First things first; as I said above, get those lower wings glued on so they can set up solid. Note the gap between the wings and the fuselage. This is supposed to be there, so don't panic.

They will be covered up later by side panels.

Next lead those aileron control cables that have been flopping around this whole time through the leading edge of the wings to the pulleys. Be careful to go through the holes in the ribs so the wires are fully within the leading edge:

If you were careful putting the pulley parts in, there will be a gap you can thread the cables though to go back to the ailerons. You were careful, right?

Once threaded aft, run the cables through the holes in the control horns and to the guide aft of it:

Don't apply glue to the control horn or guide yet, you'll need things to be able to move when you attach the top wing.

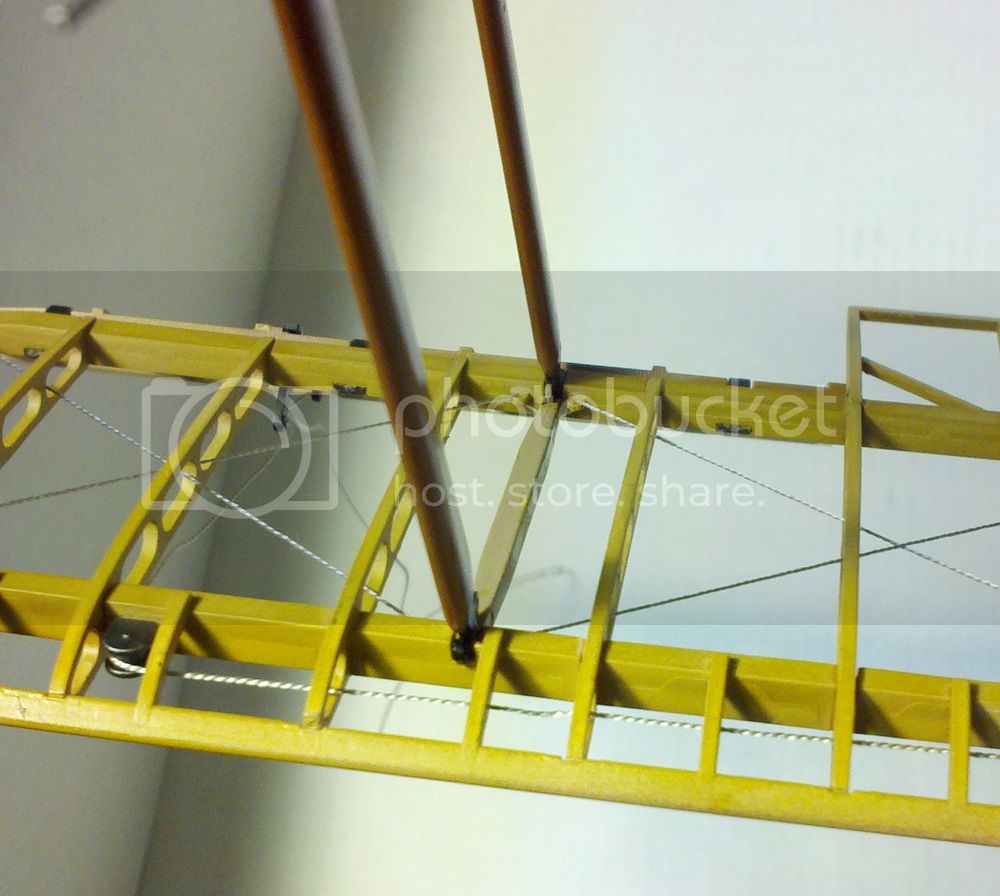

Once the aileron controls are fed through the lower ailerons, it's time to install the interplane struts into the lower wing. Here's how they fit:

You'll want to get these installed with time to install the upper wing too. As is so often true with biplanes, it's the cabane struts that really line everything up; especially on this kit where Hasegawa molded them integrally with the fuselage sides. So you'll want the interplane struts to still be a little flexible when you get the top wing on. They line up fine fore and aft, but not so much up and down.

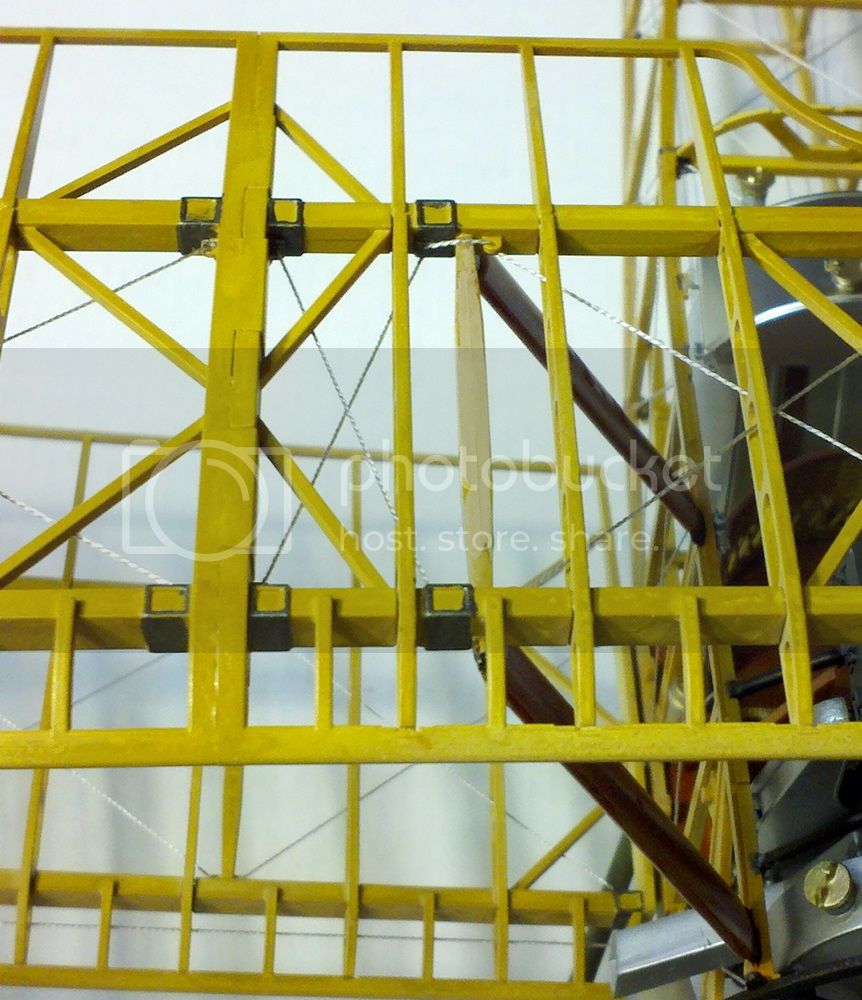

Here's the cabane struts installed in the top wing from above:

And here is what the interplane struts look like from above:

And yes, I forgot to paint the top of the struts which become a rib. What you see is the base coat of Wood Deck Tan before the clear yellow overcoat.

The upper wing has an aileron return cable that feeds though the leading edge and to the control horns on the upper ailerons much like the lower. Here it is in the leading edge:

And here's a (not so great, sorry) picture of it attached to the control horn:

Note that unlike the lower wing control cable, the control horn is not attached to the guide at the back of the aileron. The lower cables do the controlling, the upper cable is only to keep the system honest. Make sure that when you attach the two ends of the upper return cables to their control horns the ailerons are in neutral position (or one up and one down) so it does its job correctly. Then hook up the control cables from the bottom ailerons to the anchor at the back end of the top ailerons. Make sure everything (including the control stick) is in neutral position when you commit to glue. Two or three extra hands help.

By the way, I didn't actually glue the thread at the lower control horns until everything was set up. This allowed me to make sure the control stick and the ailerons matched up. It'll make more sense when you actually do it. I hope.

Right! Now it's time to start the outer wing bracing. First step is easy enough, one wire each side between the cabane struts:

And that's where the easy stops. Hasegawa would have you do each side with only two more pieces of thread each. And lo and behold, it works! But it's complicated and requires you to be very careful (again) not to tangle things up. This is especially important with the doubled wires (ask me how I know). Here's the port side with the first thread done:

Here's the anchor point where it started:

Again, I did not cut off a length of line but just fed it through this hole and then led it through the others as shown in the instructions. This actually worked, by the way. Once I was at the end (I believe it was the top of the aft interplane strut, but I could be wrong) I glued it there and let it set up. Then I made sure everything was taut (but not enough to pull anything out of line) and glued it back at the starting point, then cut the line there. Next on to thread number two, starting this time at the bottom of the forward cabane and going from there:

This also worked, and when it was done, the entire port side was rigged! Frankly I still can't believe this actually did the job. So, to be sure, I did the starboard side. Pretty crazy, basically four steps and it's all done:

OK, I promised you I would get done with this thing and I will, but not until the next post. See you then!

Michael