Many thanks.

Now.....

Bonus material time....

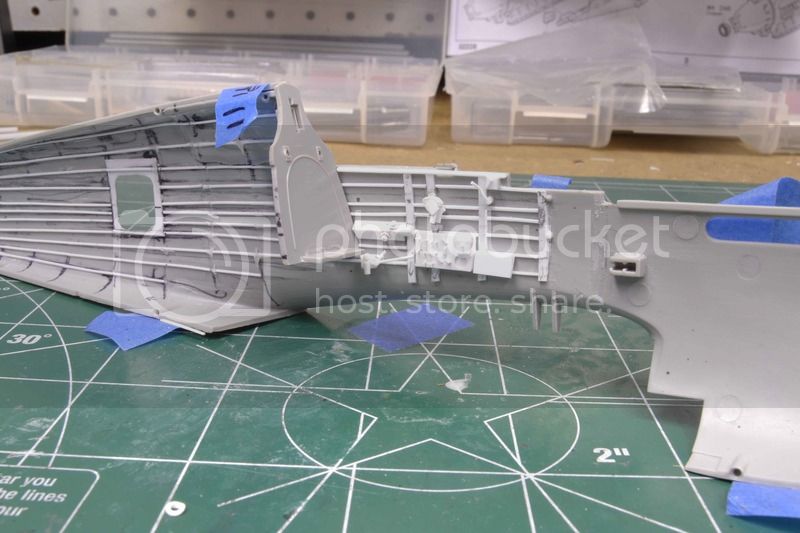

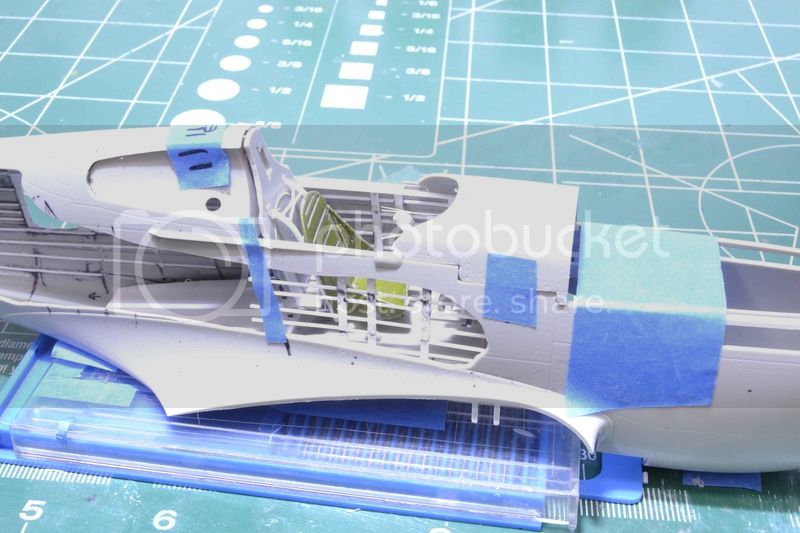

As I started out today I thought why not show what I was doing. Just a small assembly but it is worth the time.

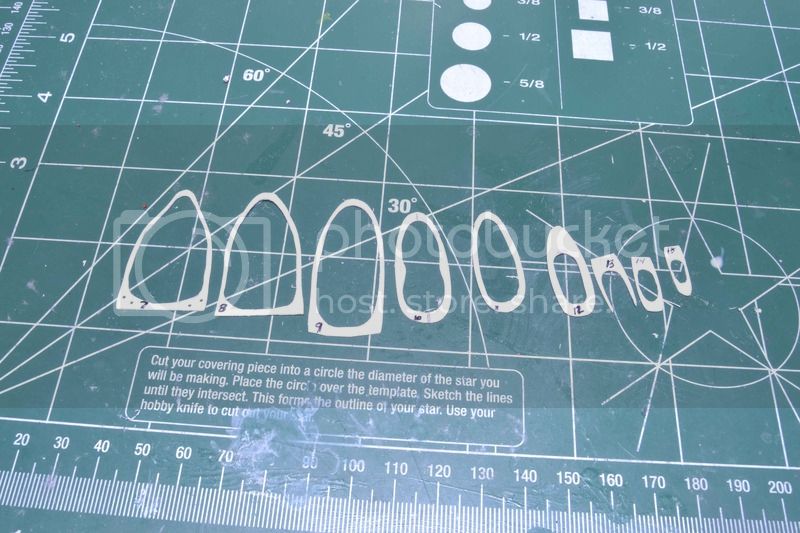

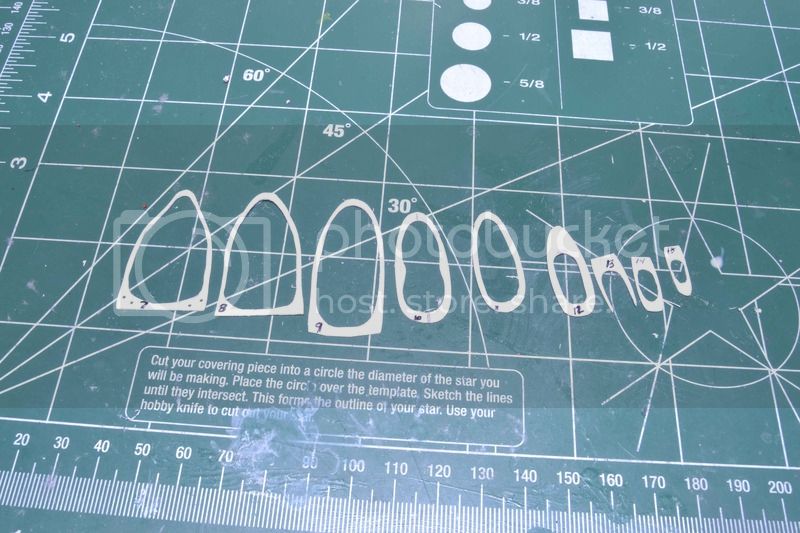

Today I began by cleaning up the bulkheads. Remember those....

Well I began with punching out a hole, the largest my punch set has, and then using the dremel I worked the bulkheads out to where they looked more like they do in my drawings. I then went in with 320 sandpaper and cleaned them up.

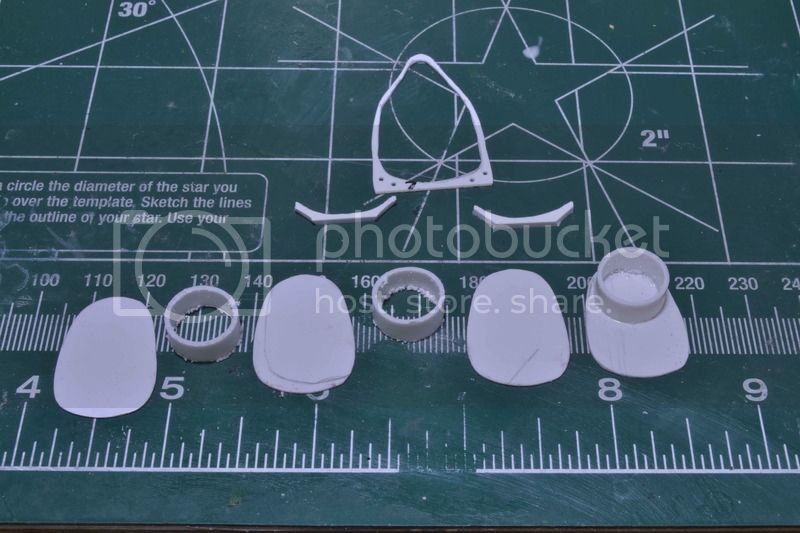

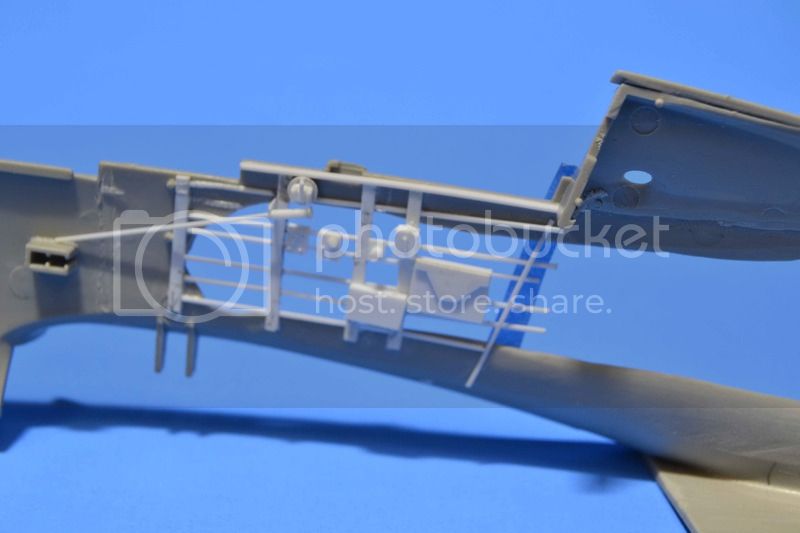

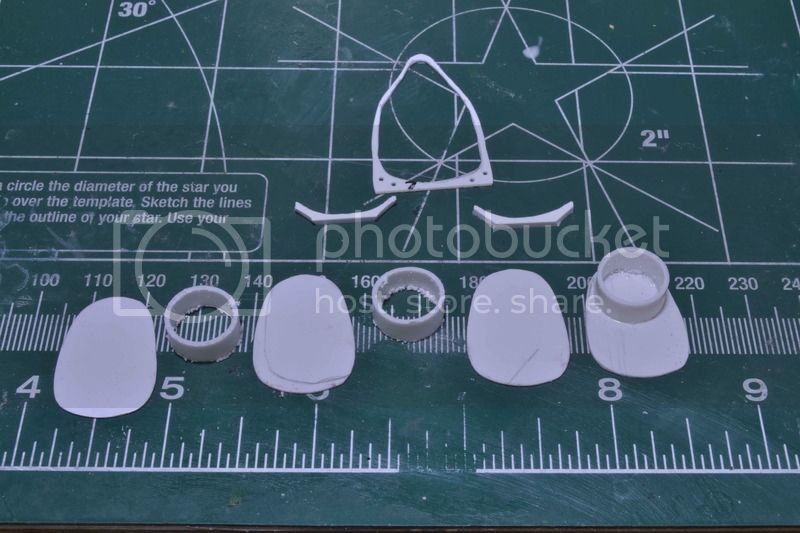

Once that was done I was able to start on the fuel cell. Using bulkhead #7 as a reference I sketched out the form, that was cut out, cleaned up, and then used as a master to form 3 pieces of sheet styrene. I then cut two pieces of tube styrene, size isnt important as long as it fits. I glued the tube to the sheet and then put them all together.

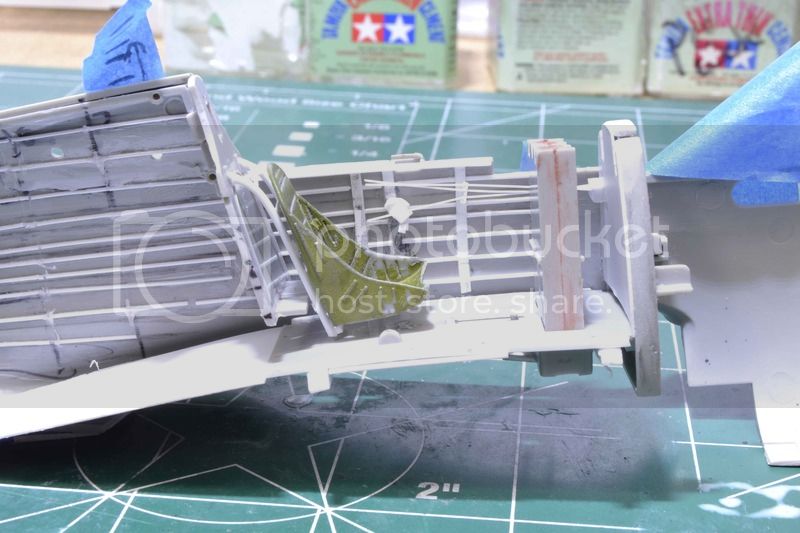

I then used .010 sheet styrene and skinned the framework. Also using the same bulkhead I fashioned a stand to keep the fuel cell in place.

Just that simple.

Ok next will be to continue to work the interior, most likely starting with the tail and moving forward. I do need to add detail to most of the bulkheads as well as the fuel cell.

I hope you enjoyed the bonus.

All comments, critiques, and criticism are encouraged.

Joe