Merci de m'avoir ramené ŕ la maison. . . (Thanks for bringing me home)

Greetings All!

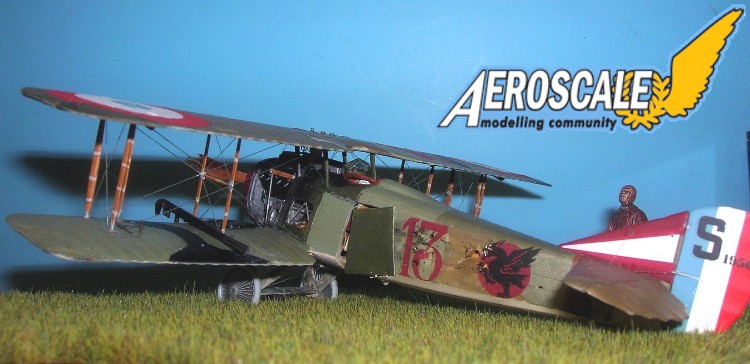

In recent weeks I have been doing a bit of research, backdating and detailing a DML / Dragon Spad XIII to an early model version with round wing tips. Since there were several RFC units to have the type I thought I might post some comments while I await the first images to be returned from the photolab.

Please note that I have included on this build brass parts from Tom’s Modelworks ply pockets for the early round tipped Spad XIII types. The following is an excerpt from recent correspondence with Mr. Alan Toelle. He is probably the finest authority on the French 5 colour camouflage extant. Also he knows the Spad XIII from rudder to prop boss. Mr. Toelle’s lifetime studies into various licensed built Spad XIII types and the layout of their cockpits are a ‘must-read’ to the builder/ researcher/ devotee.

"...Mr. Carrick’s drawings of the Spad XIII (the basis for the DML Spad XIII, STL) are in my opinion very accurate - as accurate as they can be at that scale. He did a very conscientious job and knew a lot about the subject..."

"...I provided him with quite a bit of information and we talked over some issues. The wing tips, however should not show the airfoil when viewed from the end as the spars turned down near the ends and the tip bow was flat in the plane of the leading and trailing edge - as a dinner plate laid upside down..."

"...As for the subject [Hangar Queens] Spad XIII types were all Hangar Queens, relatively speaking. They were reported out of service more than 30% of the time on average. Motor replacement was very common but they had all kinds of other maintenance problems aside from damage due to operations. A good example is Joe Eastman’s Spad XIII S.15006 (Squadron Aircraft) #19 of the 94th Aero Squadron. The following are extracts from Eastman’s diary:..."

"...July 24,(1918): My Spad after five changes of oil pumps, was again given me to make a practice flight this morning in preparation for the regular patrol at 15:00 this afternoon. I no more than cleared it off the field when something - a connecting rod - broke - smoke blew into the pit, the entire plane shook with vibration, and I was barely able to regain the field again without accident. This was my lot after nearly a week in fussing with the tub (aircraft). Rankin at luncheon told me to take (Squadron Aircraft)#10, which he said was in good condition. Later I learned it was the machine that (Lts.) Coolidge and Sherry has unsuccessfully attempted to use. I went out to it and found it still in the process of repair. I waited until time for the patrol and learned in that time further of its disquieting departure from a machine in good condition. The motor is an unheard - of make; (?) The throttles are offset and require a new technique in manipulation; its gas thumb lever needed a pair of pliers to move; and neither guns nor sights had ever been tested. Although my habitual appearance is one of cow-like docility and temperamental imperviousness. I left the ground in a state of mind that jumps out of a chair when a door is closed above a whisper. After two minutes in the air, I began to gather the evidence of my switchboard (Instrument Panel.) Both the air and oil pressures were less than half the normal figure - and the important little temperature hand was doing a comedy skit in the region of 105 degrees or 25 degrees hotter than is conducive to successful flying. A few minute spent hopefully in pursuit of the patrol failed to influence the gauges for the better. I piqued (a sharp roll with wings at near vertical) for the field and instead of the temperature cooling it continued to augment in its own cheery fashion. The motor stopped firing over Coulommiers, struggled to life, coughed, missed and revolved feebly by turns letting me down nearer and nearer to an unpromising landscape - which by the grace of GOD, I was enabled to clear...Plane #10 received a new motor..."

"...On 28 July (Eastman again tested his own plane #19): My plane is still in the hospital this morning. I would have taken it to the range, but on testing the motor could throttle no more than 900 RPM - so I look forward to trying the guns and a flight this afternoon..."

"...29 July: Motor troubles still beset my can (aircraft.) In the vain hope that it might have changed its mind, I took it for a tour of the field, but was drenched by overheated water as before. The mechanics, with whose business I’m daily growing more acquainted, are changing the radiator. These planes are certainly causing a lot of trouble as compared to the 28's (Nieuport types) which were at least simple to keep on the line.’

"...10 August: My motor still knocks and vibrates which I hope can be remedied. Spark plugs, I hope..."

"...13 August: My plane developed trouble on patrol...the motor was knocking and the oil no longer passed through the glass (gauge.) At that instant there was the gentle rap of a broken connecting rod on its way through the casting and I could go no further..."

"...7 September: It seems that no day is complete without some remark on motors. At supper it was said that the Hispano 220 is valued at $5,000.00. And after today I’m ready to send my sixth, I believe it is, back to the shops, each having an average life of say seven hours flying!...In order to give me an opportunity to test out my fancied troubles, Thorne sent me above on the field patrol last evening, although knocking like mischief, she carried one up to 4,000 meters...Thanks to these interminable annoyances. I’ve several times come to the point where I could hardly trust myself to declare faulty on the ground what I’ve been positive of in the air. Today as the Captain seemed dubious of my report - I had (Lt.) Jeffers try my bus (aircraft) out; but he was glad to regain the field after making a half turn in it. Steam was shooting off the top a foot high..."

"...And so it went. In a period (discussed) of 75 days, plane # 19 (S.15006) had three motor replacements and was reported as unserviceable on 38 days, which is 50.7% of the time! In addition, it had two forced landings at which point it was condemned.. Alan Toelle"