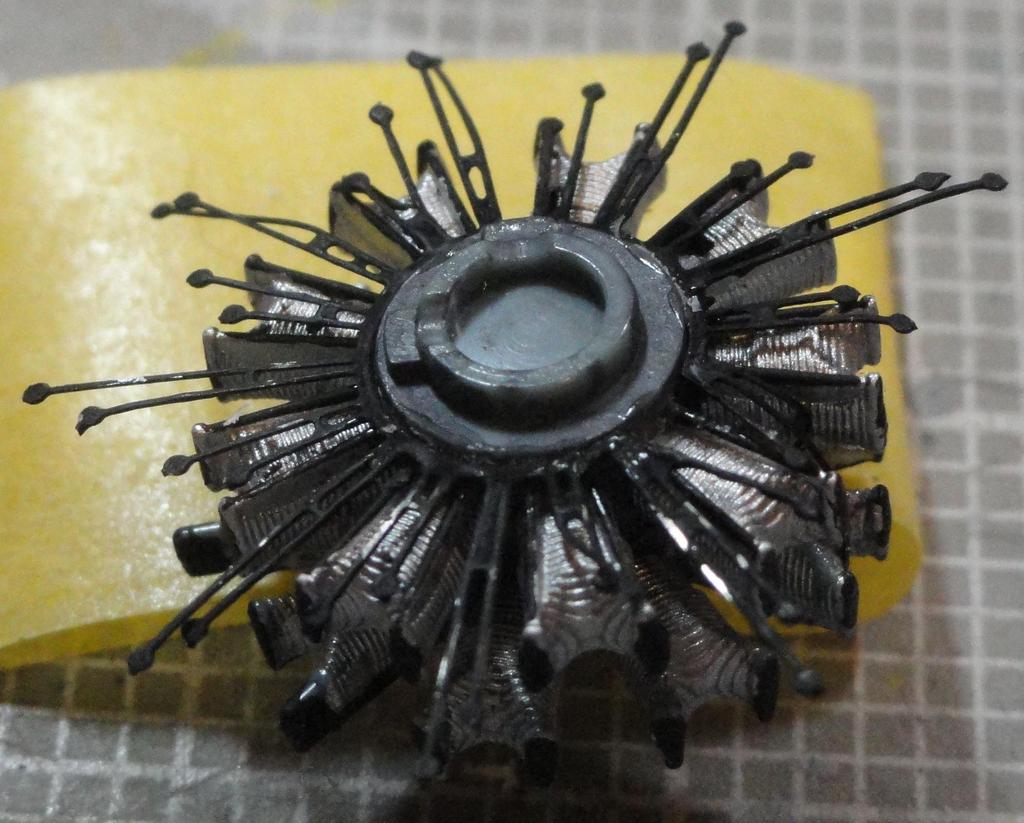

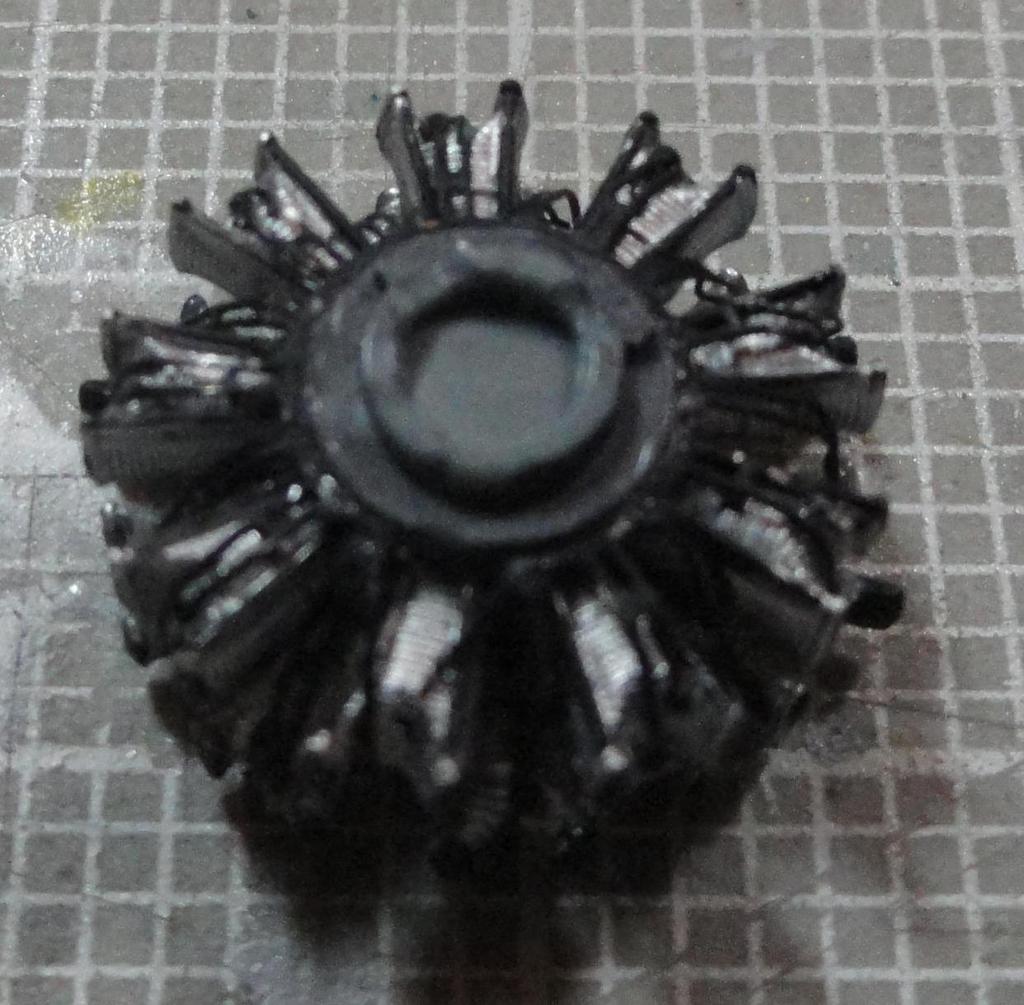

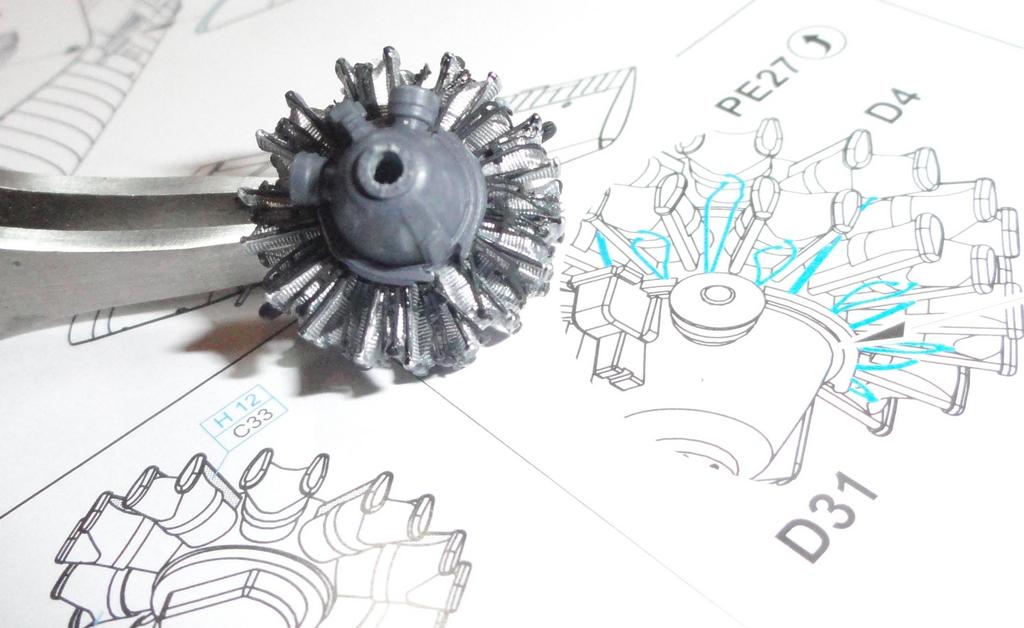

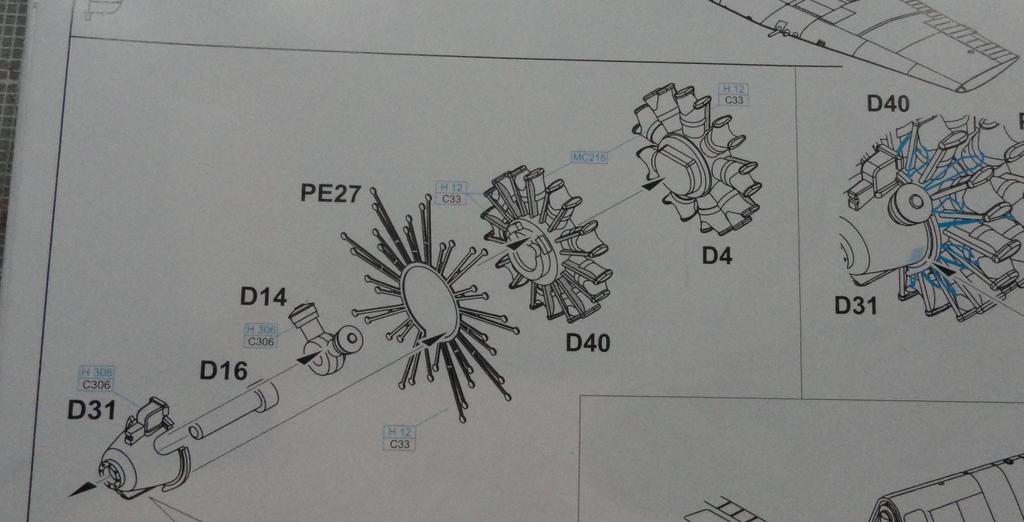

A 5 part engine? 36 spark plug wires? I'm sure I need epoxy or superglue, but how? No way I can get that many wires routed and placed during the epoxy's 5 minute pot life. Mix a batch fix a few, mix a new batch and fix a few more, lather, rinse and repeat? What about superglue, set out a small puddle, transfer a dot to the 'spark plug', apply a dot of accelerator to the wire and press to the spark plug, over and over for 36 spark plugs?