Greetings all;

There has been a good deal of confusion over the years concerning the Mercedes engine variants. Mercedes enigine branch is of course Diamler. Hence the D. signant. I ran into this text recently and thought it would make a good resource for all modelers of stringbags. I did a thread awhile back concerning the BMW engines here we will look at Mercedes D. types for 1915-19. I hope the author stops by and is able to enlighten us further.

1. Mercedes D.II -- rated at 100-120hp, can be recognized by the dual-cylinder water jackets.

2. Mercedes D.III -- rated at 160hp It was introduced around 15 Aug 1916. It used concave pistons and can be recognized by:

Rocker Arm Position -- the rocker arms come out of the middle of the camshaft bearing boxes.

Water Pump Location -- the water pump is above the crankshaft on the jackshaft that goes from the crankshaft to the camshaft between and above the magnetoes.

Air Pump -- the fuel pressurization air pump is a single cylinder model mounted at the rear of the engine on top of the camshaft assembly.

Crankcase Shape -- the crankcase has a smooth, tapering profile from the main body forward to the front main bearing.

3. D.IIIa -- rated at 170 -175hp is the early F1466a Mercedes D.IIIa motor - rated at 170 -175hp variation is almost identical to the D.III, except that

a. Air Pump -- the fuel pressurization air pump is a single cylinder model mounted at the front of the engine on top and infront of the first cylinder.

b. The concave pistons were replaced with flat pistons that raised the compression. This model was introduced around 1 Feb 1917 for the Albatros D.III. Late in 1917 flat pistons were replaced by domed types. This became the late production D.IIIa 170-180hp motor.

4. D.IIIa -- rated at 170 -180hp variation is identical to the early D.IIIa, except that;

a. Air Pump -- the fuel pressurization air pump is a thicker single cylinder model mounted at the front of the engine on top and infront of the first cylinder.

b. Late in 1917 flat pistons were replaced by domed types. Domed pistons being the primary method of describing the later 180hp. Being over compressed still by definition makes it an "aŘ". Ř= uber.

c. The water Pump Location -- the water pump is moved down below the crankcase at the bottom of the motor.

5. Mercedes D.IIIaŘ -- is rated at 180 -200hp. This model introduced the redesigned crankcase. It also had a new type of carburator and other "minor changes". It was introduced in Alb. production batches around Nov. 1917 and it can be recognized by:

Rocker Arm Position -- the rocker arms are mounted on the ends of the camshaft bearing box assemblies. The boxes were moved further back.

Water Pump Location -- the water pump is still down below the crankcase at the bottom of the motor.

Air Pump -- There were two types used. The first is a upright. vertical fuel pressurization air pump and is a single cylinder model that mounts to the front of the camshaft assembly at the front of the engine, above & in front of the No. 1 cylinder. The second (later type mid summer 1918) is a dual horizontal fuel pressurization air pump mounted to the front of the camshaft assembly at the front of the engine, above & in front of the No. 1 cylinder.

Crankcase Shape -- the crankcase at the front main bearing has a flat face surrounded by 12 drilled/tapped holes that were used to fasten it to a factory assembly fixture.

Water-Heated Intake Manifold -- This appears to have the heated intake manifold. I've always thought that this feature was began with to the 180 - 200hp D.IIIaŘ model.

6. Mercedes D.IIIav -- it was rated at 200- 220hp. High compression domed pistons and an altitude-compensating carburator/throttle was added. and was introduced around 1 Mar 1918. It can be recognized by:

Air Pump -- this model used a two-cylinder air pump mounted to the front of the camshaft assembly at the front of the engine, above & in front of the No. 1 cylinder.

Water-Heated Intake Manifold -- This appears to have the heated intake manifold. I've always thought that this feature was began with to the 180 - 200hp D.IIIaŘ model.

Camshaft Bearing Box Nuts -- the nuts that fastened the tops of the camshaft bearing boxes to the bodies are flush with the surface of the tops. The D.III and D.IIIa nuts protrude above the top surface. This is mentioned in one of the Windsock Fokker D.VII Anthologies -- I haven't seen it anywhere else. Comment?

7. Mercedes D.IIIavŘ -- It is rated at 220 -230hp. Oversized cylinders with aluminum pistons were added, changing the bore size and was introduced around 15 Oct 1918. I have no pictures of this variant & don't know if any were used operationally. (possibly in the last batch of Fokker D.VII from Schwerin delivered after the war.)

8. Mercedes D.IV -- it is rated at 240hp easily recognized because it's an 8-cylinder model with an offset reduction-gear housing at the front of the engine. it was used in the AEG G.III and the Albatros C.V. It was first introduced around 1 Dec 1915.

9. Mercedes D.IVa -- it is rated at 260hp. A high-compression 6-cylinder model Introduced around 1 Jan 1917, first used in the AEG G.IV. Overall a larger and heavier engine than the D.IIIa.

I have also heard that overhaul kits were available to upgrade earlier versions of the engine to current specs. So a 160 hp D.III might become a 175hp model after an overhaul. It was possible to take an earlier 160hp D.III model and upgrade it to a 185hp D.IIIa or aŘ

Early Aviation

Discuss World War I and the early years of aviation thru 1934.

Discuss World War I and the early years of aviation thru 1934.

Hosted by Jim Starkweather

Mercedes D. type motors

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, October 15, 2006 - 04:47 PM UTC

PatrickD

Joined: October 18, 2006

KitMaker: 1 posts

AeroScale: 0 posts

Posted: Wednesday, October 18, 2006 - 10:57 AM UTC

Hi Stephen & all, the post on the Mercedes D-series engines was an attempt to provide an easy way to ID specific models from photos. In general, it's pretty accurate. However there is one characteristic mentioned that has since proven to be unreliable. I had a theory (as did many others who have studied these engines) that you could identify the D.III varient (early D.III, later D.III, D.IIIa, D.IIIaŘ or D.IIIaŘv) by the type and location of the small air pump used to pressurize the fuel system. This would be quite useful since the air pump is always mounted on top of either the No. 1 or No. 6 cylinder and is often the only distinguishing feature visible in vintage photos. Sadly, this is not a reliable method of identification. Although the air pump type and location I gave in the original post is generally correct, there were many variations. In corresponding with some persons who do restorations of these engines, I've been told that there may have been as many as 10-12 different models of air pumps from different vendors, and their location on the engine could vary too. Engines were often rebuilt in the field using factory upgrade kits (I received confirmation that older engines were updated with newer components) resulting in a mix of old and new parts. It is entirely possible for an engine to begin it's service life with an old-style single cylinder air pump mounted on the front of the engine and after a rebuild it would be replaced with a late model dual cylinder model. In general, the air pump is not a reliable way to ID the model or power output of a specific engine.

If anyone has other questions about these engines, please post & I'll be happy to try to answer them.

If anyone has other questions about these engines, please post & I'll be happy to try to answer them.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Thursday, October 19, 2006 - 02:23 AM UTC

Greetings all. Here is a bit of fun. The Pavala Mercedes D.IIIa (?) But is it a D.IIIa, D.IIIaŘ, D.IIIav or a D.IIIaŘv?

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Thursday, October 19, 2006 - 03:57 AM UTC

I was asked offline about the reason that Fokker D.VII types had Spandau guns that were raised at three specific levels. The height of the cylinders of various engines caused the need for The Spandaus to be raised to clear the cylinder tops.

The overall height from the center line to the top of the cam gear housing of;

A. Mercedes D.III & D.IIIa is 665mm

B. Mercedes D.IIIaŘ & D.IIIav is 670 mm...

C. BMW IIIa is 687 mm.

The difference in B & C. 17 mm = .68 inch, just a bit under 11/16 of an inch.

Even though engines were up graded as performance developments were developed, the crank case usally remained the same and were embossed with "160hp". In our terms this is the Mercedes D.IIIa 170 -175hp. It had flat piston heads where the 160hp had concave piston heads.

Now the the air pump was moved on the motor too. On the 160hp it was at the back of the motor after the #6 cylinder. On the 170-175hp it was moved to the front and at first came in two versions. The tall skinny profile matched both.

The fat thicker profile air pump began being seen on late production versions of the 170-175hp(Fall 1917. The water pump was moved on this later production series from the rear tower to an area under the crank case. This then became the standard.

The Merc. D.IIIaŘ 180hp had all of the late production D.IIIa progressions plus piston heads that were convex - domed shaped. This was the over-compressed version. Though still identified as a D.IIIa. The major visual difference was that the rocker box covers were no longer centered on the rocker arms but the boxes were now moved back and the rocker arms were at the leading edge of the cover. I am confident that the first installations were in the Alb.D.Va types.

There were further developents like altitude compensating linkages and water jacketed intakes to keep the incoming air temps low.

Power ratings determined the roman numerl identifiers in the motor designations.

0= 80hp

I= 100hp

II= 110-130hp

III= 160hp

IIIa= 170hp-200hp

IV= 220-260hp

The a & b suffix was a notation that this was a progression of a standard within a horsepower rating.

The overall height from the center line to the top of the cam gear housing of;

A. Mercedes D.III & D.IIIa is 665mm

B. Mercedes D.IIIaŘ & D.IIIav is 670 mm...

C. BMW IIIa is 687 mm.

The difference in B & C. 17 mm = .68 inch, just a bit under 11/16 of an inch.

Even though engines were up graded as performance developments were developed, the crank case usally remained the same and were embossed with "160hp". In our terms this is the Mercedes D.IIIa 170 -175hp. It had flat piston heads where the 160hp had concave piston heads.

Now the the air pump was moved on the motor too. On the 160hp it was at the back of the motor after the #6 cylinder. On the 170-175hp it was moved to the front and at first came in two versions. The tall skinny profile matched both.

The fat thicker profile air pump began being seen on late production versions of the 170-175hp(Fall 1917. The water pump was moved on this later production series from the rear tower to an area under the crank case. This then became the standard.

The Merc. D.IIIaŘ 180hp had all of the late production D.IIIa progressions plus piston heads that were convex - domed shaped. This was the over-compressed version. Though still identified as a D.IIIa. The major visual difference was that the rocker box covers were no longer centered on the rocker arms but the boxes were now moved back and the rocker arms were at the leading edge of the cover. I am confident that the first installations were in the Alb.D.Va types.

There were further developents like altitude compensating linkages and water jacketed intakes to keep the incoming air temps low.

Power ratings determined the roman numerl identifiers in the motor designations.

0= 80hp

I= 100hp

II= 110-130hp

III= 160hp

IIIa= 170hp-200hp

IV= 220-260hp

The a & b suffix was a notation that this was a progression of a standard within a horsepower rating.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, December 10, 2006 - 04:02 PM UTC

Greetings all also from the Fokker Royal thread. Mercedes D.IIIaŘ 180hp. The back of the engine in this image is at the right side.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, December 10, 2006 - 04:07 PM UTC

Now from the other oe exhaust attachment side. The rear of the engine is at the left side in this image.

Lucky13

Joined: June 01, 2006

KitMaker: 1,707 posts

AeroScale: 1,119 posts

Posted: Sunday, December 10, 2006 - 04:19 PM UTC

Just of curiousity O' Enlighted One. Is it possible to build these engines new? Do the plans still exist?

Kitboy

Joined: July 20, 2006

KitMaker: 258 posts

AeroScale: 256 posts

Posted: Sunday, December 10, 2006 - 05:01 PM UTC

You are in need of a new landmower?

Nico

Edit: or should it have been lawnmower, mmh...

Nico

Edit: or should it have been lawnmower, mmh...

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, December 10, 2006 - 07:06 PM UTC

Quoted Text

Just of curiousity O' Enlighted One. Is it possible to build these engines new? Do the plans still exist?

Yes as a matter of fact I know two people that have Diamler licenses to build these. One in the USA one in Germany. Got lots of money?

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Friday, January 12, 2007 - 02:22 AM UTC

Here is a bit of fun for Mercedes - Diamler detail hounds.

http://www.idflieg.com/mercedes-diii.htm

http://www.idflieg.com/mercedes-diii.htm

Familyman

Joined: January 11, 2007

KitMaker: 88 posts

AeroScale: 87 posts

Posted: Friday, January 12, 2007 - 01:30 PM UTC

Folks!

I've been wondering about the material of the pipes on the port side of Mercedes engines. In Mercedes D.II engines they were made of copper:

D.IIIa, D.IIIaŘ etc. had them made of steel (or aluminium perhaps?):

How about early 160 hp D.III? Copper or steel?

Yours Mikko

I've been wondering about the material of the pipes on the port side of Mercedes engines. In Mercedes D.II engines they were made of copper:

D.IIIa, D.IIIaŘ etc. had them made of steel (or aluminium perhaps?):

How about early 160 hp D.III? Copper or steel?

Yours Mikko

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Friday, January 12, 2007 - 02:48 PM UTC

Greetings Mikko;

As the war progressed it seems that more and more engines had to be rebuilt and brought up to the existing front line requirements. Some materials seems to be substituted or even fully replaced with what was available for manufacture. Even in some of the later 180hp Mercedes these air induction pipes tended to be wrapped in tar soaked asbestos chords. Totally covering up any evidence of the type metal.

As Duraluminum became the source for most light metals toward the end of the war its not too surprising to see it turn up more and more after 1917.

As the war progressed it seems that more and more engines had to be rebuilt and brought up to the existing front line requirements. Some materials seems to be substituted or even fully replaced with what was available for manufacture. Even in some of the later 180hp Mercedes these air induction pipes tended to be wrapped in tar soaked asbestos chords. Totally covering up any evidence of the type metal.

As Duraluminum became the source for most light metals toward the end of the war its not too surprising to see it turn up more and more after 1917.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Friday, March 05, 2010 - 05:57 PM UTC

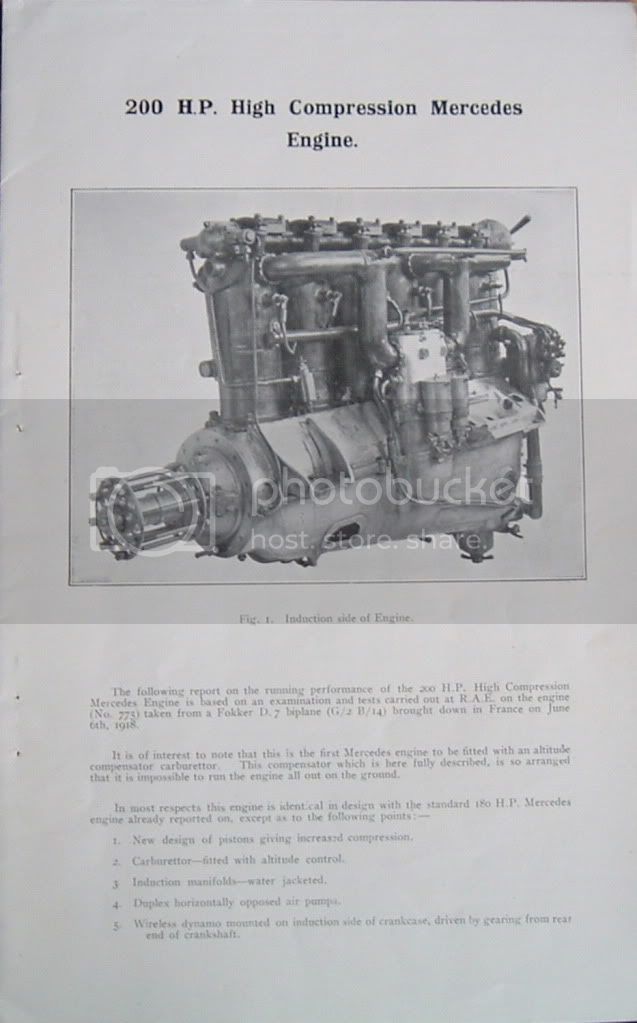

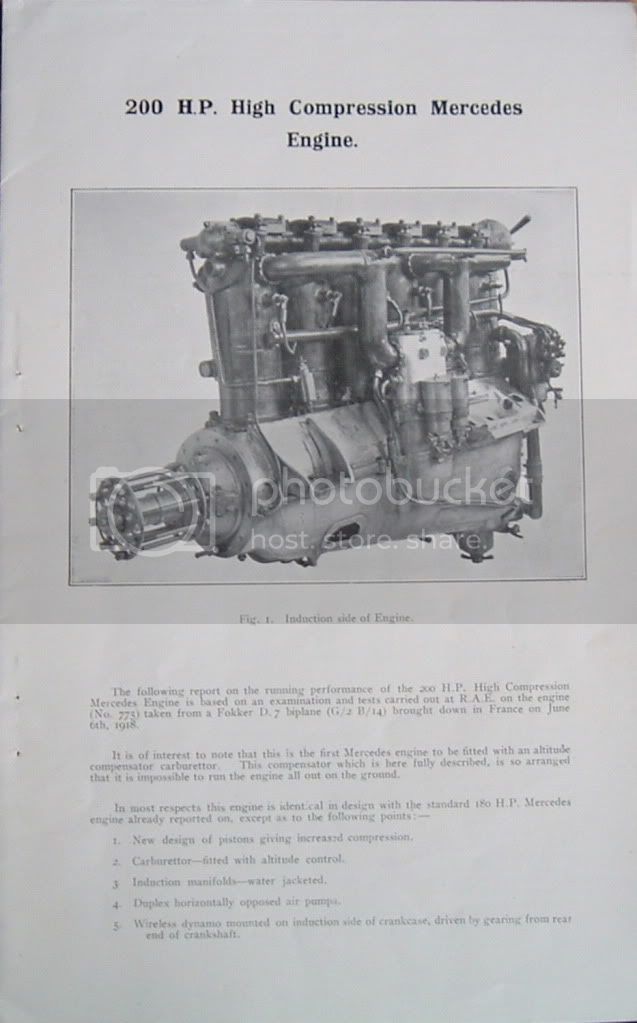

Lets discuss these shall we? Note these are in English -post war.

Here is a bit of fun on the engines in the type.

Here is a bit of fun on the engines in the type.

mrockhill

Joined: June 17, 2009

KitMaker: 566 posts

AeroScale: 507 posts

Posted: Saturday, March 06, 2010 - 10:07 AM UTC

This older thread has already learnt me a bunch of stuff, cant wait to see what comes next.

gajouette

Joined: February 01, 2007

KitMaker: 365 posts

AeroScale: 356 posts

Posted: Saturday, March 06, 2010 - 11:31 AM UTC

Stephen,

Wow thanks for the great details.This thread is much appreciated,and certainly be of greatest help for detailing Mercedes engine for my projects.

Regards,

Gregory Jouette

Wow thanks for the great details.This thread is much appreciated,and certainly be of greatest help for detailing Mercedes engine for my projects.

Regards,

Gregory Jouette

badwolf

Joined: November 16, 2009

KitMaker: 79 posts

AeroScale: 75 posts

Posted: Sunday, March 07, 2010 - 03:40 AM UTC

Thanks for that Stephen, very useful, but with regards kitmakers

Iam building an Albatros B.IIa in 1/48 th and needed a 100 hp Mercedes motor. Aerocub in England had a Tom's Modelworks in stock, while i was waiting for that, i used one form an Eduard Albatros C.III just to give me an idea of clearance etc, few days later my new motor arrived. Only then did i see that the Tom's one is clearly bigger. Even bigger on my plans, anyone else had this type of problem? I am still thinking, what i am going to do?

Iam building an Albatros B.IIa in 1/48 th and needed a 100 hp Mercedes motor. Aerocub in England had a Tom's Modelworks in stock, while i was waiting for that, i used one form an Eduard Albatros C.III just to give me an idea of clearance etc, few days later my new motor arrived. Only then did i see that the Tom's one is clearly bigger. Even bigger on my plans, anyone else had this type of problem? I am still thinking, what i am going to do?

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, March 07, 2010 - 03:27 PM UTC

Quoted Text

'. . .[5. Mercedes D.IIIaŘ -- is rated at 180 -200hp. This model introduced the redesigned crankcase. It also had a new type of carburator and other "minor changes". It was introduced in Alb. production batches around Nov. 1917 and it can be recognized by:

Rocker Arm Position -- the rocker arms are mounted on the ends of the camshaft bearing box assemblies. The boxes were moved further back.

Water Pump Location -- the water pump is moved down below the crankcase at the bottom of the motor.

Air Pump -- There were two types used. The first is a upright. vertical fuel pressurization air pump and is a single cylinder model that mounts to the front of the camshaft assembly at the front of the engine, above & in front of the No. 1 cylinder. The second (later type mid summer 1918) is a dual horizontal fuel pressurization air pump mounted to the front of the camshaft assembly at the front of the engine, above & in front of the No. 1 cylinder.

Crankcase Shape -- the crankcase at the front main bearing has a flat face surrounded by 12 drilled/tapped holes that were used to fasten it to a factory assembly fixture.

. . . "

From Dan san Abbott, ". . .The earliest Fokker built D.VII with the dual opposed (horizontal) air pumps is Fok.D.VII 258/18, w.n.2344 with Mercedes D.IIIaŘ engine serial number 37689, Bestell Nr. 715 was accepted by Fabrikaufsicht at the Daimler factory on 4 March 1918. This then is a totally rebuilt engine and brought up to the latest design at the Daimler Motoren Gesellschaft factory in Stuttgart-UntertŘkheim.

This is the first Fokker D.VII with the Mercedes D.IIIaŘ 180hp that has the dual horizontal air pump.

There was also a Daimler engine overhaul/rebuild facility in Brussel, Belgium. A good number of Mercedes engines were sent there from the front to be rebuilt and brought up to the latest configuration. . ."

(Note! Major rebuilds took place in Aachen, Brussels and there are reports of a facility at Adlershof. As 1918 progressed, an increasing amount of motors were brought up to the standards of new-build D.IIIaŘ types but wastage will have to be taken into consideration before assuming that all motors were brought up to a consistant standard by late 1918. Mercedes D.IIIaŘ types were in chronic short supply and there are reports of as many as every10 of Fokker D.VII airframes being delivered from the factories without motors.)

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Tuesday, April 13, 2010 - 04:51 PM UTC

Bringing this up for the WNW GB folks.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Sunday, December 05, 2010 - 05:37 PM UTC

Dave Watts has sent this along for those of us trying to pin down the variations of the late Mercedes inline six in 1918. This only concerns the early Fokker D.VII types and NOT the Albatros D.Va types of late 1917.

"Hi all . . .I was finally able to get to my records and dig out the information.

Thank you for getting me to look into this as I've been able to break out the D.IIIaŘ from the D.IIIa overall production. There are some overlapping of monthly production that I will only be able to break out from looking at each motor for that particular month, but I have the minimum of D.IIIa's and maximum of D.IIIaŘ's it could be for those months in question. The totals are not in question as once I identified the demarcation motor from D.IIIa to D.IIIaŘ I was able to extract those numbers from the order records made by Daimler showing the B.N./M.N. numbers on the "D.IIIa" sheets for all motors.

Daimler monthly production of the Mercedes D.IIIa/D.IIIaŘ for 1918.

January 428 (D.IIIa)

February 328 (D.IIIa)

March 283 (D.IIIa)

April 370 (min.200-D.IIIa/max.170-D.IIIaŘ)

May 405 (min.110-D.IIIa/max.295-D.IIIaŘ)

June 413 (min.22-D.IIIa/max.391-D.IIIaŘ)

July 498 (1-D.IIIa/497-D.IIIaŘ)

August 495 (D.IIIaŘ)

September 480 (D.IIIaŘ)

October 229 (D.IIIaŘ)

November 100 (D.IIIaŘ)

December 15 (D.IIIaŘ)

Total 4044 for 1918, = 1359 D.IIIa motors + 2685 D.IIIaŘ motors.

I can identify the introduction of the D.IIIaŘ. There were many changes that went into the D.IIIaŘ, including high compression pistons, (one of the biggest improvements).

The Řberverdichtete came in with B.N. 783, Motor Number 41300. These motors would have began to come off the line as early as the last week of April. There appears to be a slight drop off in D.IIIa production before May, (around March), so it may be true it slowed things down for a bit.

These first D.IIIaŘ motors were finding themselves accepted in D.VII airframes as early as May 10th, (M.N. 41412/D.VII 372/18). Only 14 D.VII aircraft were accepted in May with D.IIIaŘ motors, (from Fokker Schwerin).

May 10th, D.VII 372/18

May 17th, D.VII 398/18

May 23rd, D.VII 419/18

May 25th, D.VII 423/18

May 27th, D.VII 430/18

May 28th, D.VII 428/18

May 28th, D.VII 432/18

May 28th, D.VII 433/18

May 29th, D.VII 416/18

May 29th, D.VII 420/18

May 29th, D.VII 431/18

May 29th, D.VII 438/18

May 30th, D.VII 447/18

May 31st, D.VII 412/18

These aircraft would have gone to the Flug Park and then on to the Jastas, so it was no earlier than June before any quantity of the D.IIIaŘ powered D.VII types were in action at the front.

Hope that helps out with your question. That was fun!

Best,

Dave W."

Here is a bit of fun on the engines in the type.

"Hi all . . .I was finally able to get to my records and dig out the information.

Thank you for getting me to look into this as I've been able to break out the D.IIIaŘ from the D.IIIa overall production. There are some overlapping of monthly production that I will only be able to break out from looking at each motor for that particular month, but I have the minimum of D.IIIa's and maximum of D.IIIaŘ's it could be for those months in question. The totals are not in question as once I identified the demarcation motor from D.IIIa to D.IIIaŘ I was able to extract those numbers from the order records made by Daimler showing the B.N./M.N. numbers on the "D.IIIa" sheets for all motors.

Daimler monthly production of the Mercedes D.IIIa/D.IIIaŘ for 1918.

January 428 (D.IIIa)

February 328 (D.IIIa)

March 283 (D.IIIa)

April 370 (min.200-D.IIIa/max.170-D.IIIaŘ)

May 405 (min.110-D.IIIa/max.295-D.IIIaŘ)

June 413 (min.22-D.IIIa/max.391-D.IIIaŘ)

July 498 (1-D.IIIa/497-D.IIIaŘ)

August 495 (D.IIIaŘ)

September 480 (D.IIIaŘ)

October 229 (D.IIIaŘ)

November 100 (D.IIIaŘ)

December 15 (D.IIIaŘ)

Total 4044 for 1918, = 1359 D.IIIa motors + 2685 D.IIIaŘ motors.

I can identify the introduction of the D.IIIaŘ. There were many changes that went into the D.IIIaŘ, including high compression pistons, (one of the biggest improvements).

The Řberverdichtete came in with B.N. 783, Motor Number 41300. These motors would have began to come off the line as early as the last week of April. There appears to be a slight drop off in D.IIIa production before May, (around March), so it may be true it slowed things down for a bit.

These first D.IIIaŘ motors were finding themselves accepted in D.VII airframes as early as May 10th, (M.N. 41412/D.VII 372/18). Only 14 D.VII aircraft were accepted in May with D.IIIaŘ motors, (from Fokker Schwerin).

May 10th, D.VII 372/18

May 17th, D.VII 398/18

May 23rd, D.VII 419/18

May 25th, D.VII 423/18

May 27th, D.VII 430/18

May 28th, D.VII 428/18

May 28th, D.VII 432/18

May 28th, D.VII 433/18

May 29th, D.VII 416/18

May 29th, D.VII 420/18

May 29th, D.VII 431/18

May 29th, D.VII 438/18

May 30th, D.VII 447/18

May 31st, D.VII 412/18

These aircraft would have gone to the Flug Park and then on to the Jastas, so it was no earlier than June before any quantity of the D.IIIaŘ powered D.VII types were in action at the front.

Hope that helps out with your question. That was fun!

Best,

Dave W."

Here is a bit of fun on the engines in the type.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Wednesday, January 19, 2011 - 05:26 AM UTC

In a recent discussion another fellow and I hashed through some unique issues concerning the Mercedes D.IIIa vs the D.IIIaŘ.

Furthermore it is a 1919 decription of the type. The earliest we have.

Essentially we are dealing with the factory including the umlauts where possibly they don't belong and omitting them where they do? If we have the domed pistons in the late model 170hp That easily makes it a 180hp. Next we have the a or the aŘ designation. "a" is any thing over the 160hp basic motor that raises the horse power. "u" if for uber meaning over compressed. thats where the designation comes from.

But everyone seems to be good with the domed pistons being the primary method of describing the 180hp. Being over compressed still by definition makes it an "aŘ". That is what the quoted document is saying. For completeness "v" is for volume. The cylinder was lengthened to acquire more horse power without changing the piston size.

Quoted Text

Bill Gill says ". . .Daimler monthly production of the Mercedes D.IIIa/D.IIIaŘ for 1918.

January 428 (D.IIIa)

February 328 (D.IIIa)

March 283 (D.IIIa)

April 370 (min.200-D.IIIa/max.170-D.IIIaŘ)

May 405 (min.110-D.IIIa/max.295-D.IIIaŘ)

June 413 (min.22-D.IIIa/max.391-D.IIIaŘ)

July 498 (1-D.IIIa/497-D.IIIaŘ)

August 495 (D.IIIaŘ)

September 480 (D.IIIaŘ)

October 229 (D.IIIaŘ)

November 100 (D.IIIaŘ)

December 15 (D.IIIaŘ)

Total 4044 for 1918, = 1359 D.IIIa motors + 2685 D.IIIaŘ motors.

Which would indicate that D.IIIaŘ engines were produced until April 1918. . ."

Quoted Text

Dave Watts says ". . .The title of the three page document is "Gewichts - Aufnahme", or translated "Weights - Acceptance/Recorded).

The motor is listed as,

"des 160 PS VI Cyl. Flugmotors, Typ: 1466, D IIIaŘ, Best. Nr. 711/91, Motor-Nr. 37490, Bohrg. 140 mm, Hub 160 mm."

This easliy translates to;

"160 HP Six-cylinder aircraft motor, Type 1466, D IIIaŘ, Builder Group Number 711/(91st motor of 100), Motor Serial Number 37490, Bore. 140 mm, Stroke 160 mm."

I don't know why this motor is termed as a D.IIIaŘ, when it has the smaller 140 bore of the D.IIIa, and the Builder Group Number of 711 is earlier than the 773, (as I've deducted it to be for the D.IIIaŘ motor introduction). . ."

Furthermore it is a 1919 decription of the type. The earliest we have.

Essentially we are dealing with the factory including the umlauts where possibly they don't belong and omitting them where they do? If we have the domed pistons in the late model 170hp That easily makes it a 180hp. Next we have the a or the aŘ designation. "a" is any thing over the 160hp basic motor that raises the horse power. "u" if for uber meaning over compressed. thats where the designation comes from.

But everyone seems to be good with the domed pistons being the primary method of describing the 180hp. Being over compressed still by definition makes it an "aŘ". That is what the quoted document is saying. For completeness "v" is for volume. The cylinder was lengthened to acquire more horse power without changing the piston size.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Saturday, February 04, 2012 - 06:14 PM UTC

A bit of text for the development of the F1466.

The Mercedes D.III, or F1466 as it was known internally, was a six-cylinder, liquid cooled inline aircraft engine built by Daimler and used on a wide variety of German aircraft during World War I. The initial versions were introduced in 1914 at 120 - 160 hp, but a series of changes improved this to 170 hp in 1917, and 180 by mid-1918. These later models were used on almost all late-war German fighters, and its only real competition, the BMW III, was available only in very limited numbers. Compared to the Allied engines it faced, the D.III was generally outdated.

Like most inline engines of that era, it used a large aluminum crankcase as the main structural component, with separate cylinders made from steel bolted onto it. The technology for screwing a threaded cylinder of steel into an aluminum crankcase did not exist at that time. Jackets for cooling water covered the top 2/3 of the cylinder, feeding a radiator via connections at the back of the engine.

The D.III featured a rather prominent overhead cam operating the single intake and exhaust valves, powered by a shaft running up from the crankshaft at the rear of the engine. Ignition was provided by two sets of spark plugs, one located on either side of the cylinders, each powered by a separate magneto for redundancy. The ignition cables were protected in tubes running down either side of the cylinders. Fuel was fed into the cylinders via pipes on the left side of the engine as viewed from the rear, supplied from a twin-barrel carburetor located just above the crankcase. Both the fuel and oil reservoirs were pressurized by an air pump run off the crank, The only obvious design change from the earlier D.II was to use separate cooling jackets for each cylinder, whereas the D.II used one jacket for every two cylinders

The original D.III was introduced in 1914. It saw widespread use in 1915-1916 examples of the B & C series of German, two-seat general-purpose biplanes. The D.III did not see use in fighters until 1916 when the fighters grew to need that level of power to reach altitude and combat two seat aircraft of the enemy. By 1917 the D.III was being widely used in fighters, most notably on the famous Albatros D.I & D.II types. Production of these 160hp motors were essentially wound down by May 1917, with only a handful of the 160hp motors continuing to be delivered until October 1917 for use in unarmed trainer aircraft.

Continued development of the basic design led to the slightly modified 170hp D.IIIa, which took over on the production lines in June 1917. The main change was to change the piston profile to have a flat head instead of the former concave one, thereby slightly increasing maximum compression. Other changes were mainly in design details, notably a redesigned crankcase and new carburetor. Many of the accessories were also redesigned or moved around on the engine. One such visual change was to move the narrow upright air pump from the rear to the front of the motor. This model was produced and used from about summer to fall 1917. From early models through the late 170hp motors had rocker arms that operated the valves had square covers positioned directly over the cylinders with the rocker arms exiting through vertical slots cut into the sides of the boxes.

A more "radical" upgrade was the 180/200 hp D.IIIaŘ, introduced in late 1917, the D.IIIaŘ was a standardized refinement of the D.III and D.IIIa design and the Ř designation was never official. This engine changed the pistons again, this time to a domed profile that further increased the maximum compression ľ the Ř was for "Řber", meaning "overcompressed". Additionally, a new altitude-compensating carburetor was added, which improved performance at higher altitudes. To support operations at these altitudes, water from the radiator was used to heat the air intake and prevent icing in the carburetor. The ôaŘö model, which included upgraded / rebuilt D.III and D.IIIa engine blocks, was the most prolific German fighter engine of 1918 and designed into most fighter designs from late 1917 on. This included most of the entries in the First Fighter Competition at Adlershof in January 1918, notably the famed Fokker D.VII.

In this version of the engine, the boxes covering the rocker arms that operated the valves were moved rearward and the cylindrical rocker arm shafts protruded forwards through the front surfaces of the boxes, operating the now fully exposed rocker arms with the exposed shaft ends. The newer arrangement were stated as being interchangeable as a set with the complete camshaft, rocker boxes, rocker arms and valve springs, with the D.III's earlier cam drive system design. Also the air pump was now thicker in profile. Late in May 1918 a flat profile dual air pump was developed and seen on many of the up and coming Fokker D.VII types.

In British post war evaluations the D.IIIaŘ 180hp fresh from the factory floor demonstrated 200hp according to the British standards. The British manuals we have seen are from this time.

A final version attempting to keep the D.III block competitive was the 200 hp (200-217hp) D.IIIav(or avŘ in some references), introduced mid-October 1918. The ôavö used slightly longer pistons made of aluminum (possibly a first for a production engine), increasing the compression yet again, while at the same time allowing them to move faster due to the reduced weight. The maximum allowable RPM increased from 1,400 in the earlier models to 1,600 in the ôavö type. This accounted for most of the gains in power. It is unclear if any av's saw service use. The increased use of Benzine in German aviation fuel may have helped this final upgrade of power, the higher octane rating being better suited for the higher compression ratio.

Confusingly, the "Ř" was not an official part of the name. This leads to a number of problems in various references, which often confuse the IIIa with the IIIaŘ, listing the former as a 180 hp engine. It should also be noted that there are two D.IV engines, one the 220-240hp eight-cylinder based on the D.III pistons, and the later six-cylinder D.IVa 260hp which was essentially unrelated as it was a bigger over all motor. (Highly Modified by me from Wikipedia effort.)

Here is a bit of fun on the engines in the type.

The Mercedes D.III, or F1466 as it was known internally, was a six-cylinder, liquid cooled inline aircraft engine built by Daimler and used on a wide variety of German aircraft during World War I. The initial versions were introduced in 1914 at 120 - 160 hp, but a series of changes improved this to 170 hp in 1917, and 180 by mid-1918. These later models were used on almost all late-war German fighters, and its only real competition, the BMW III, was available only in very limited numbers. Compared to the Allied engines it faced, the D.III was generally outdated.

Like most inline engines of that era, it used a large aluminum crankcase as the main structural component, with separate cylinders made from steel bolted onto it. The technology for screwing a threaded cylinder of steel into an aluminum crankcase did not exist at that time. Jackets for cooling water covered the top 2/3 of the cylinder, feeding a radiator via connections at the back of the engine.

The D.III featured a rather prominent overhead cam operating the single intake and exhaust valves, powered by a shaft running up from the crankshaft at the rear of the engine. Ignition was provided by two sets of spark plugs, one located on either side of the cylinders, each powered by a separate magneto for redundancy. The ignition cables were protected in tubes running down either side of the cylinders. Fuel was fed into the cylinders via pipes on the left side of the engine as viewed from the rear, supplied from a twin-barrel carburetor located just above the crankcase. Both the fuel and oil reservoirs were pressurized by an air pump run off the crank, The only obvious design change from the earlier D.II was to use separate cooling jackets for each cylinder, whereas the D.II used one jacket for every two cylinders

The original D.III was introduced in 1914. It saw widespread use in 1915-1916 examples of the B & C series of German, two-seat general-purpose biplanes. The D.III did not see use in fighters until 1916 when the fighters grew to need that level of power to reach altitude and combat two seat aircraft of the enemy. By 1917 the D.III was being widely used in fighters, most notably on the famous Albatros D.I & D.II types. Production of these 160hp motors were essentially wound down by May 1917, with only a handful of the 160hp motors continuing to be delivered until October 1917 for use in unarmed trainer aircraft.

Continued development of the basic design led to the slightly modified 170hp D.IIIa, which took over on the production lines in June 1917. The main change was to change the piston profile to have a flat head instead of the former concave one, thereby slightly increasing maximum compression. Other changes were mainly in design details, notably a redesigned crankcase and new carburetor. Many of the accessories were also redesigned or moved around on the engine. One such visual change was to move the narrow upright air pump from the rear to the front of the motor. This model was produced and used from about summer to fall 1917. From early models through the late 170hp motors had rocker arms that operated the valves had square covers positioned directly over the cylinders with the rocker arms exiting through vertical slots cut into the sides of the boxes.

A more "radical" upgrade was the 180/200 hp D.IIIaŘ, introduced in late 1917, the D.IIIaŘ was a standardized refinement of the D.III and D.IIIa design and the Ř designation was never official. This engine changed the pistons again, this time to a domed profile that further increased the maximum compression ľ the Ř was for "Řber", meaning "overcompressed". Additionally, a new altitude-compensating carburetor was added, which improved performance at higher altitudes. To support operations at these altitudes, water from the radiator was used to heat the air intake and prevent icing in the carburetor. The ôaŘö model, which included upgraded / rebuilt D.III and D.IIIa engine blocks, was the most prolific German fighter engine of 1918 and designed into most fighter designs from late 1917 on. This included most of the entries in the First Fighter Competition at Adlershof in January 1918, notably the famed Fokker D.VII.

In this version of the engine, the boxes covering the rocker arms that operated the valves were moved rearward and the cylindrical rocker arm shafts protruded forwards through the front surfaces of the boxes, operating the now fully exposed rocker arms with the exposed shaft ends. The newer arrangement were stated as being interchangeable as a set with the complete camshaft, rocker boxes, rocker arms and valve springs, with the D.III's earlier cam drive system design. Also the air pump was now thicker in profile. Late in May 1918 a flat profile dual air pump was developed and seen on many of the up and coming Fokker D.VII types.

In British post war evaluations the D.IIIaŘ 180hp fresh from the factory floor demonstrated 200hp according to the British standards. The British manuals we have seen are from this time.

A final version attempting to keep the D.III block competitive was the 200 hp (200-217hp) D.IIIav(or avŘ in some references), introduced mid-October 1918. The ôavö used slightly longer pistons made of aluminum (possibly a first for a production engine), increasing the compression yet again, while at the same time allowing them to move faster due to the reduced weight. The maximum allowable RPM increased from 1,400 in the earlier models to 1,600 in the ôavö type. This accounted for most of the gains in power. It is unclear if any av's saw service use. The increased use of Benzine in German aviation fuel may have helped this final upgrade of power, the higher octane rating being better suited for the higher compression ratio.

Confusingly, the "Ř" was not an official part of the name. This leads to a number of problems in various references, which often confuse the IIIa with the IIIaŘ, listing the former as a 180 hp engine. It should also be noted that there are two D.IV engines, one the 220-240hp eight-cylinder based on the D.III pistons, and the later six-cylinder D.IVa 260hp which was essentially unrelated as it was a bigger over all motor. (Highly Modified by me from Wikipedia effort.)

Here is a bit of fun on the engines in the type.

J99Hasso

Joined: March 06, 2012

KitMaker: 5 posts

AeroScale: 4 posts

Posted: Tuesday, March 06, 2012 - 09:53 AM UTC

Hi, could you please tell me the source of infomation about the production and use Mercedes D III and D IIIa engine?

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Tuesday, March 06, 2012 - 10:21 AM UTC

Myself and several other research fiends pulled this information together. Including Dave Watts one of the few people actually licensed by Daimler to rebuild the F1466 & F1466a. That is his motor in the color image below.

J99Hasso

Joined: March 06, 2012

KitMaker: 5 posts

AeroScale: 4 posts

Posted: Tuesday, March 06, 2012 - 10:30 AM UTC

Thank you for your quick response and information. We are also seeking infomation and we lack evidence, when each motor (D III and D IIIa) was eingbaut in which machine.

JackFlash

Joined: January 25, 2004

KitMaker: 11,669 posts

AeroScale: 11,011 posts

Posted: Tuesday, March 06, 2012 - 10:42 AM UTC

As I mentioned in he Halberstadt thread you should find at least half of what you want in the Daimler factory archives. We are still searching for answers by the way.

|