Time for an update! Been crazy busy with work the past few weeks, but found a bit of time to make some progress on this build.

While making some progress on the cockpit and doing some dry fitting, I found that in my case the top of the IP slanted a little rearward when installed, so I recommend you sand down the area indicated if you run into the same issue during your dry fitting:

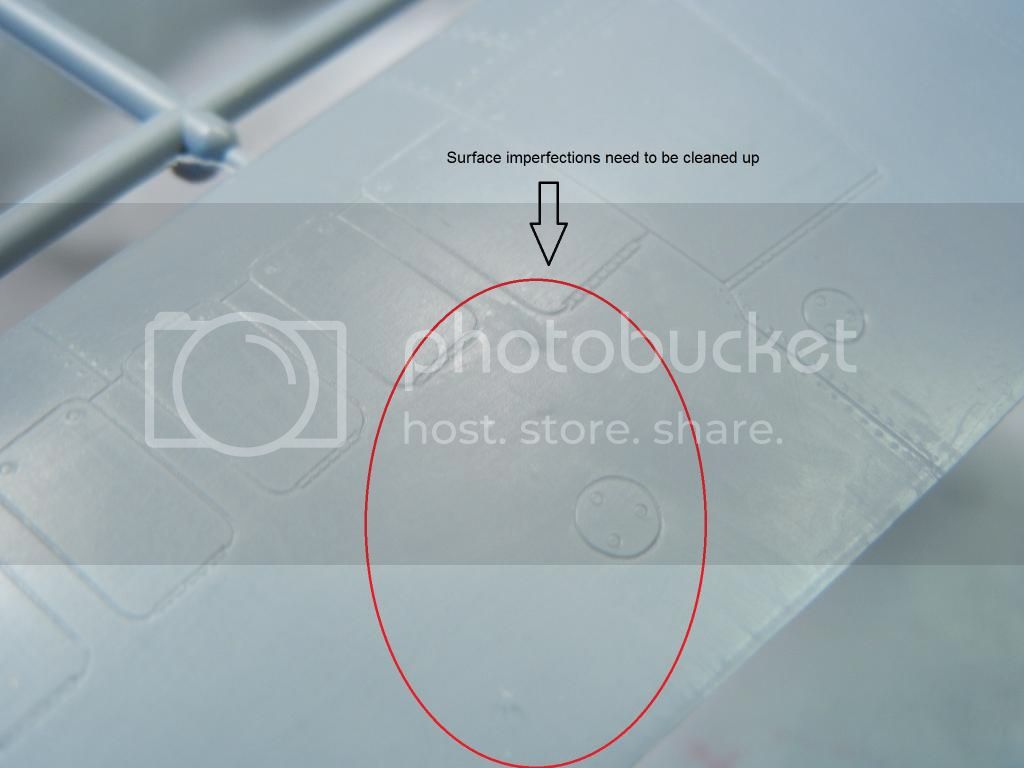

I also decided to assemble the wing. When prepping the parts I noticed that the port upper wing has some surface imperfections that need to be sanded away (took about 2 mins) as indicated in here:

I checked my other kit and it was identical, so I'm guessing all kits will have these imperfections.

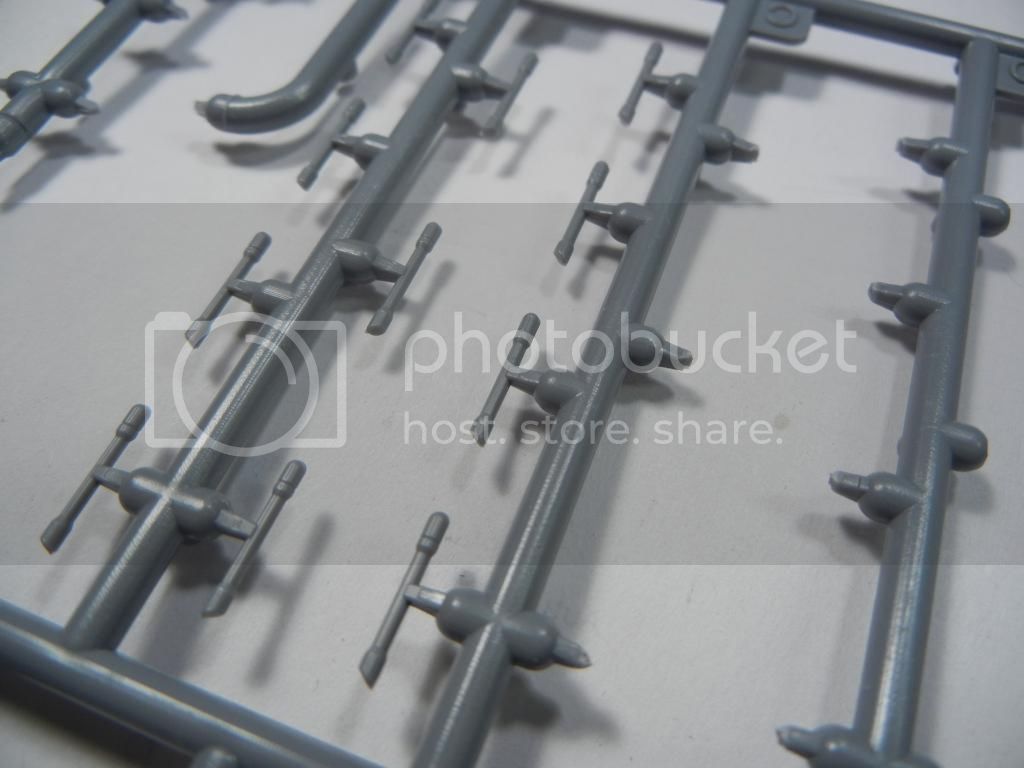

There are a lot of injector release pin marks on the inside surfaces, but only these two seemed to have any impact on fit:

After getting everything cleaned up, I installed the two oil radiator duct "screens" as shown here:

After that, I was able to glue the upper and lower wings together. Interestingly, I noticed that both upper wing parts had the same curved "gap" in the center area of the leading edge:

Fortunately, this was easily addressed with a sanding stick when they were dry.

Again, sorry for the delay and the quick update. Hopefully I'll have more time next week to make some more progress!

Thanks for looking! Comments/critique/questions always welcome!

Doug