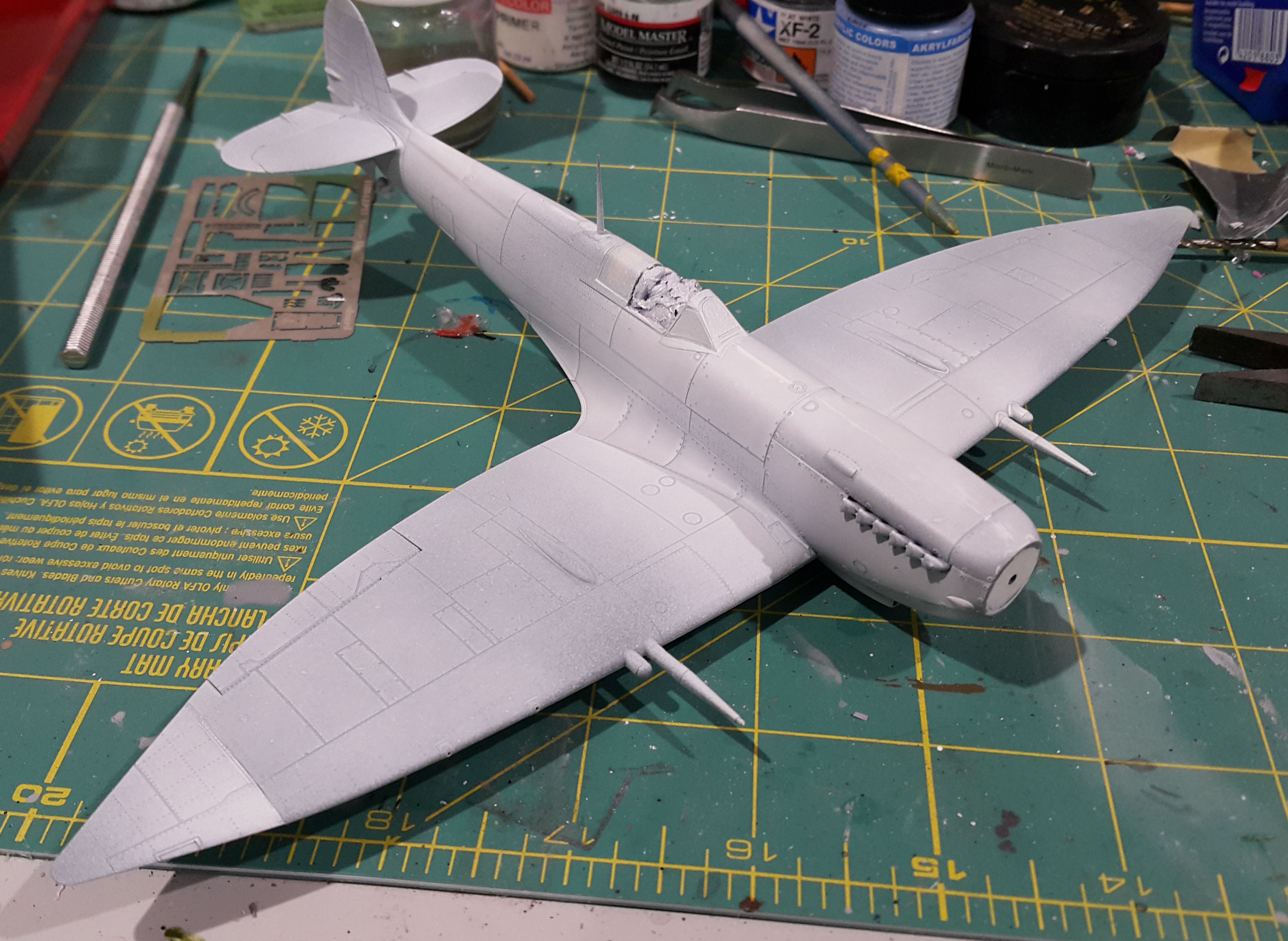

This will be my (probably very), slow build log of these two aircraft.

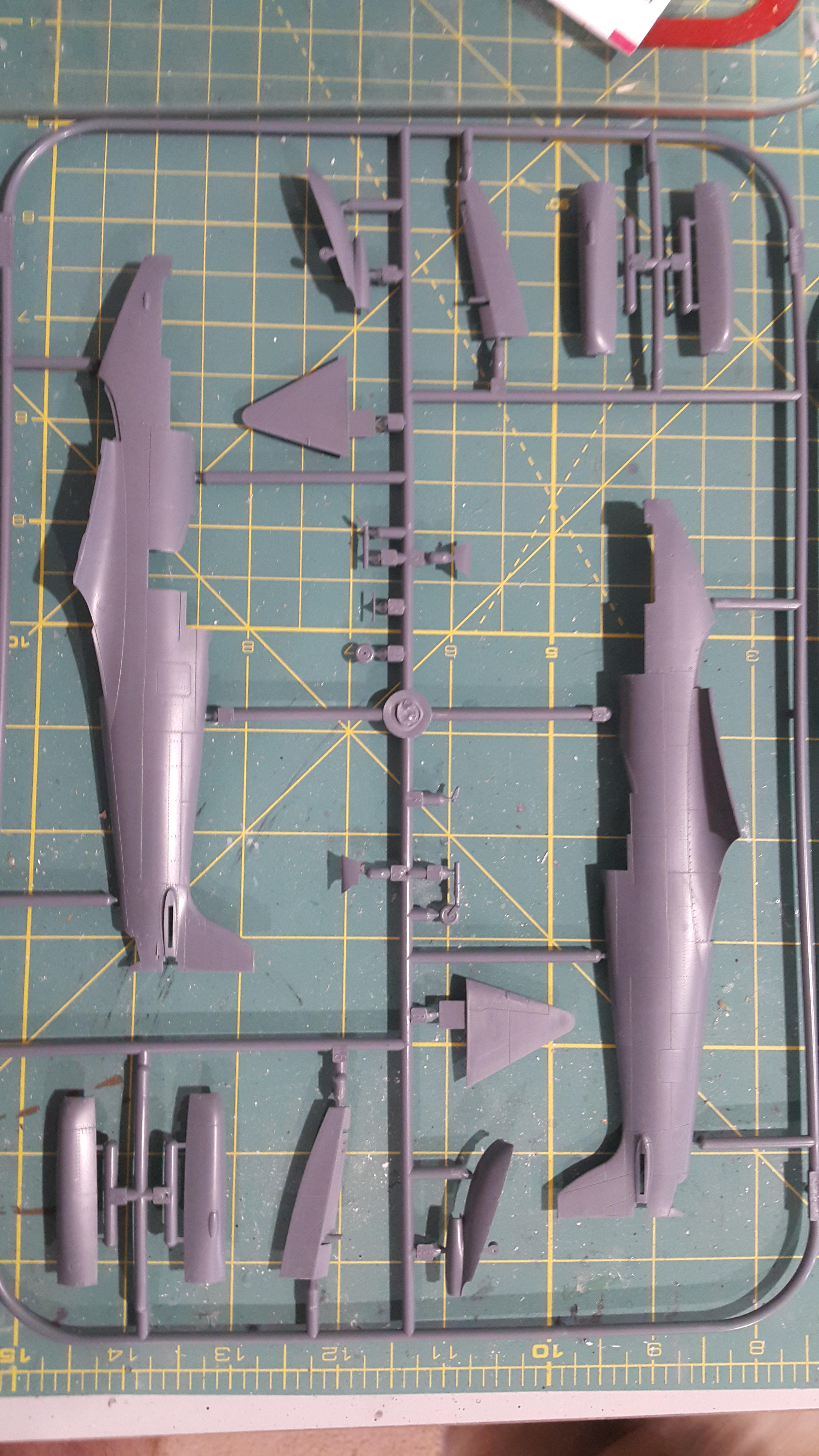

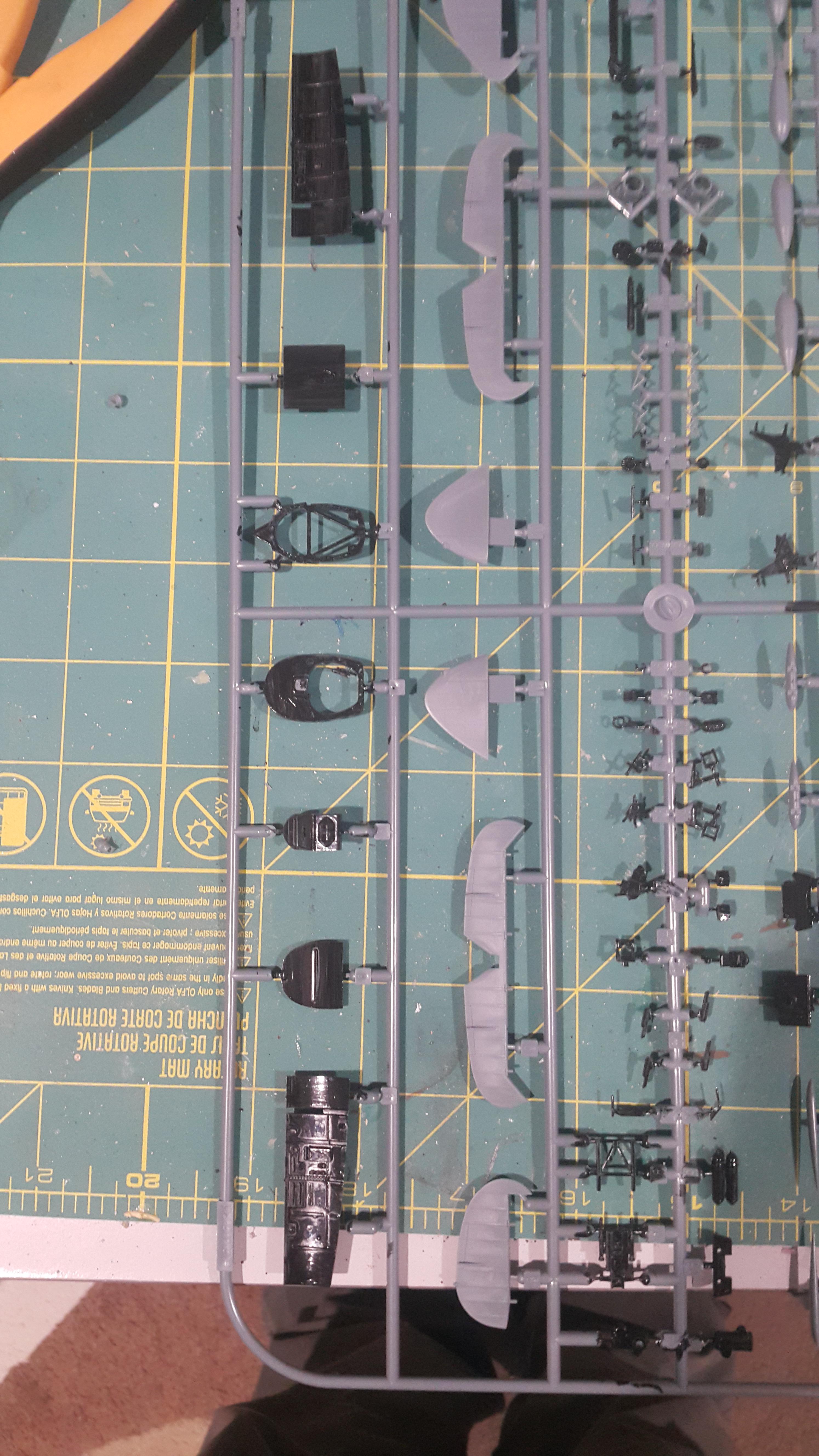

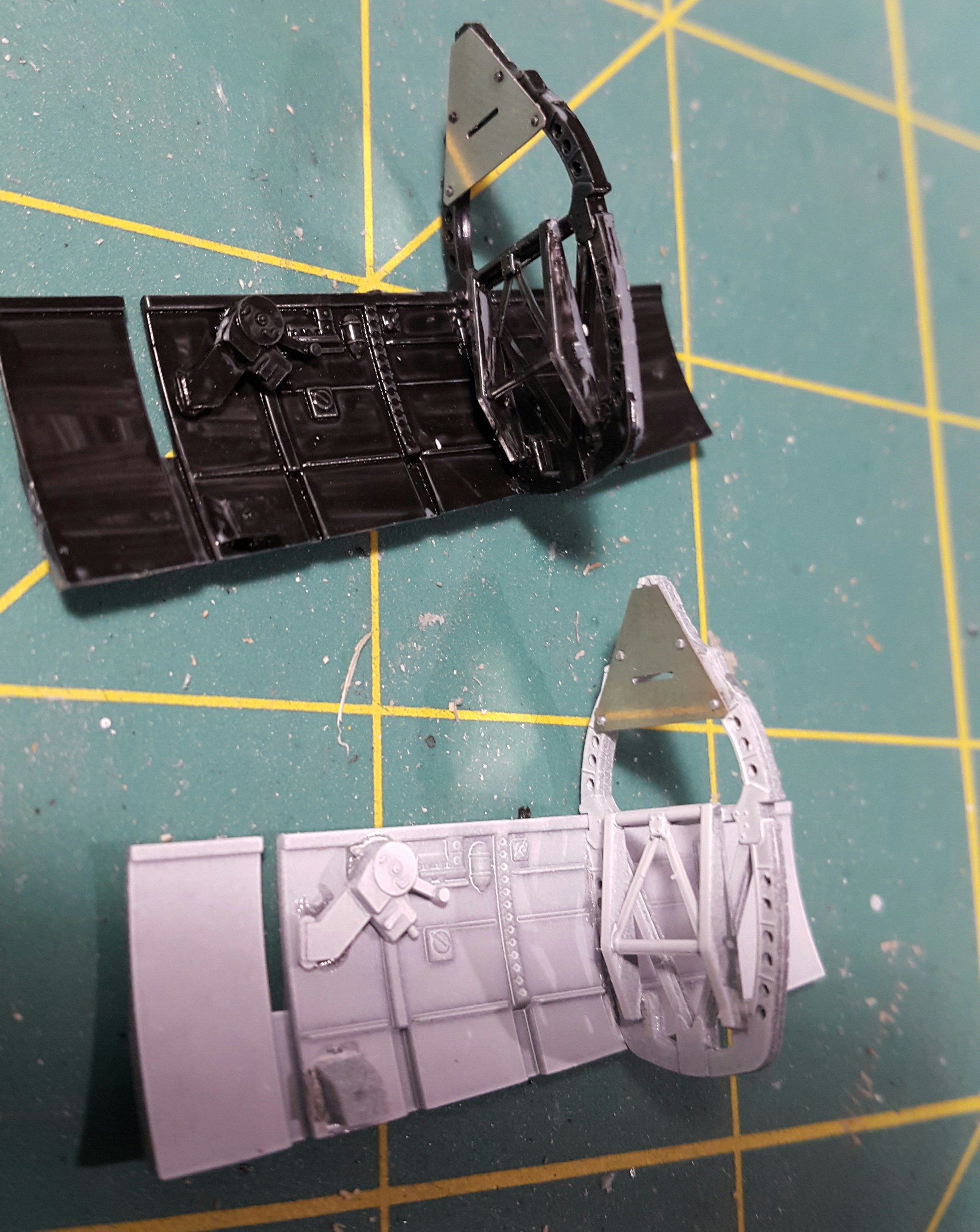

Opened up on the bench.

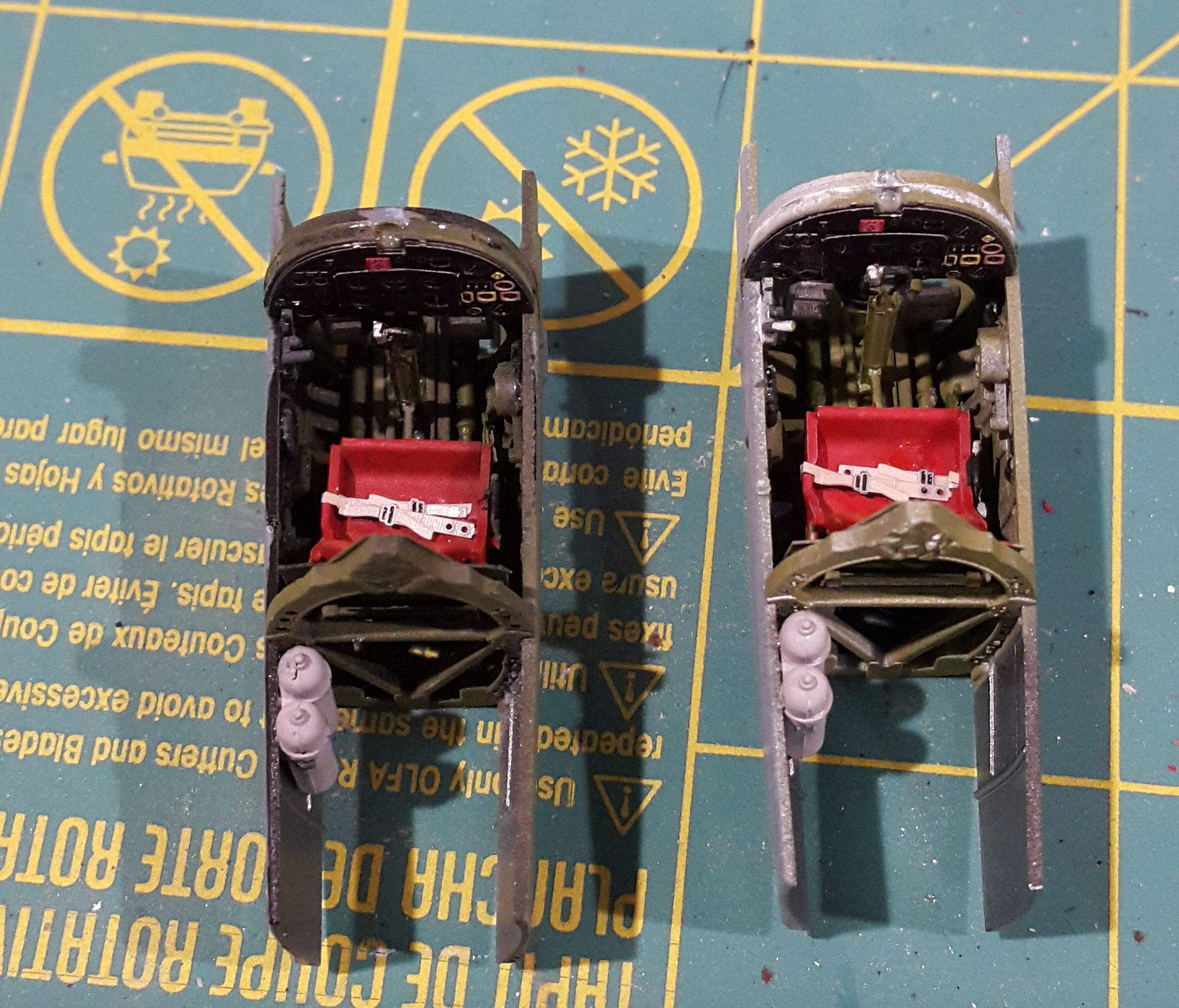

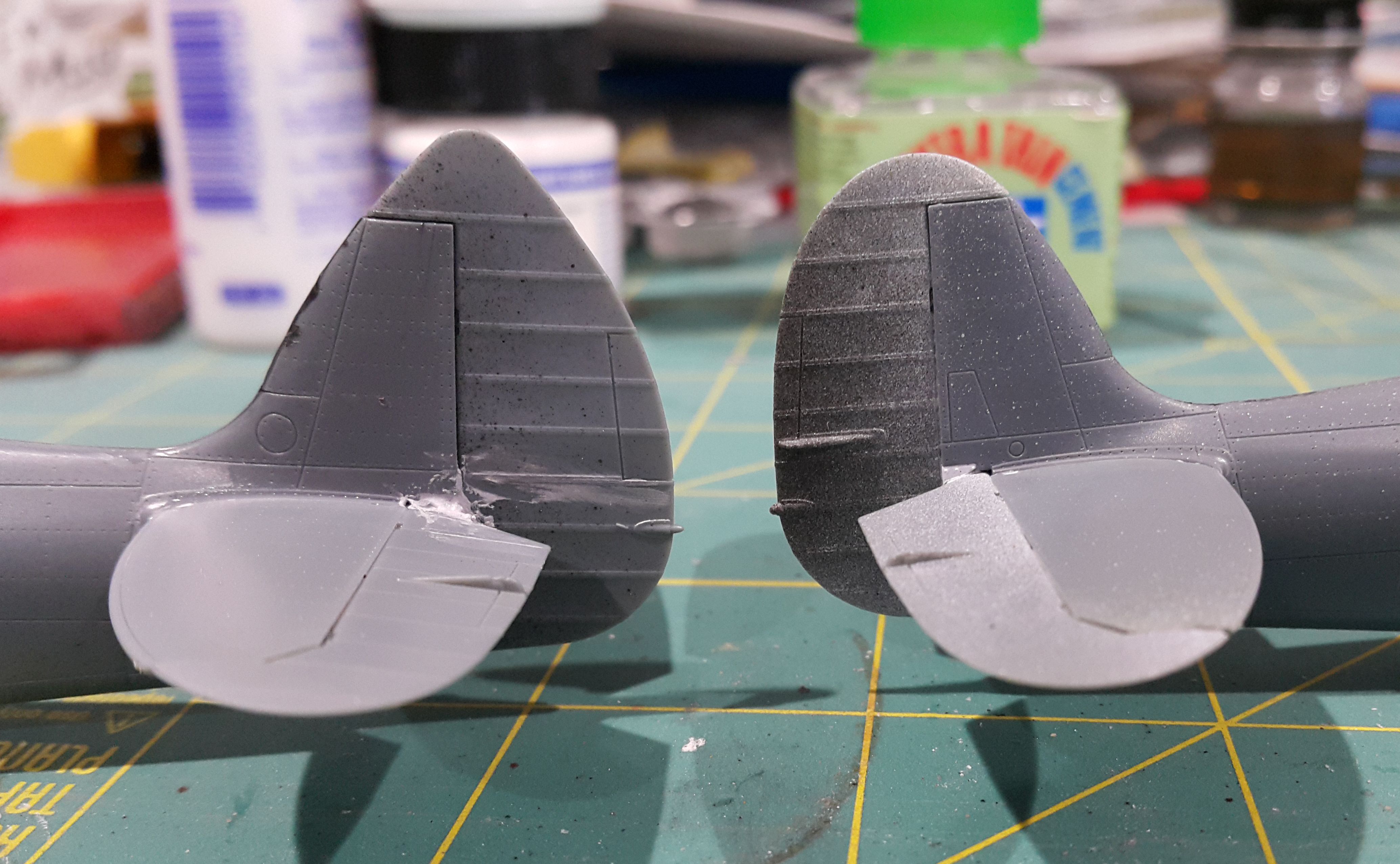

The plan to stay organised is to build the CBI Spit on the right, and the ETO on the left. Plastic tubs will keep any sub-assemblies seperate, though I don't expect there will be a huge amount of those.

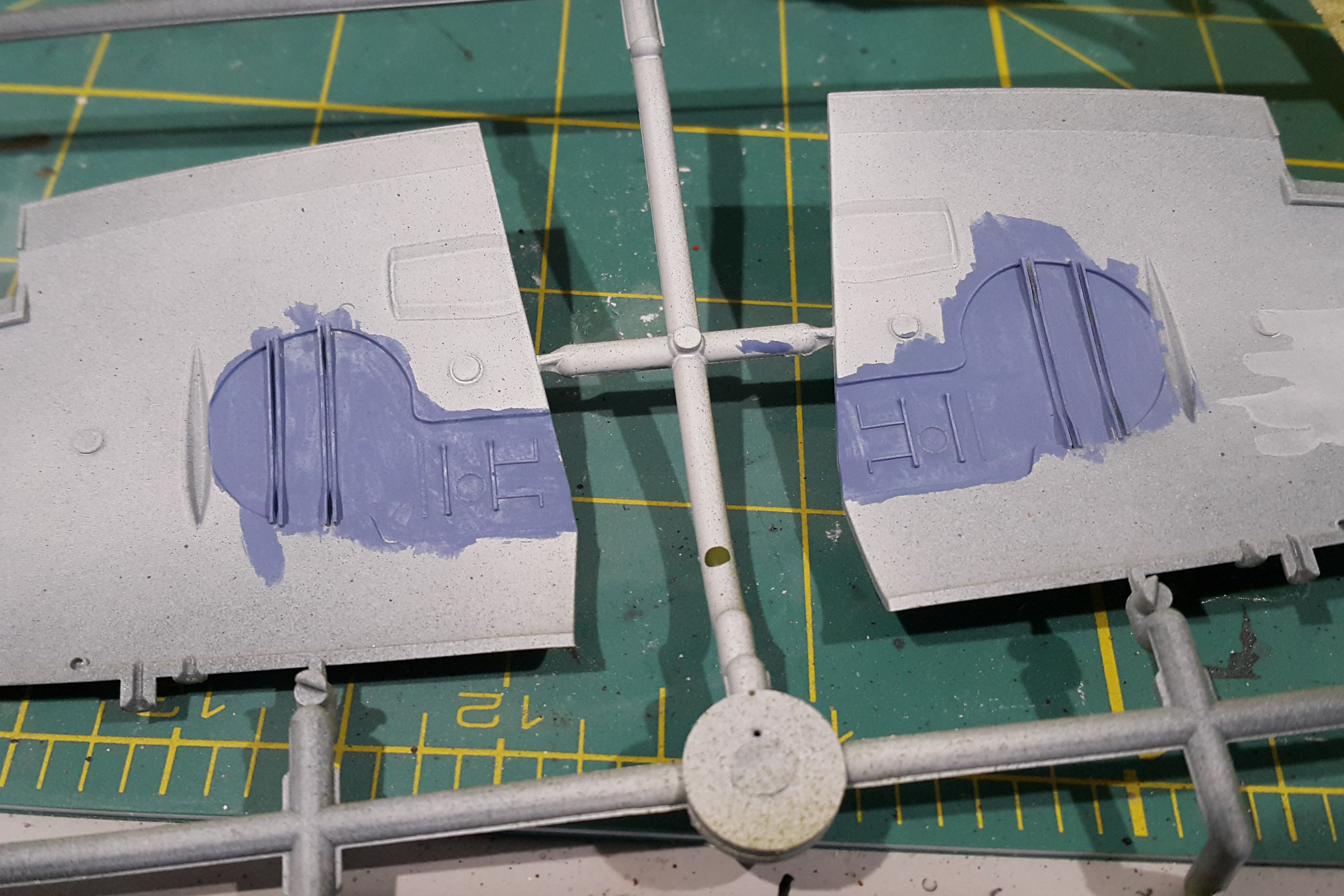

Since it's a dual combo, surprise surprise, you get two of everything:

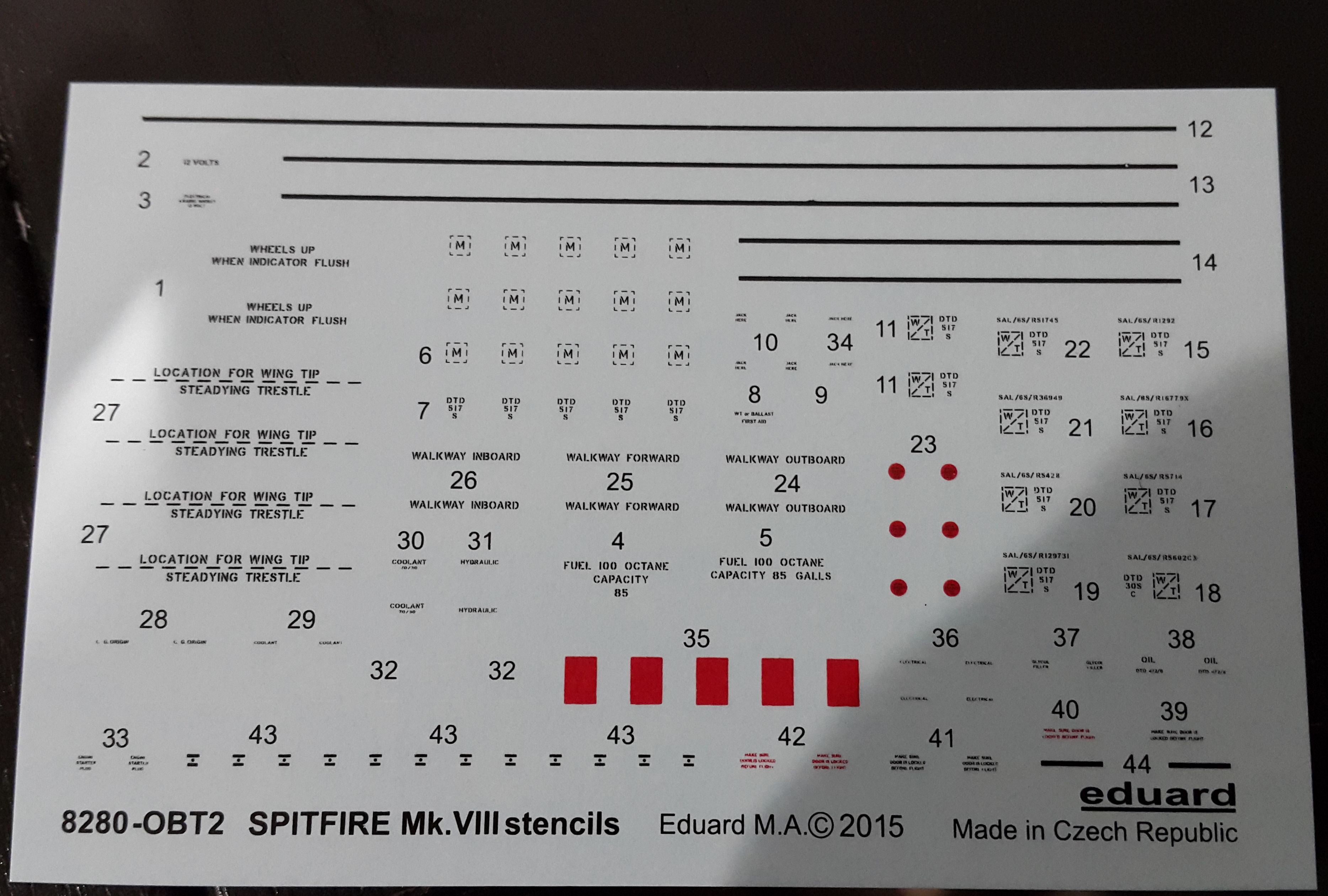

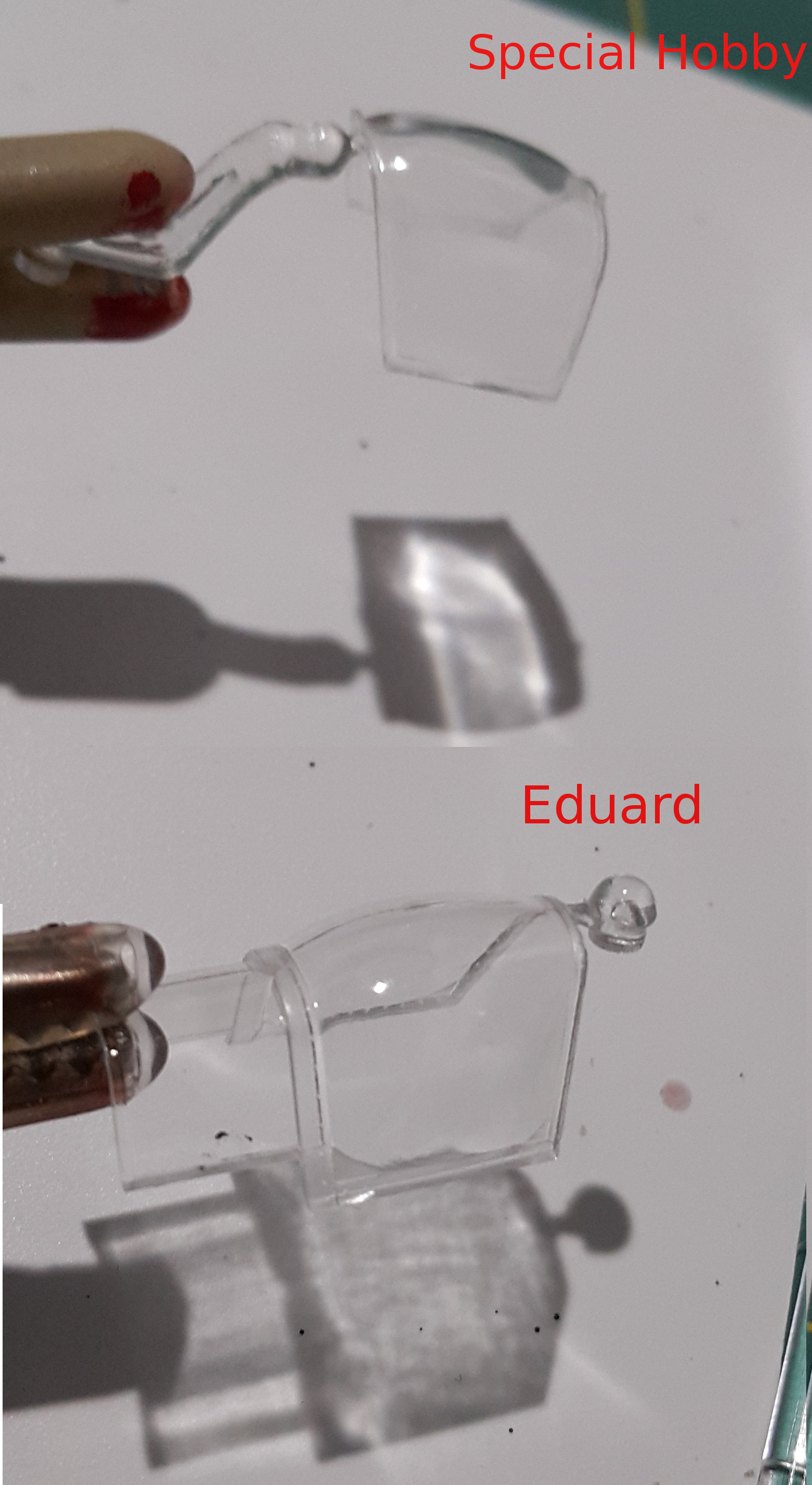

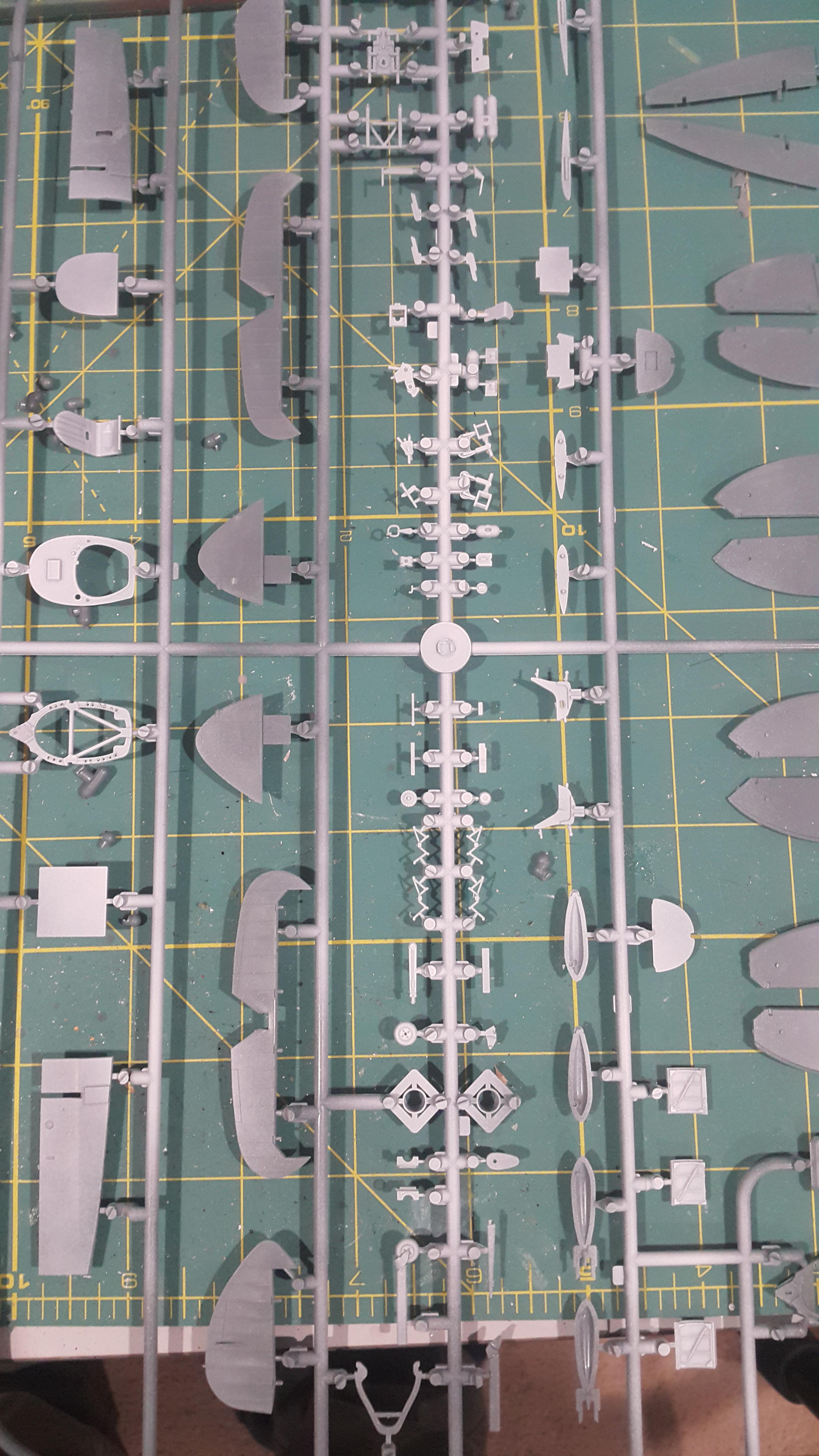

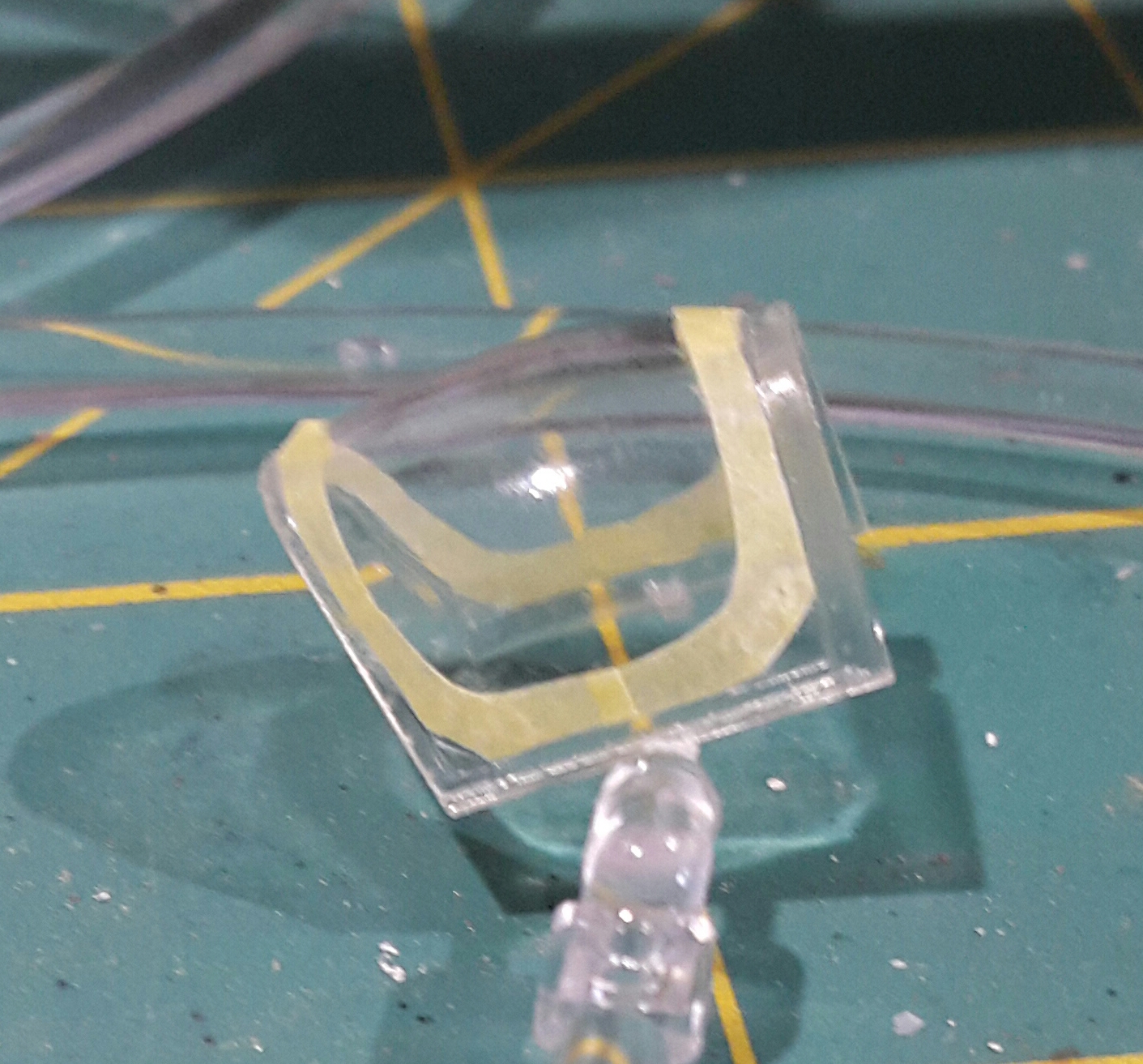

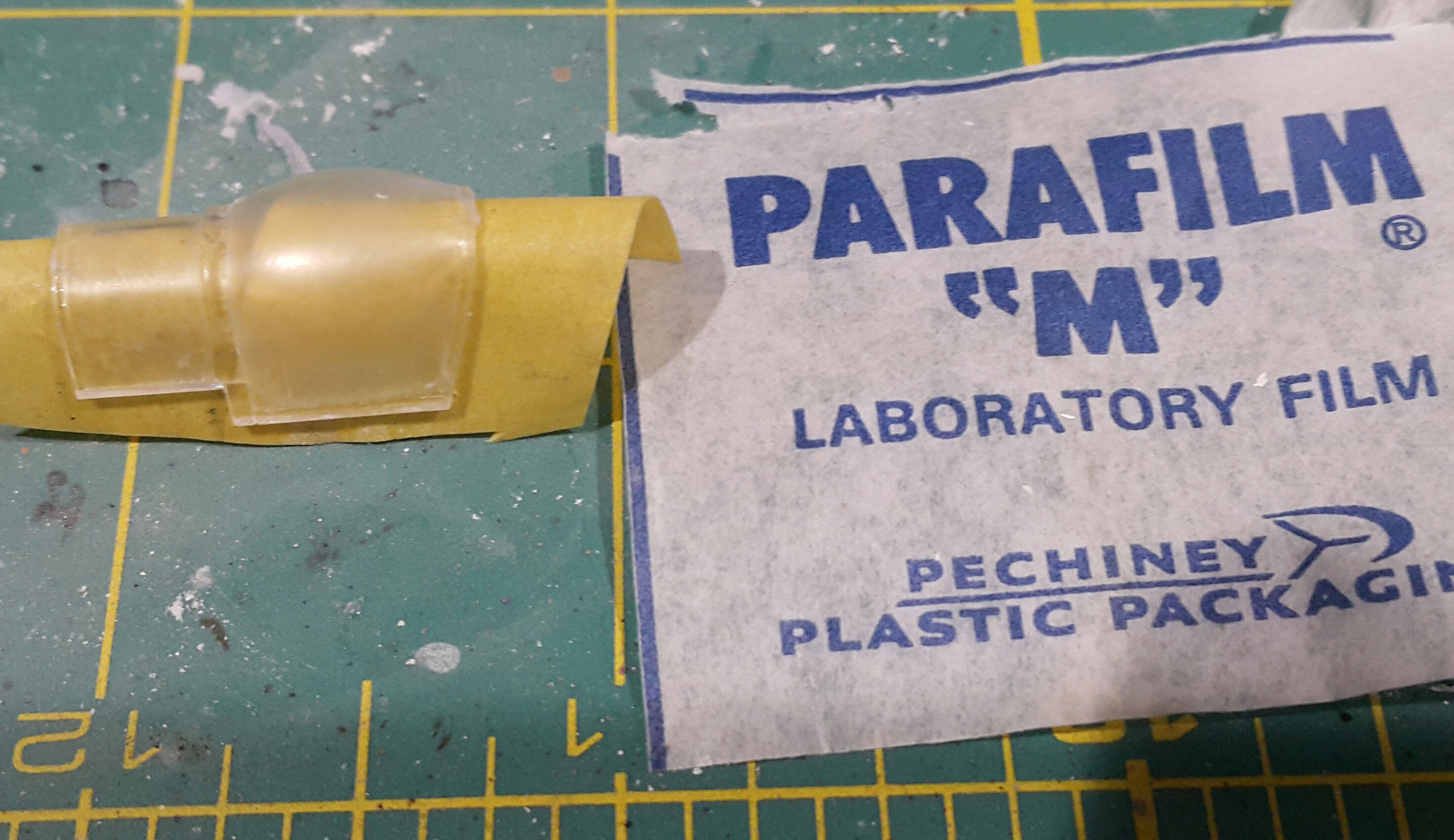

Transparencies:

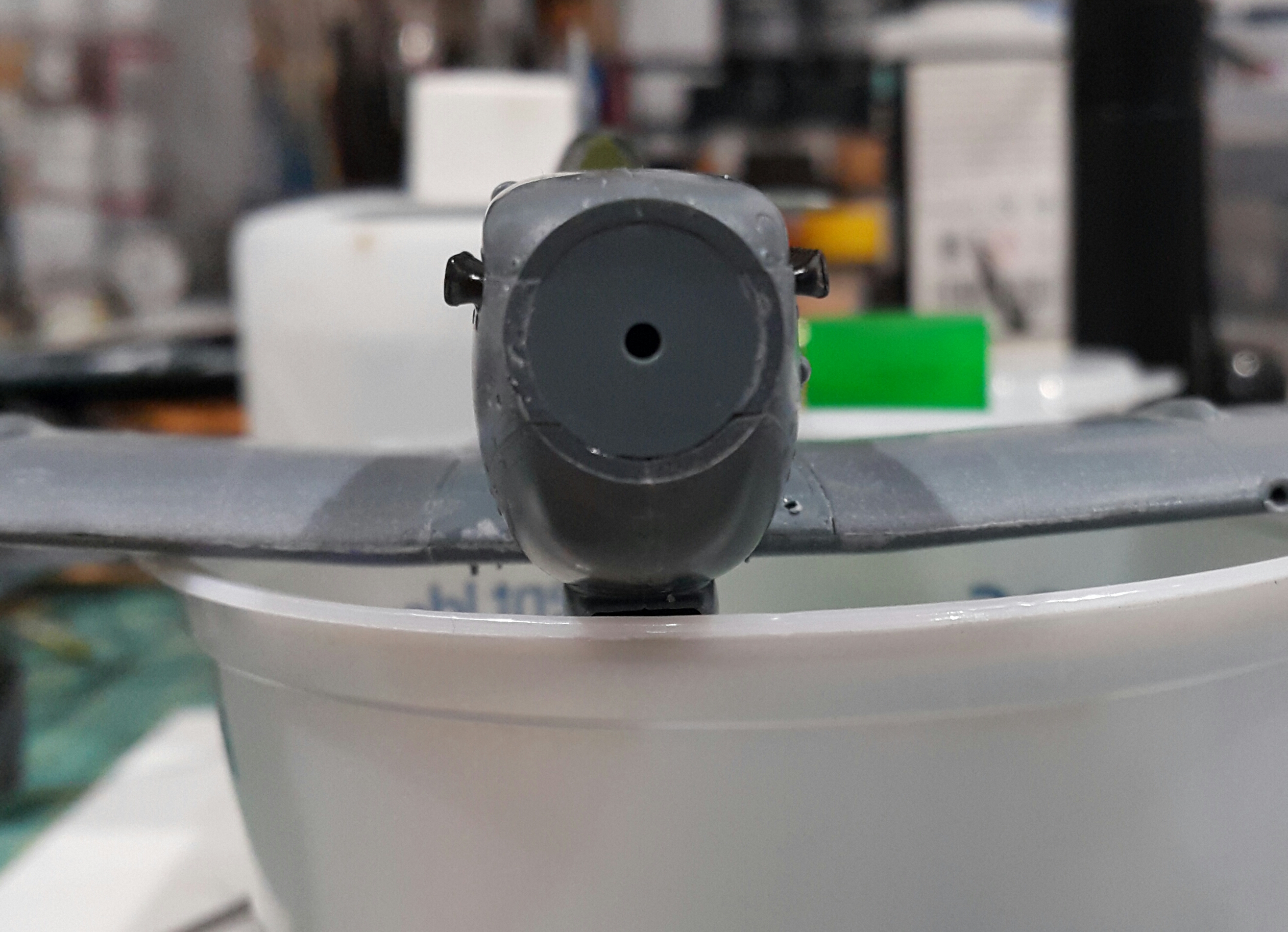

Fuselages

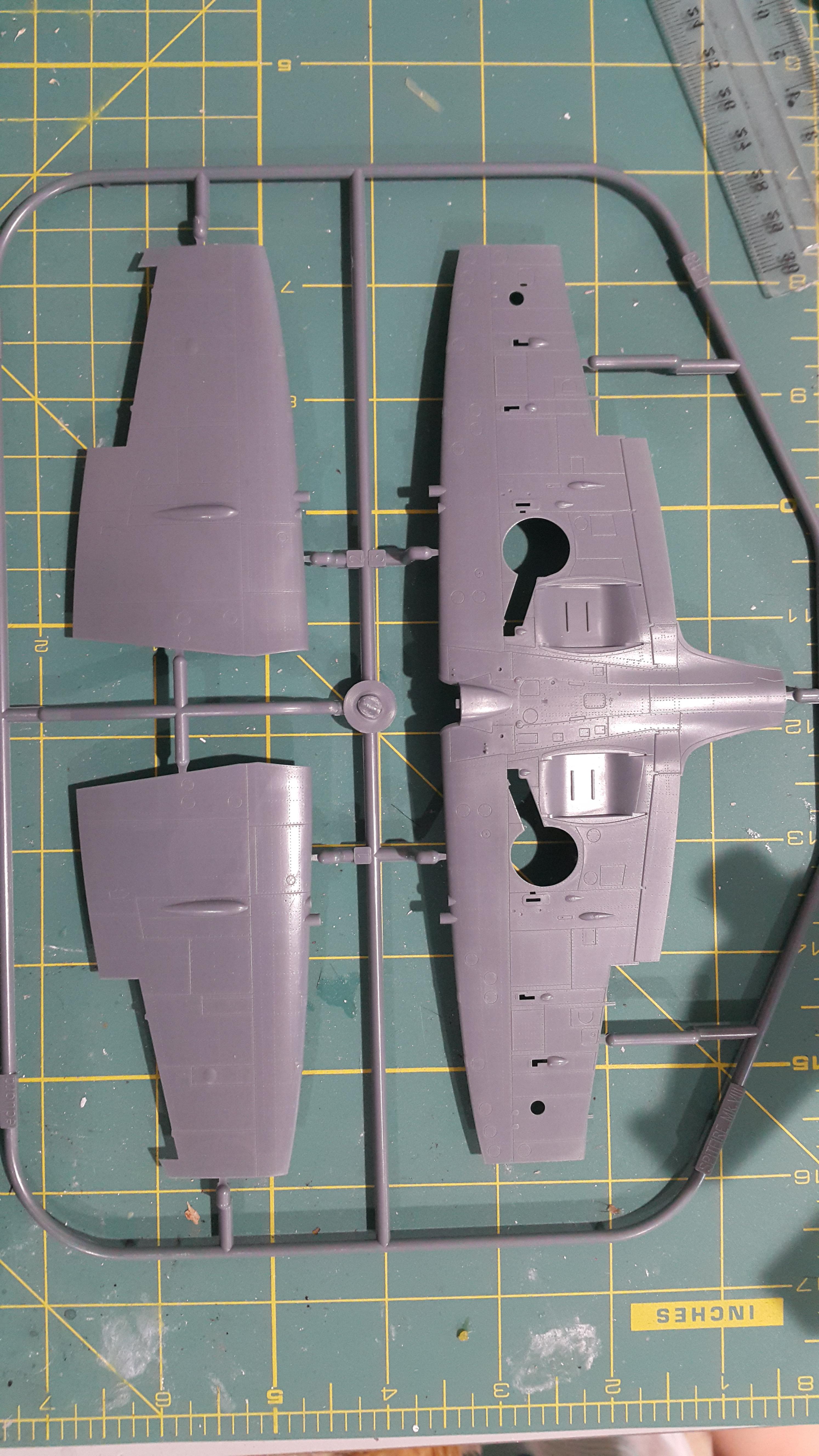

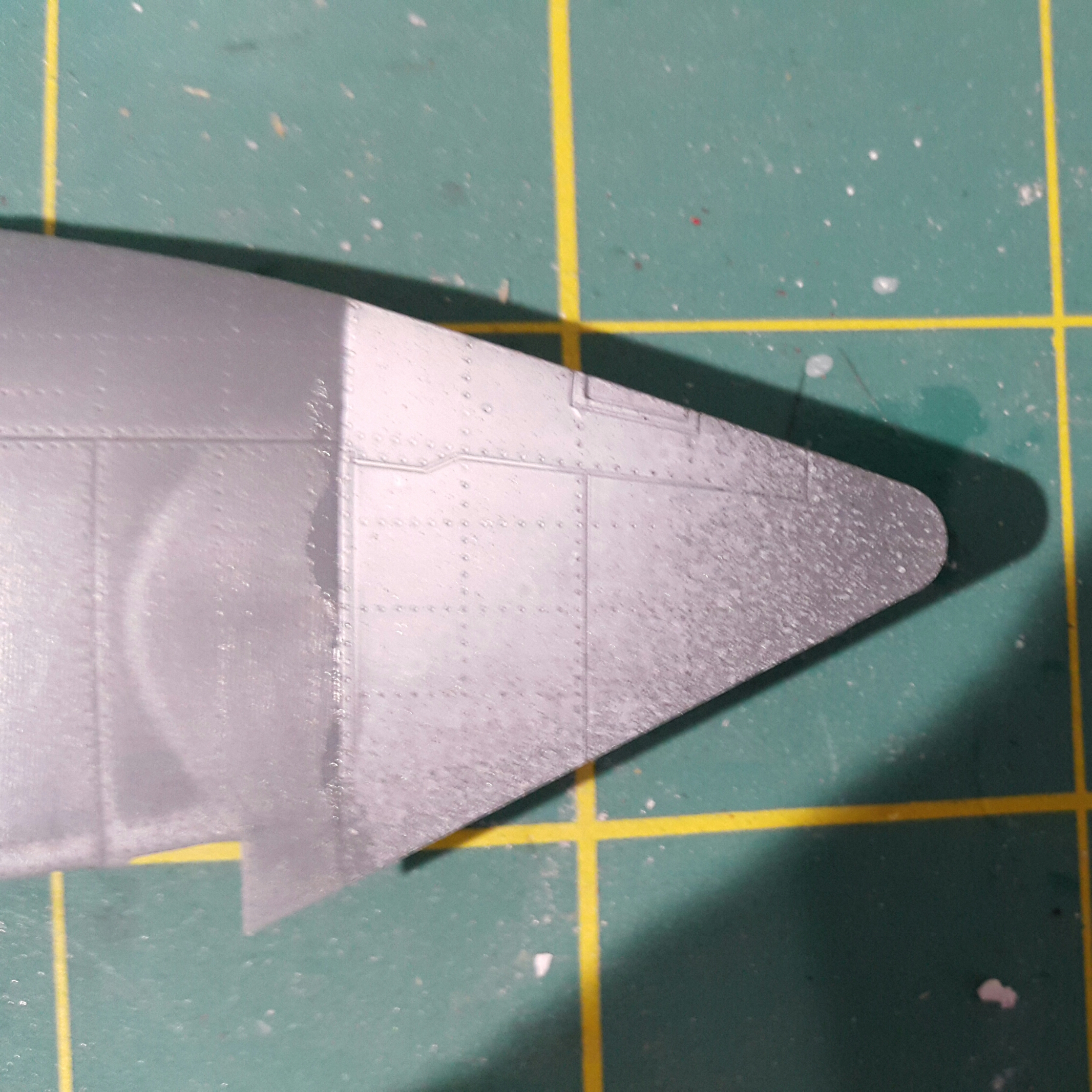

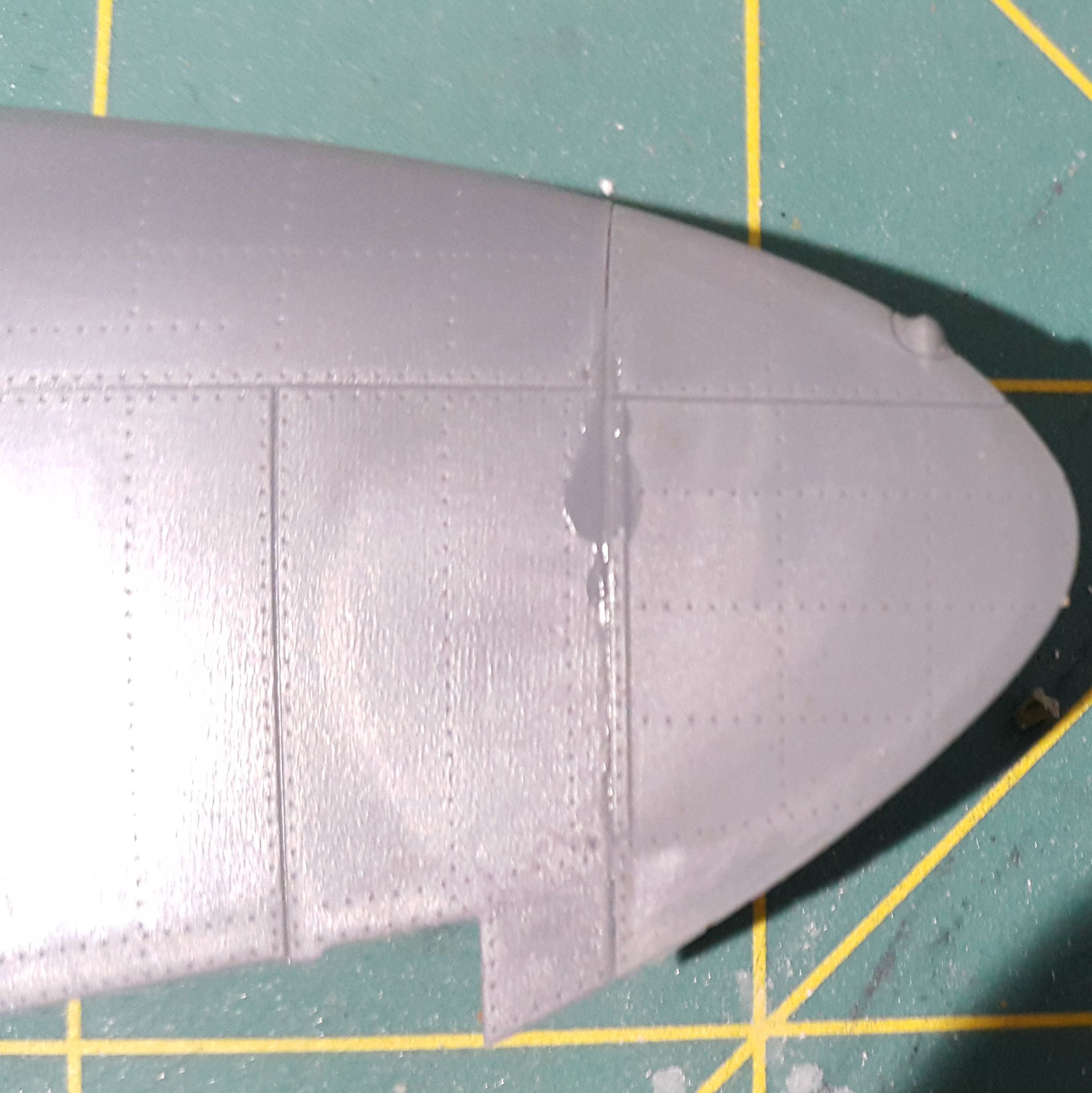

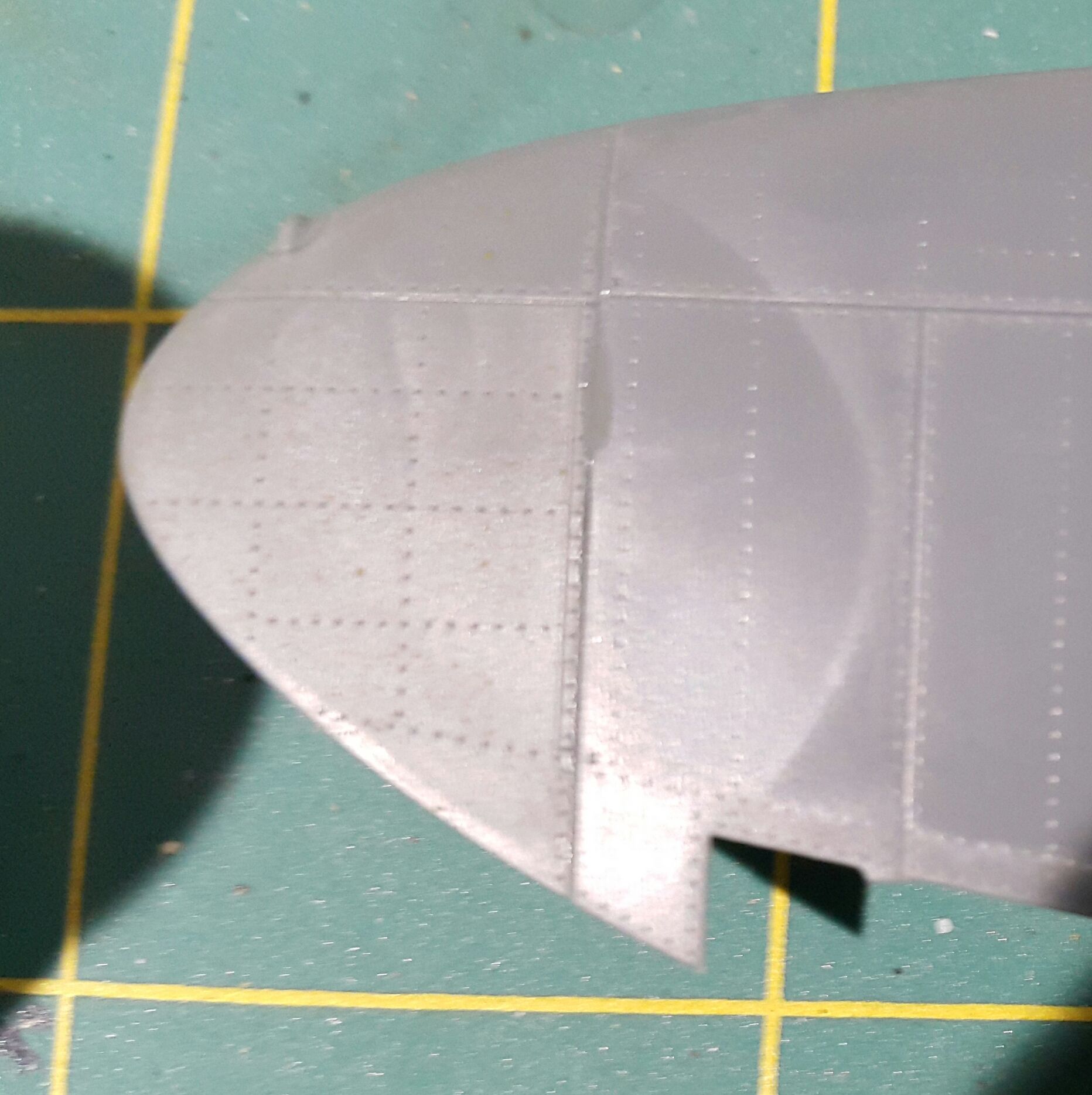

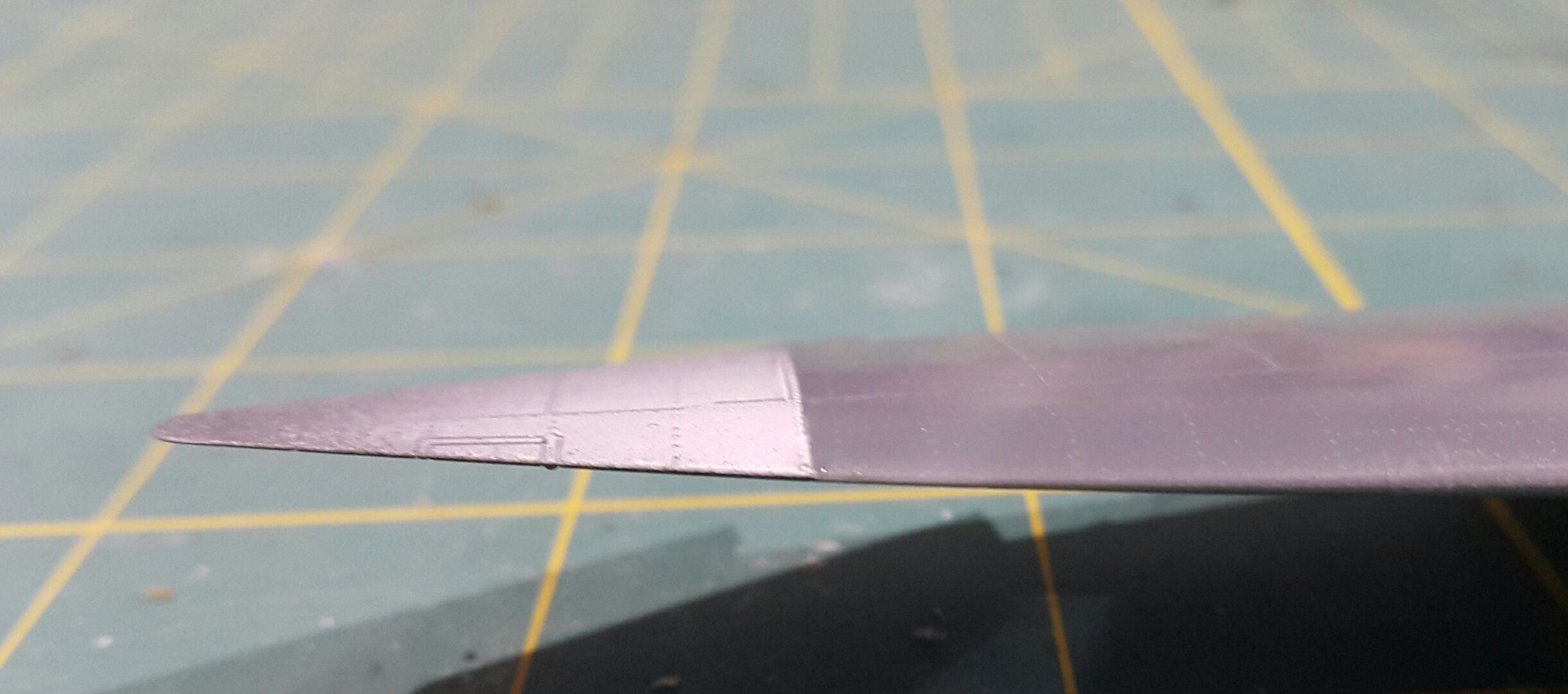

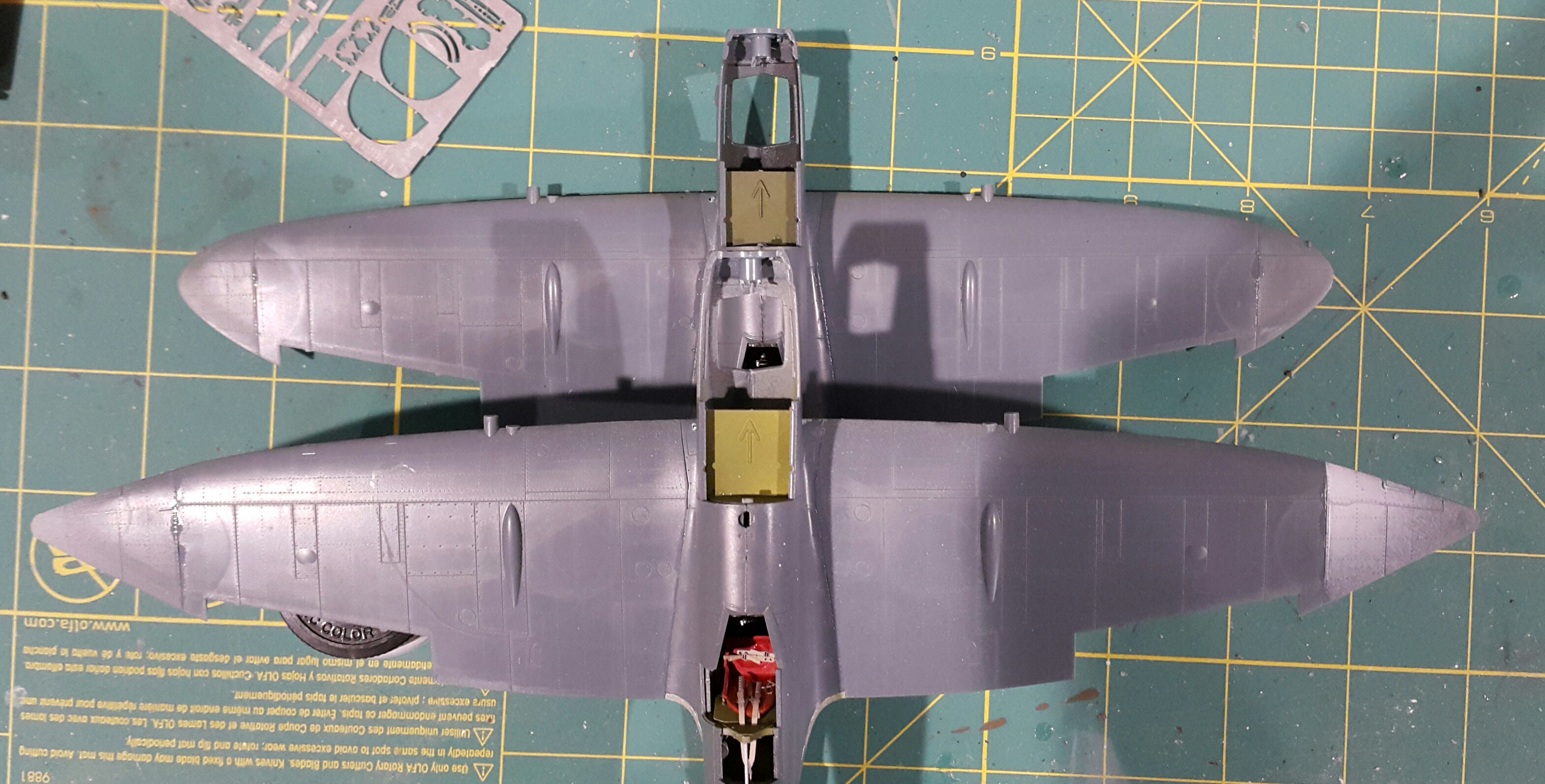

Wingy bits

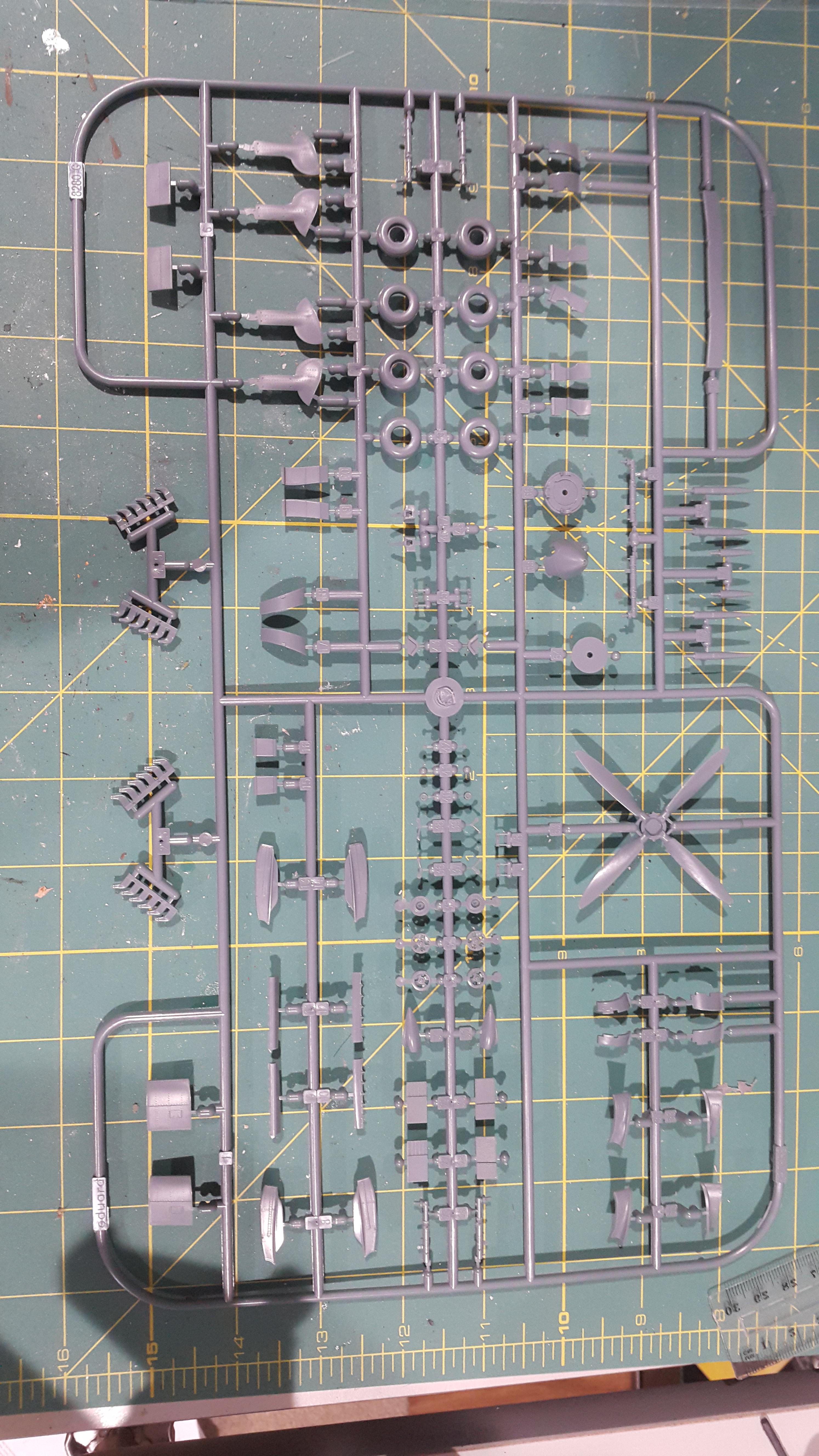

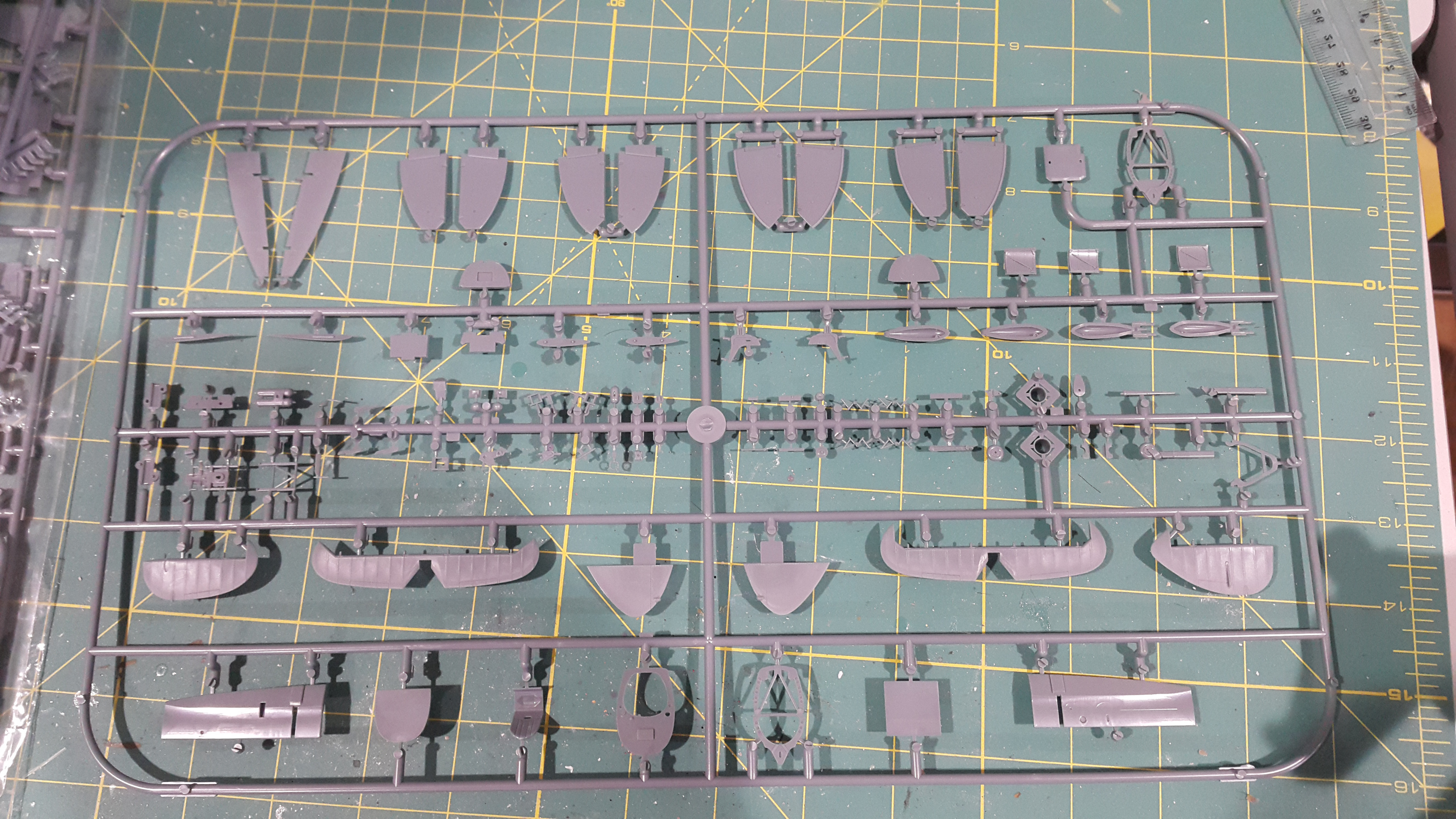

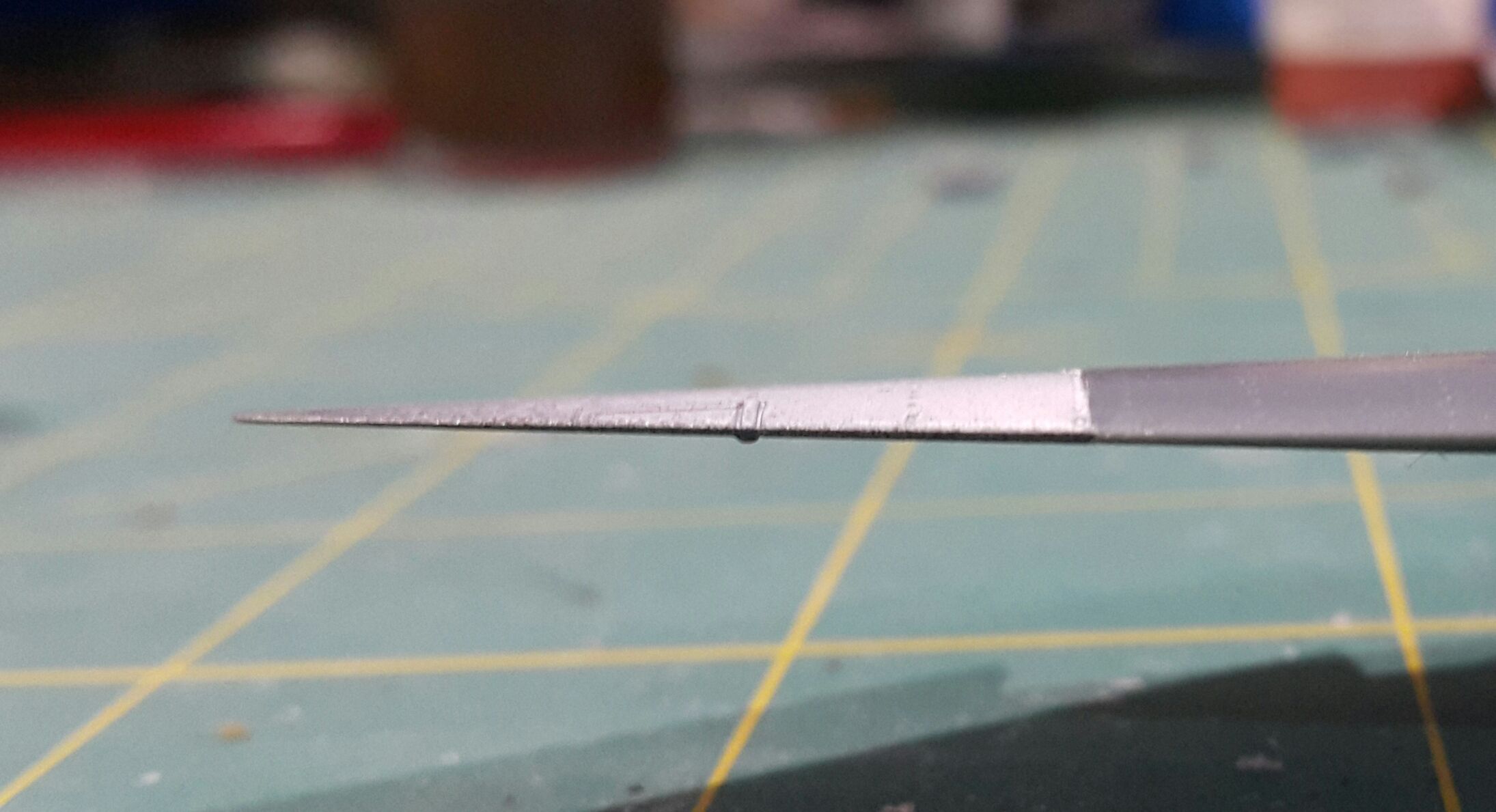

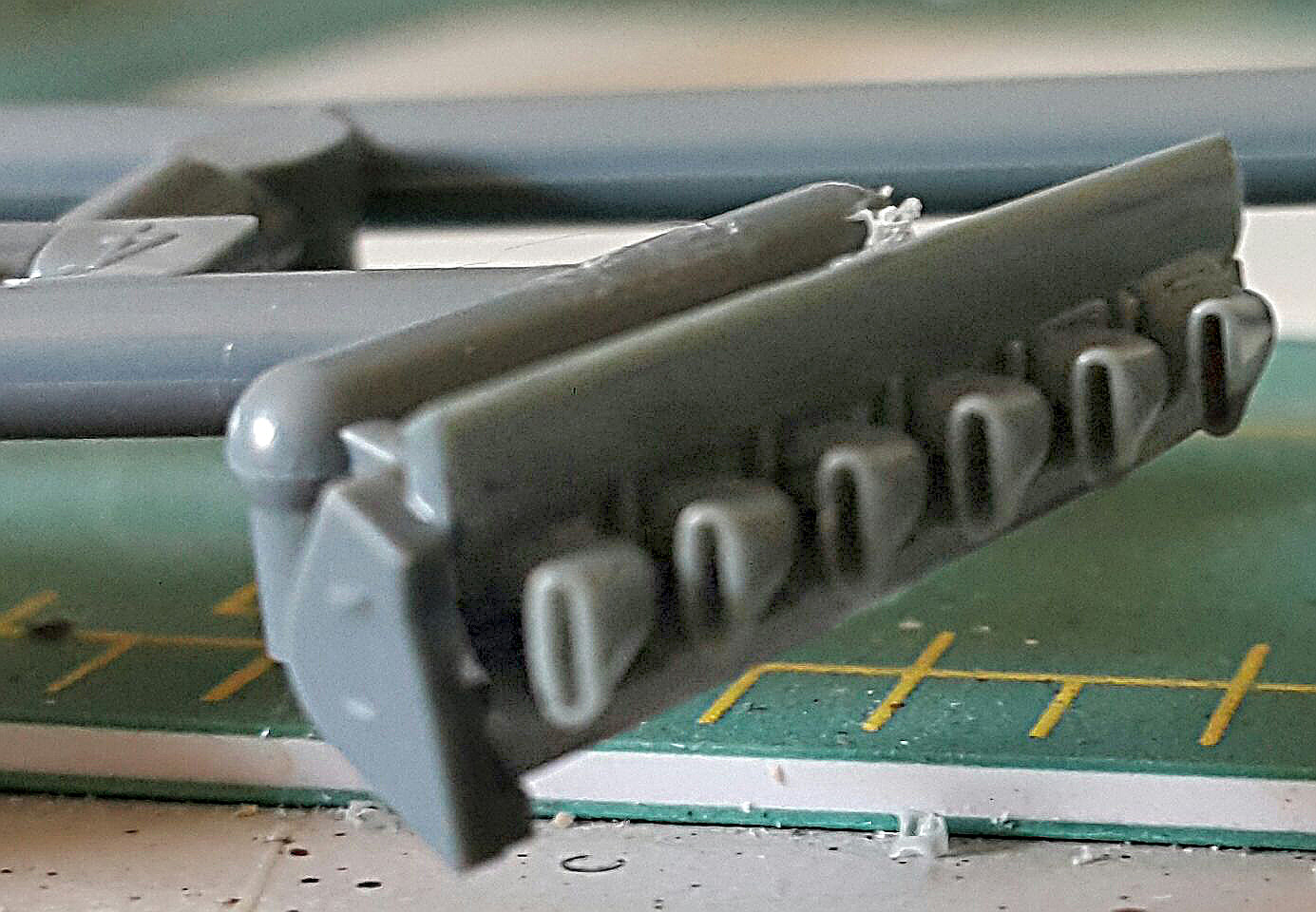

Stickery outery bits

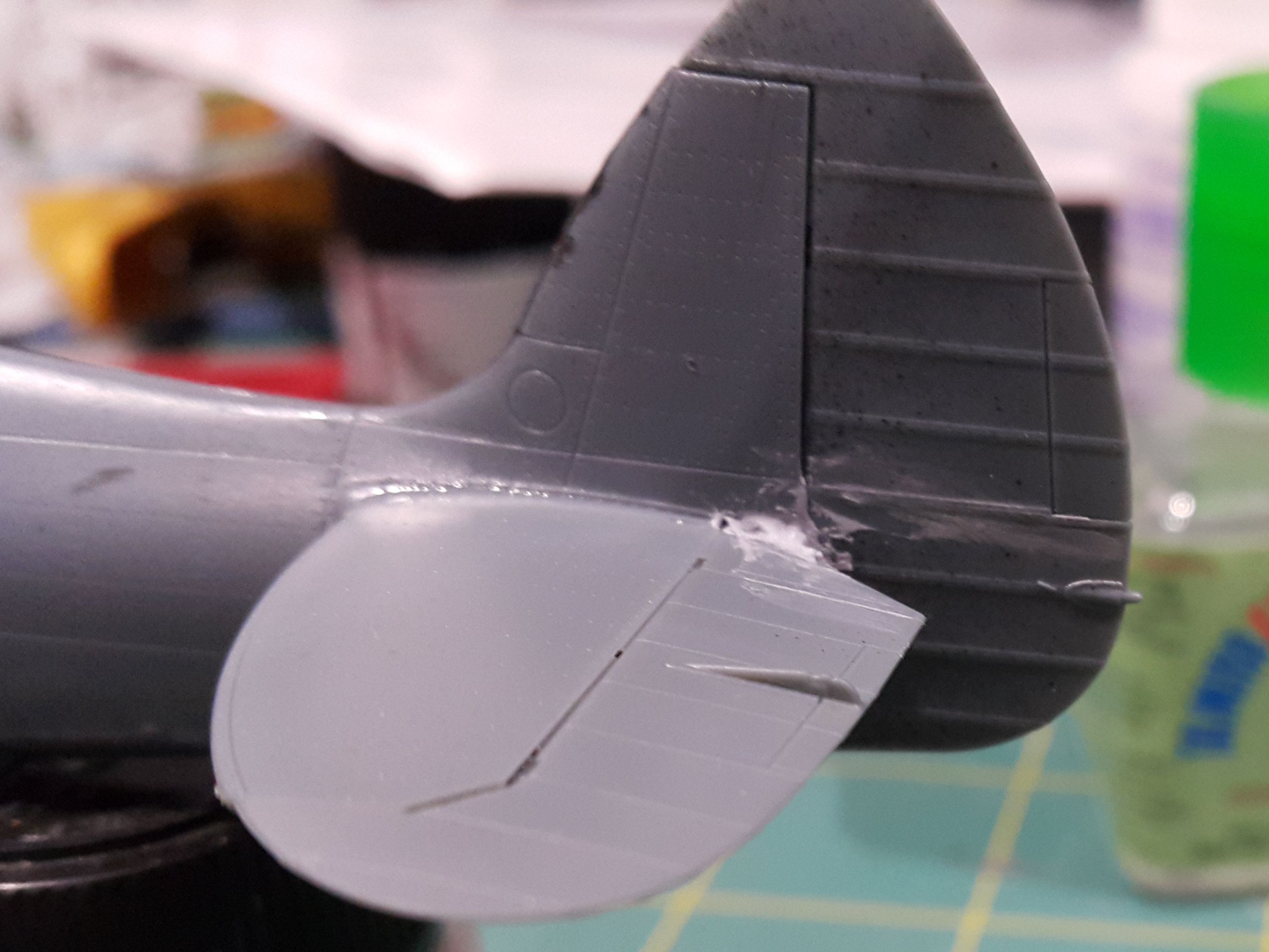

Flappy twitchy bits

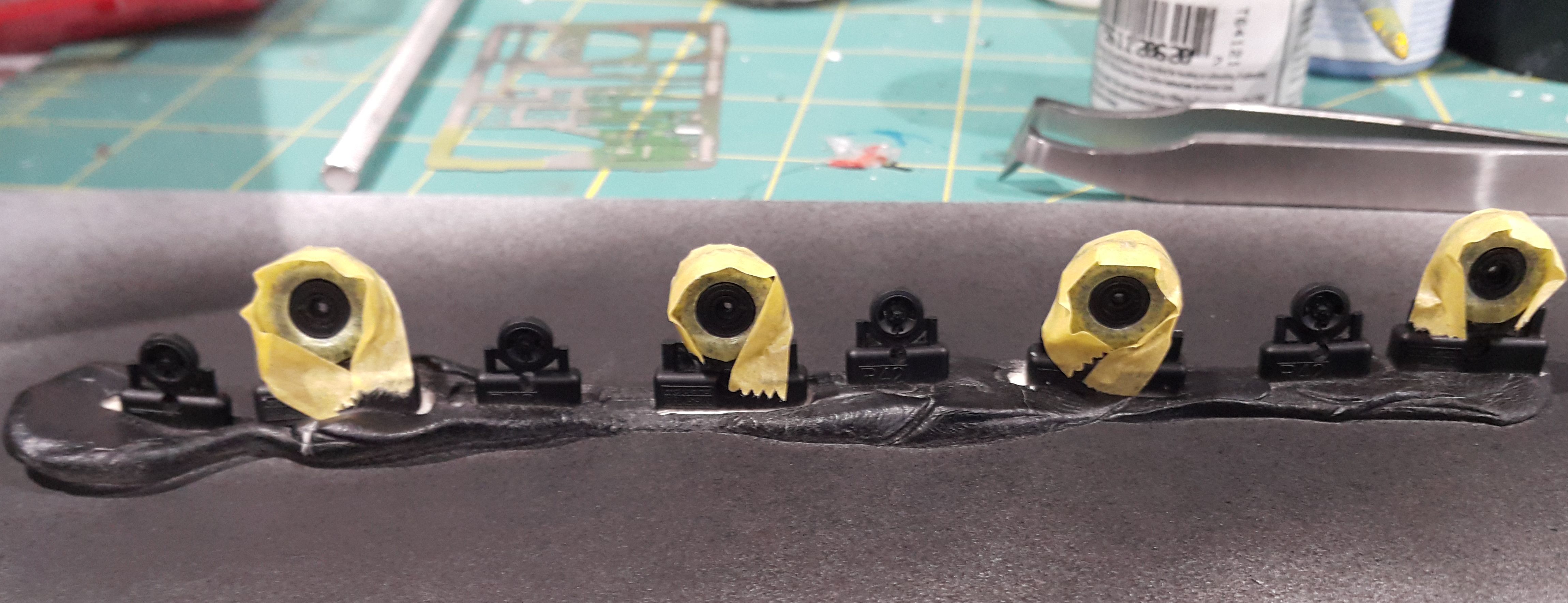

Operator distraction panels

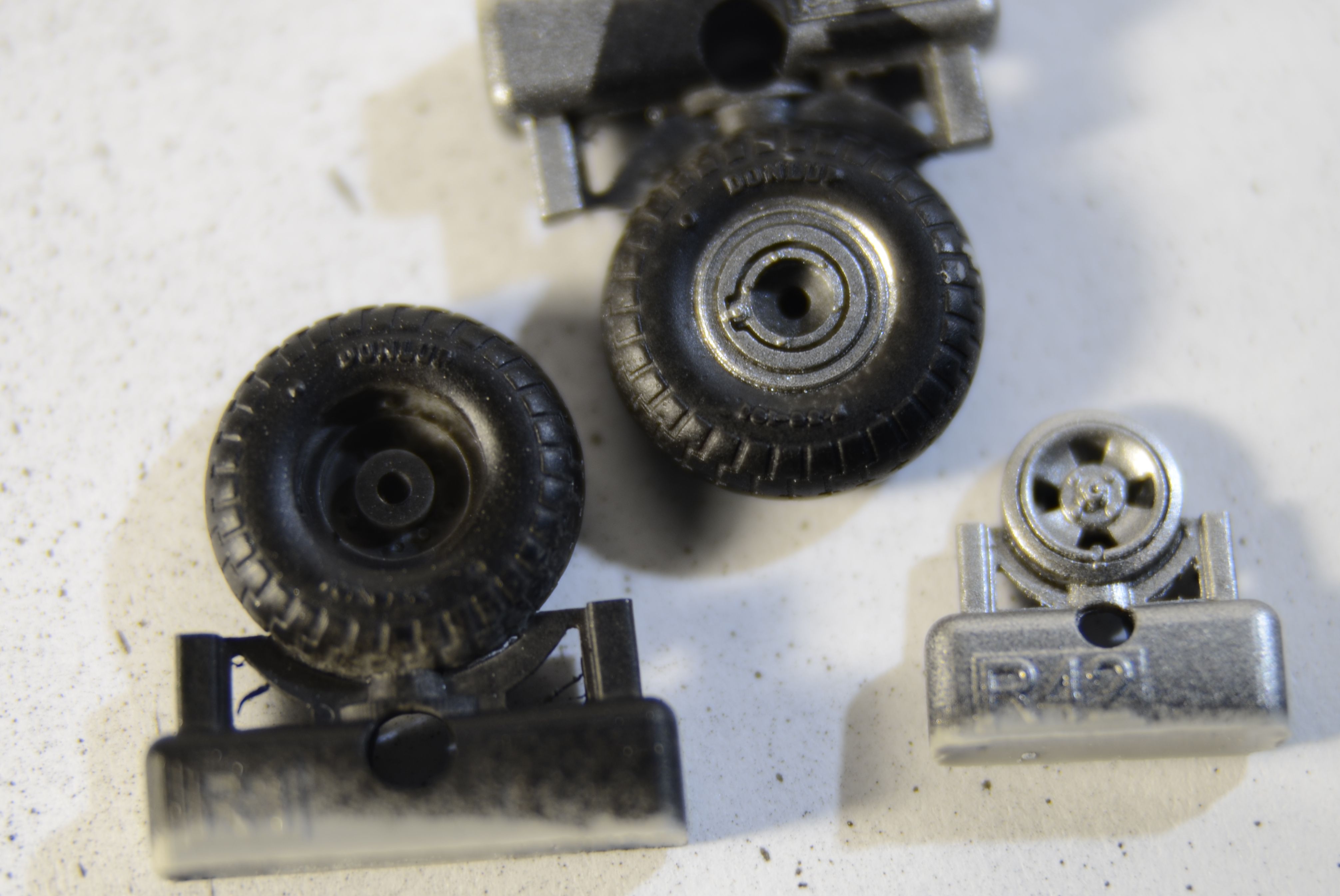

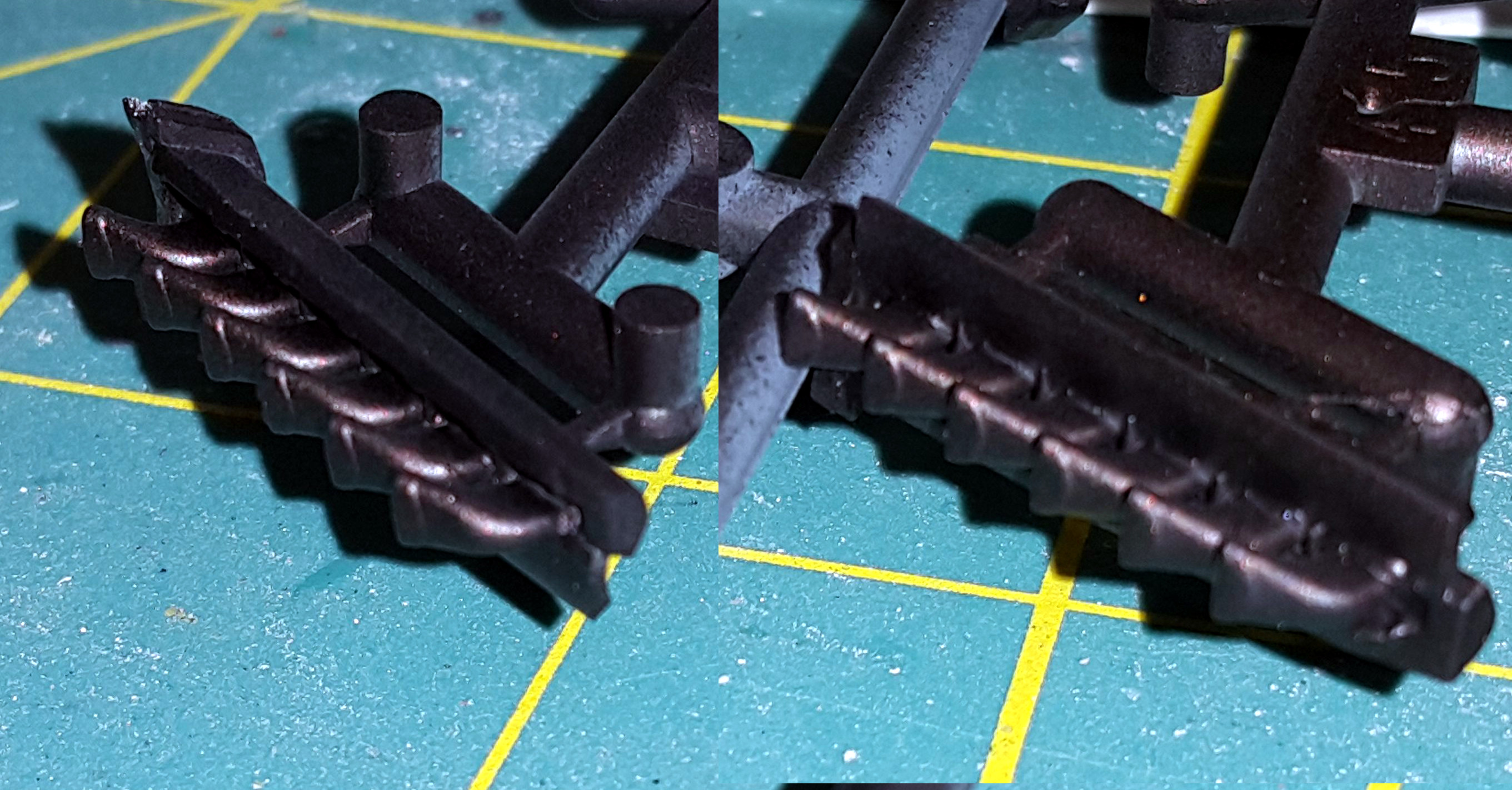

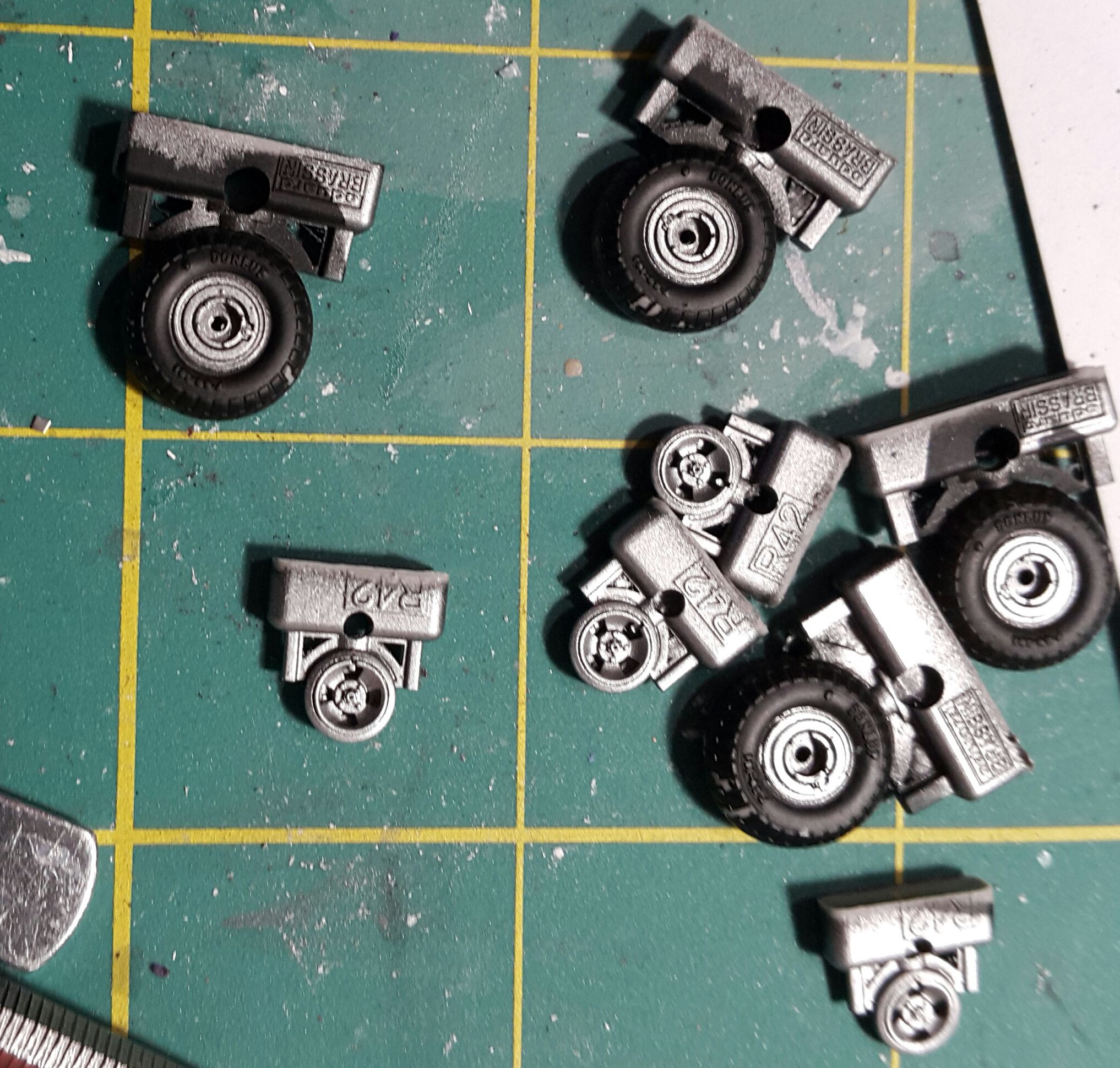

Bouncy ground touchers

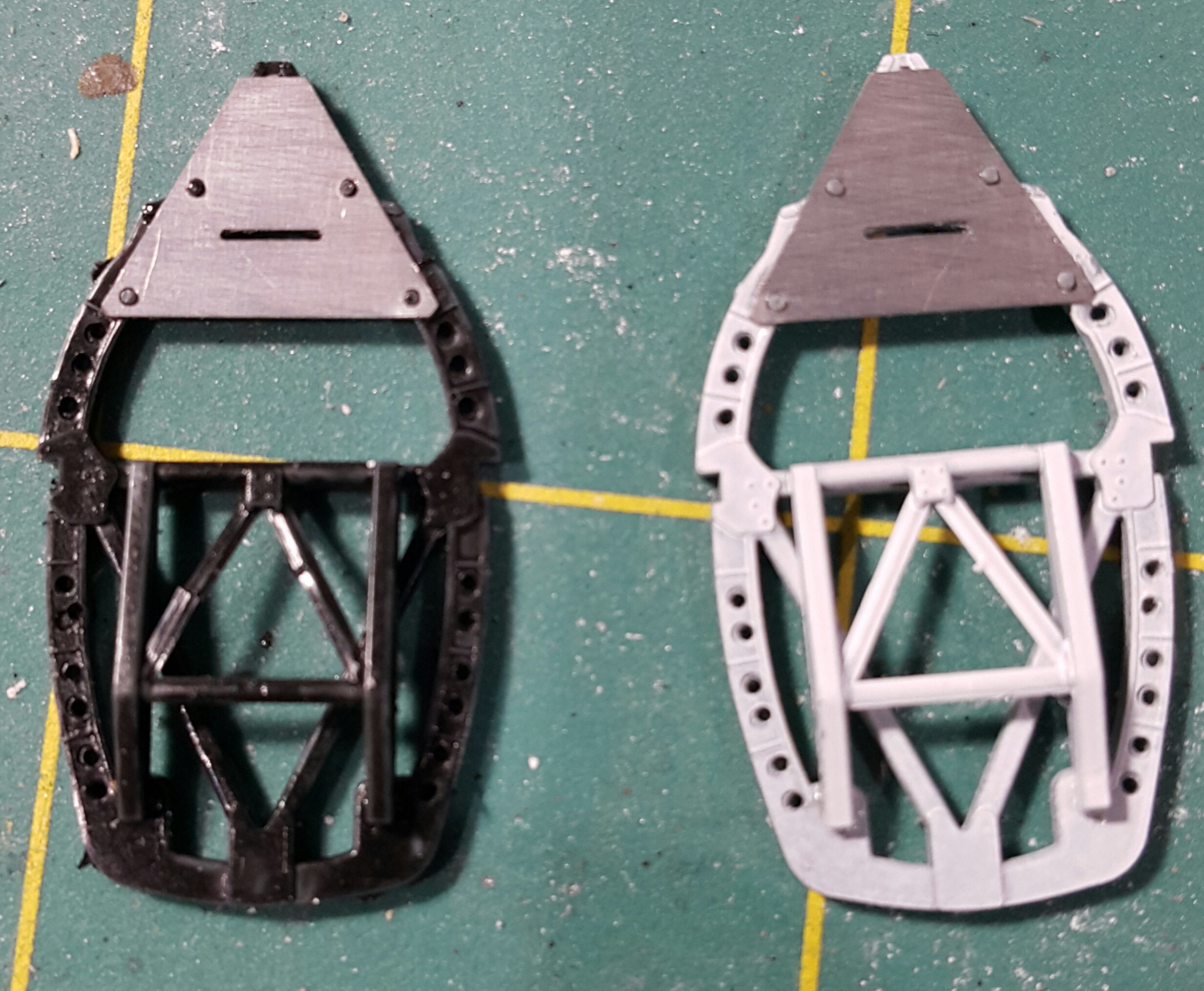

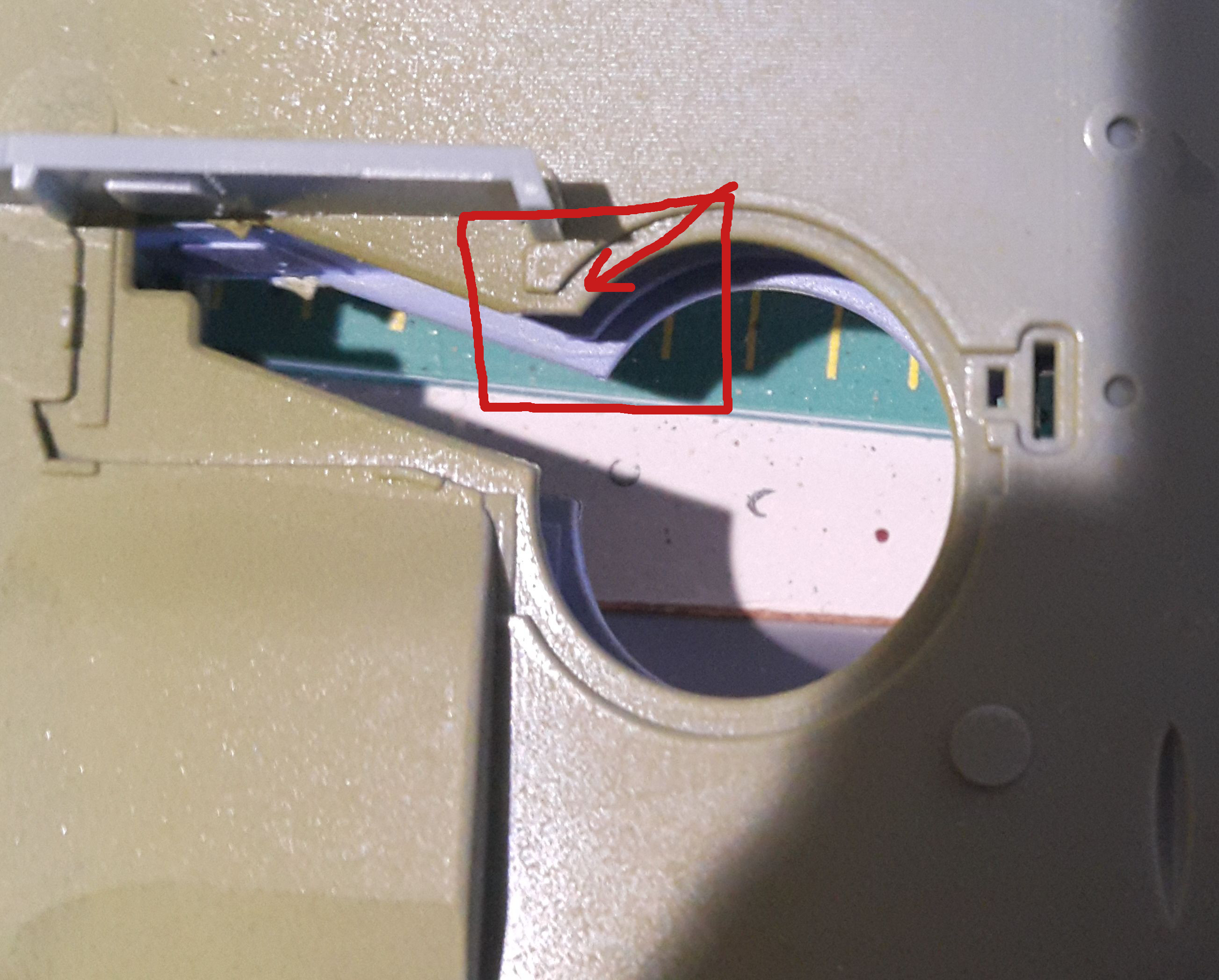

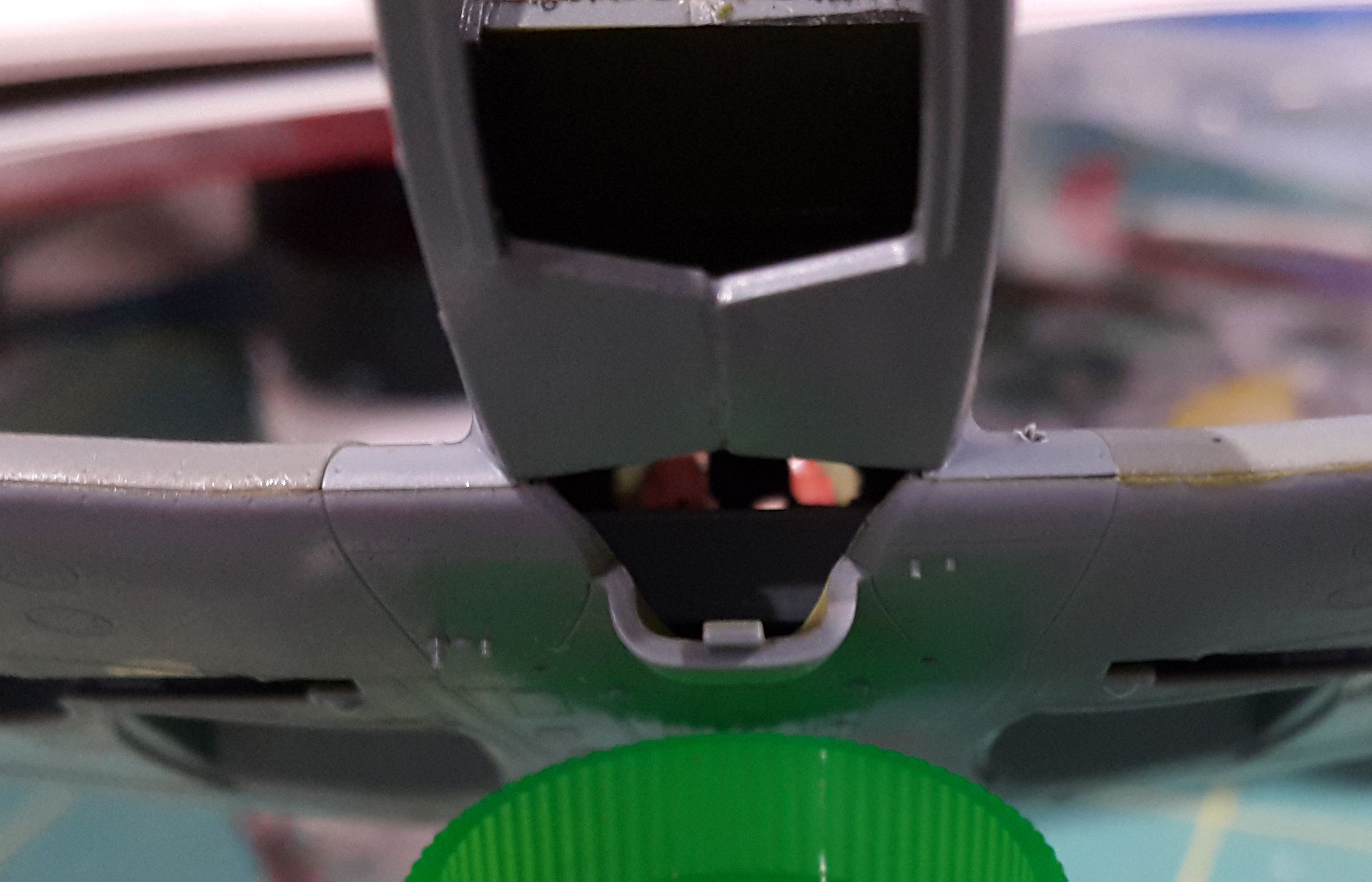

Quality and detail looks pretty good. I did have some concerns over the transparencies, as there seem to be quite a few obvious distortions present, especially in the Malcolm hood. So as bit of a test I have placed it under some light next to a Special Hobby Canopy from a Spitfire V.

WARNING: LIMITED OR NO SCIENCE CONTENT IS CONTAINED WITHIN THE FOLLWING TESTS:

Two tests, one with light from almost directly above, and one with light from slighty off to one side.

From above:

With light from close to directly above(slightly left), the Eduard canopy shows significant shadowing due to refraction, whereas the Special Hobby canopy is showing more focusing of the light which would be expected from the shape of the canopy, indicating less imperfections (not none however).

From one side:

From slightly offset to the right, the Eduard canopy is starting to show more light focusing, and depending on the exact angle, improves significantly compared to its overhead results. This is not entirely surprising, as this angle provides light passage through the area of the canopy with the least amount of curvature.

All 4 Eduard Malcolm hoods(2 open, 2 closed), showed almost identical diffraction behaviour.

No real conclusions on my part, I simply though theses results were interesting, and as I stated, they are really almost entirely unscientific. Ultimately it won't make any difference to me, as the canopies will be posed open on both builds, so won't affect visibility into the cockpit.

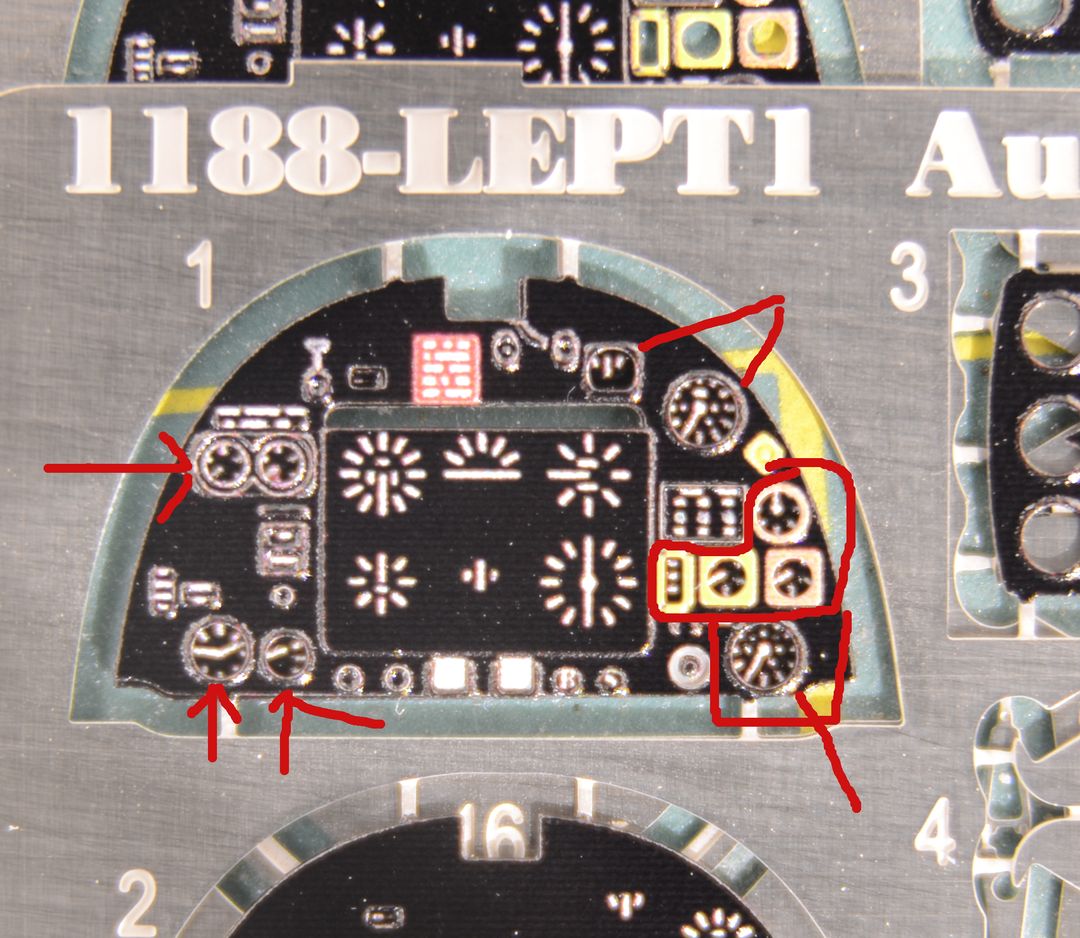

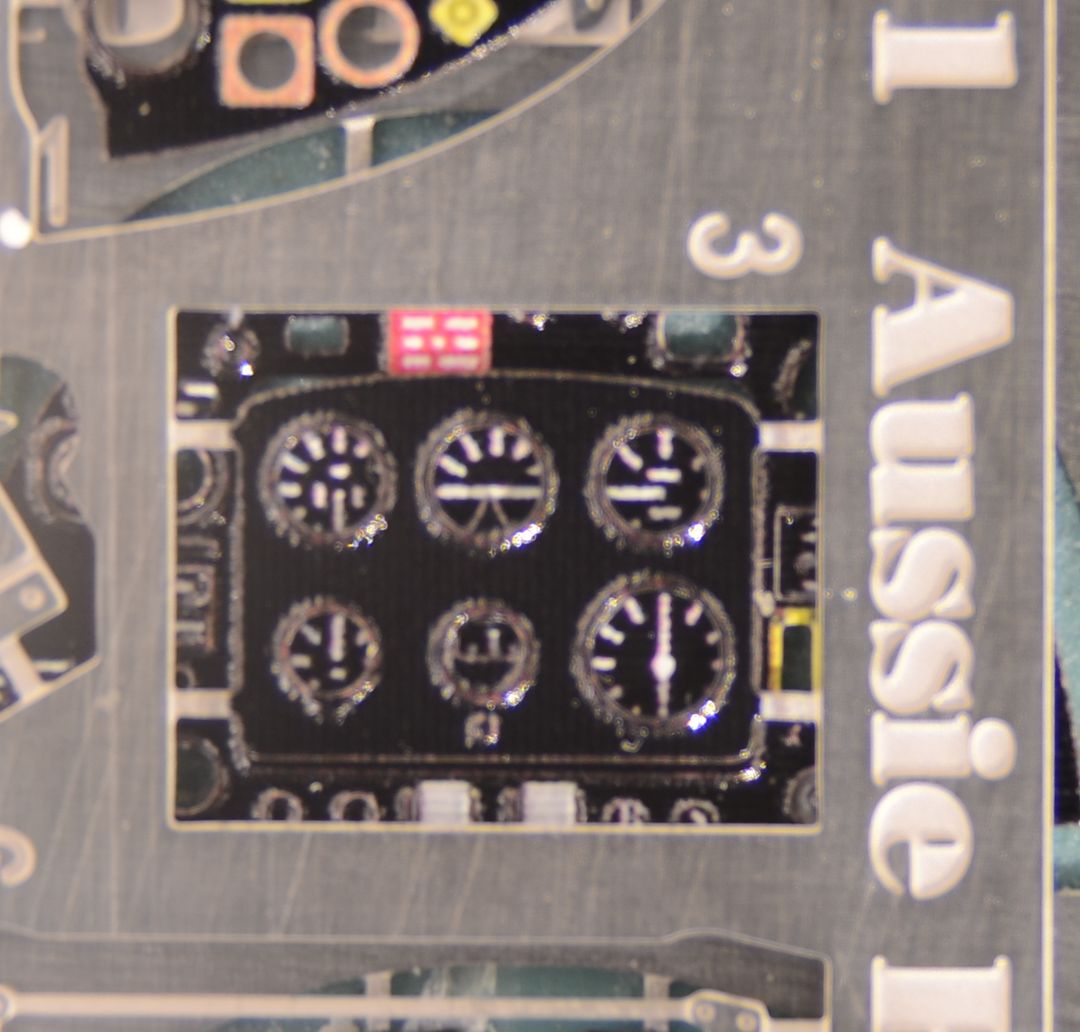

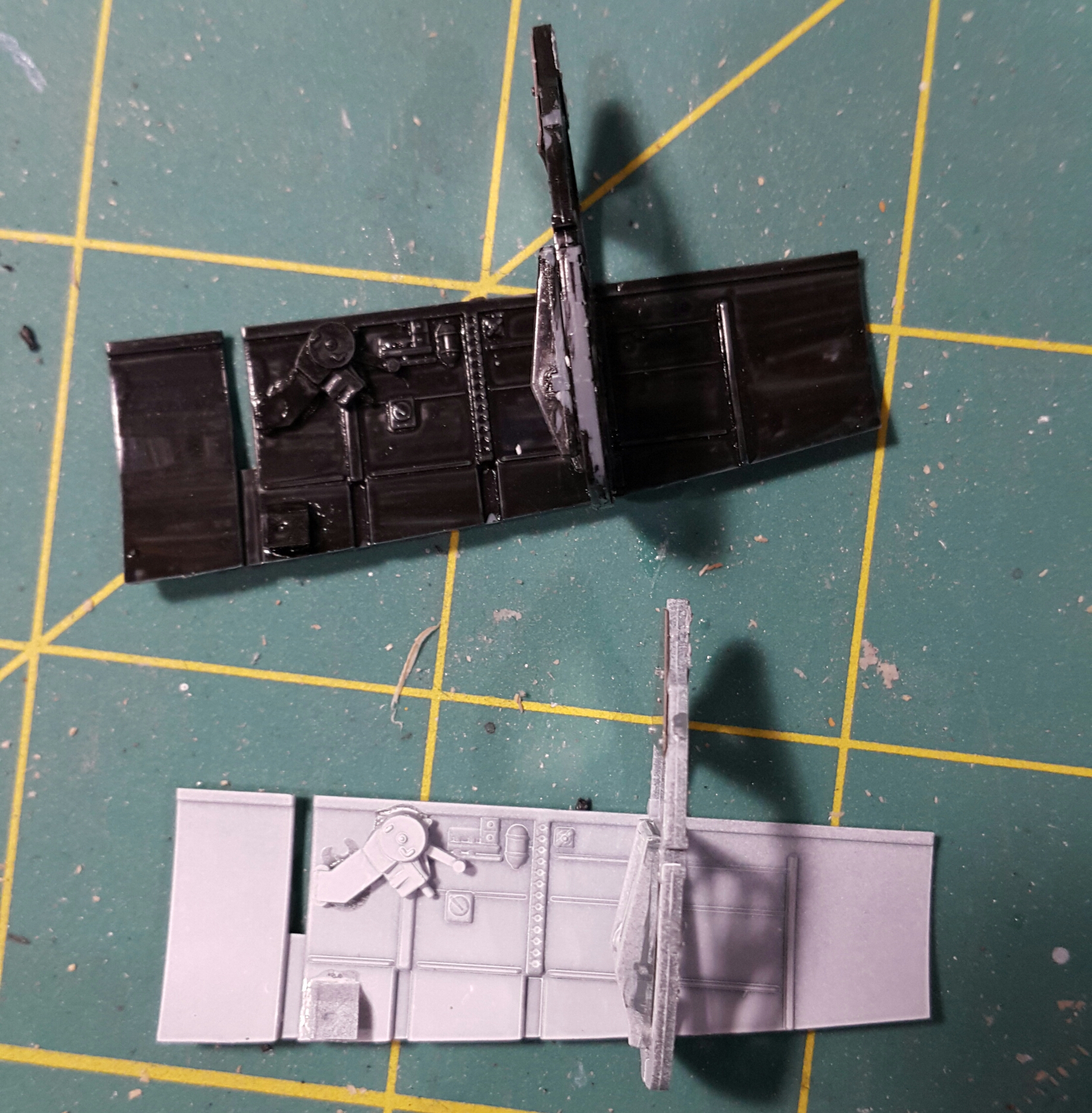

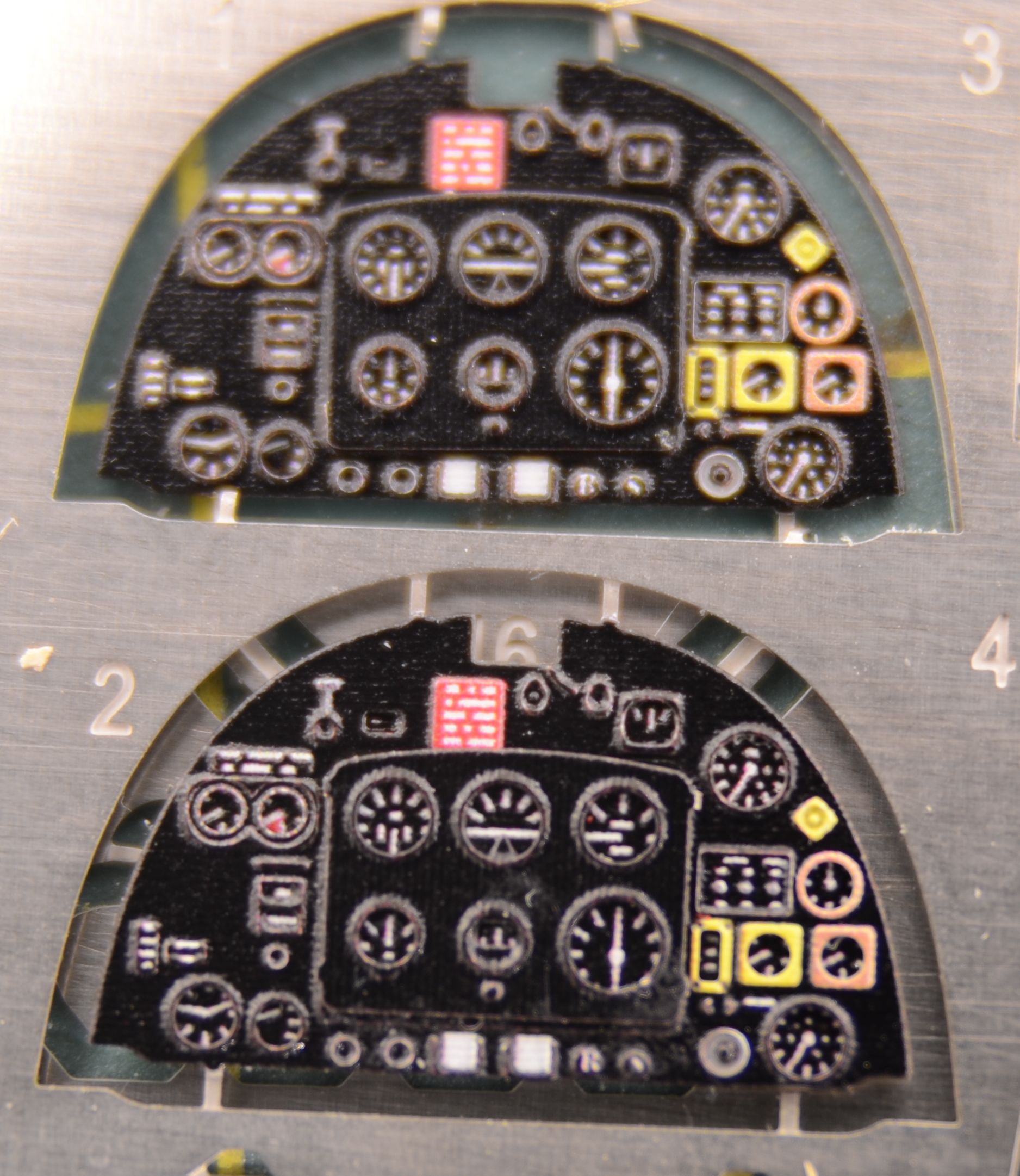

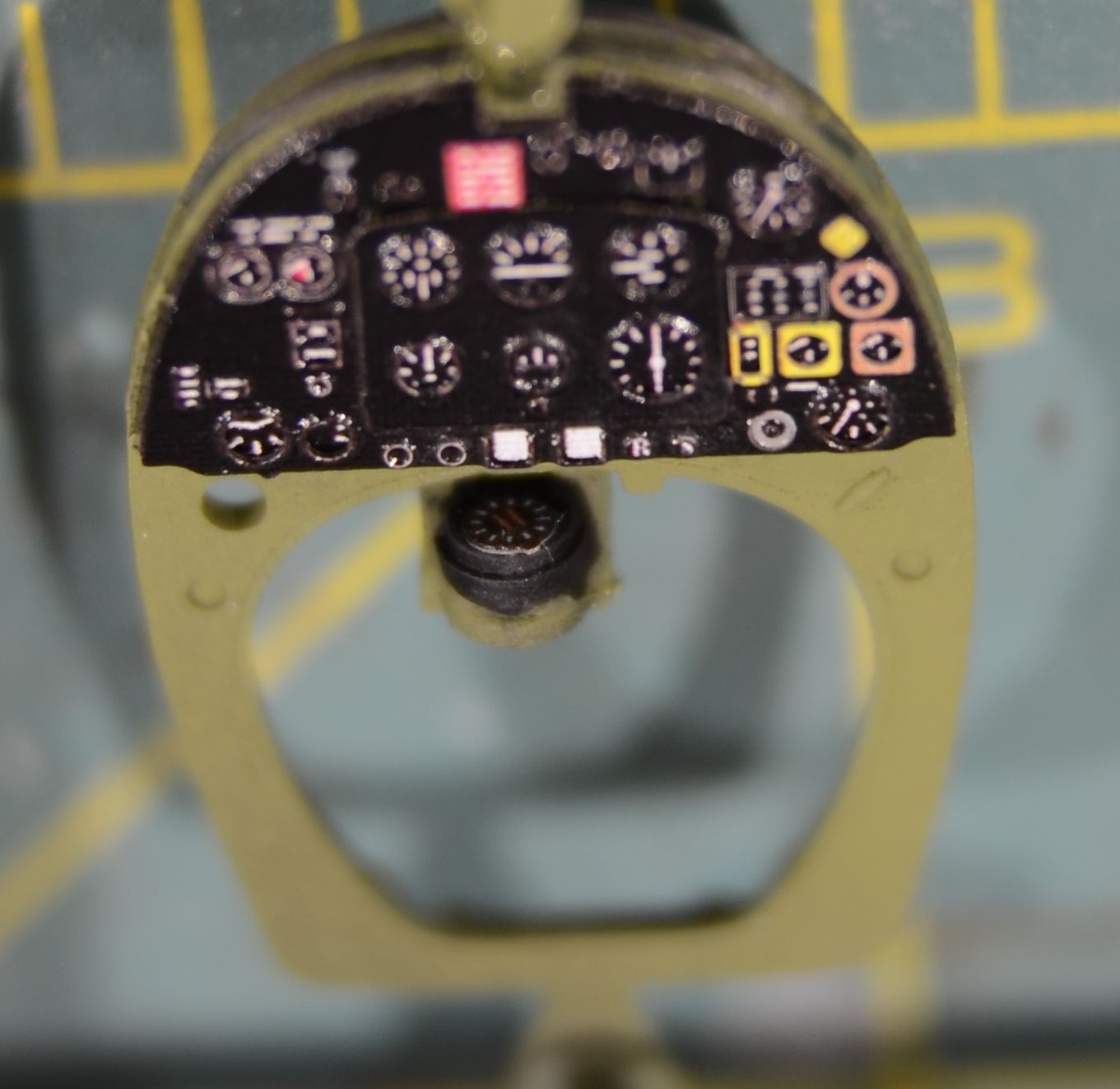

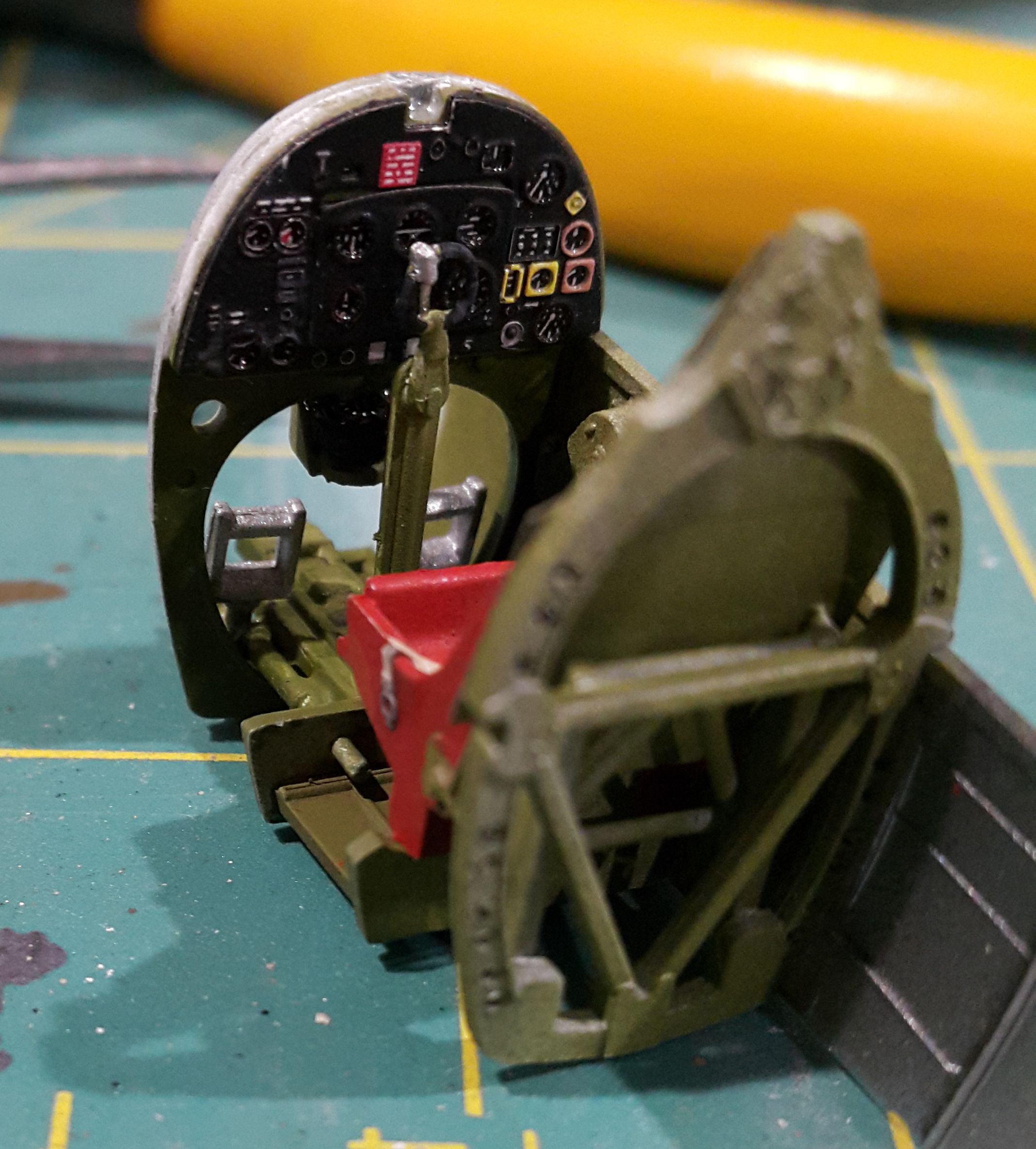

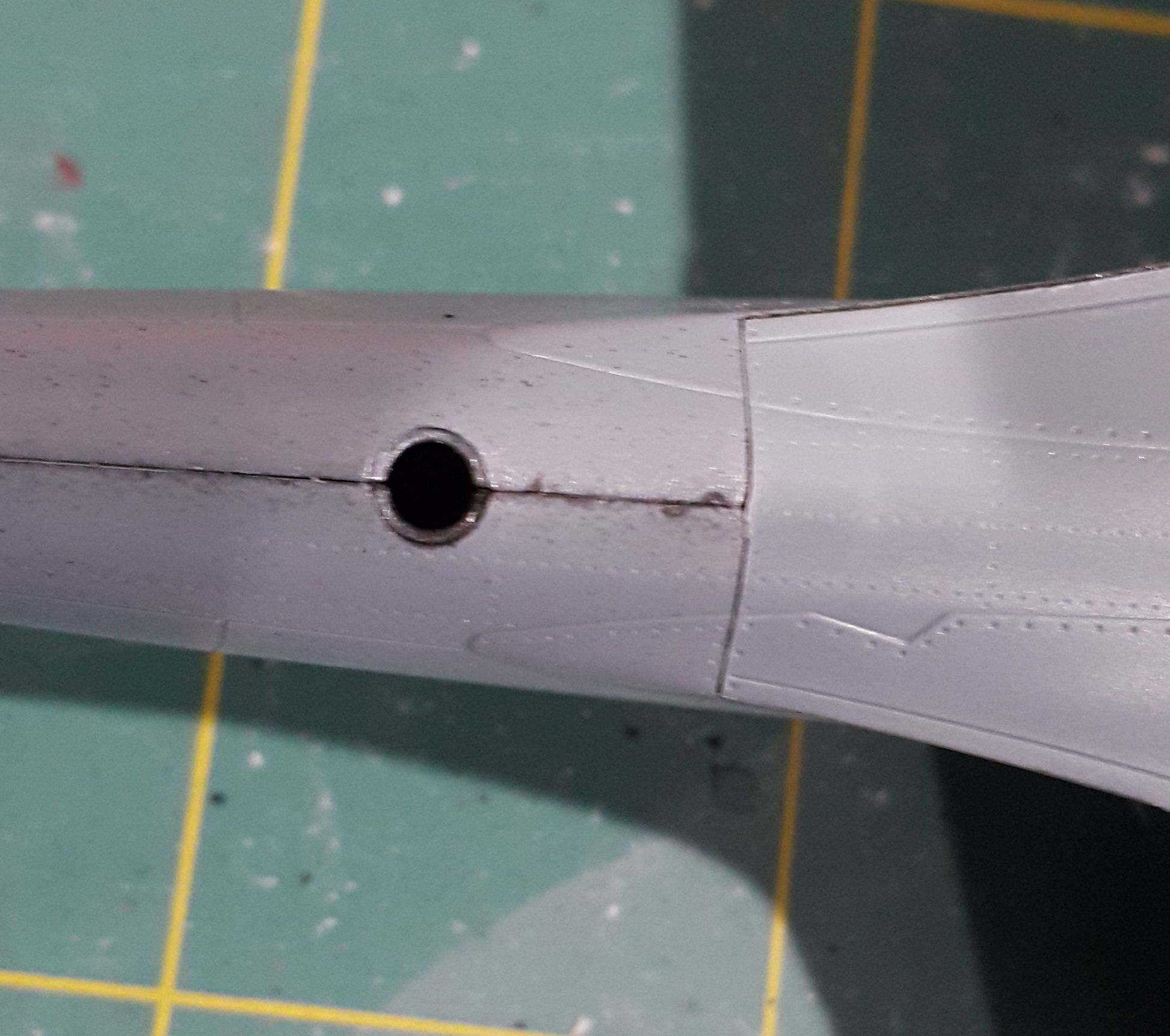

Also roughly checked the alignment of the pre-coloured instrument panel pieces:

And alignment looks pretty good.

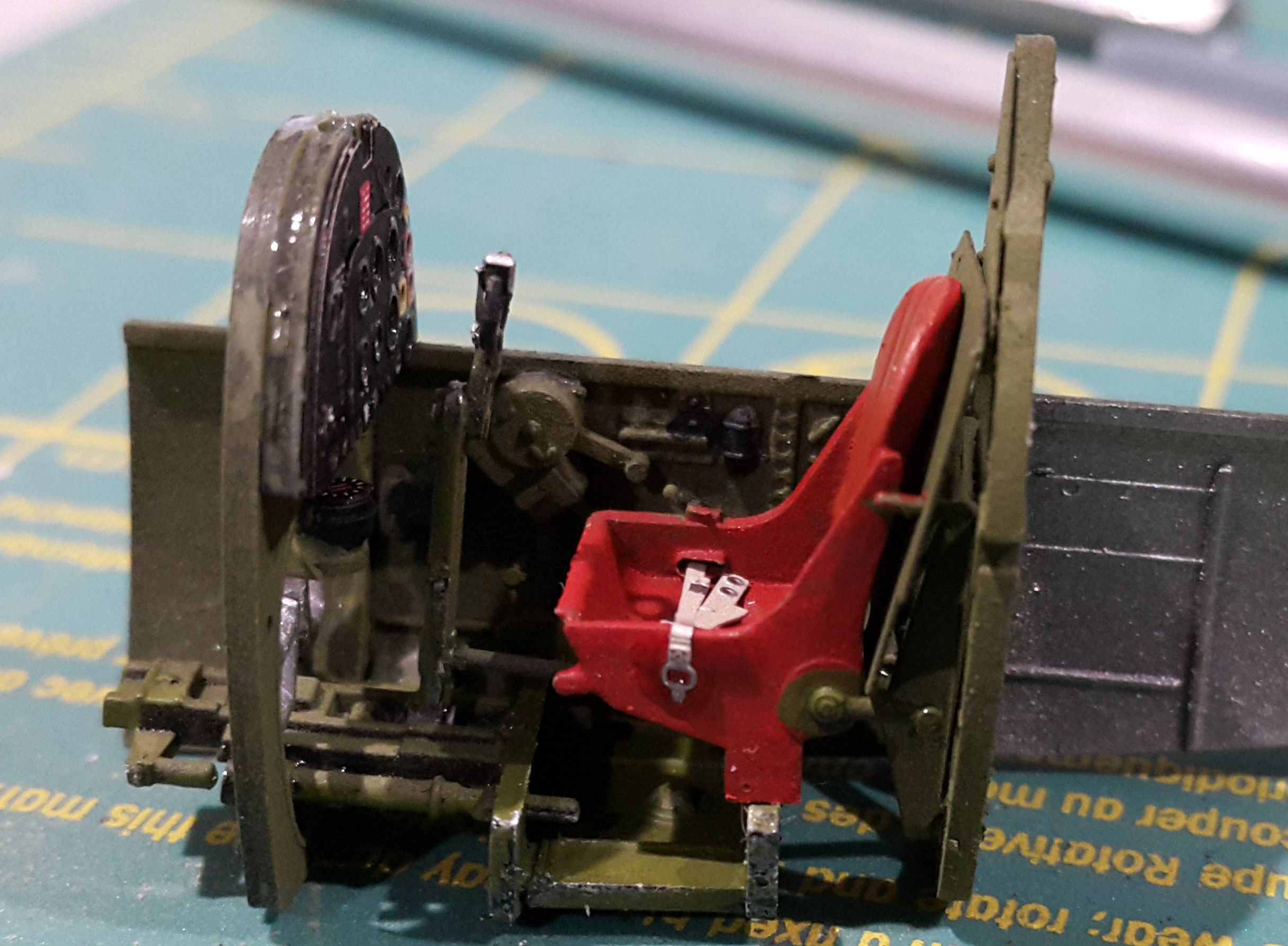

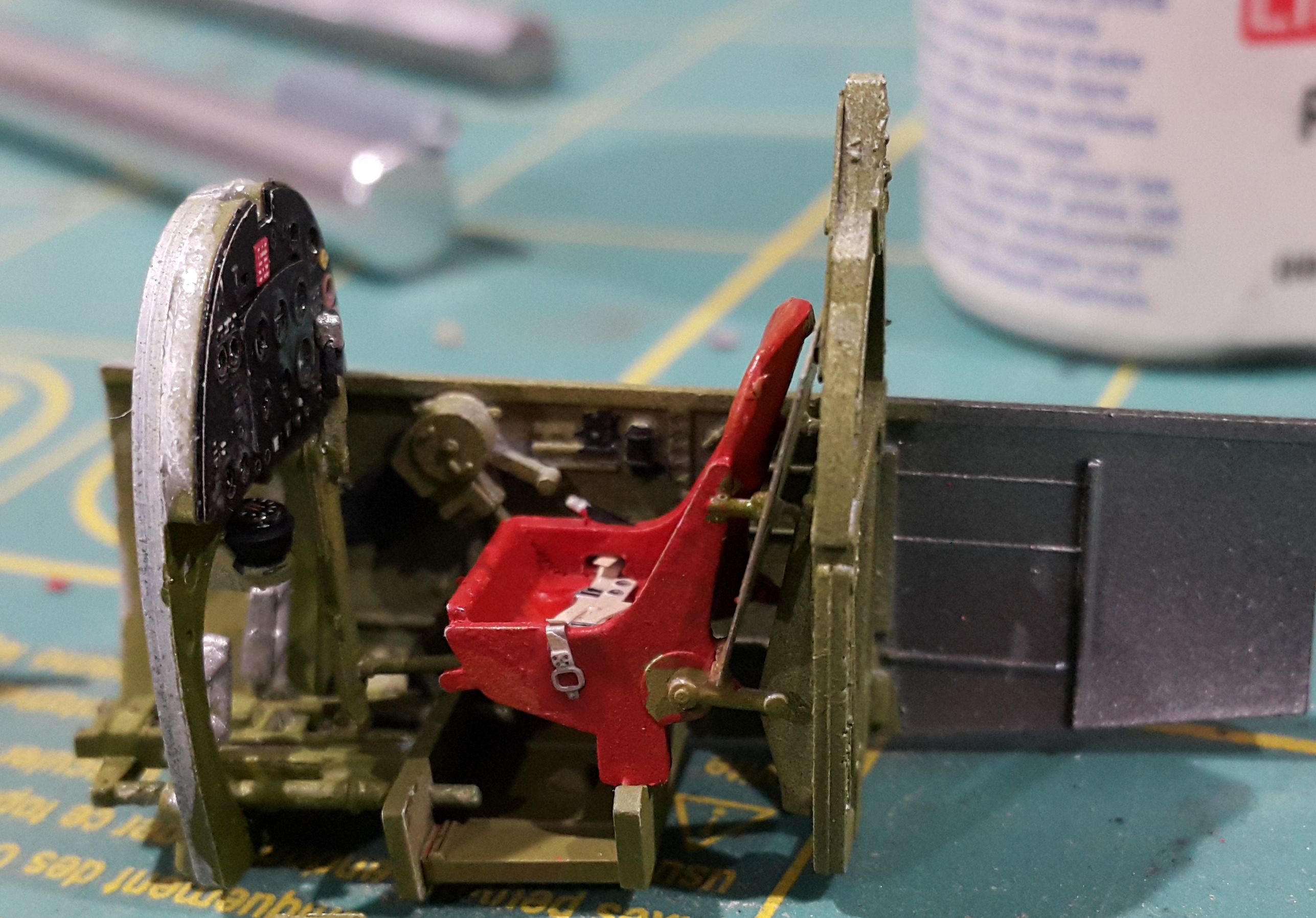

And on to the build!

.

.

.

.