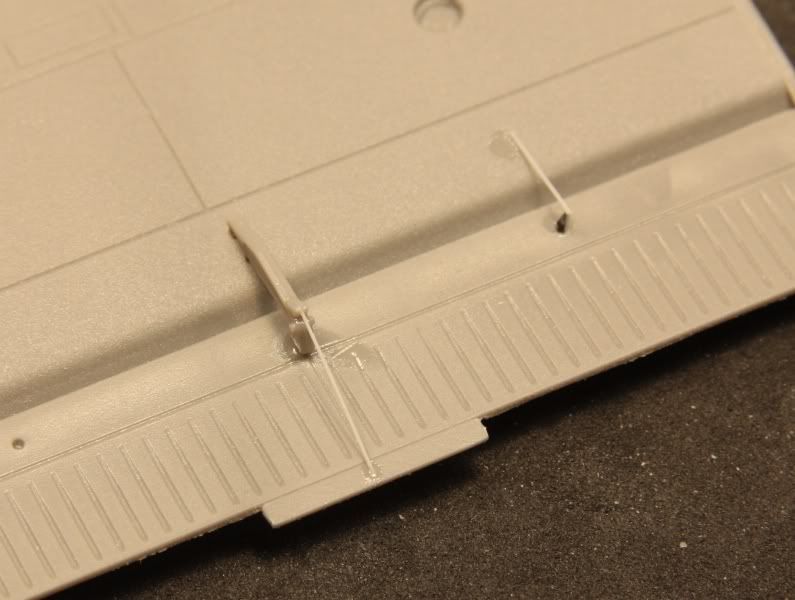

While cleaning up the actuator arm for the trim tab, the carpet monster got hungry and attacked..

I searched in vain for a few minutes then sat down and scratched a replacement piece from the .010 sheet stretched sprue and an end slice of .010 rod. Again, it should look alright under paint.

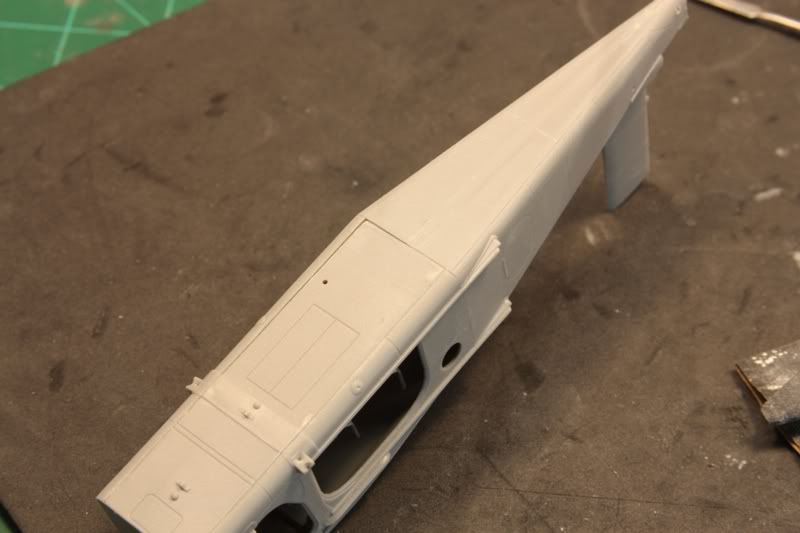

The rudder was the last thing added this morning. Everything is sitting on the bench drying. Hoping to get back to it this afternoon. Thanks for following along. "Q"

ps. This thing is quite large when everything is in its proper place...