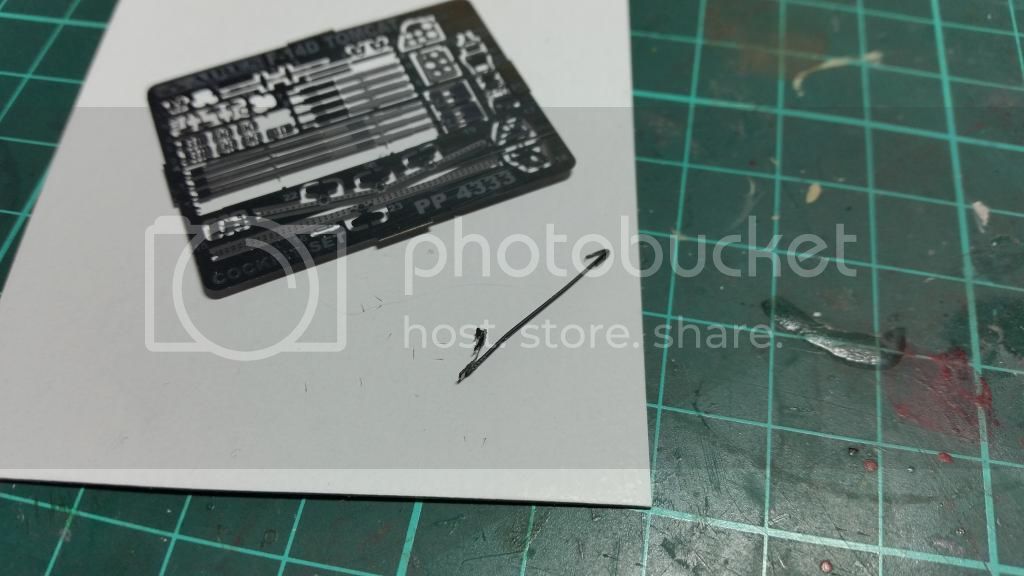

Decided to go all out for the build and ordered some extras for the 1/48 F-14D Tomcat that I'll be doing

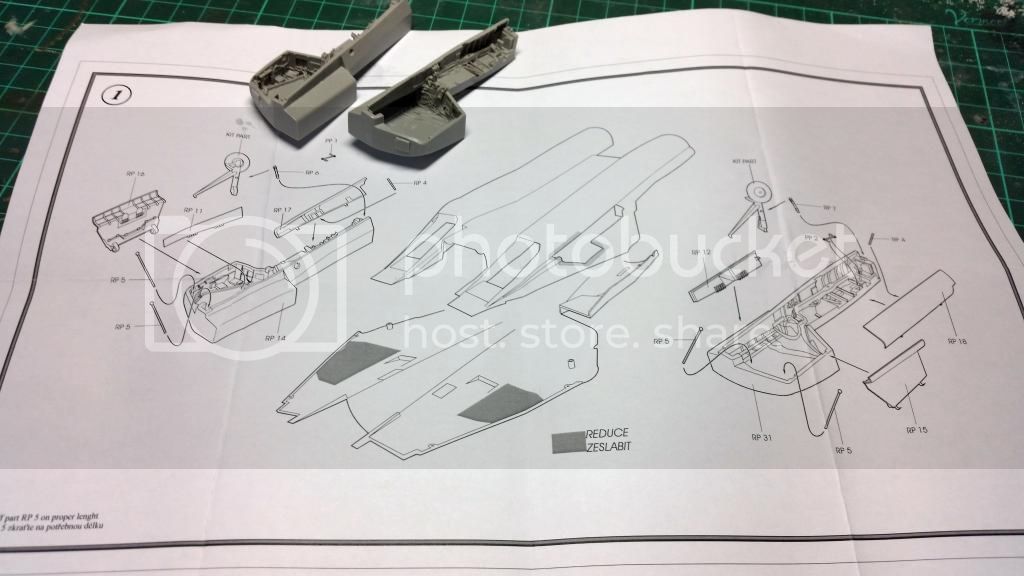

I realised after the bits arrived that I only have an the Hasegawa F-14A kit in the stash. All these 'D' parts will fit so the project has now also become a conversion

but the only thing i was short of was the Chinpod. Fortunately thanks to a kind person on the F-14 lovers facebook page I've also managed to track down an aftermarket 'D' chinpod and also a Lantrin by a company called Steel Beach. Spruebrothers stock them but I'm finding it hard at the moment to justify the high postage cost to the UK (and also risk custom charges) for such small items (unless i can find something else I would like).

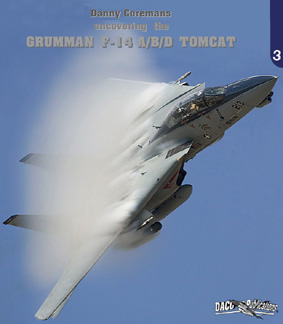

but the only thing i was short of was the Chinpod. Fortunately thanks to a kind person on the F-14 lovers facebook page I've also managed to track down an aftermarket 'D' chinpod and also a Lantrin by a company called Steel Beach. Spruebrothers stock them but I'm finding it hard at the moment to justify the high postage cost to the UK (and also risk custom charges) for such small items (unless i can find something else I would like).My primary reference book which I always seem to go to now over the vast selection of Tomact books will be this .

The first order of business was to tidy the workspace (which gets done around 3 times a year if its lucky).

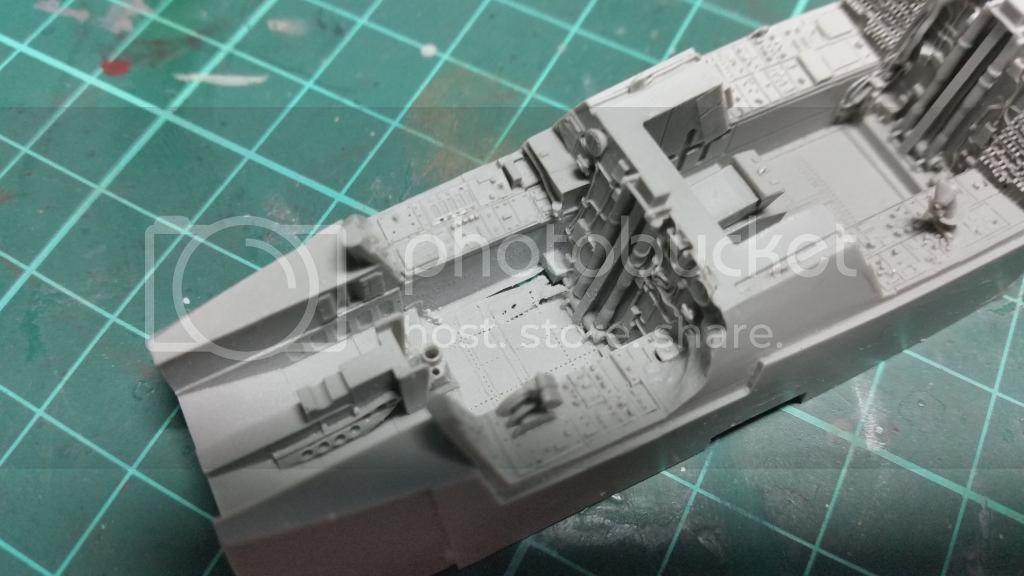

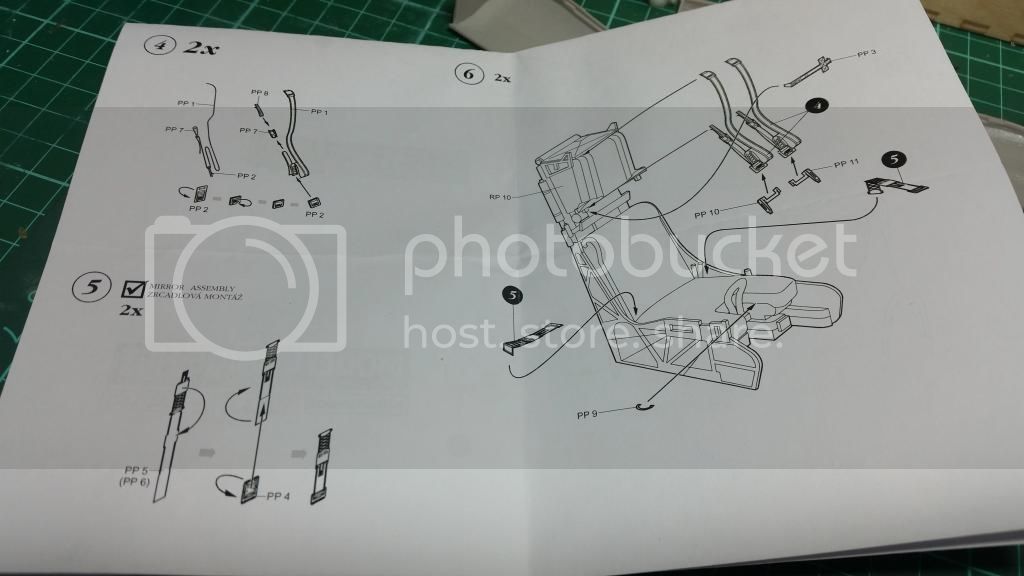

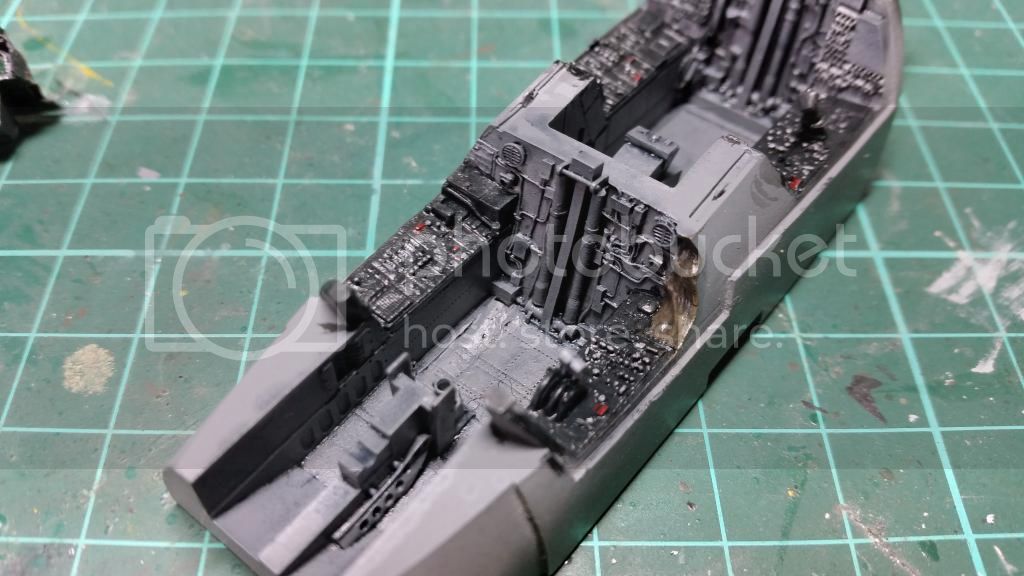

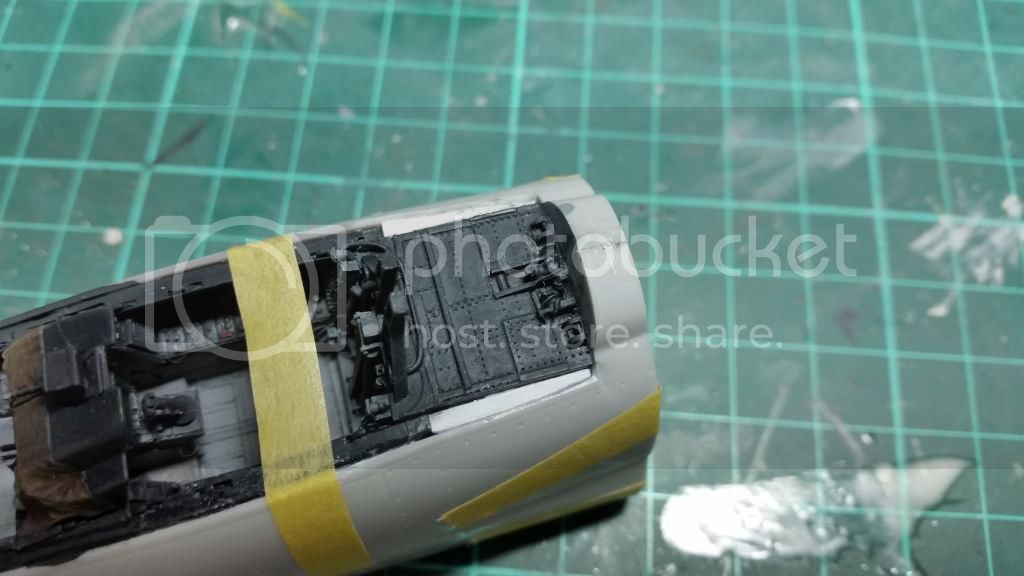

And then it was time to start. The first item on the agenda is the Aires resin cockpit with it incredible detail. These have been wash in some mild detergent and are ready for the excess resin to be removed.

Thats all for now but will hopefully get more of a start over the week.