First step is to remove some of the fuselage from the front end underside, for later installation of the 30mm cannon. After that is assembly of the cockpit. Here is how the parts built up. I only lost a couple of small bits to the carpet.

As you can see, ModelMaster RLM 02 is not the same as that provided on the etch parts.

After the pilot's seat, the rear of the cockpit was assembled. The radio suite may not have been used in the C-6, but I stuck with the instructions and built it.

Up to this point, there were no fit issues and everything went along nicely. I did forget to fill the seams on the rear gunner's seat. The join seam will need to be sanded down, but no gaps occurred here.

Next up was assembly of the nose. The lower half was also cut out for the cannon installation. None of the internal assembly of the gun platform will be visible on my kit but I provided basic detail for this review. The upper half had some flash issues and odd blobs of plastic that I had to remove. I will need to touch it up, and fix some seams here.

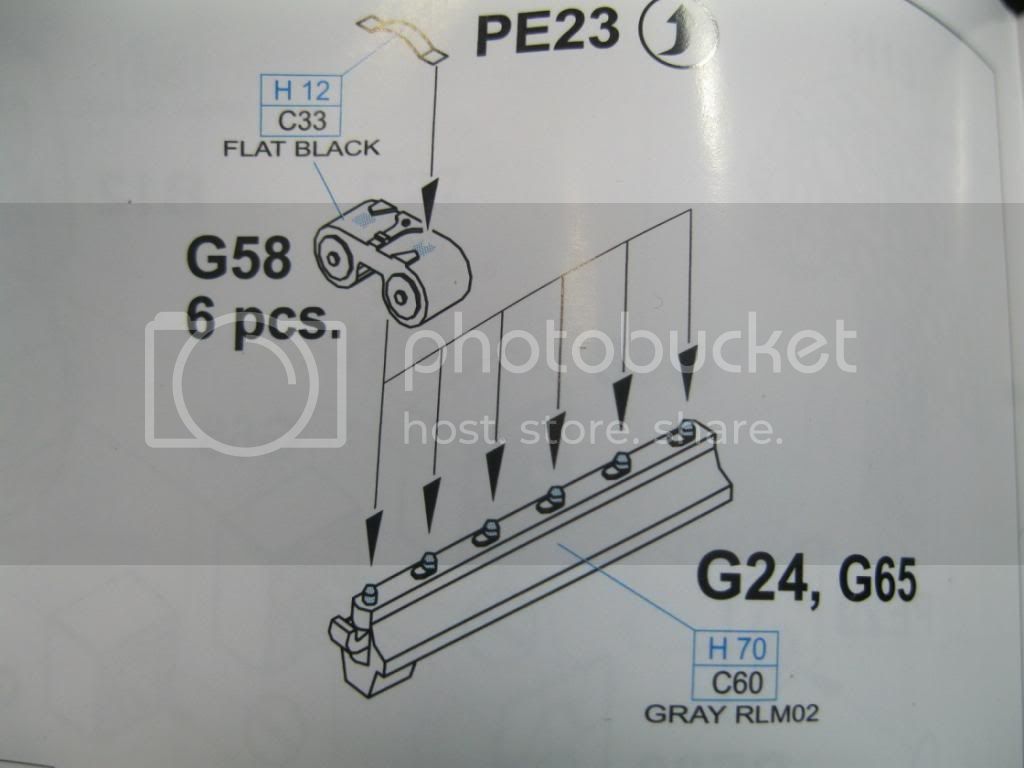

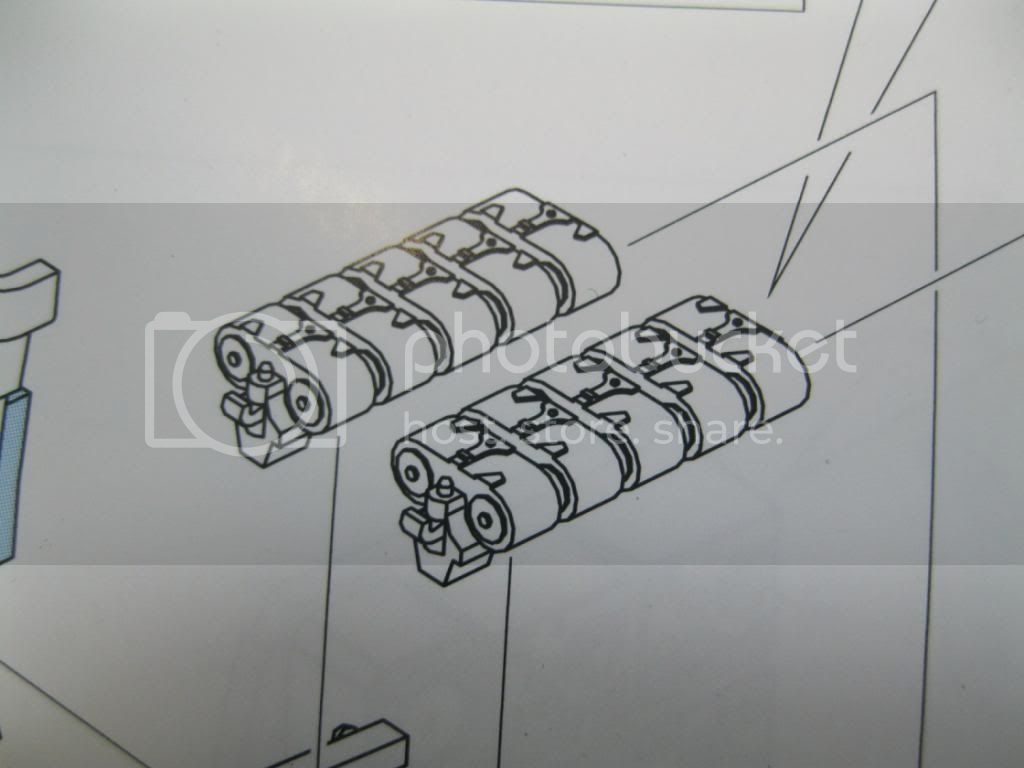

At the same time I worked on the rear gun and ammo rack. I found an issue here as the instructions show placement of 6 ammo drums, apparently on 6 pins on the rack arms. I followed this instruction and found it a little challenging to get them to fit properly. The diagram showing installation of the actual assembled ammo racks shows five ammo drums per arm, which is correct, each going between the pins on the arms. This will allow the drums to sit squarely. There is also a small strap attached across the top of the drums. Also, there are two different mounts for the machine gun. One is for the stowed position, the other for it in firing position. You will note from the position of the locator pin which is which.

I assembled the engine nacelles and installed them on the wings. These parts will require some extensive filling as there are a number of gaps present. There was also some flash present on these parts that was missed in the in box. I will need to do some riveting and learn how to re-scribe panels properly.

I will fill the gaps before I attach the wings to the fuselage as they are easier for me to manage when separate. Tips or suggestions are most welcome.