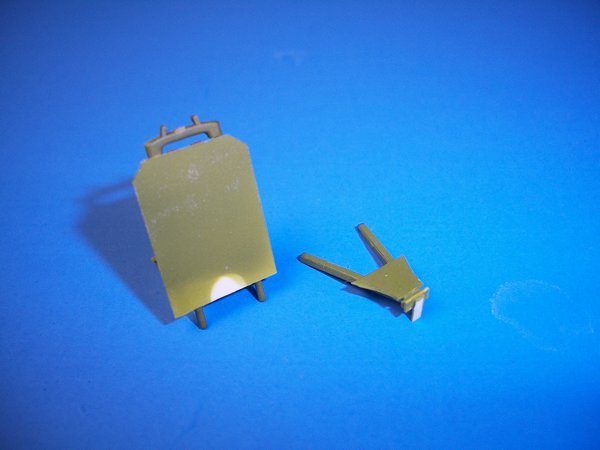

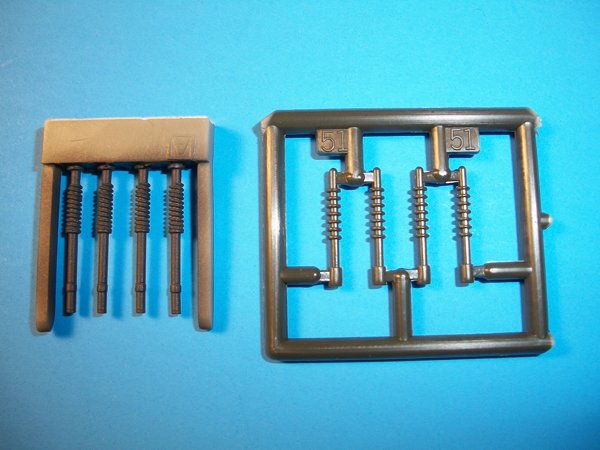

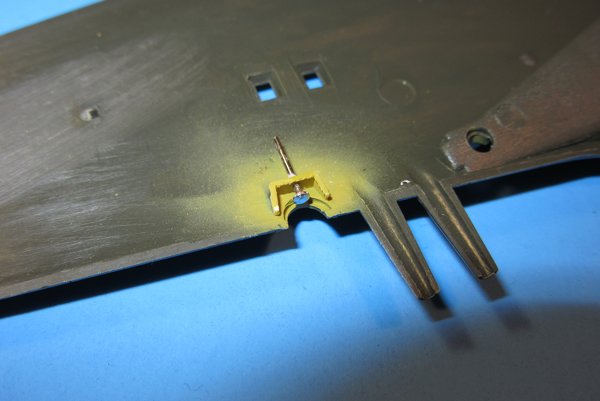

I managed to get some work done on it the last two weeks. I did not change much in the cockpit other than to cut off the oxygen regulator hose on the left side. The kit part is rather flat so I wanted to replace it with coiled wire to add a little depth to the side. I made the hose by gripping a .015" rod and a length of 34 gauge jeweler's wire in a pin vise, and then just slowly spinning the vise to tightly coil the wire around the rod. Once I had enough I just removed them from the vise and pulled out the rod, leaving a nice tight coil.

Original kit sidewalls, note the barely there oxygen hose.

Original kit sidewalls, note the barely there oxygen hose. Making a replacement that won't be as flat against the sidewall.

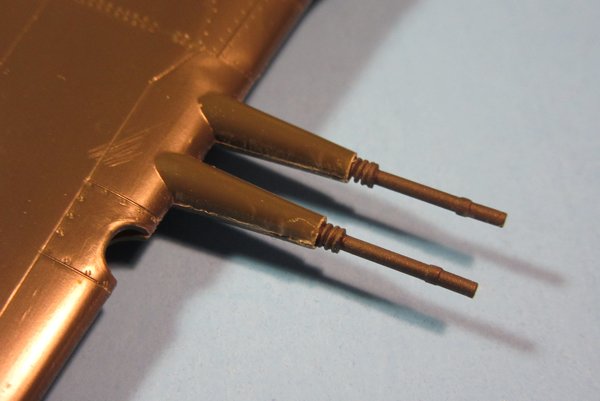

Making a replacement that won't be as flat against the sidewall.The sidewalls were tacked to the fuselage halves with a dab of clear parts cement to make painting easier. I painted all of the cockpit parts Interior Green using Tamiya XF-3 and XF-5 2:1 with a drop or two of XF-1 added in, thinned 50/50 with isopropyl alcohol. I painted the Ultracast seat zinc chromate (Tamiya XF-4) along with the tail wheel well and doors, and the rear spare inside the main wheel wells. There are a lot of opinions on proper colors for P-51 wheel wells, but I tend to go with Tom Cleaver's argument and paint them aluminum lacquer with the rear spar in zinc chromate. I had color photos of P-51 seats in NMF, zinc chromate, and interior green. I chose zinc chromate for mine to give the cockpit some color other than interior green. I let all of that cure for 24hrs and then removed the sidewalls, masked off the green and painted all of the radios black with Tamiya XF-1, along with the transmitter and receiver banks, the instrument panel, and bits on the control stick. I took a 20/0 brush and hand painted the seatbelts with Testor's Dark Tan (the little bottles) and picked out the buckles with Vallejo Model Air aluminum. I let everything cure for 24hrs and then permanently attached the sidewalls before spraying a coat of Future to prep for the cockpit wash.

I let the Future cure for 24hrs and then ran a wash around the parts. I was feeling pretty good about everything at this point, but 18hrs later when I went to remove the wash I had trouble. I used my usual pin wash I use on panel lines (gloss black enamel and dark earth enamel, 1:1, thinned down about 10:1 with enamel thinner) but for some reason this time it had eaten into a good bit of my paint. I guess I needed to give the Future more time to cure. The sidewalls were okay and the seat actually looked great, but the IP, floor, batteries and radio banks were a mess. I drybrushed highlights on everything and picked out details with a toothpick hoping to diffuse some of the bleaching, but it didn't help much. It actually made the IP far worse, to where I thought I would need to scrap the instrument decal and strip all the paint, then repaint it and try to detail it with drybrushed gauges.

Rather than get impatient and make things worse, I took a break and came back the next day with an idea. I thinned down MM Acryl flat black about 10:1 with water and then sludge washed the radio banks, batteries, and IP. I gave it a couple of hours to dry and then repeated the wash. This actually worked out great, especially with the IP, and everything seems fine now to my eye. I sealed it all up with Micro Flat and called it a day.

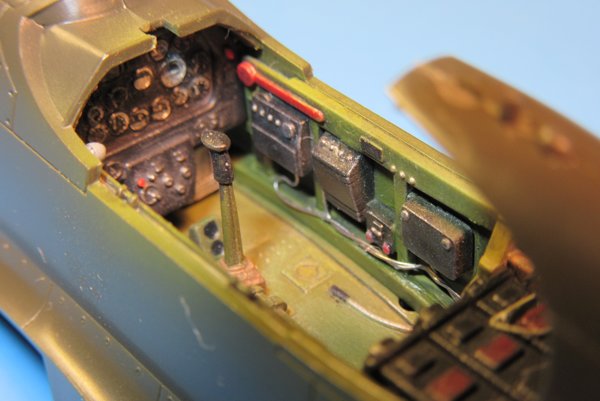

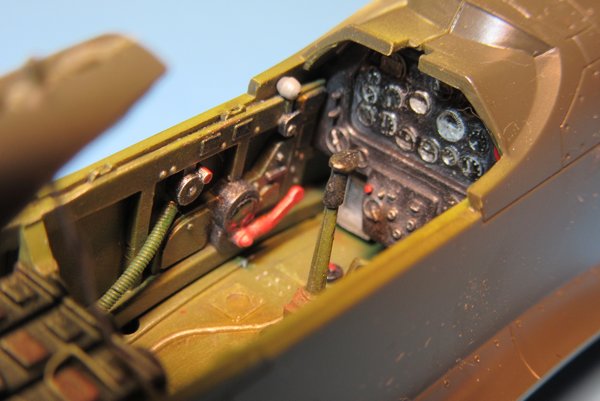

Sidewalls after painting, wash, highlights, and a little touch up with some thinned black. I'll add the oxygen regulator hose during assembly.

Sidewalls after painting, wash, highlights, and a little touch up with some thinned black. I'll add the oxygen regulator hose during assembly. Floor with control stick and the radio banks. The floor is a bit overdone but when all of the pieces are put in it isn't that visible and comes off well-used rather than sloppy.

Floor with control stick and the radio banks. The floor is a bit overdone but when all of the pieces are put in it isn't that visible and comes off well-used rather than sloppy. The Ultracast seat and the IP, which after 2 washes of thinned black around all of the gauges came out pretty good. This is the first resin seat I've used, the detail blows the kit seat away but its as expensive as an entire Eduard Zoom set.

The Ultracast seat and the IP, which after 2 washes of thinned black around all of the gauges came out pretty good. This is the first resin seat I've used, the detail blows the kit seat away but its as expensive as an entire Eduard Zoom set. Main wheel well painted after a wash and highlights were added. I had to do some corrective work here as well due to paint being eaten.

Main wheel well painted after a wash and highlights were added. I had to do some corrective work here as well due to paint being eaten.Next week I plan to mount the radio banks and the cockpit floor to the right side of the aircraft, and then add a little bit of wiring detail before I close it all up. The radio banks should be pretty visible through the vac canopy so I'd like to put a work into them.

I think I'm going to switch my wash up, I have never had an issue before but this one almost ruined a week's worth of work.