Thanks for the compliments!

And sorry for letting this project get stuck for so long. Has it really been over three weeks since my last update...

I guess I kind of lost a bit of my modeling mojo trying to hunt down proper reference pictures of the cockpit sides, and fiddling with both the resin and plastic parts, noticing stuff left and right that could use improving or fixing.

But well, on with the build then!

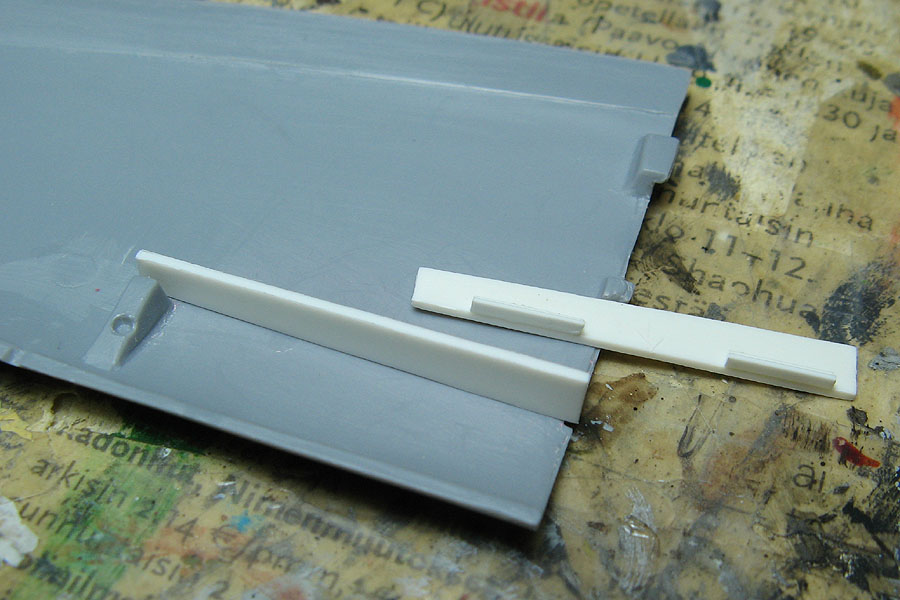

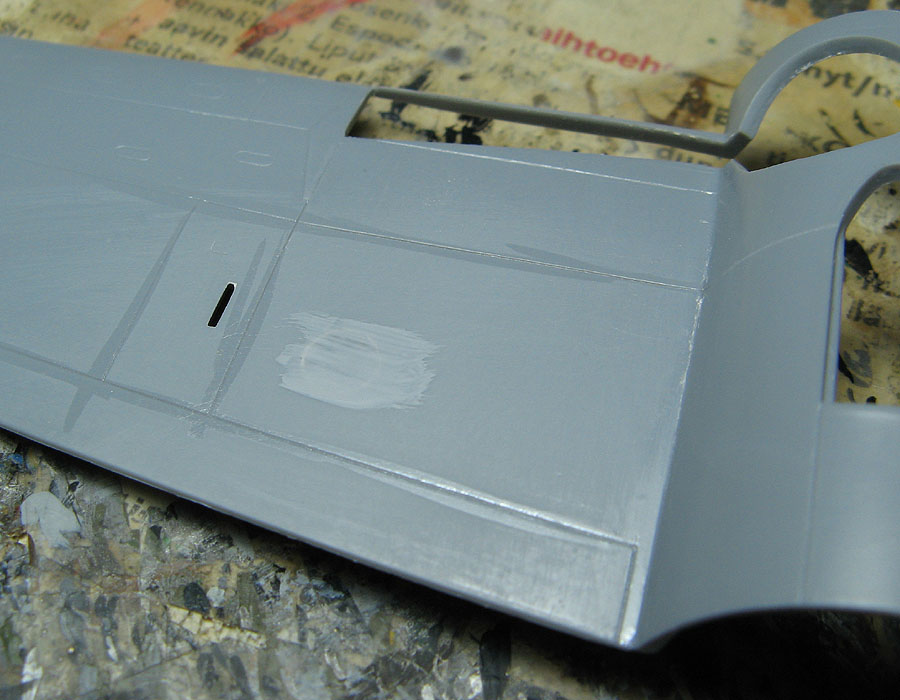

The smallest and simplest first: to make attaching the wing machine gun blast tubes nice 'n' easy during the final assembly, I made simple mounts from brass tube and L-shaped styrene channel.

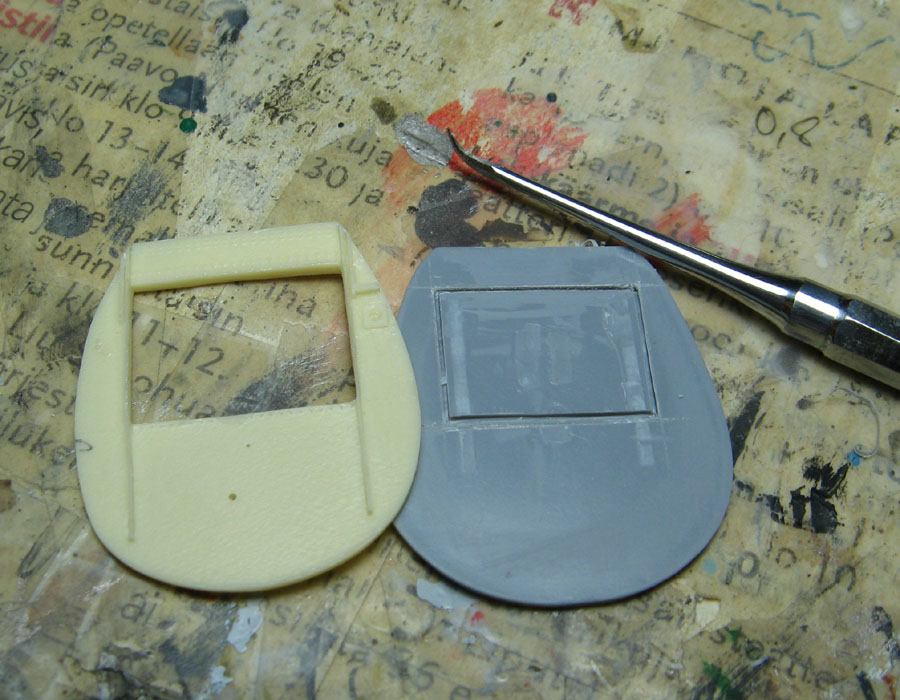

As I mentioned fiddling with the styrene and resin parts, here's one of the many areas needing attention, the seat.

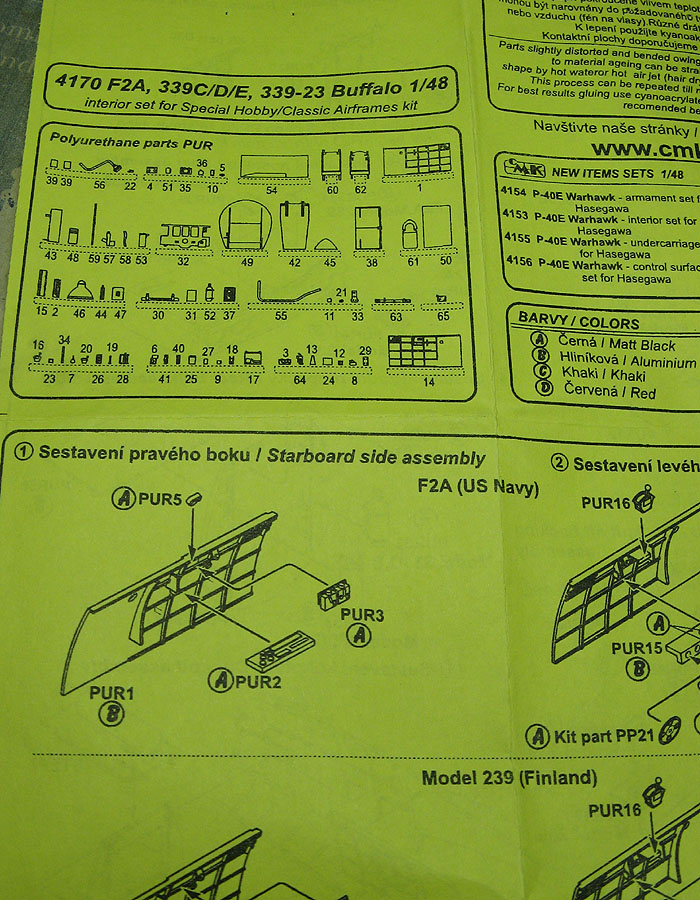

Kit seat on the left, CMK resin seat (mounts replaced with copper wire) and it's armor plate on the right. In addition to being thick like battleship plating, the CA kit part, while looking kinda, sorta like the real thing, is in the end just incorrect.

A) The extra armor wasn't integral with the seat.

B) The shape of the plate is off (should have rounded right angles instead of 45° angles near the top).

C) Head armor is separate from the back armor plate.

The seat in the CMK cockpit set is of the correct type, but the extra armor is a weird, undersized contraption, that like the CA seat, has the head armor moulded together with the back plate. Solution: use the seat - scratch-build the extra armor.

---------

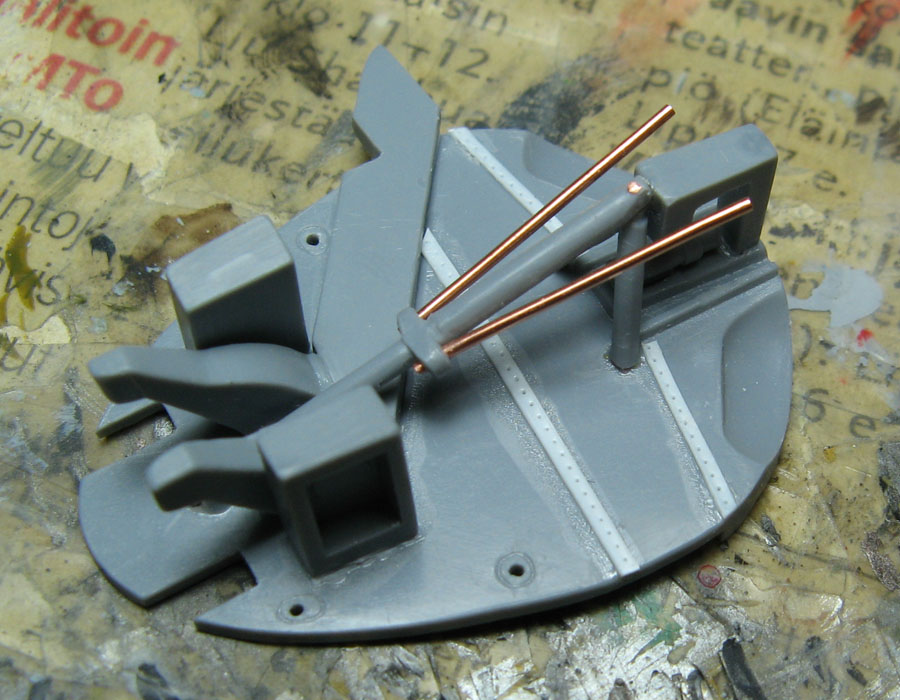

Moving on to the main part of this update: starting to figure out the engine / fuselage landing gear bay assembly, what's wrong with it, and what I plan to do about it.

One thing that has been puzzling me throughout (Well, if you can call it that... Let's say "so far") the build is the slightly raised part alignment aids moulded inside the fuselage halves. I haven't been able to quite figure out if the parts are supposed to be glued on top of them or next to them. Seems the answer is both, depending on the part.

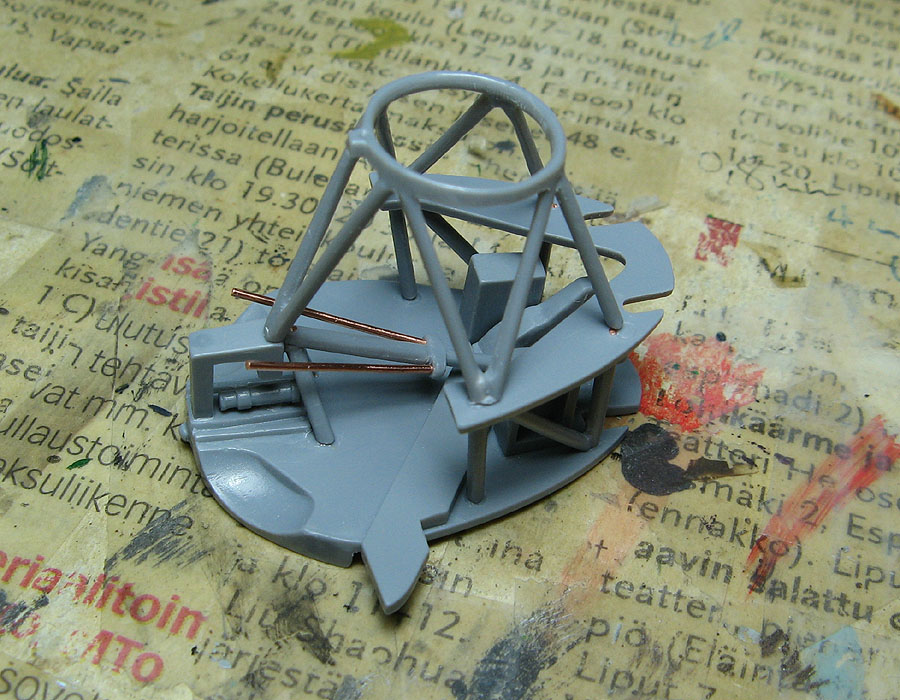

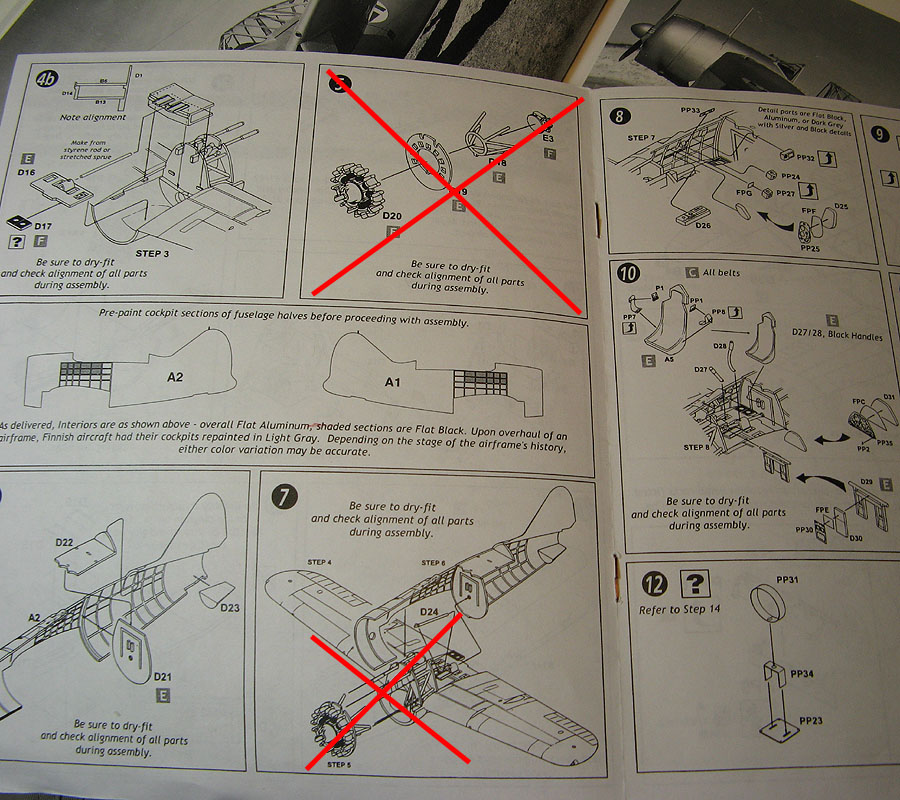

Since the kit instructions' suggested assembly sequence for the engine mount sub-assembly looked

very prone to alignment mistakes and ill-fitting parts (hmm, now what a surprise that would be...), I decided to start with the most crucial and make sure the engine would be positioned correctly and sturdily enough. So, that would be the bulkhead right behind the engine.

Looking at the raised alignment aids, the location of the one on the left fuselage half was very inconsistent, waving back and forth a whole millimeter from the front edge of the fuselage. The one on the right was OK, so I used that and glued styrene strip over it, then measured the distance from the front edge and glued a strip to the left side as well, before which I scraped off the useless wavy one.

Behind the cockpit I've made a start adding some internal structure detail.

Now with proper locators for the bulkhead, a bit of sanding for the cylinder heads and quite a lot for the bulkhead (it feels like it's meant for another kit...), the engine fits in and sits where it should be, the front almost to the level of the cowling's front edge.

^ That's dryfitted without the exhaust collector pipes in place, so I have to glue in the front bulkhead behind the styrene strip locators to move the engine back accordingly.

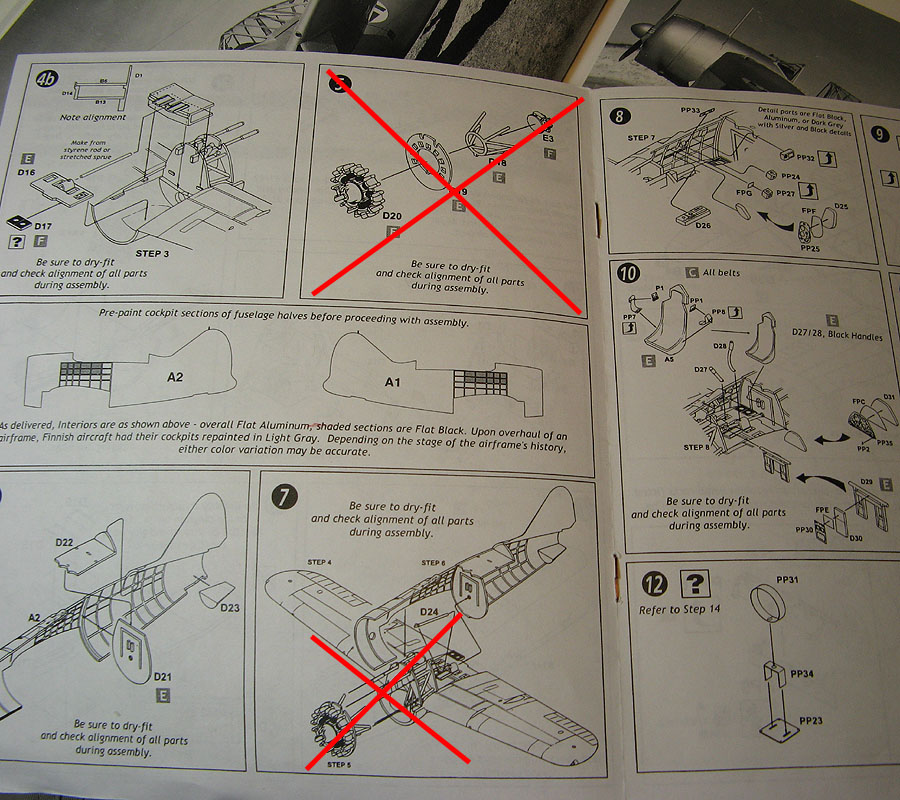

I also did some dryfitting with the engine mount assembly and figured out the reason why several build reviews of the kit reported the engine sitting too far back in the cowling. No wonder, the mount assembly is noticably too short!

(^ note the less-than-stellar match between the fuselage and the small bulkhead...)

^ Here, that circular front part of the engine mount should reach the foremost bulkhead.

I was quite puzzled by this discrepancy and couldn't think of any other explanation (apart from some very sloppy workmanship and/or lack of communication between the people working on the kit) than that the engine mounts were originally made for the shorter-nosed F2A-2/3 variants!

I hadn't thought about until now, but it all makes sense. The poor-fitting front fuselage bulkheads, engine sitting too far back on B-239/F2A-1 when instructions were followed. Indeed, the same sprue D is used in

all CA and Special Hobby Brewster kits!

Well done, well done indeed...

This was pretty much exactly my reaction. Was it really SO hard and/or expensive to make correct engine mount parts and bulkheads for each variant and put them on the fuselage sprues which are different depending on the kit?

Heck, even the instructions show a late-variant fuselage (note the location of the holes for the exhaust pipes). Guess they had in mind to release later variants first, but the plans changed and the decision was made to just go with it instead of making expensive and time-consuming changes.

So,

don't follow the instructions on mounting the engine for this or the F2A-1 kit, or you'll end up with a seriously misplaced engine.

I'll have to see if I want to be bothered to extend the engine mounts to reach the foremost bulkhead. The fuselage compartment is rather cramped and not that easily visible when finished, after all.