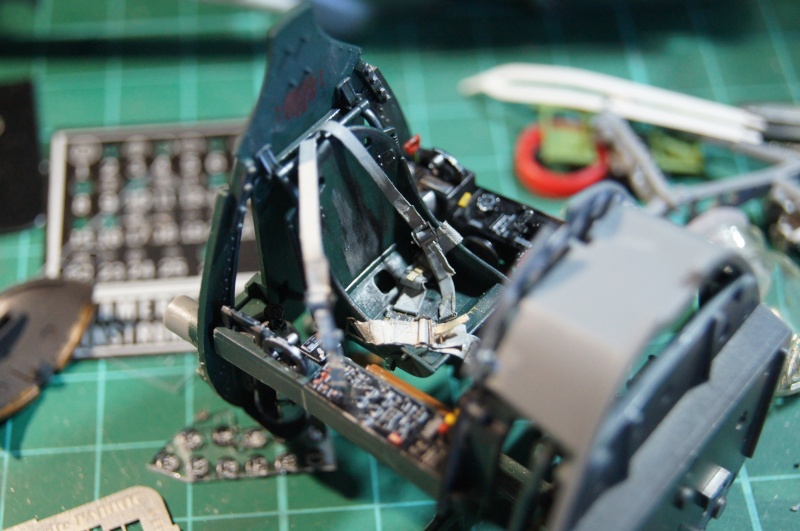

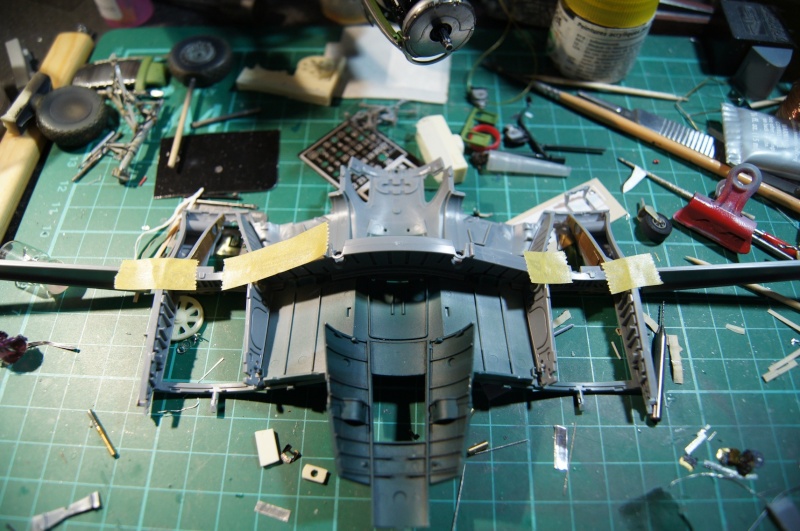

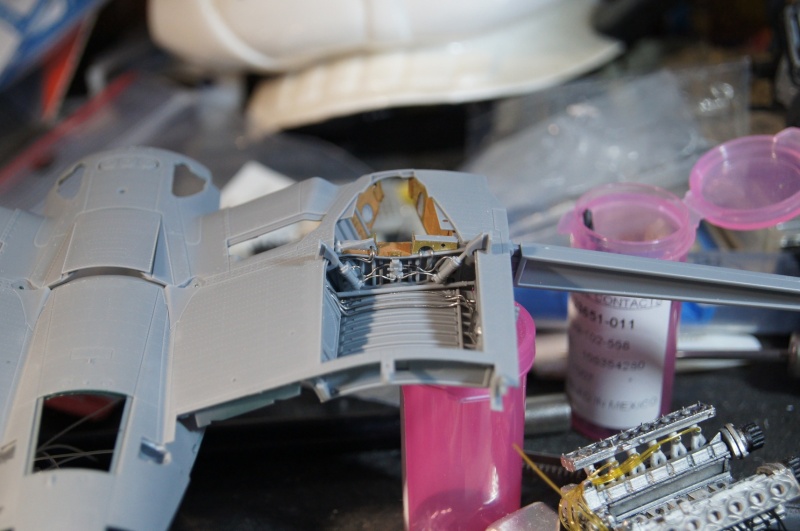

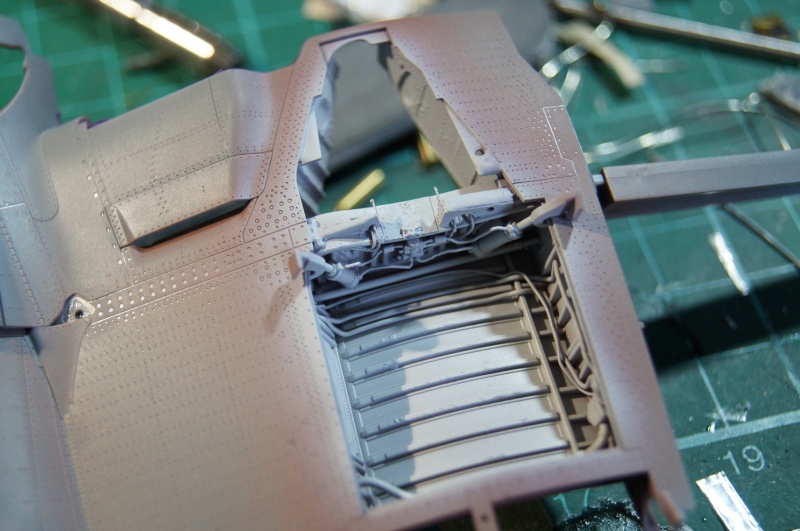

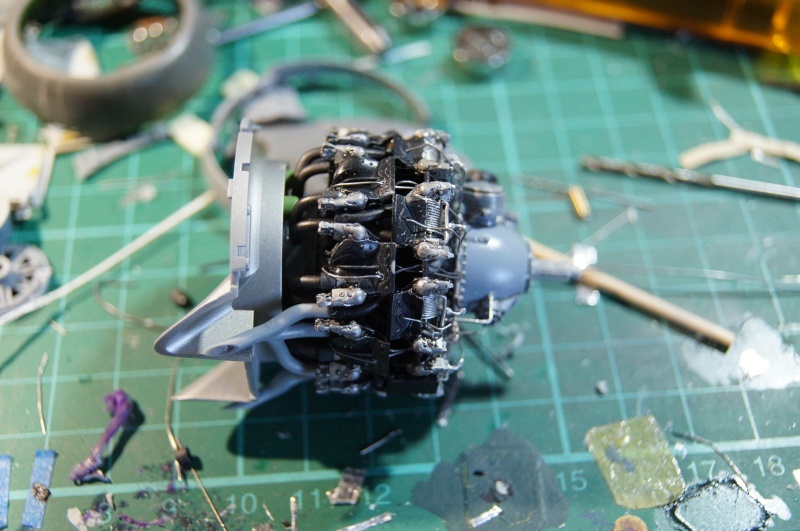

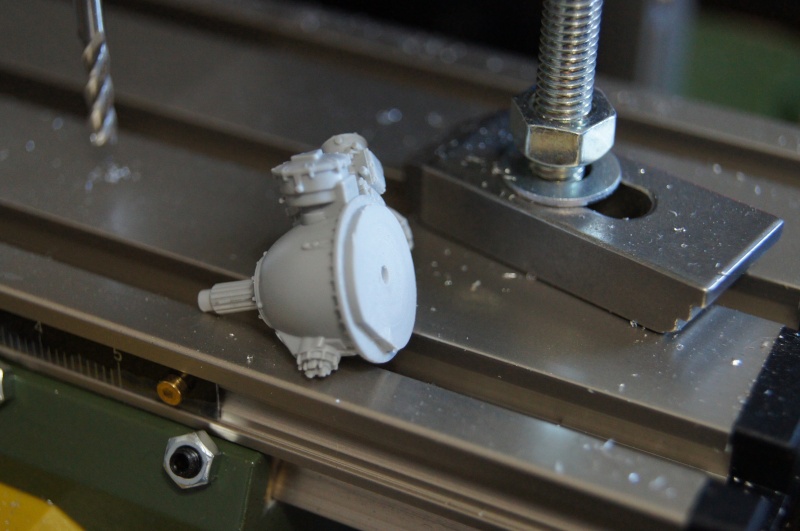

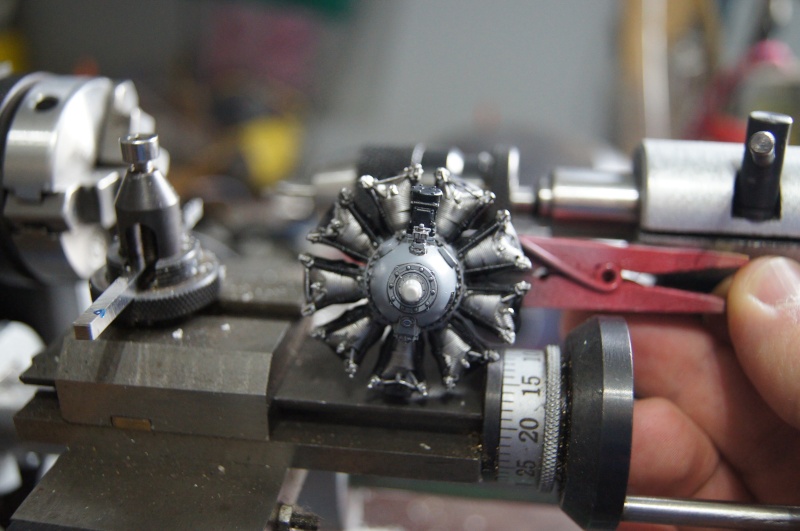

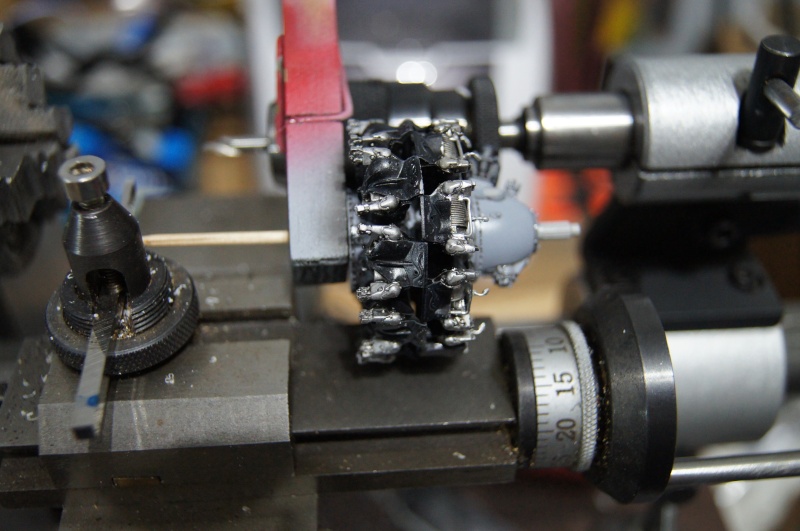

I recently started to work on the Pratt and Whitney R-2800 resin kit from Brassin, to add details to the 1/32 Tam Corsair.

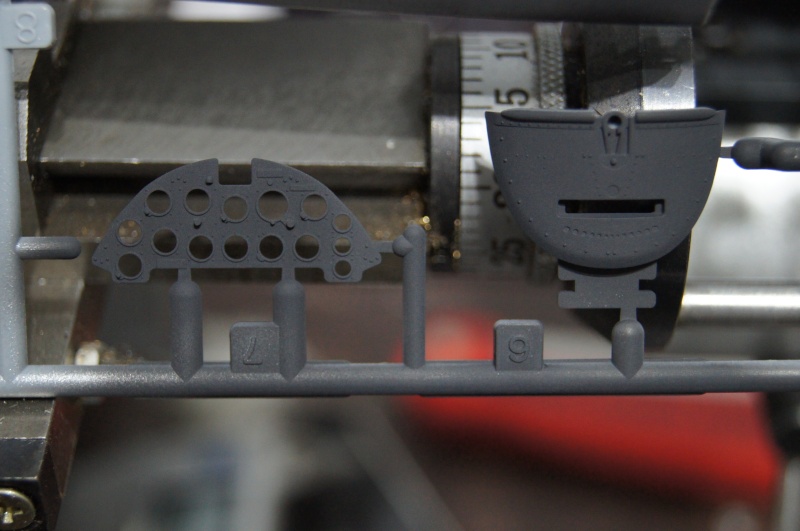

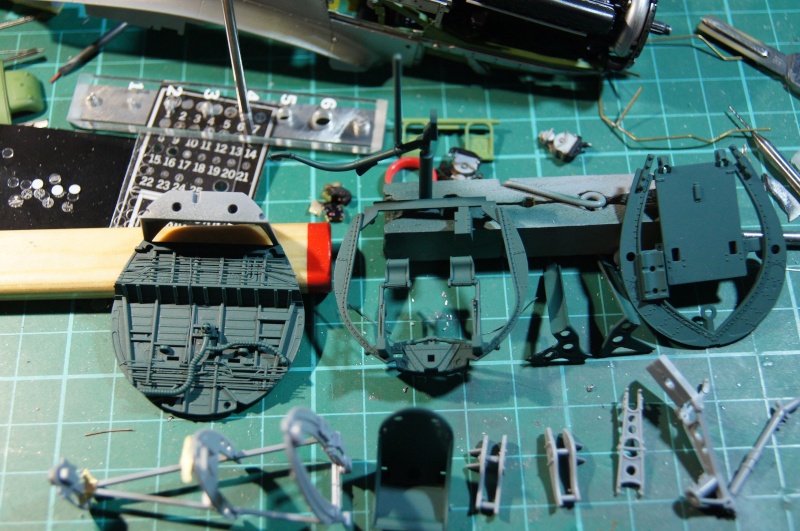

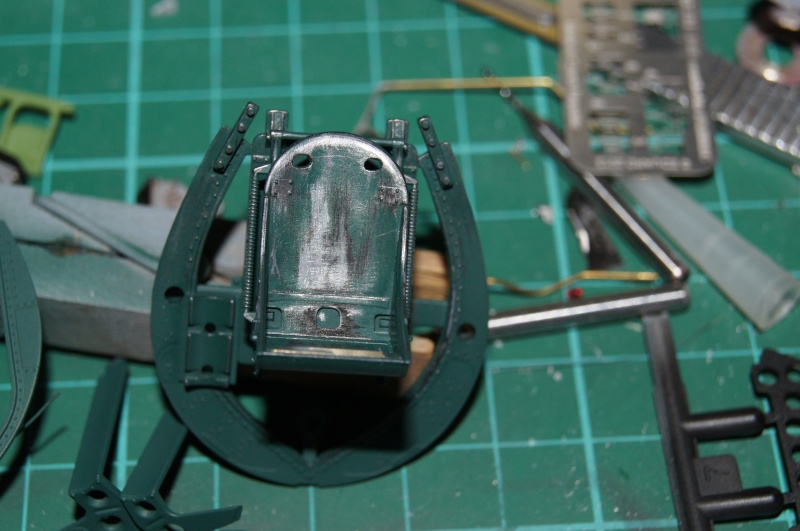

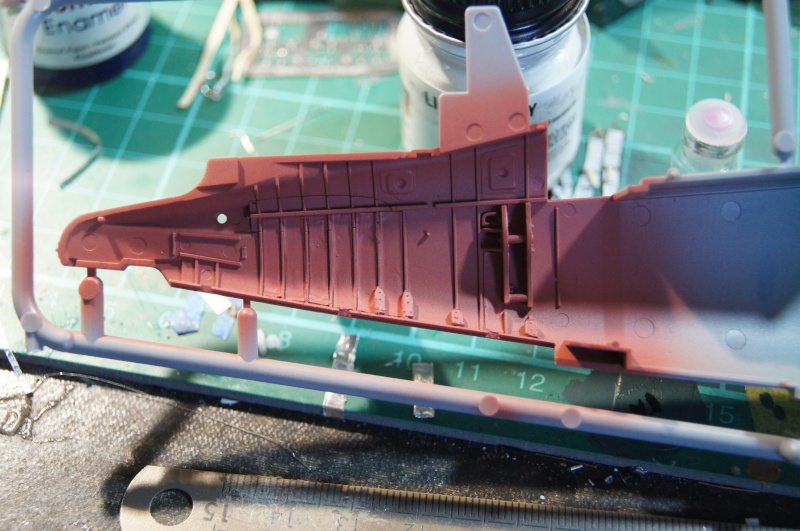

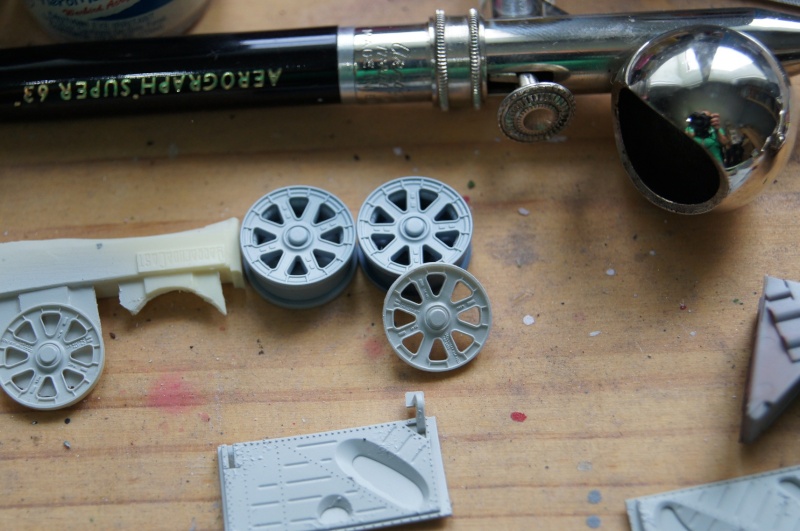

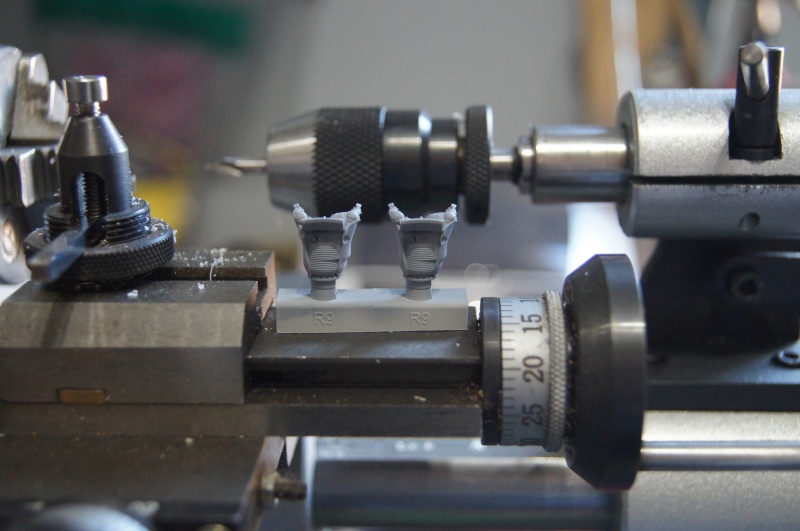

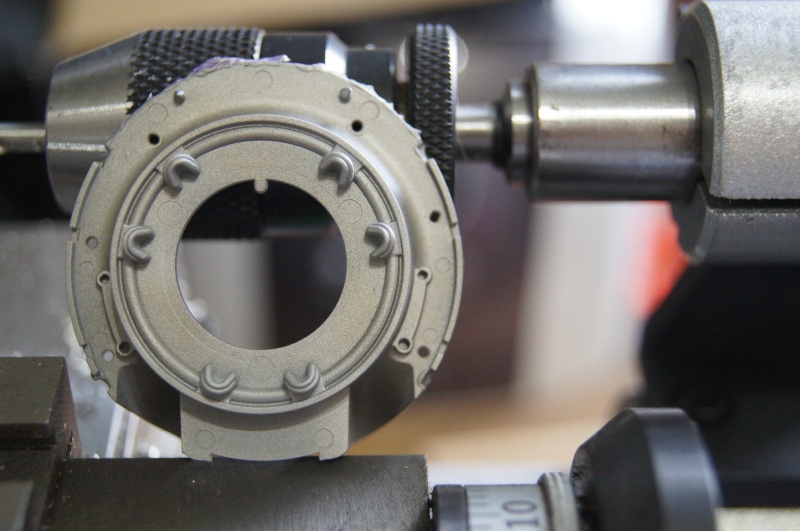

Parts cut from the resin sprue.

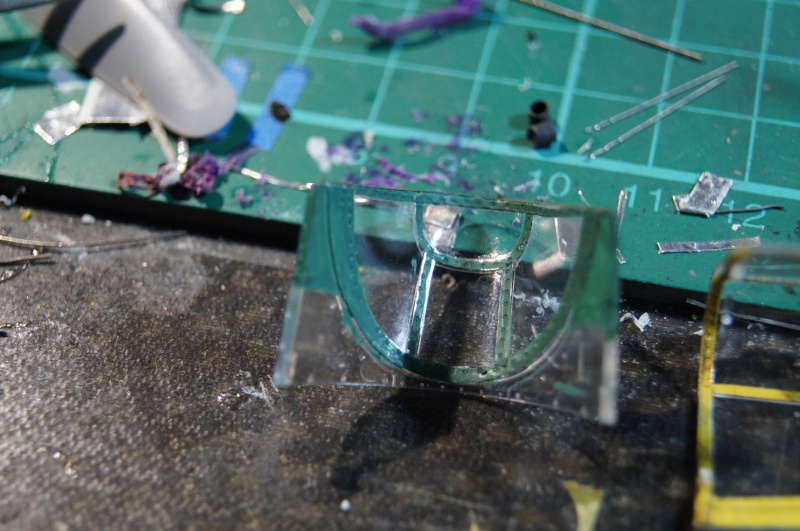

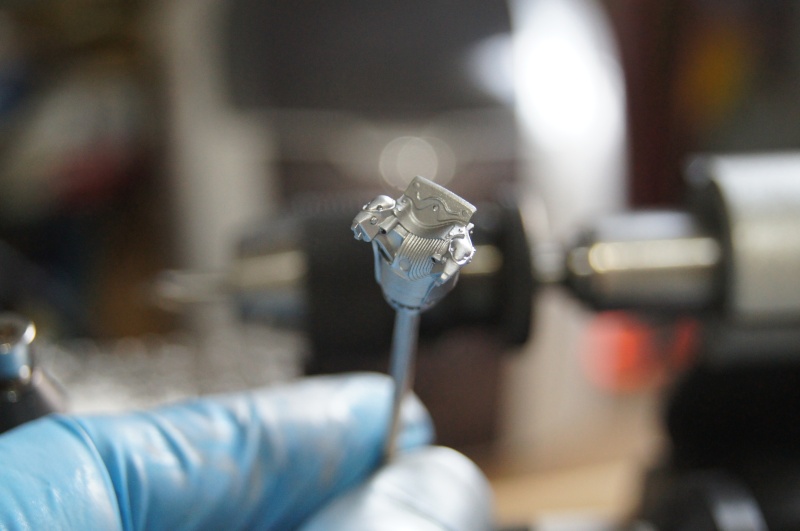

Some parts:

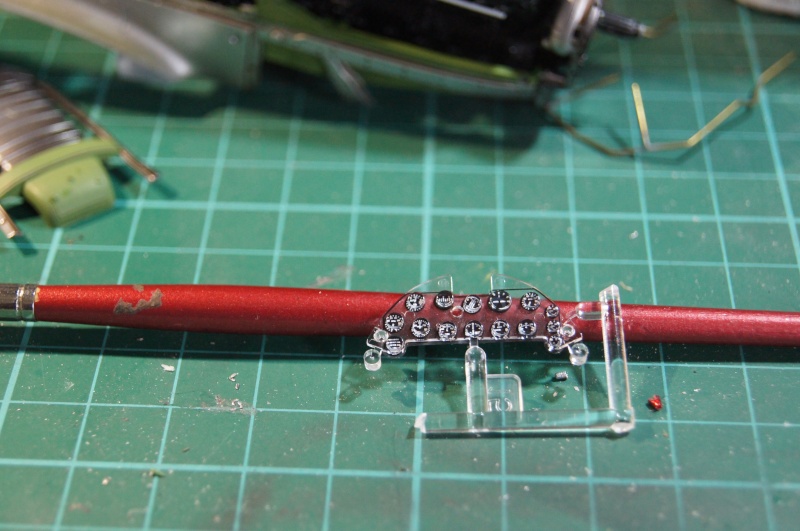

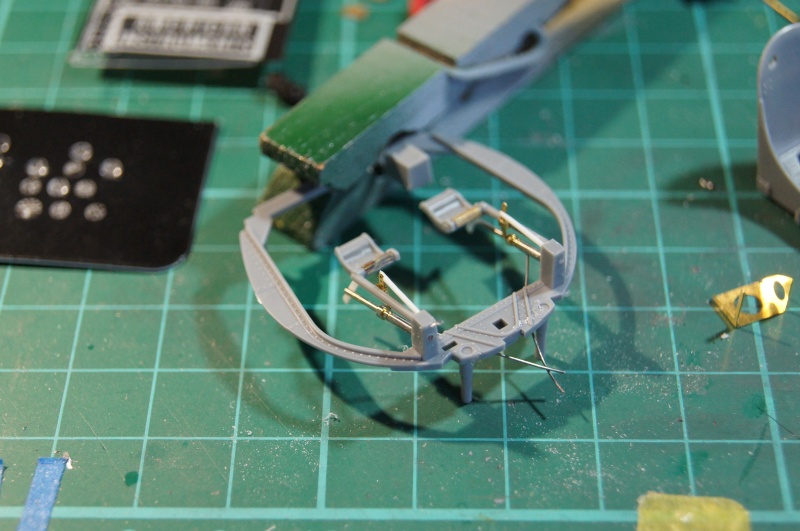

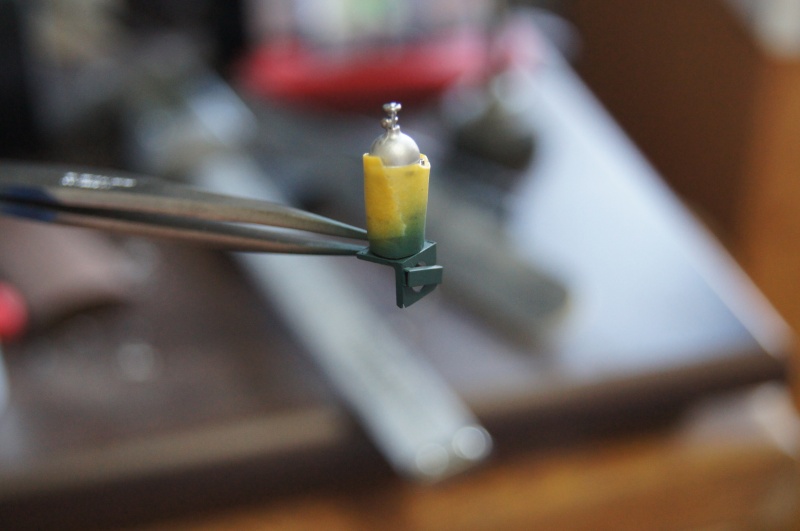

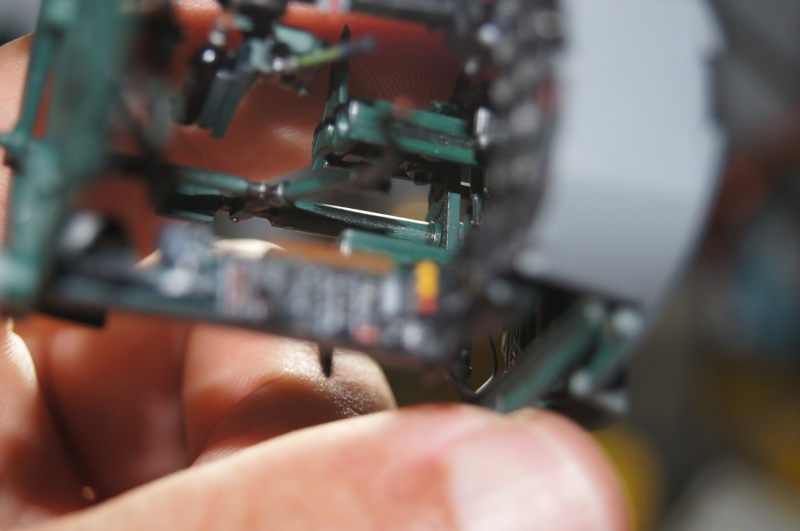

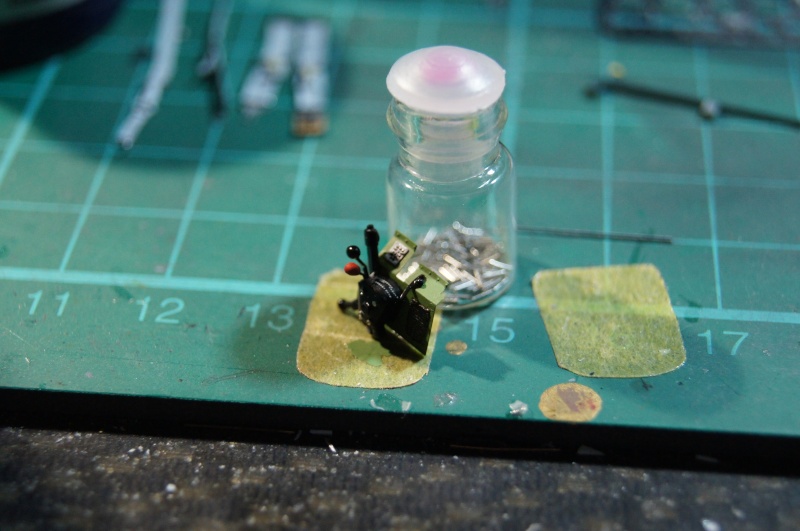

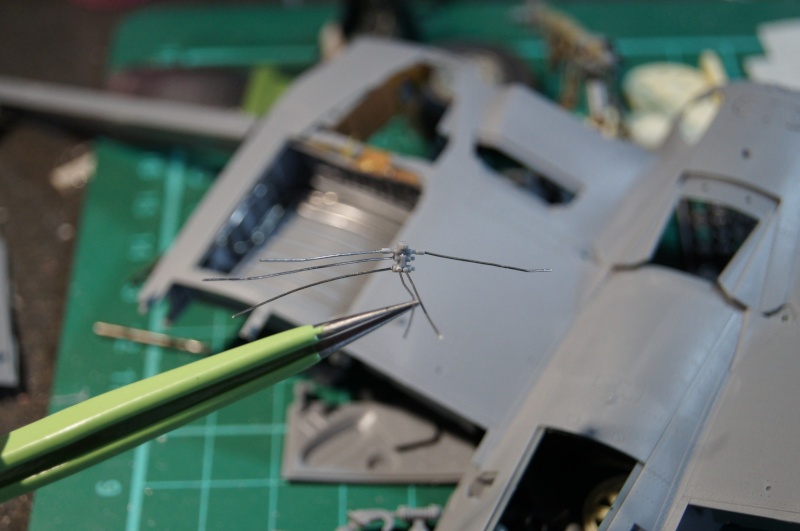

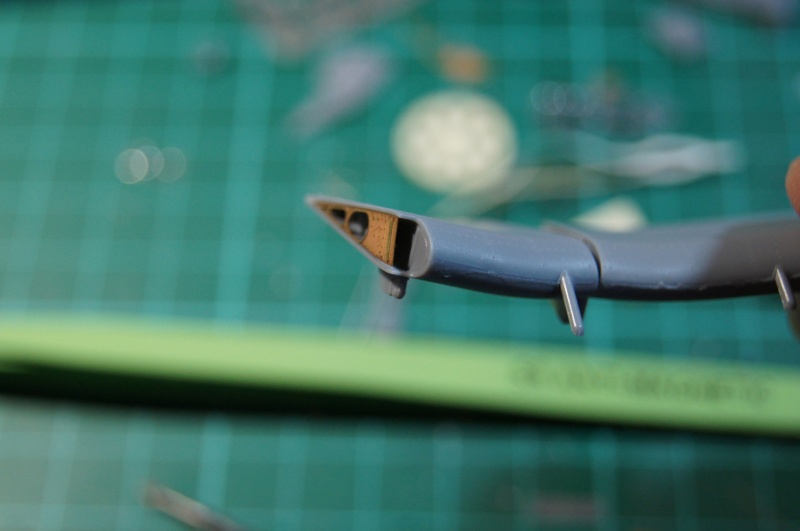

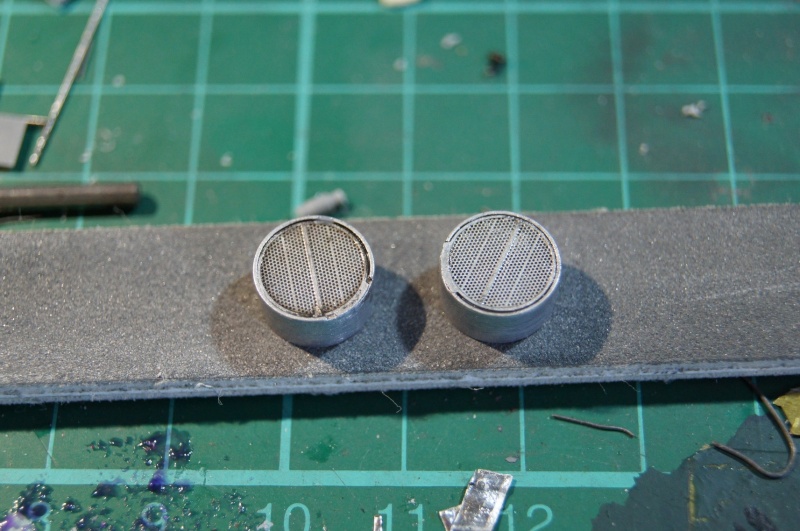

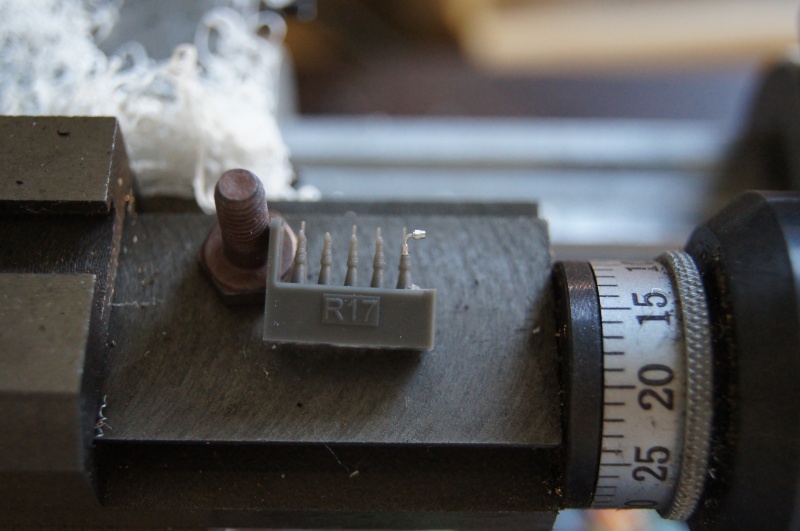

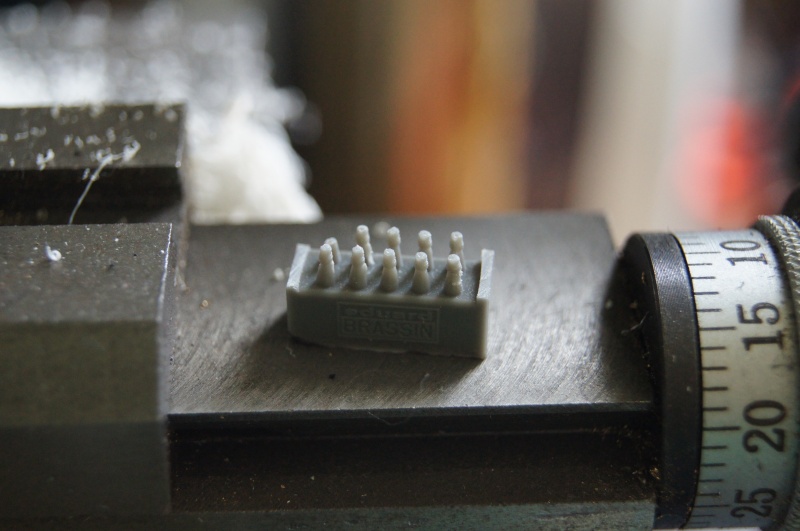

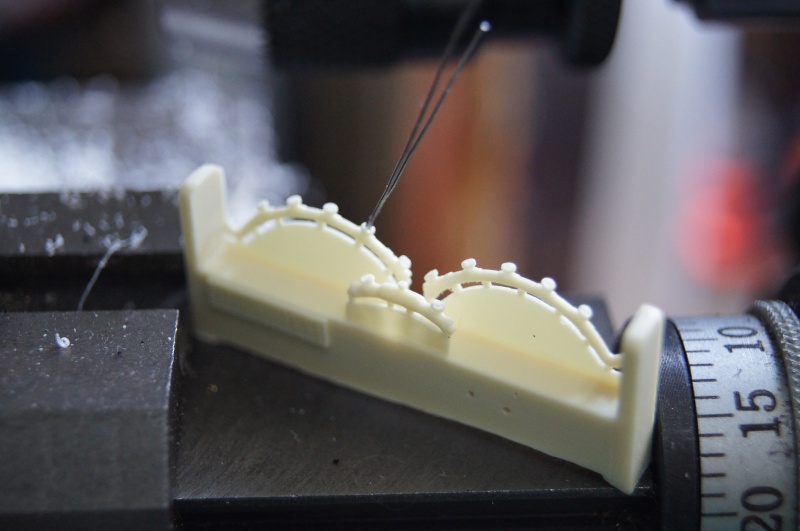

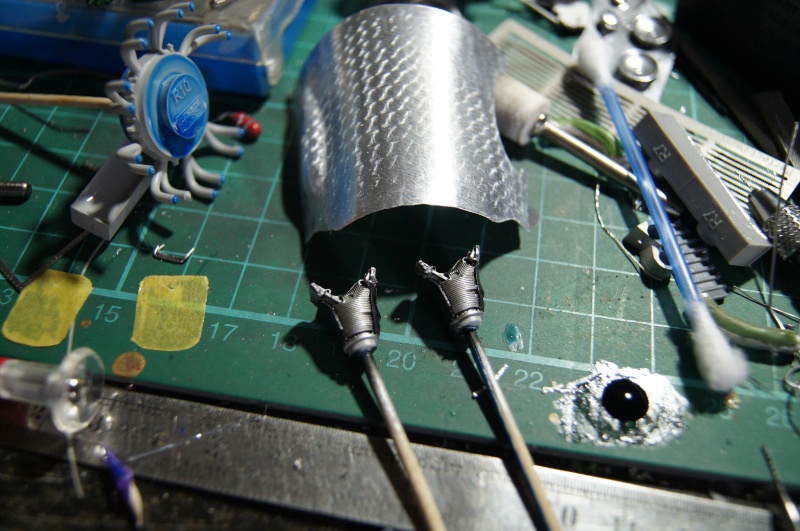

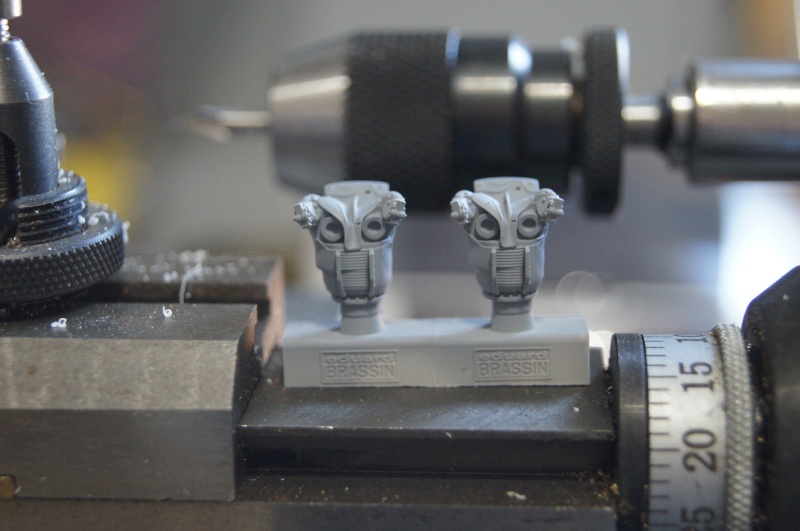

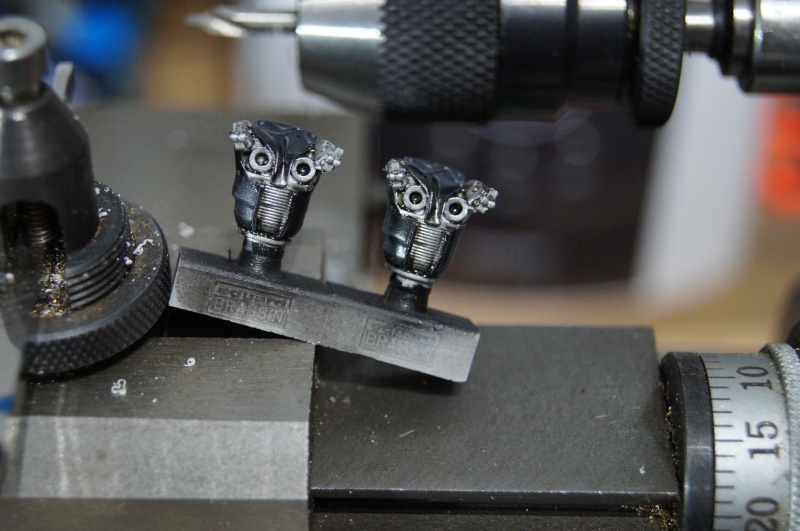

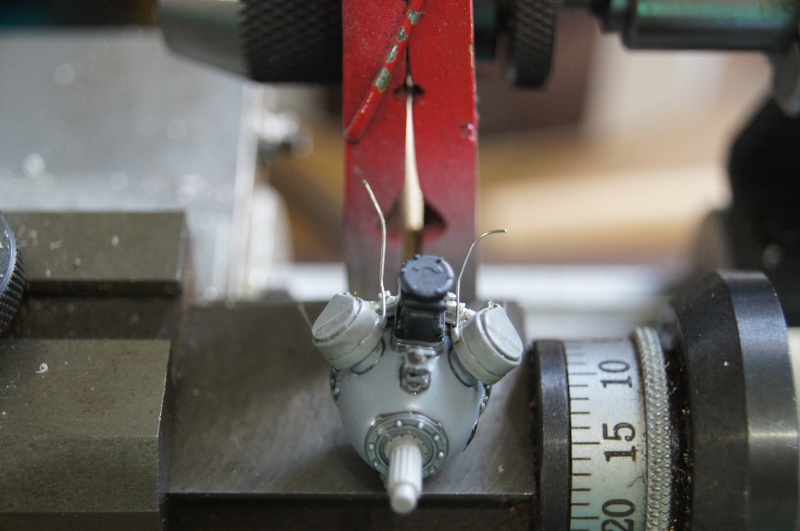

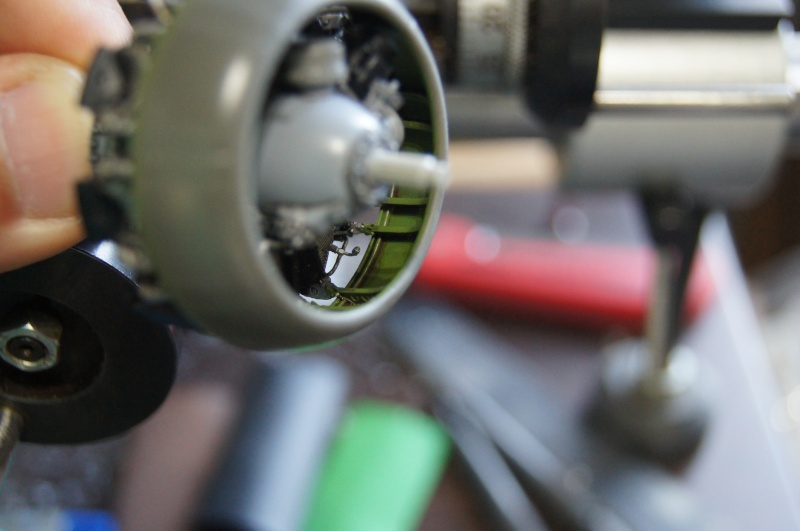

Original spark plugs are not bad, but... details can be added.

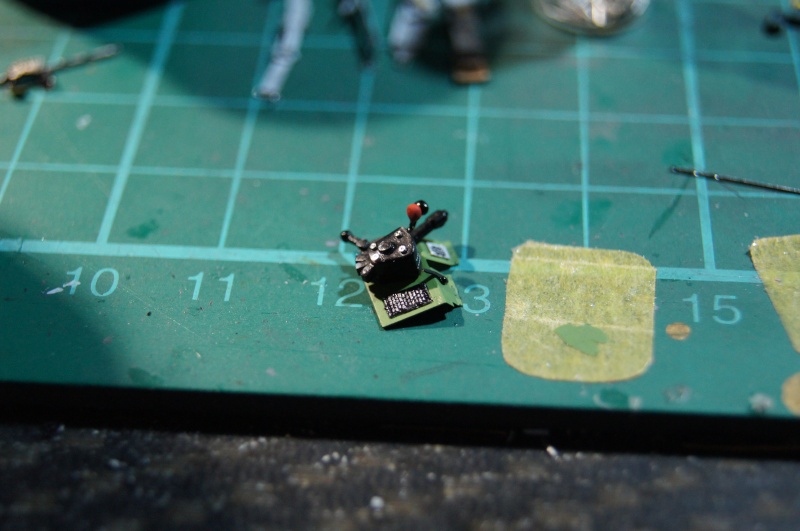

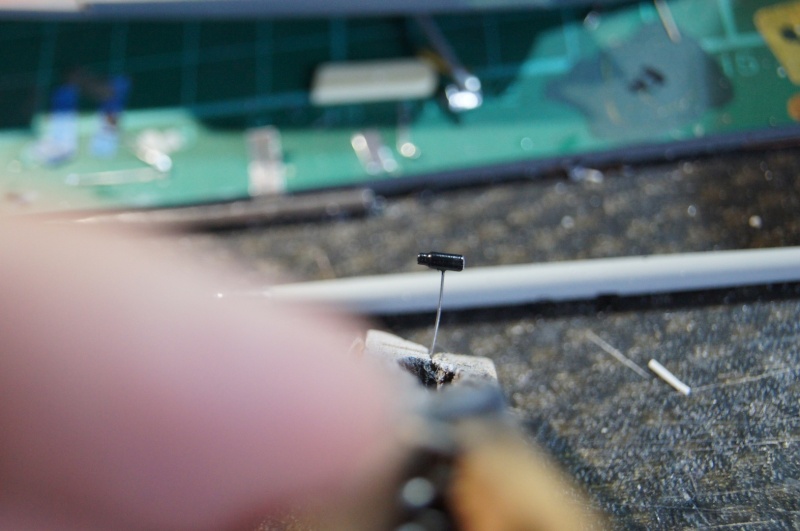

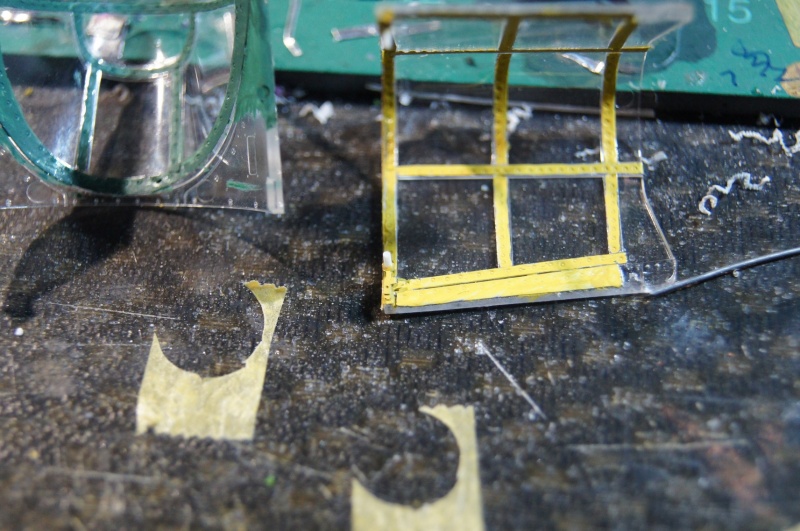

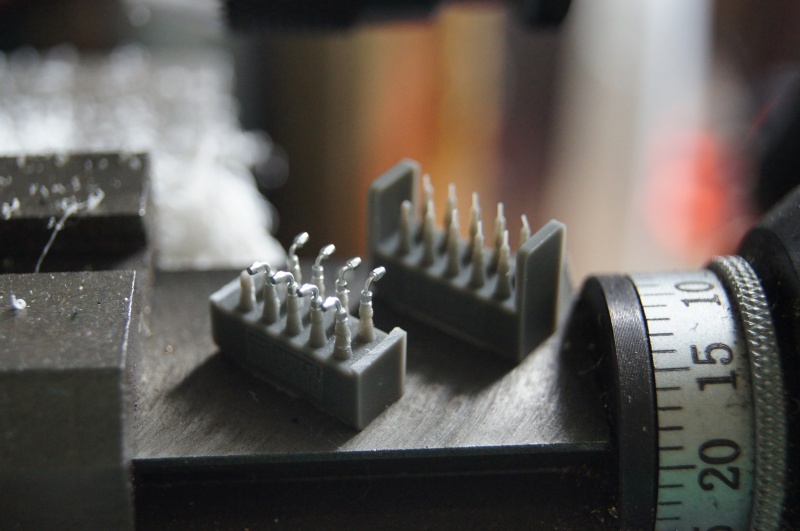

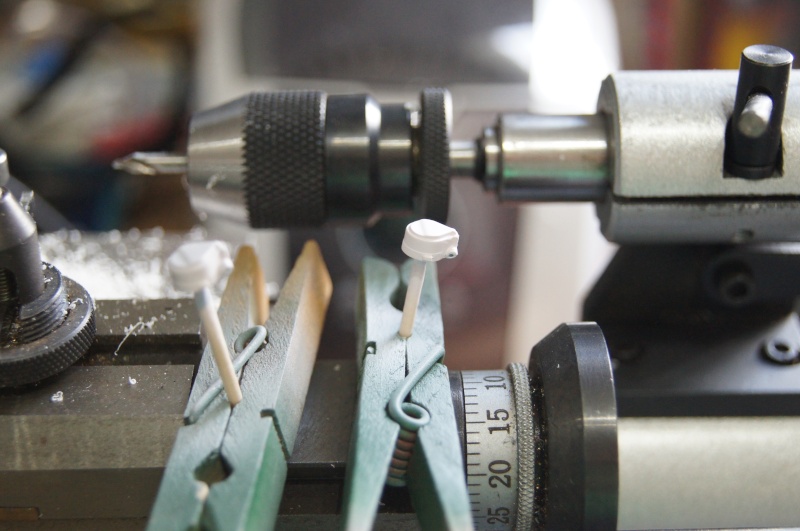

New connector.

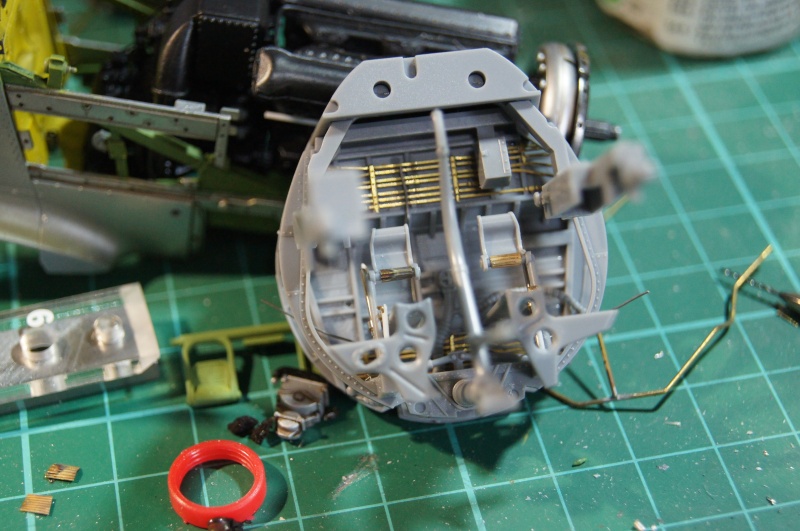

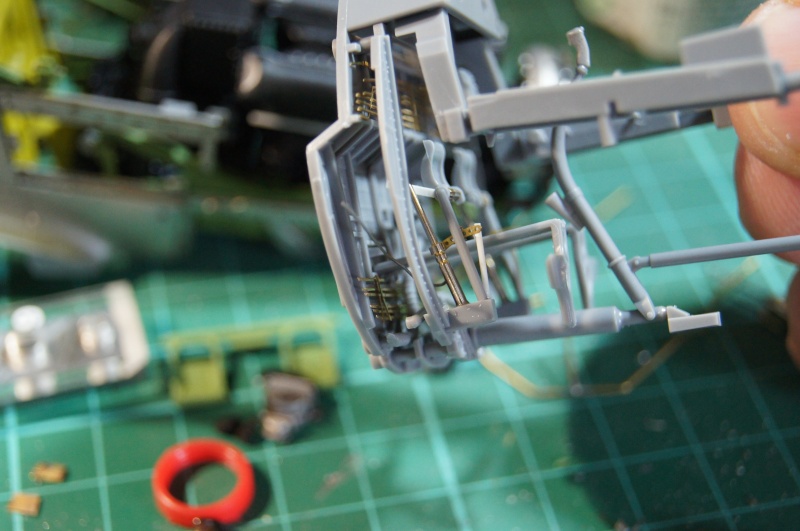

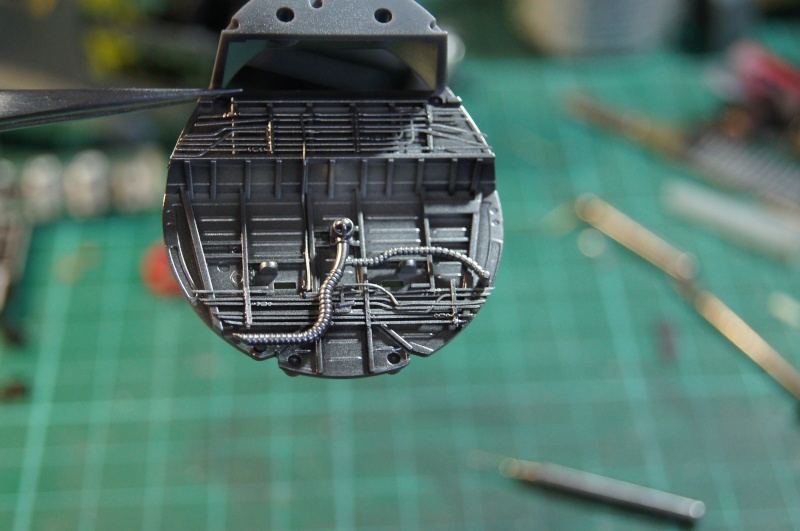

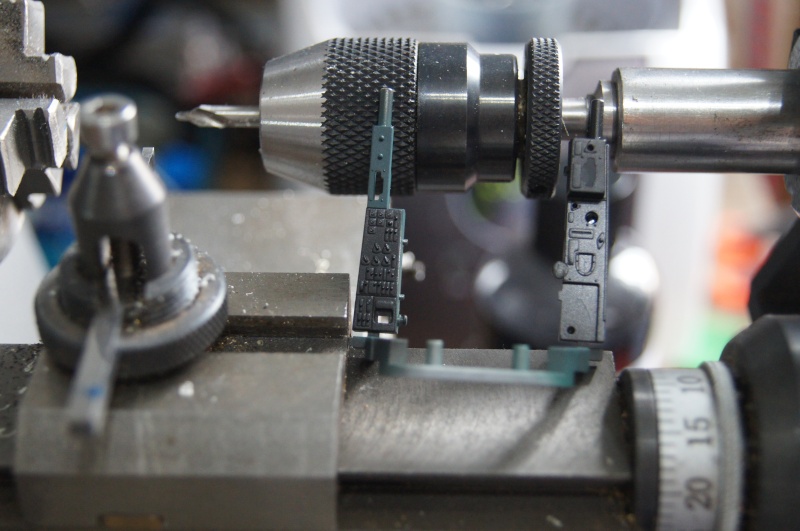

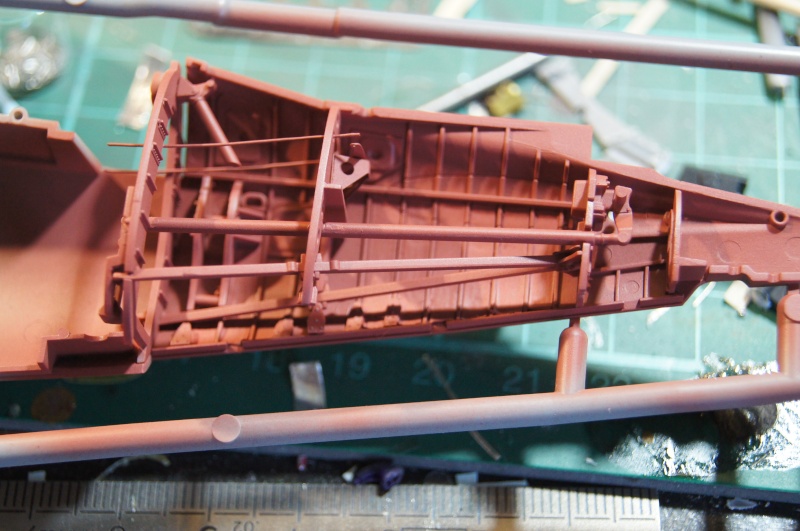

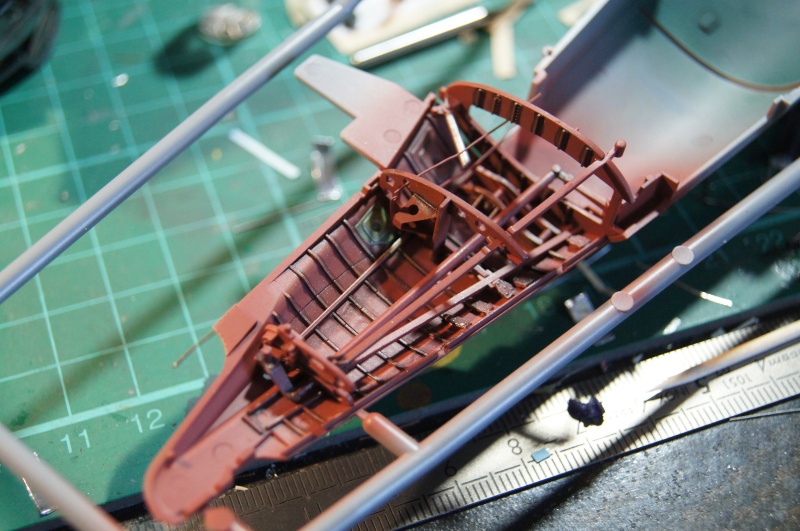

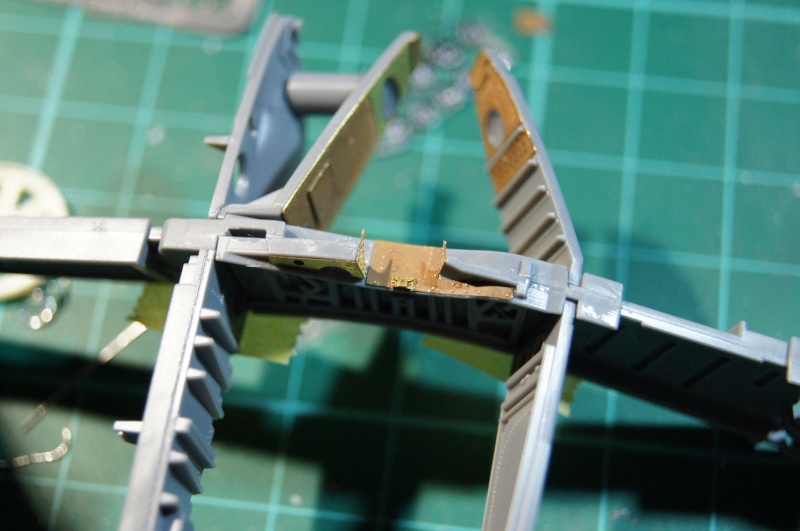

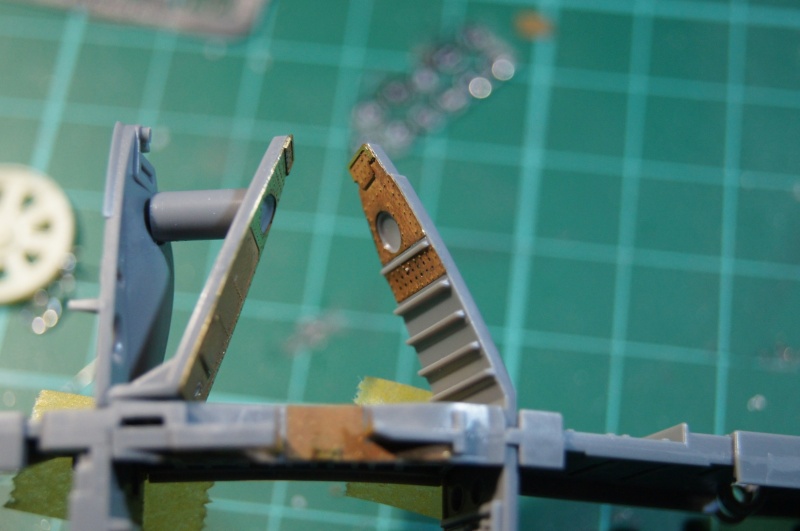

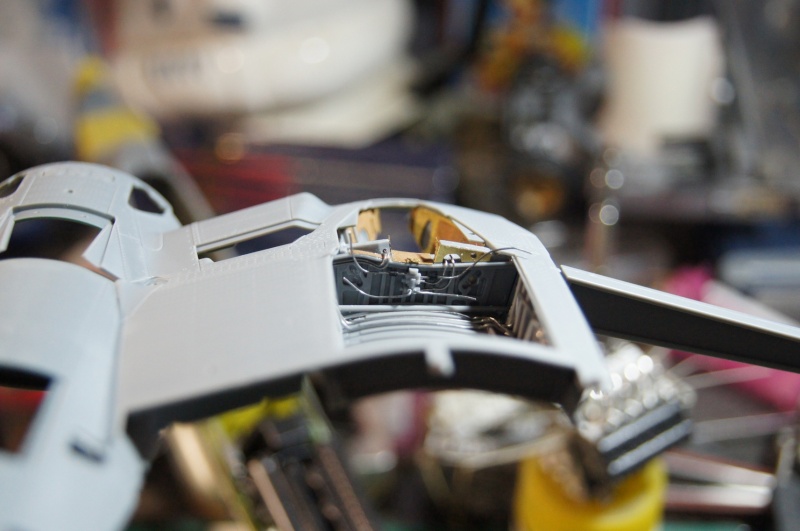

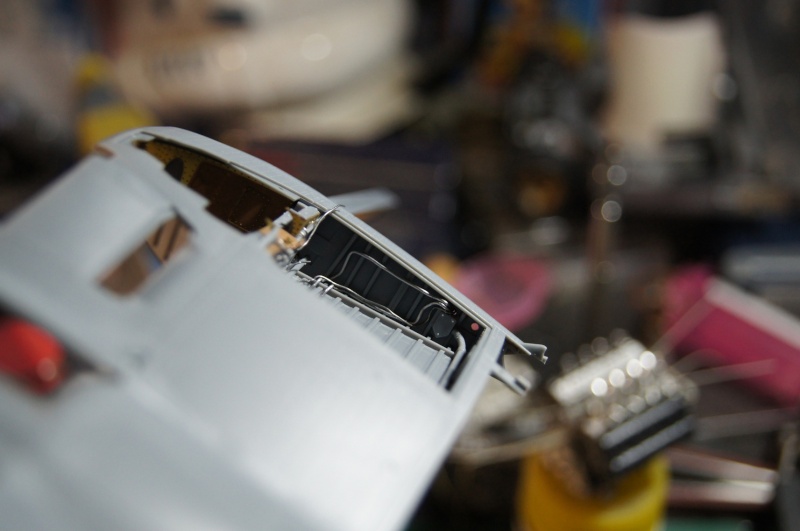

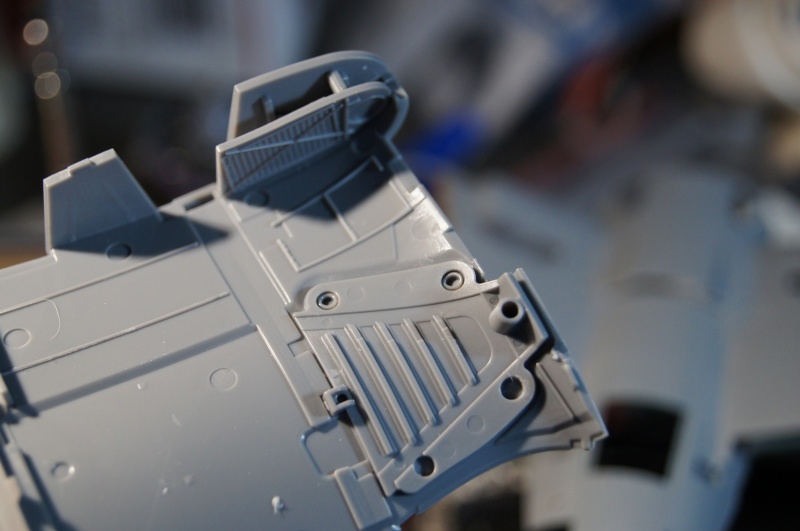

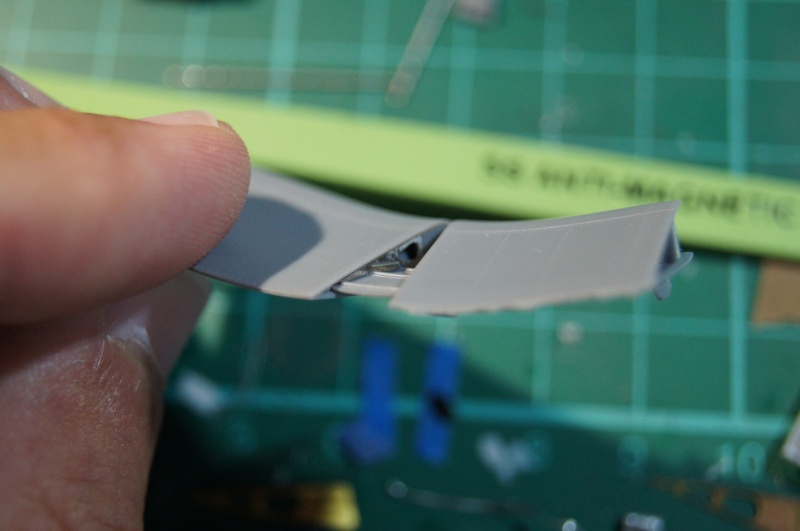

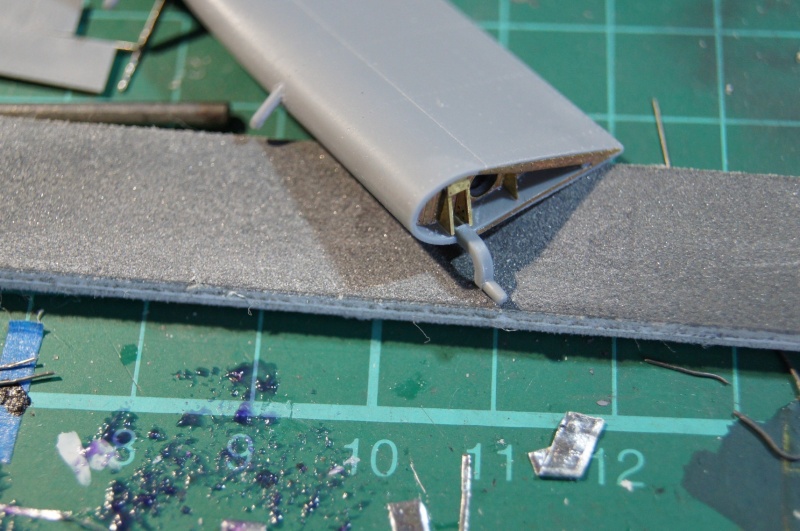

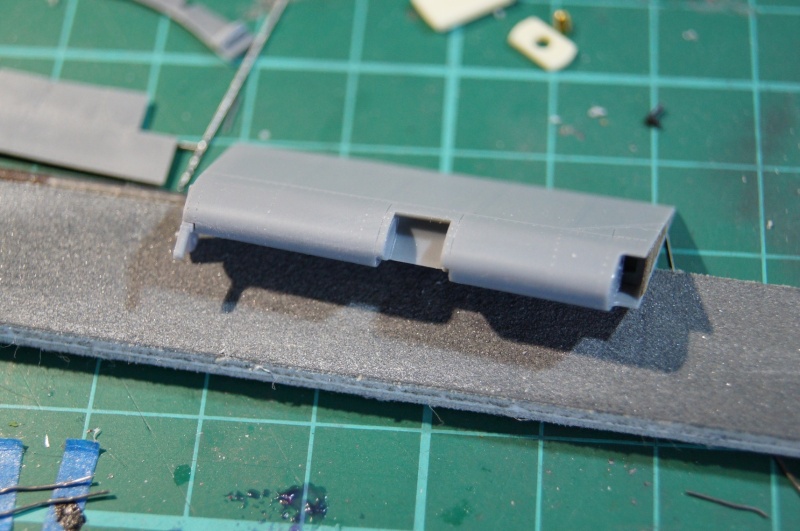

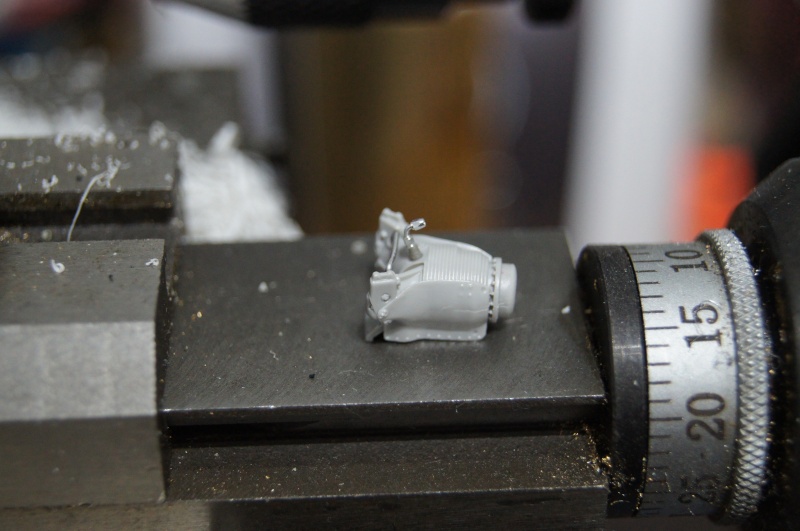

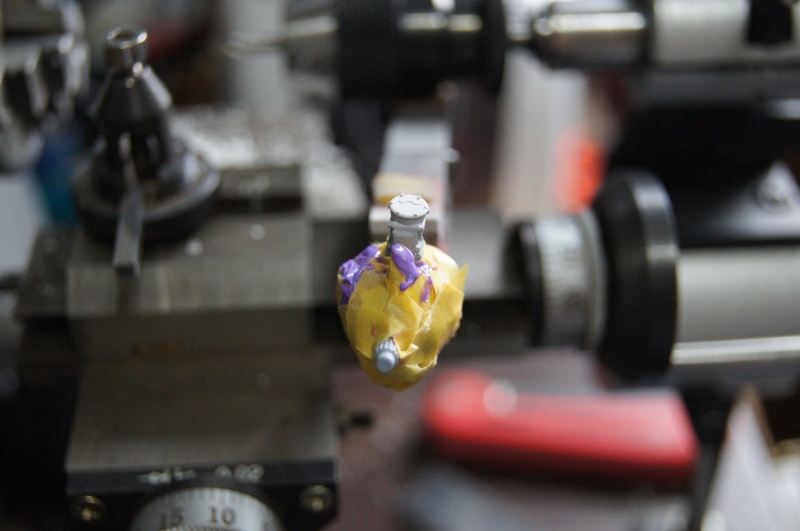

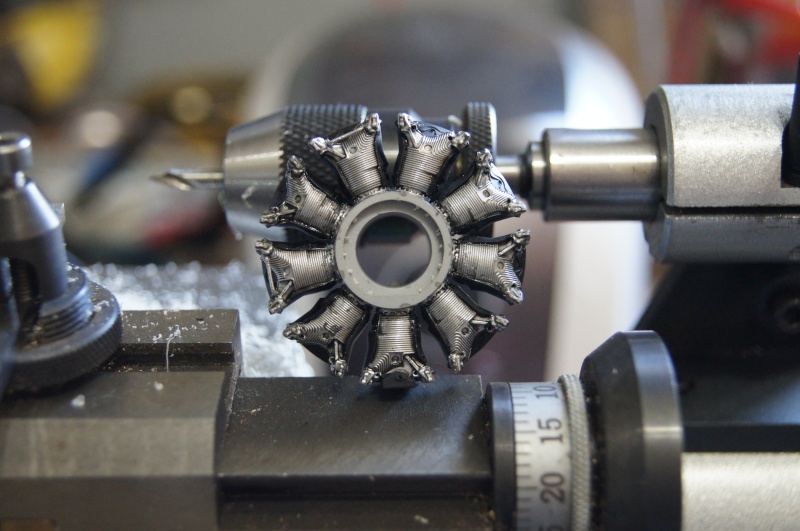

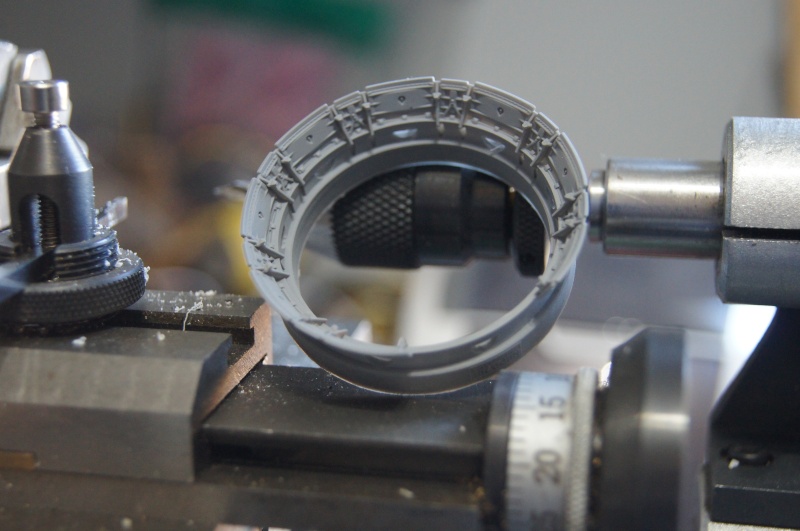

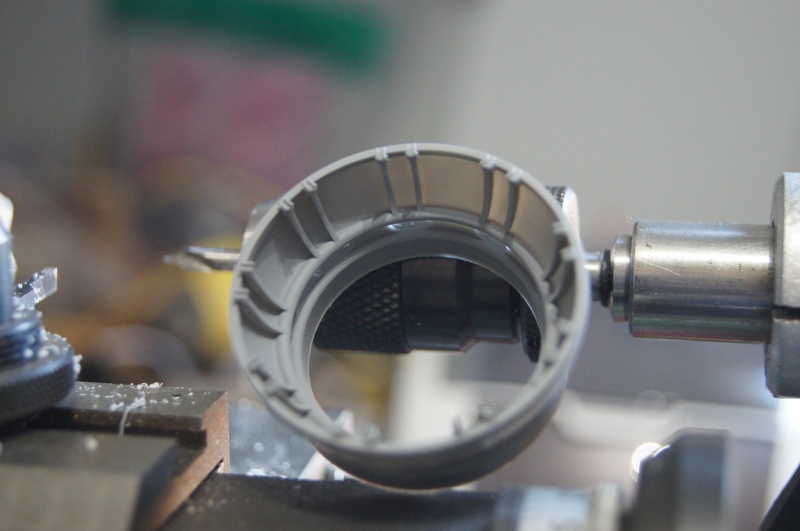

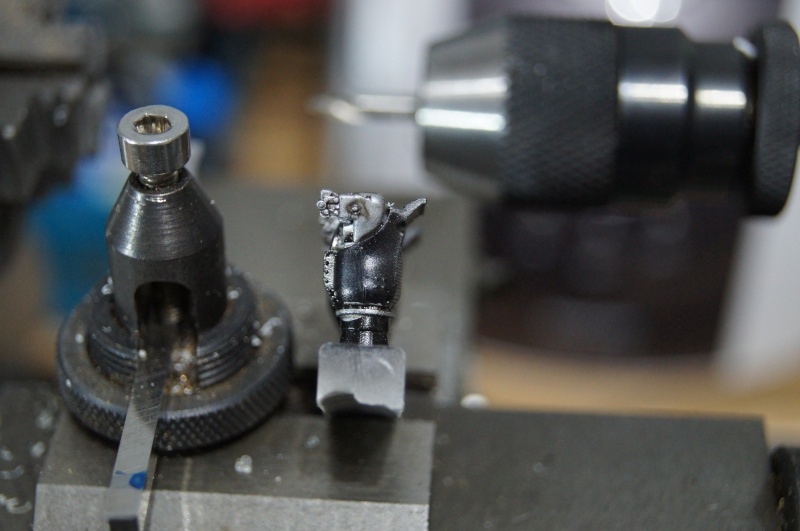

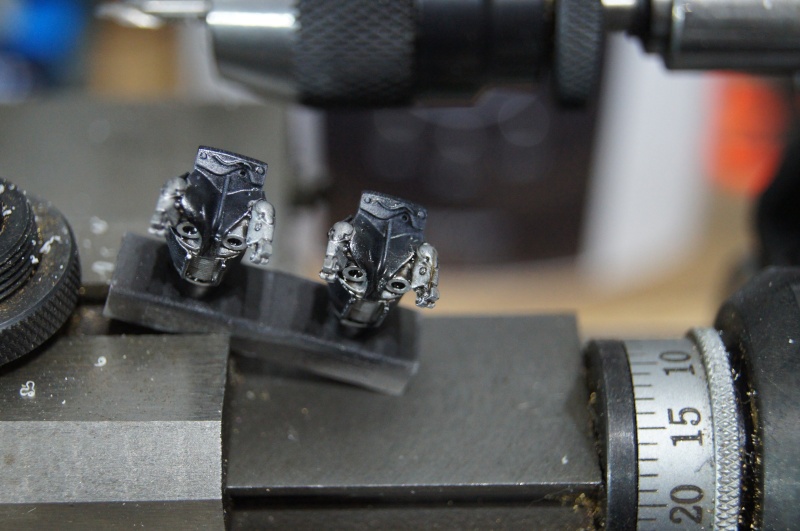

Cylinders head drilled to receive a "real" tube instead of the PE one of the Barssin kit.

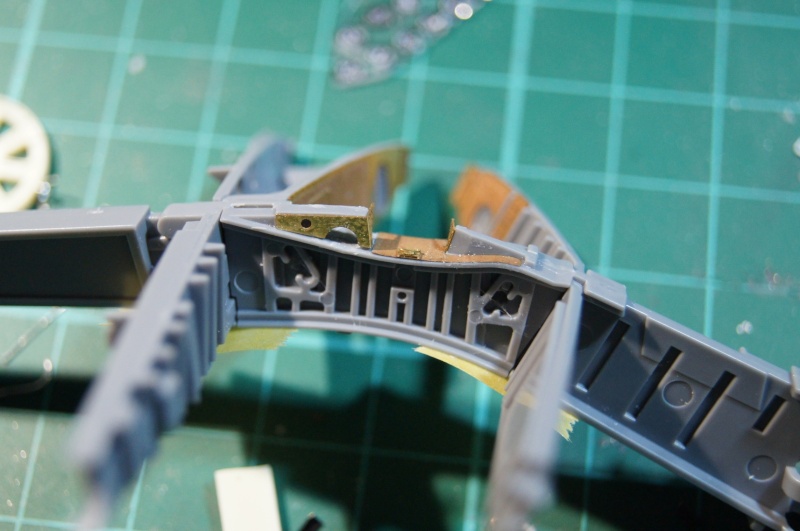

The box of the lower cylinder is also drilled to be connected to the reductor and the back of the engine.

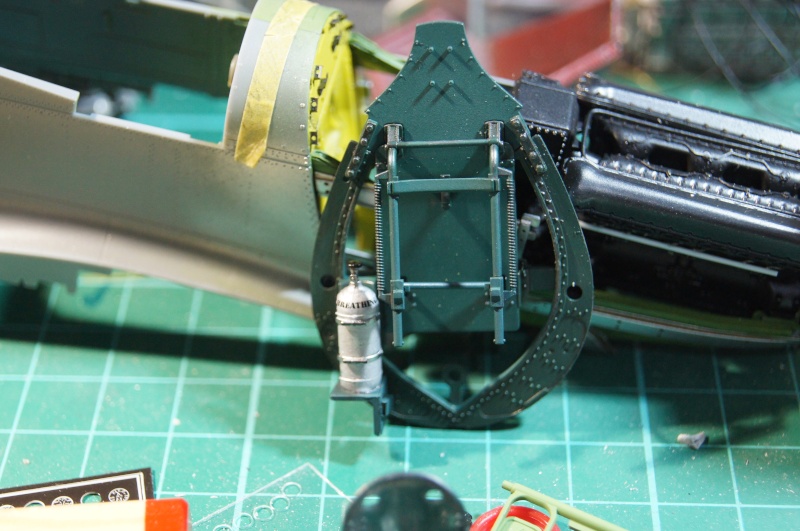

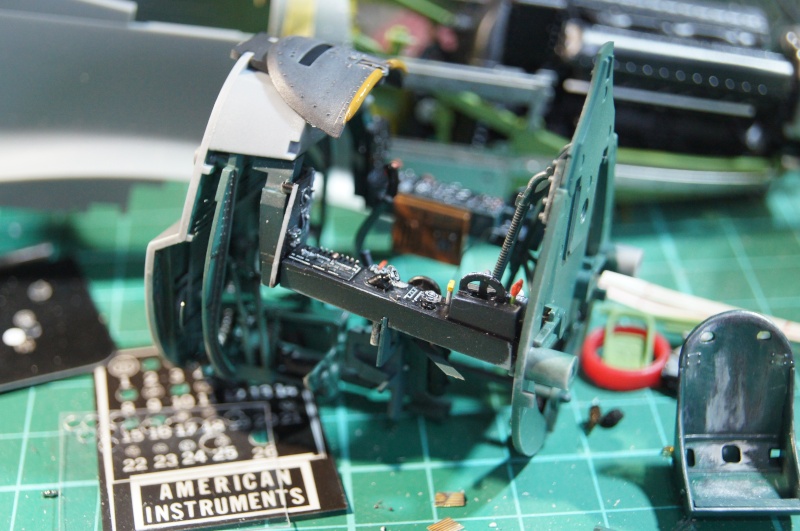

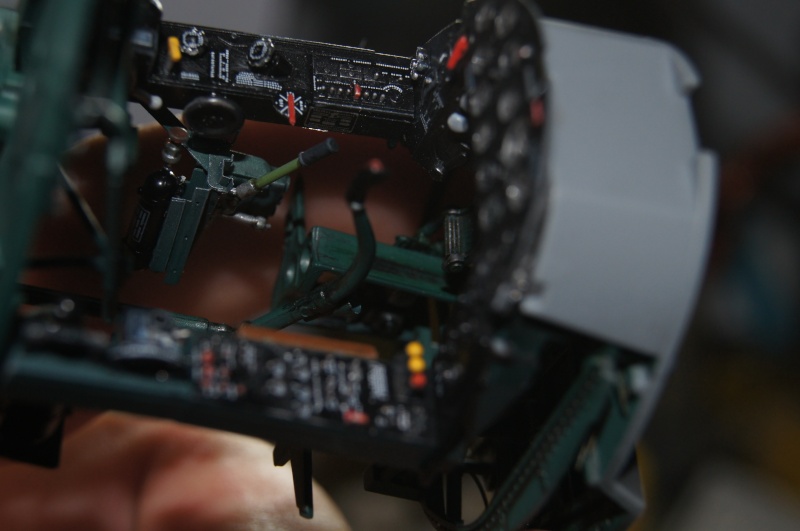

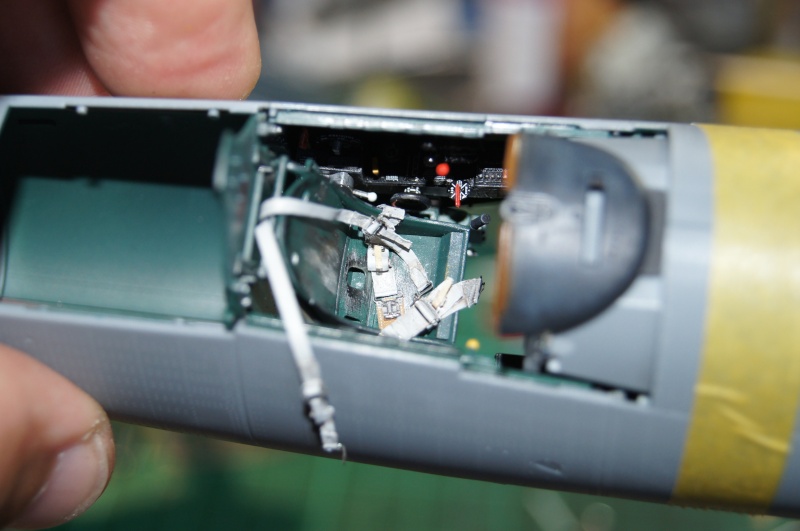

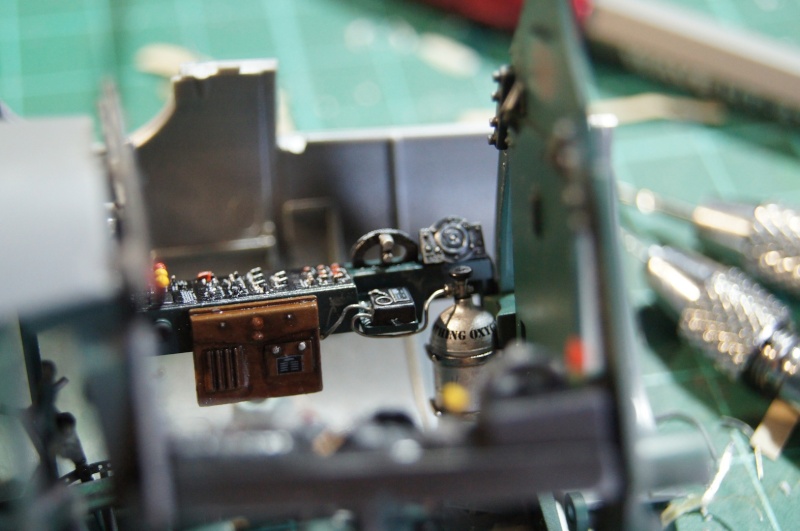

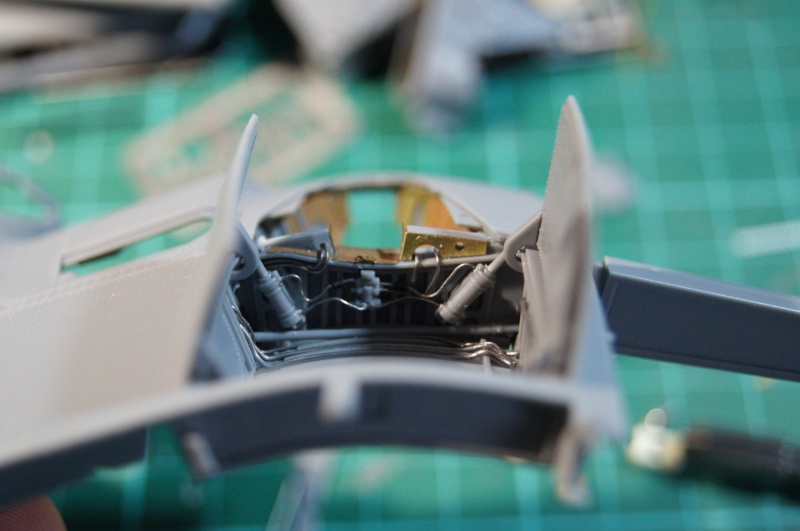

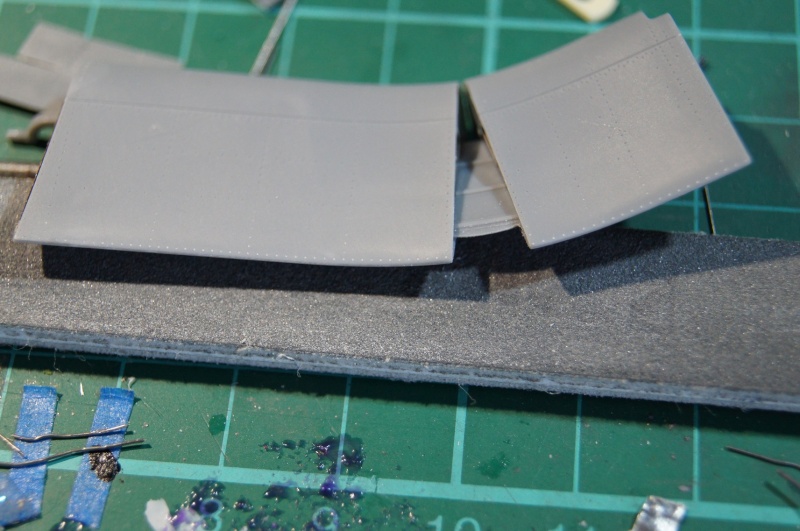

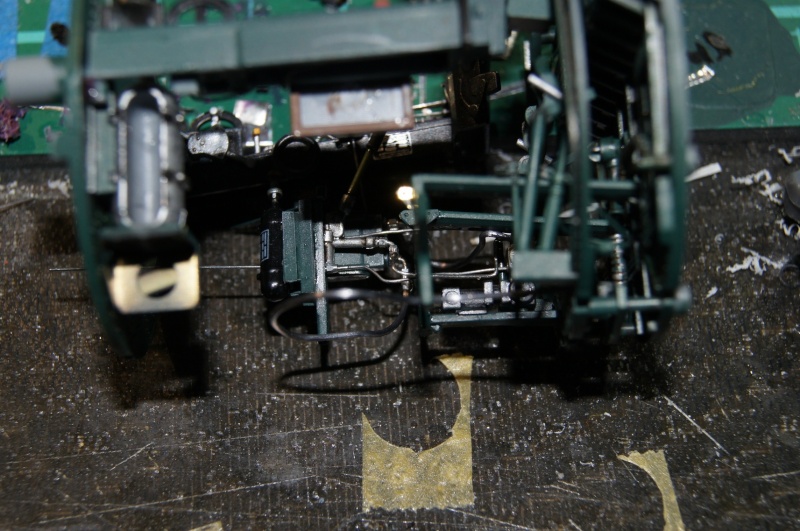

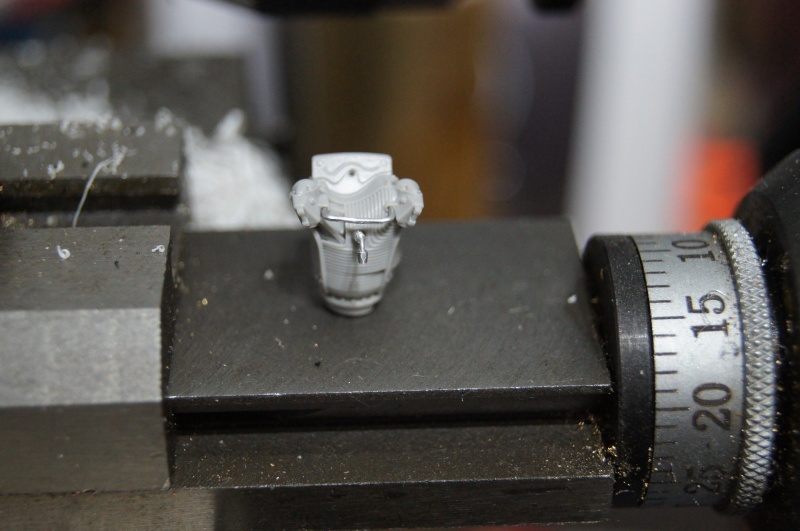

Test fit:

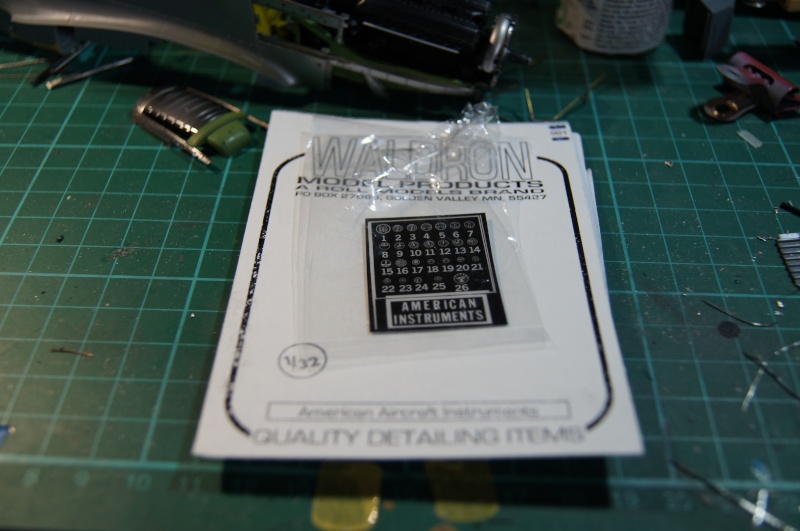

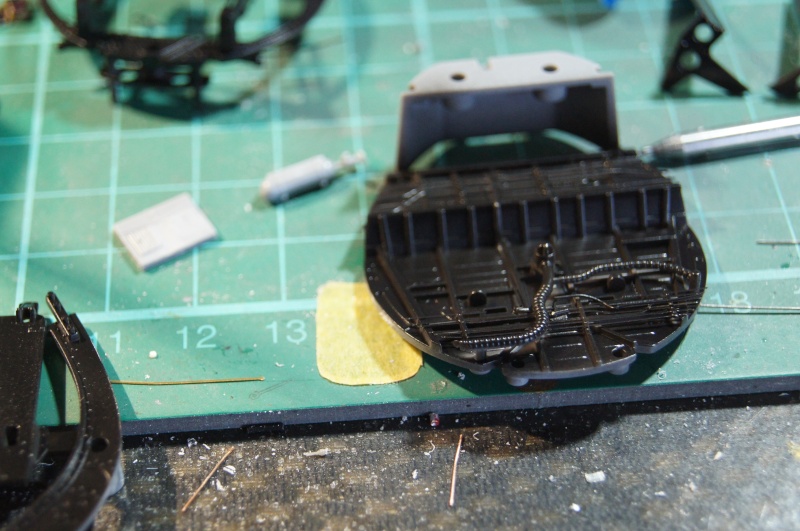

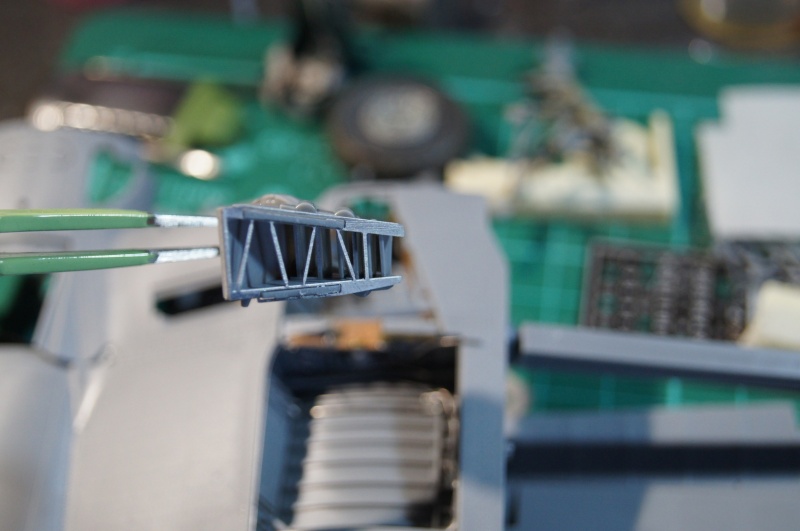

Early Bendix electrical harness from Barracuda

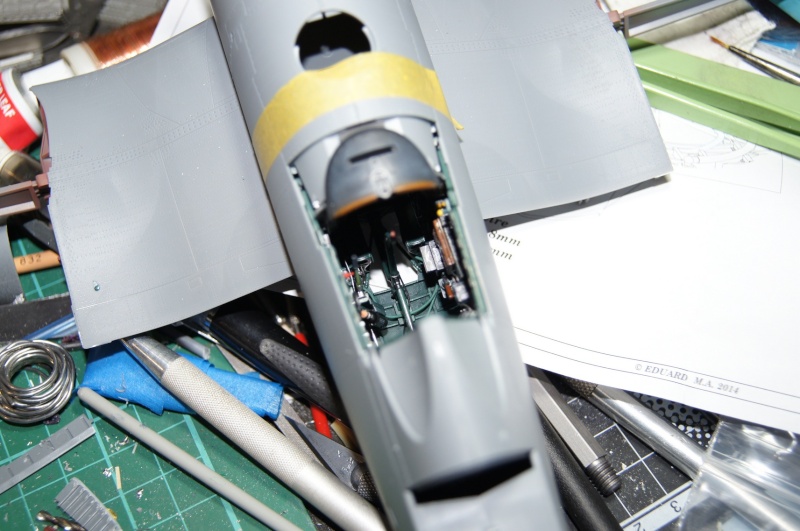

Next step: Paint.

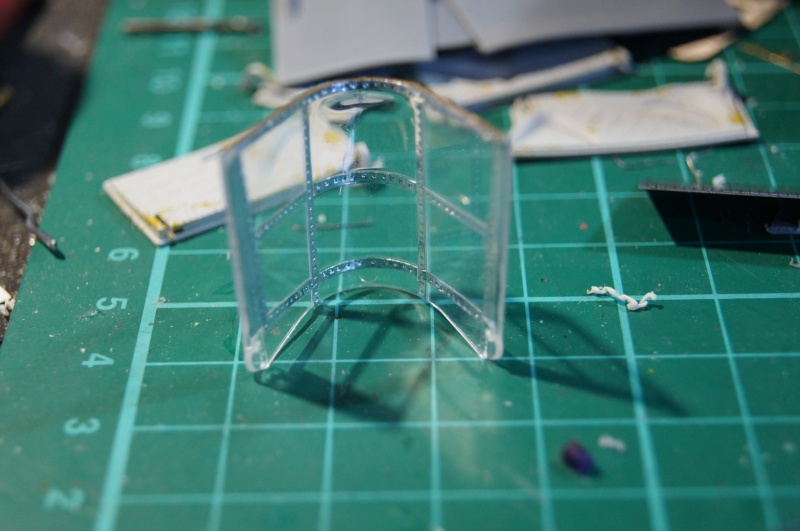

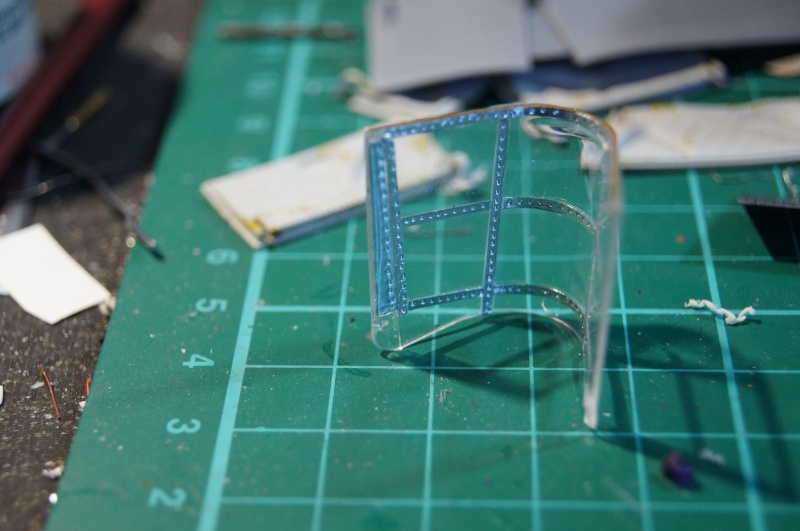

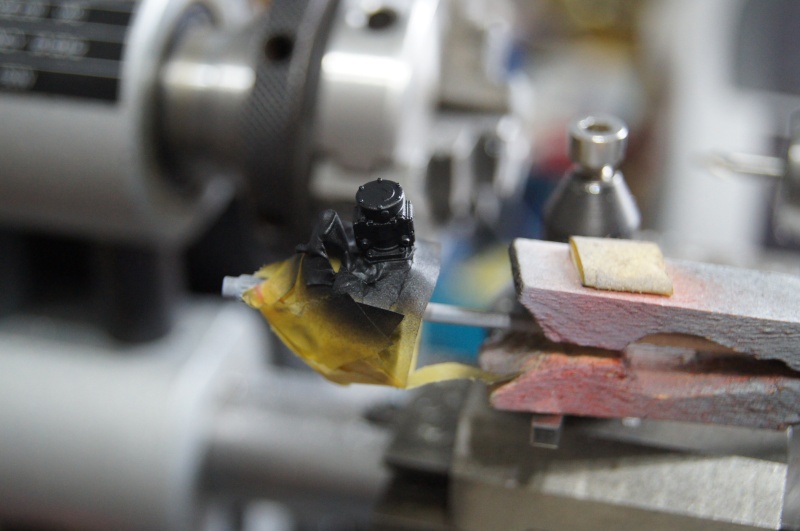

So time to mask...

Late magnetos are cut off and will be replaced by the Early ones provided by Barracuda:

More mask:

ZP primer and black before Alclad, from ZP once again:

Short dry time, then grey from Gunze: 307 & 337 with Tamiya thinner.

Alclad White Alu for the cylinders.

Black again.

Welcome to the Smurfs:

Mask off

Black here too:

Pchiiit...

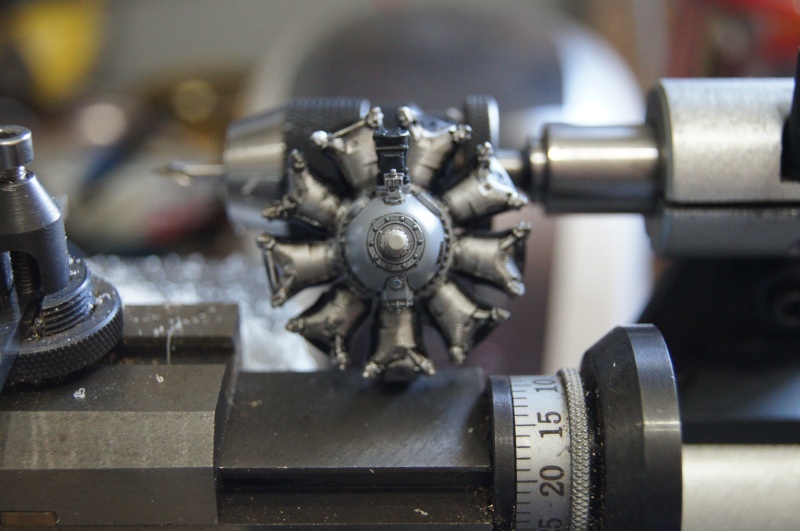

Mask off and light first weathering steps.

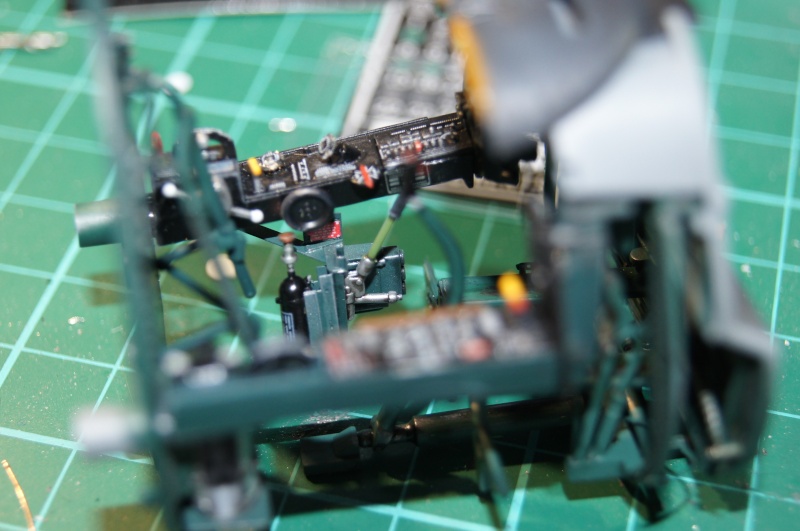

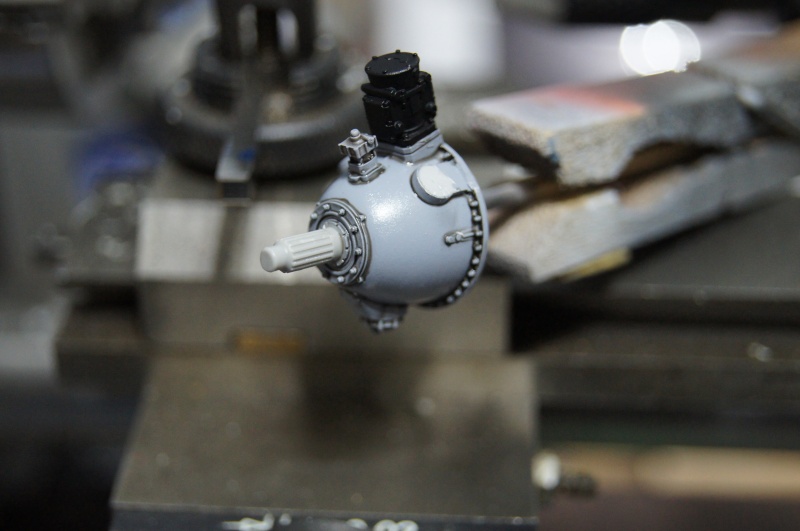

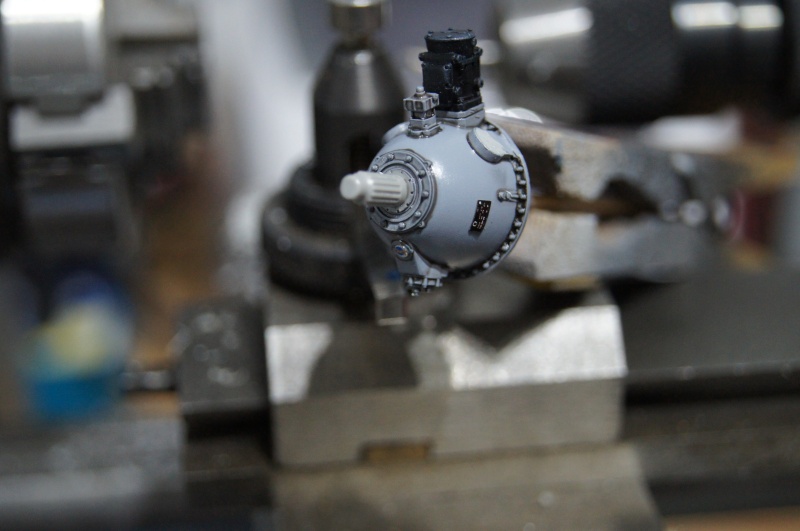

test fit:

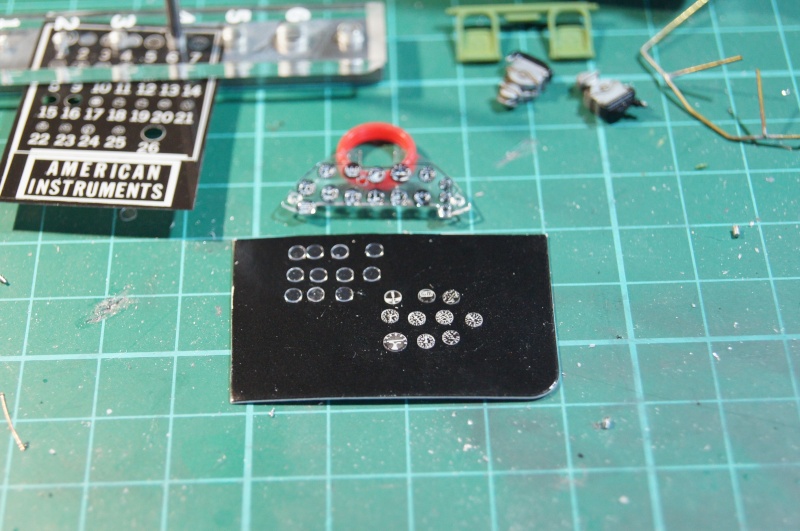

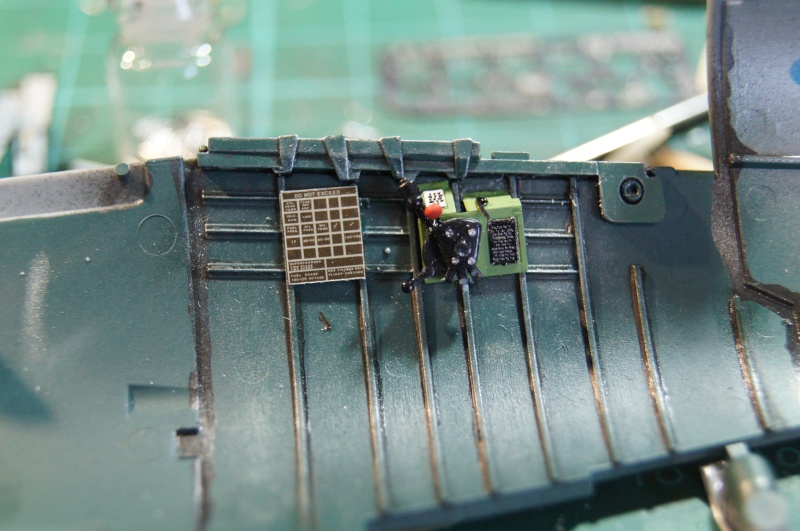

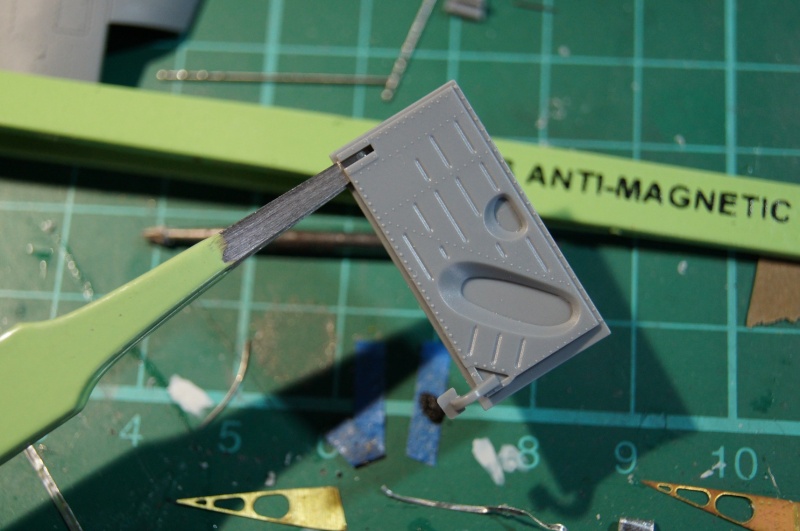

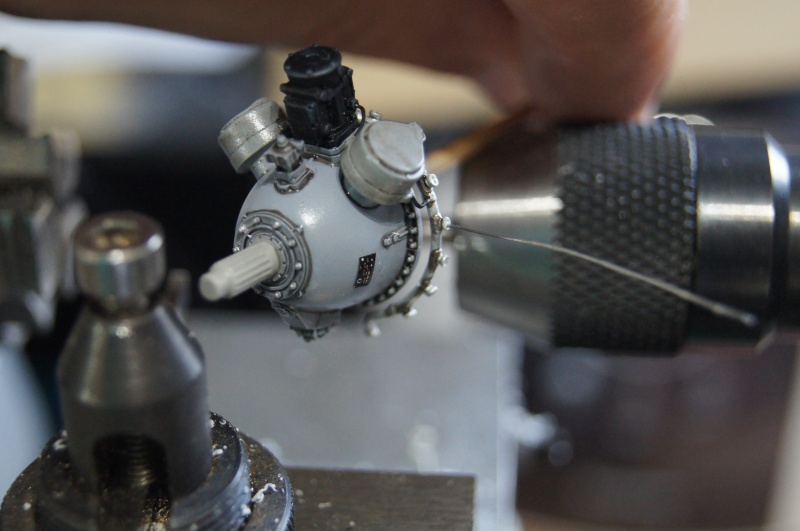

Instruction plate added

First row:

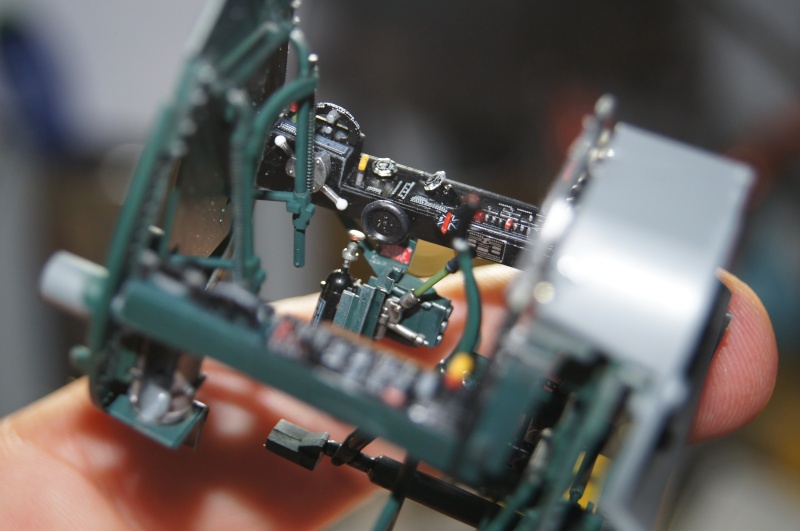

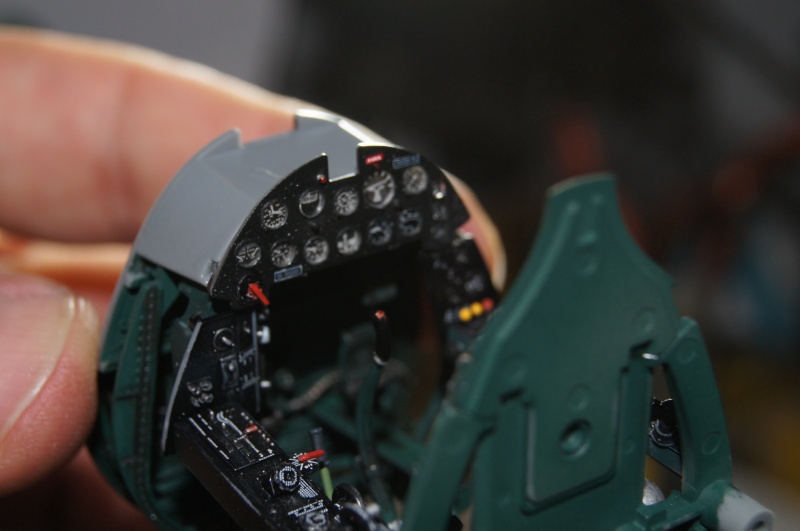

Test fit again with front end:

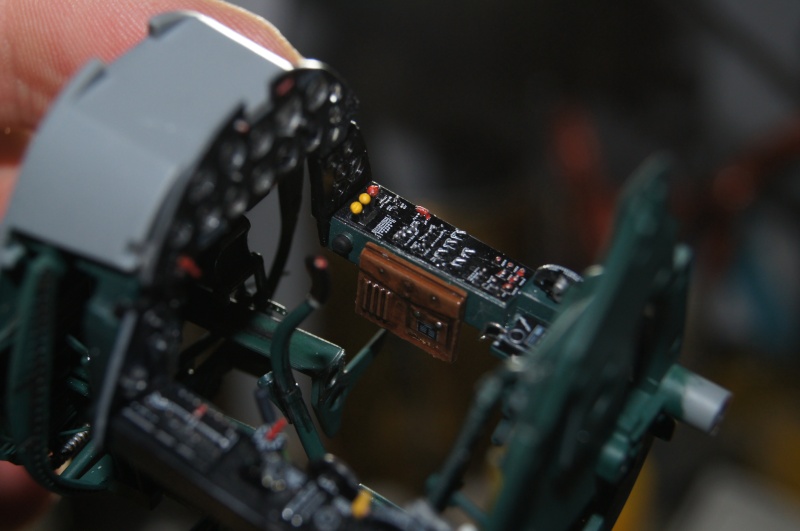

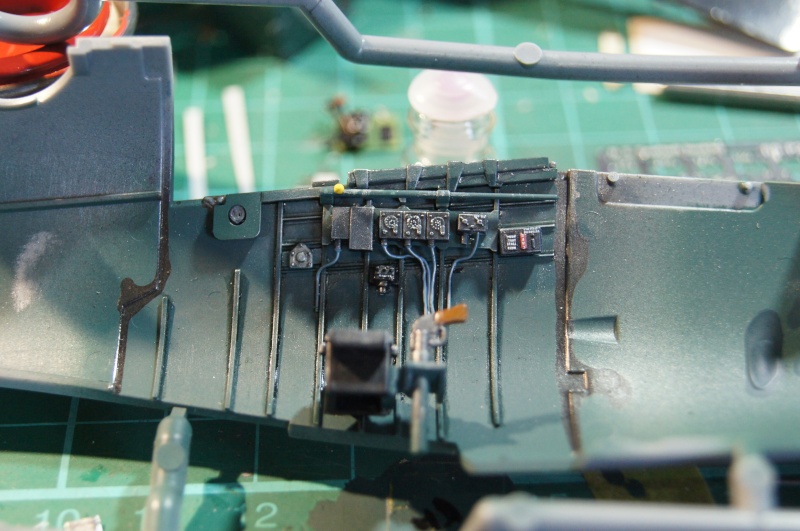

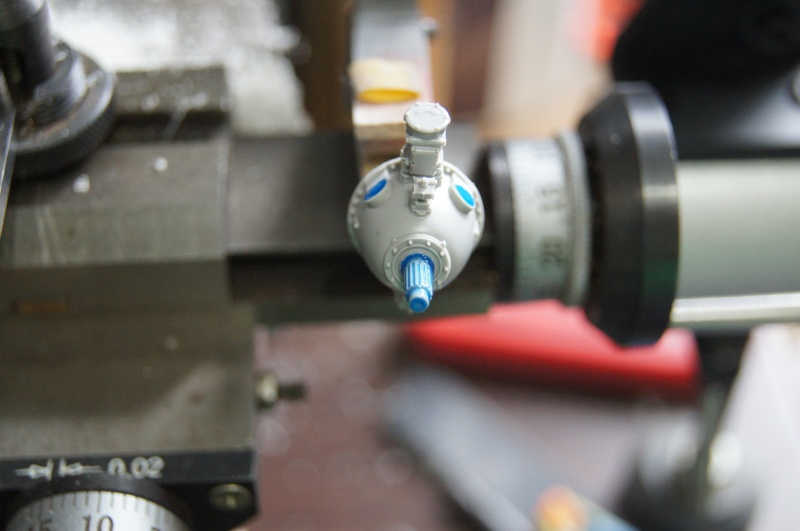

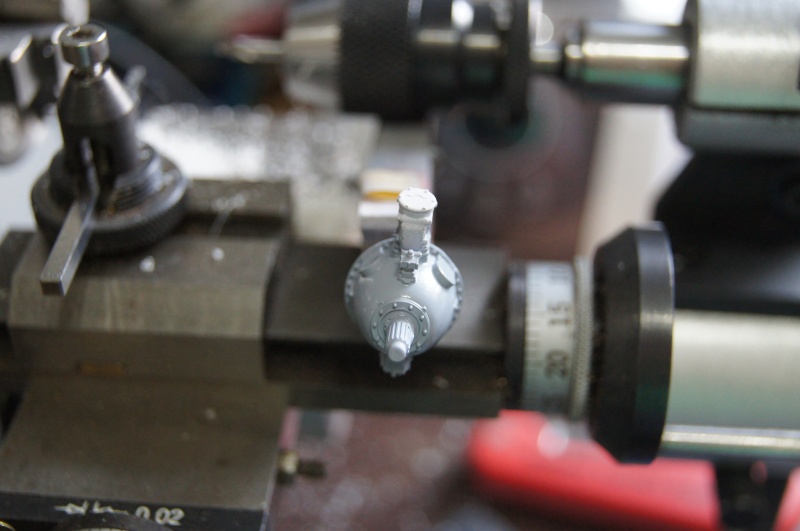

Bendix magnetos:

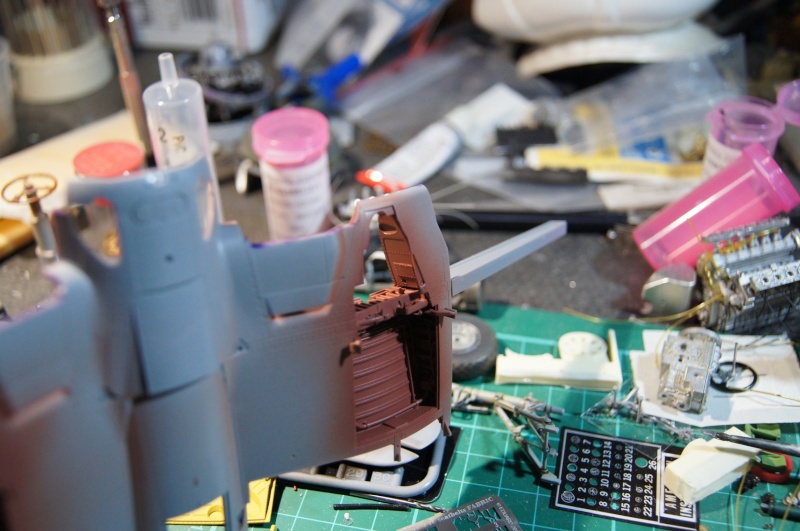

Time for primer!

Grey Micro Filler on few parts.

Cylinders:

I love the details:

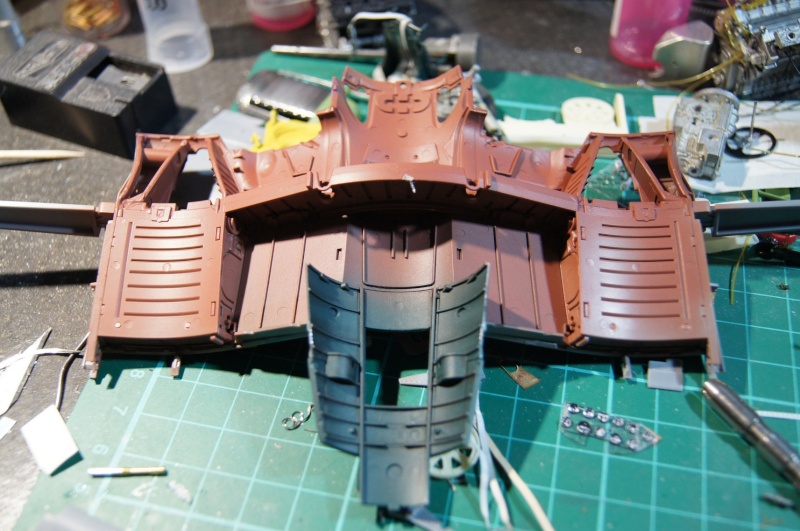

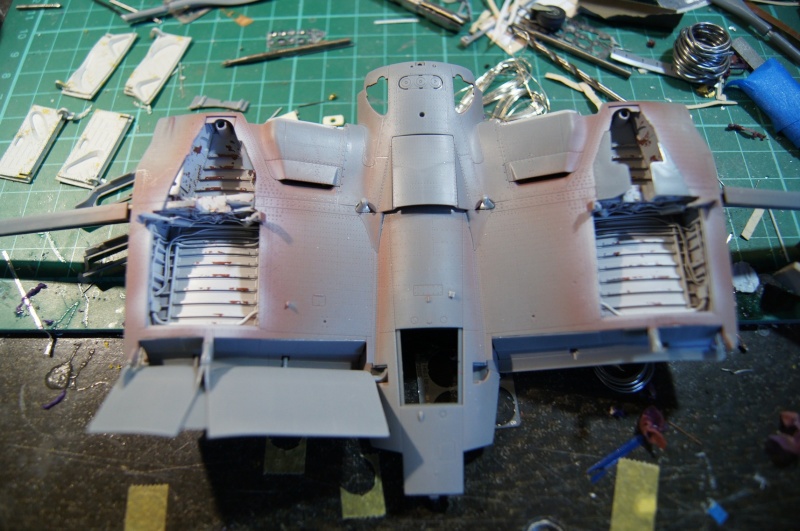

Other engine parts and cowls:

After the grey... BLACK!

Gloss Black Base from Alclad.

"Engine Manifold" from Alclad.

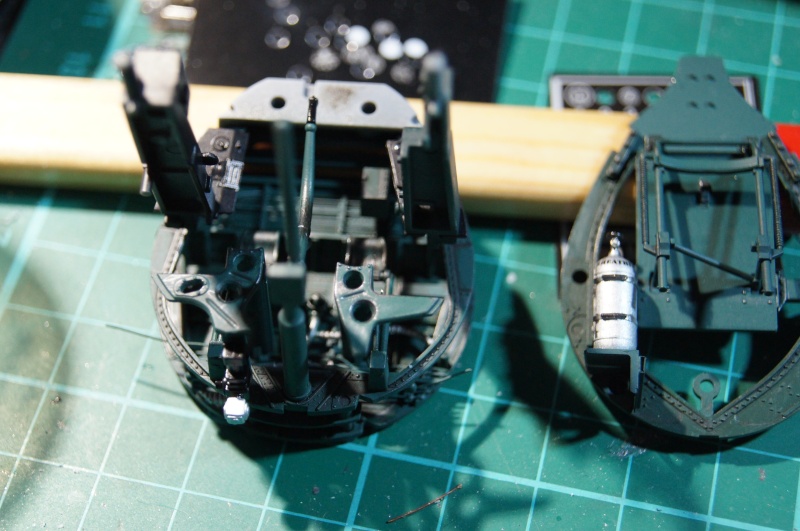

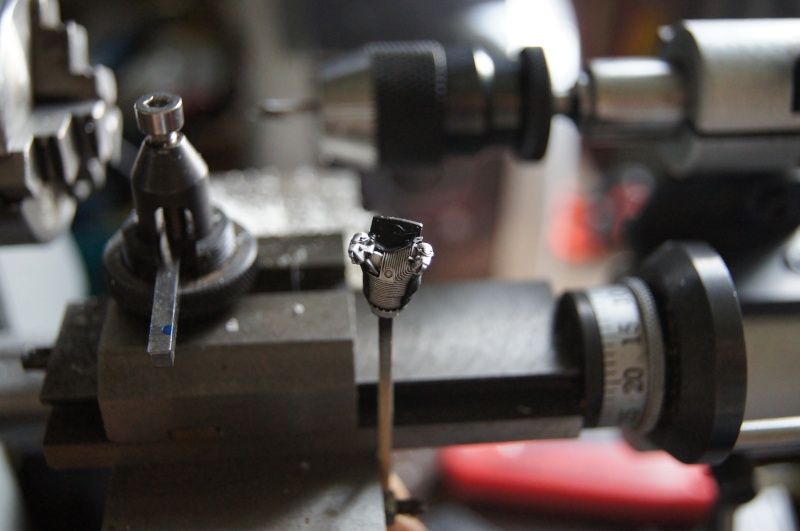

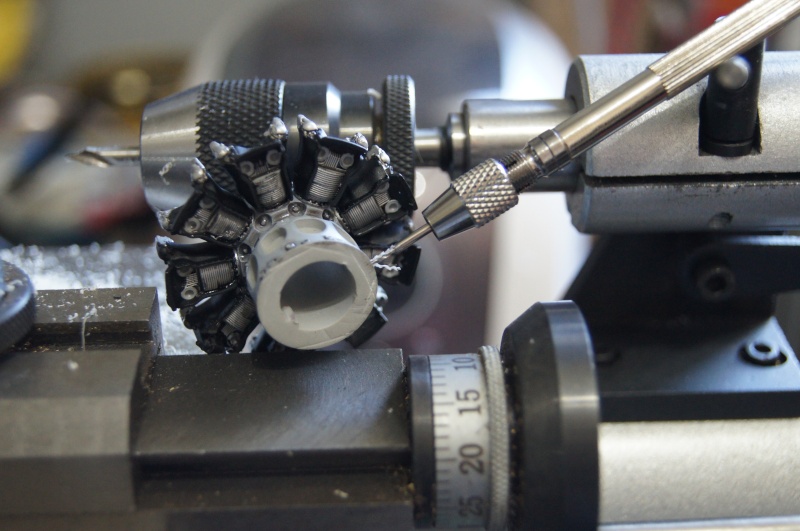

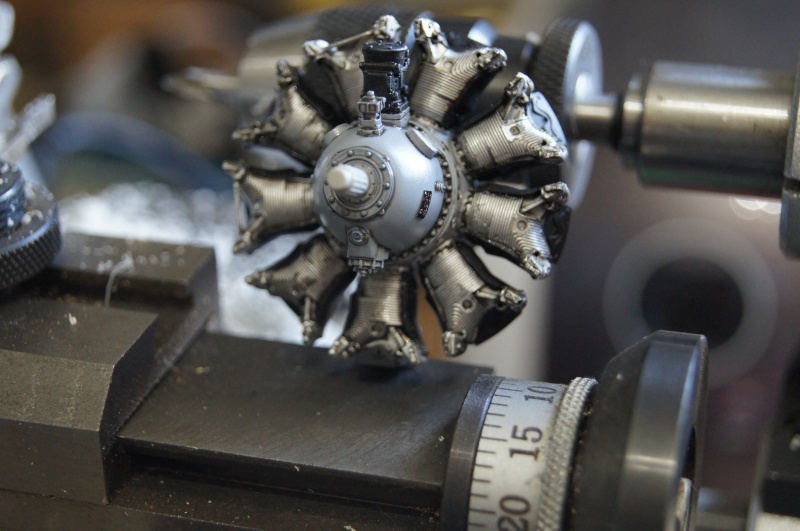

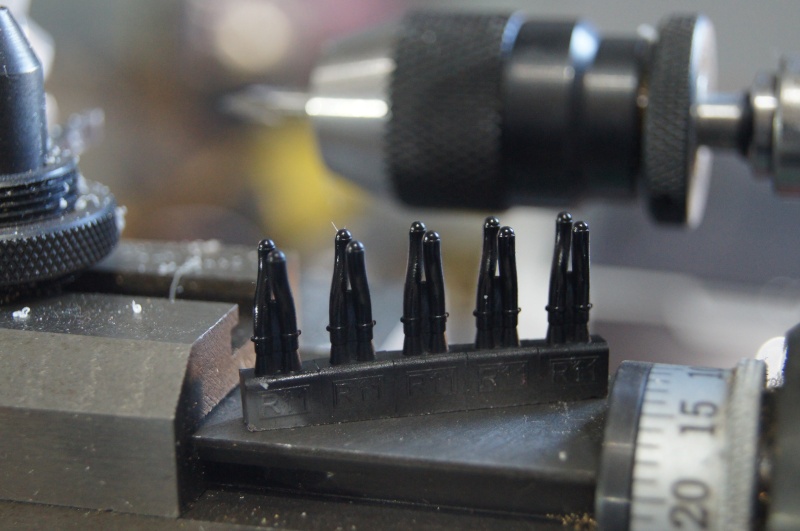

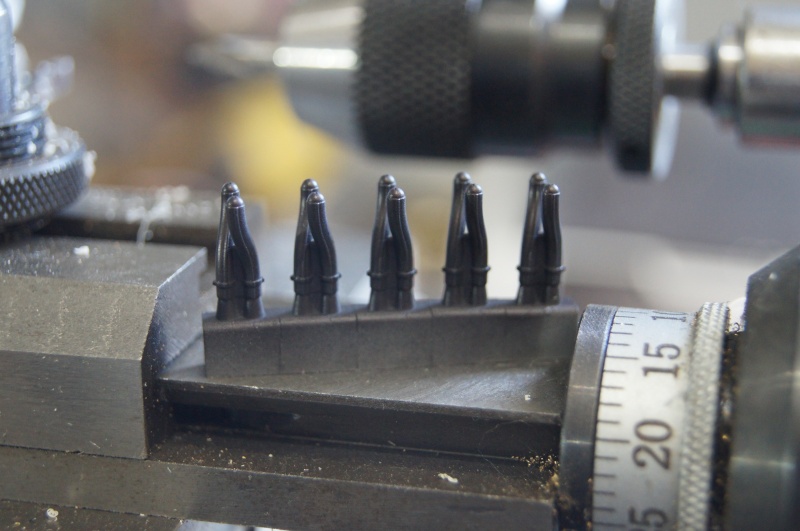

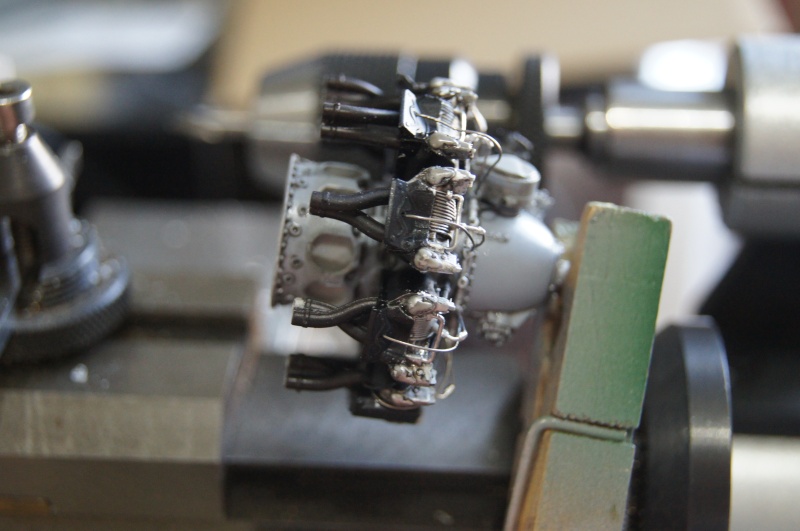

Test fitting for the push rods and spark plugs in place.

Cylinders of the first row are now complete:

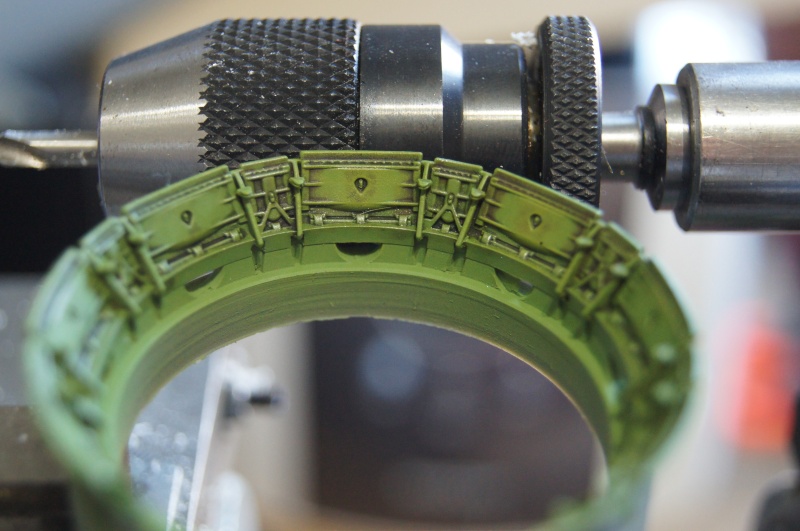

Time for the back crown.

Alu Metal Cote quickly applied with a brush then polshed with a brush once again.

Smoke and quick dry brush with "blanc de titane" and black from W&N this time.

I don't spend too much time for the details and paint work on these parts as they will not be too visible.

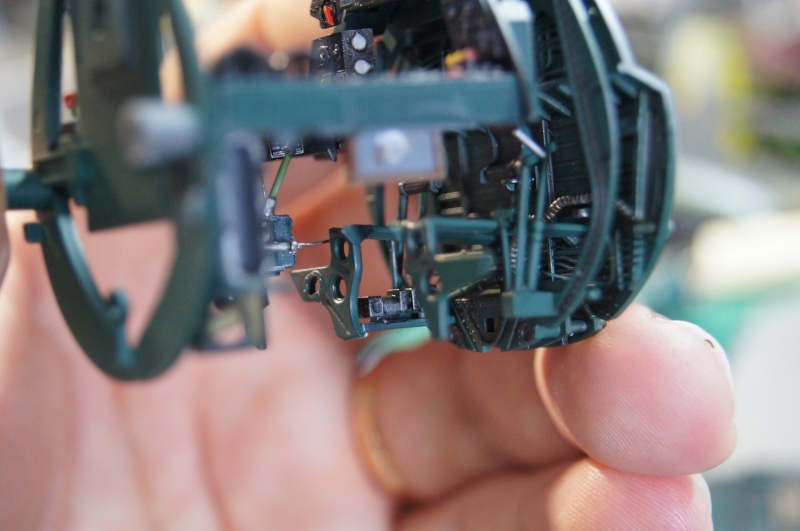

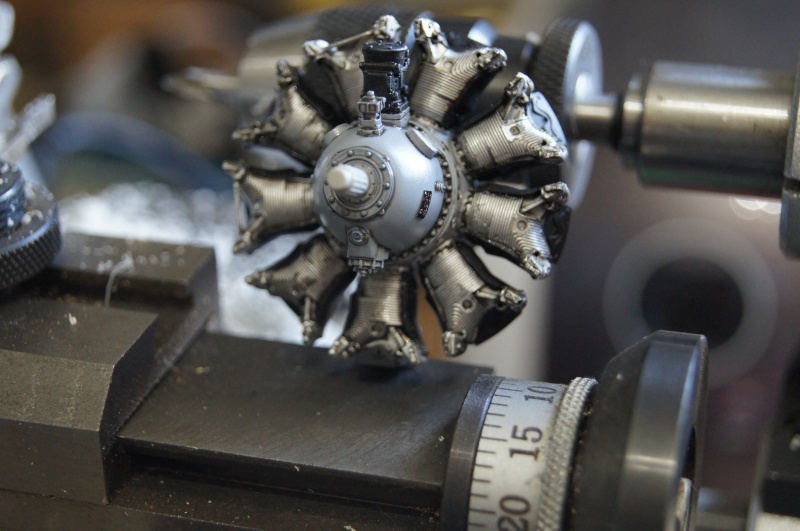

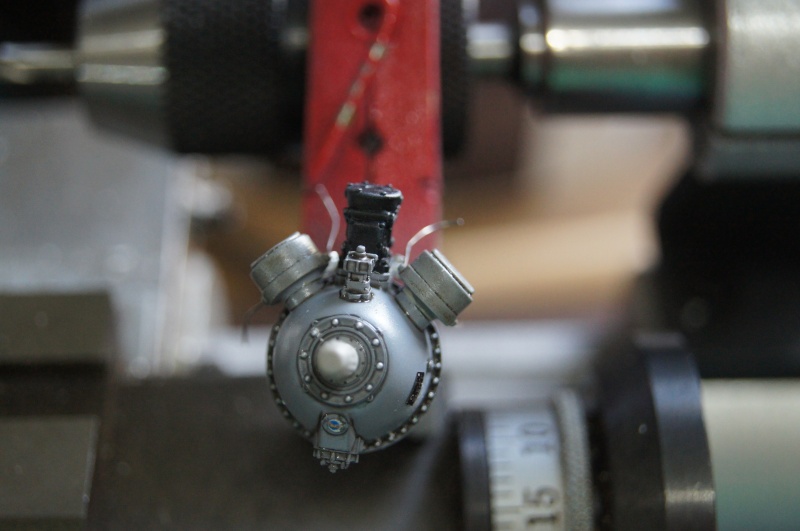

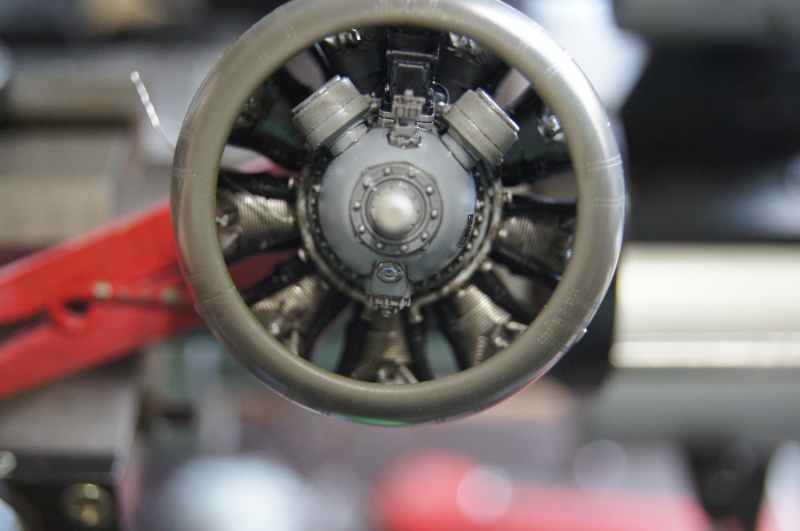

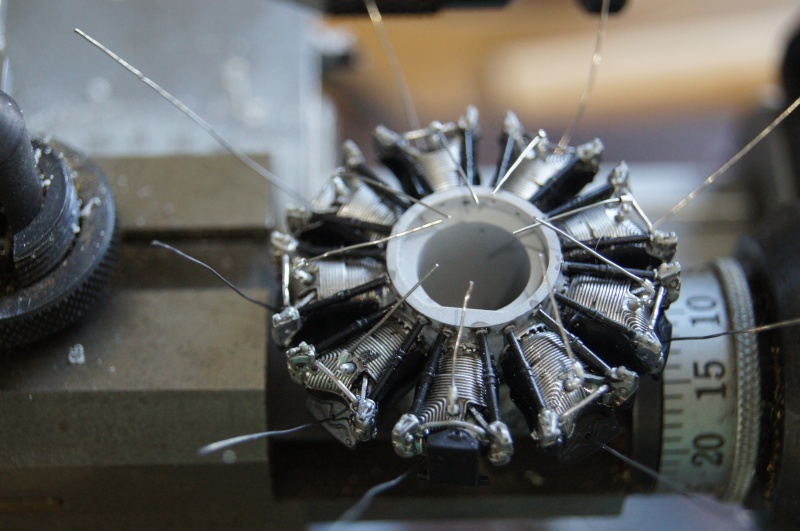

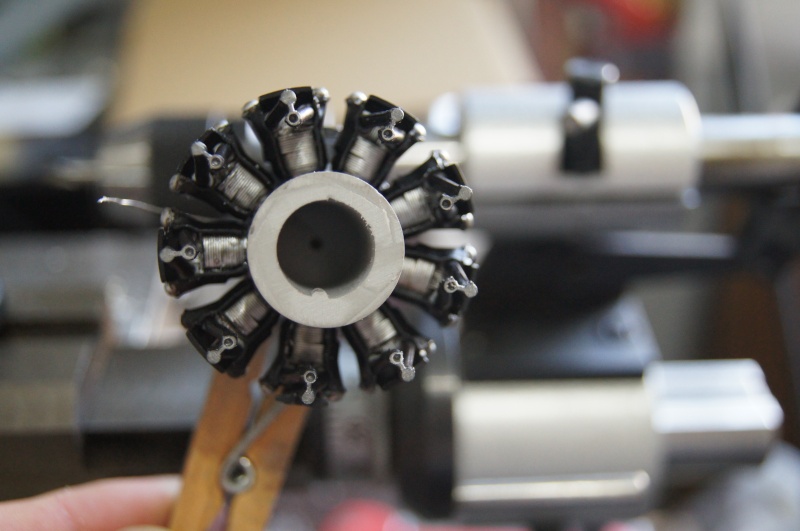

I couldn't resist to a test fit with the 18 cylinders installed

Starts to look to a R-2800 ...

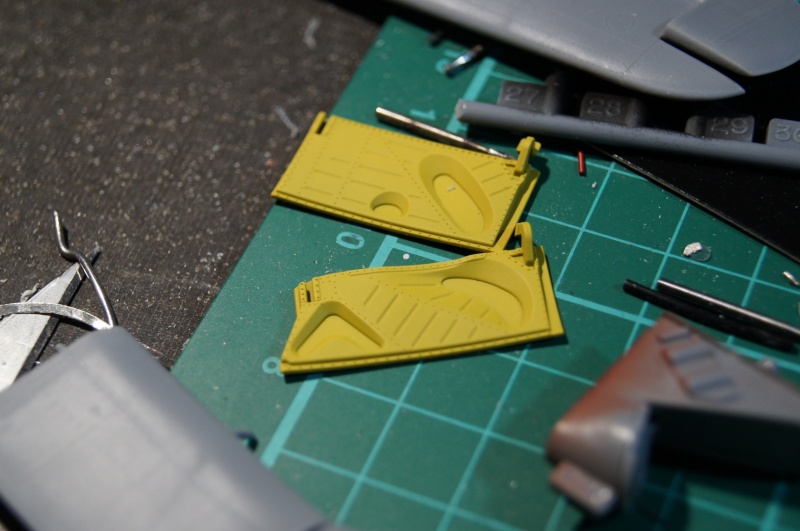

Small Paint work today.

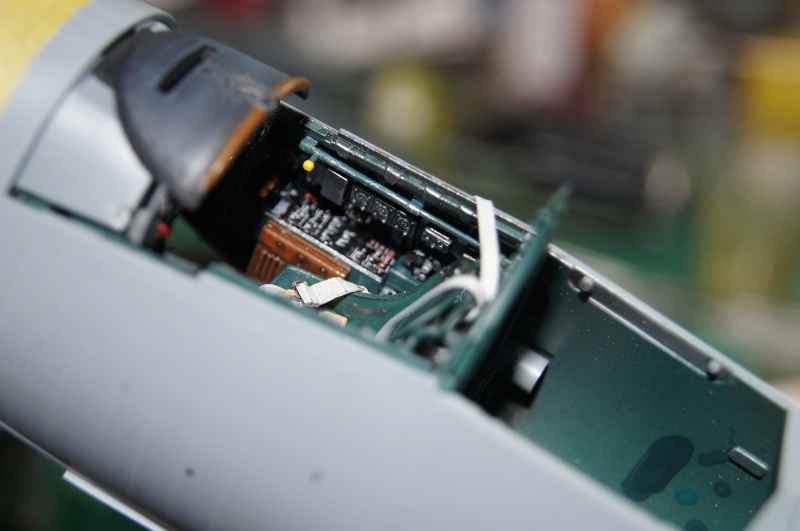

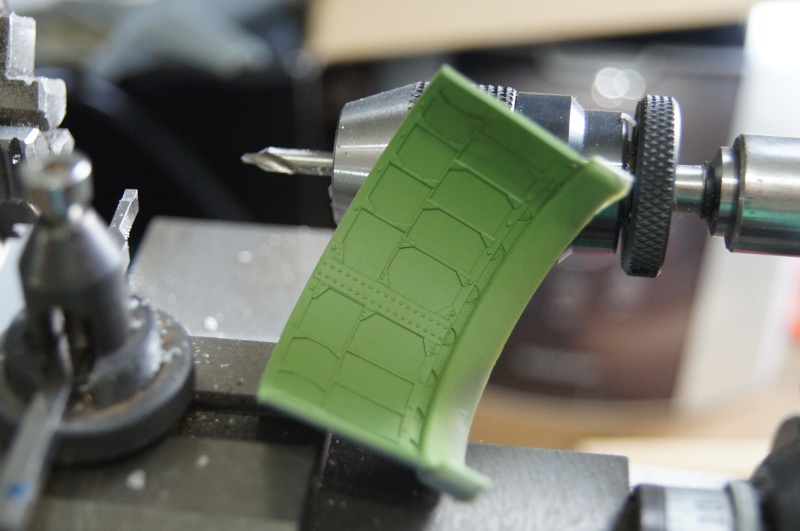

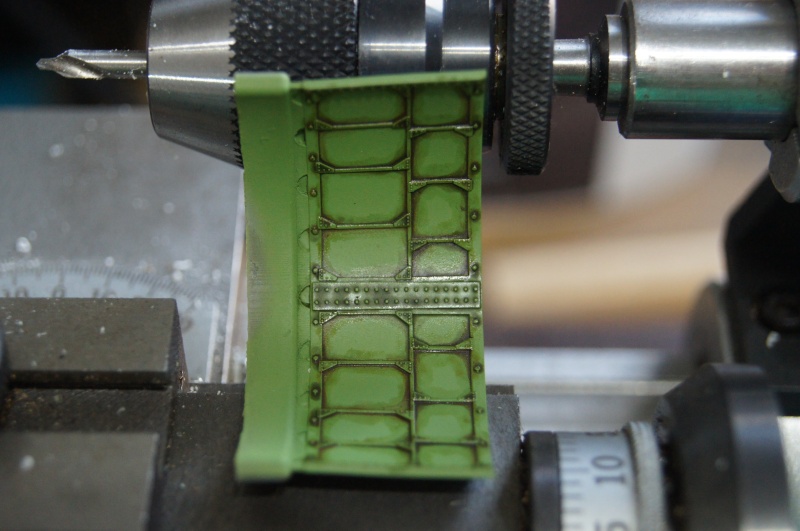

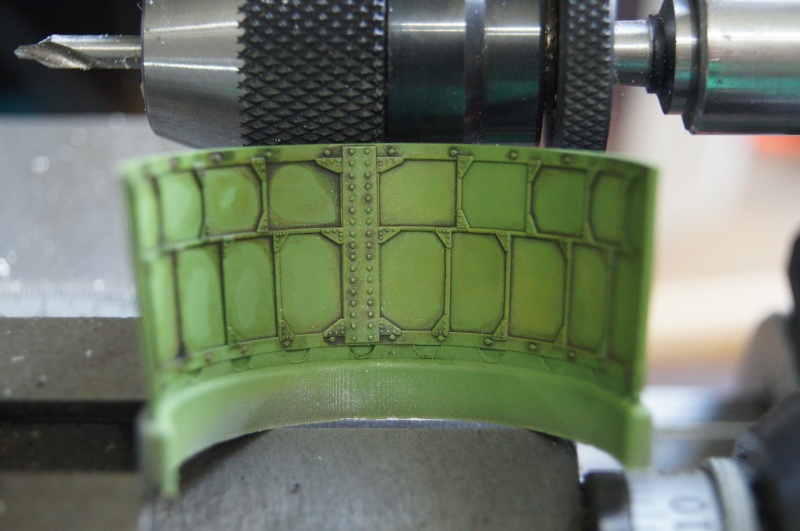

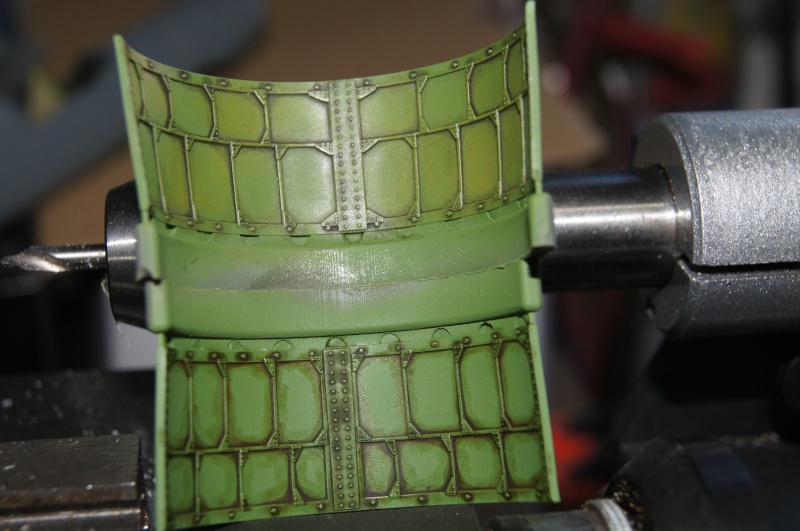

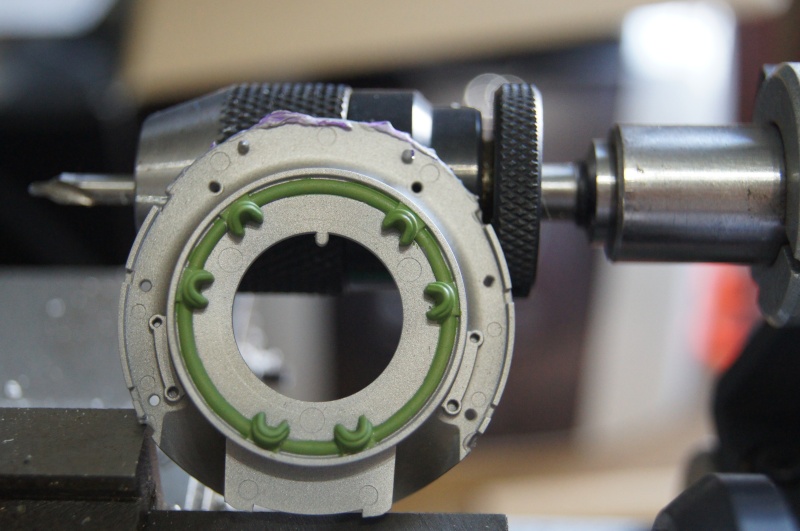

Model Master Green Zinc Chromate, Acrylic, straight from the jar:

Great molding process?...

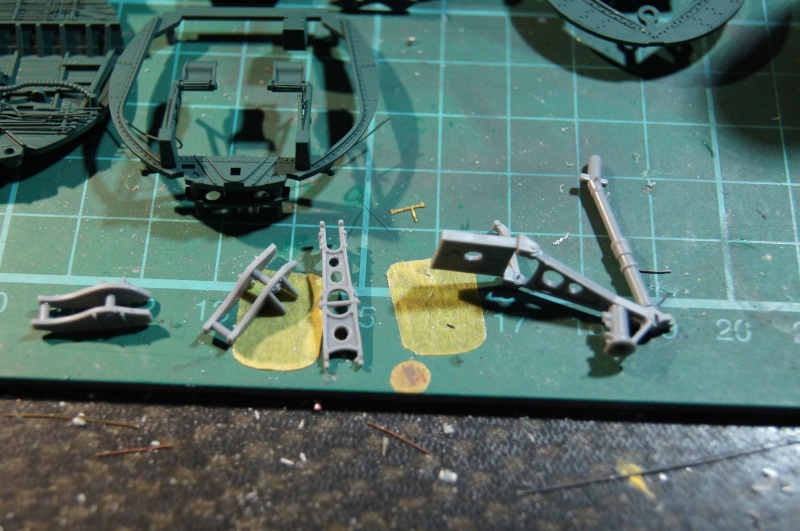

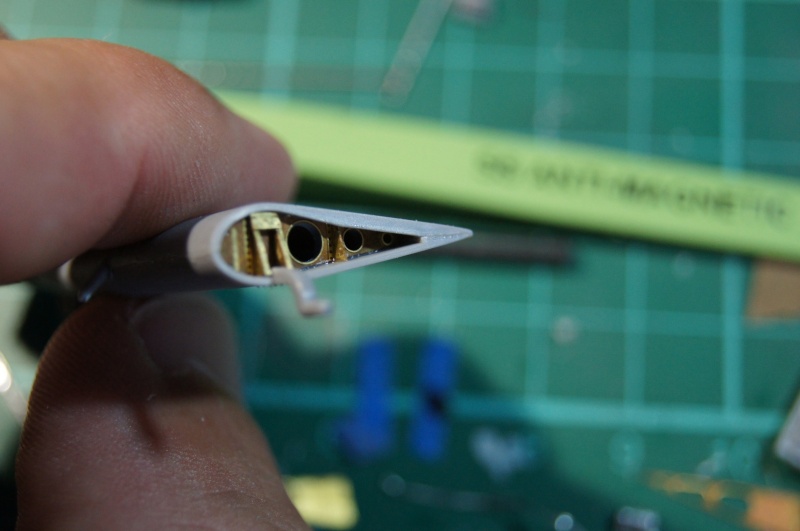

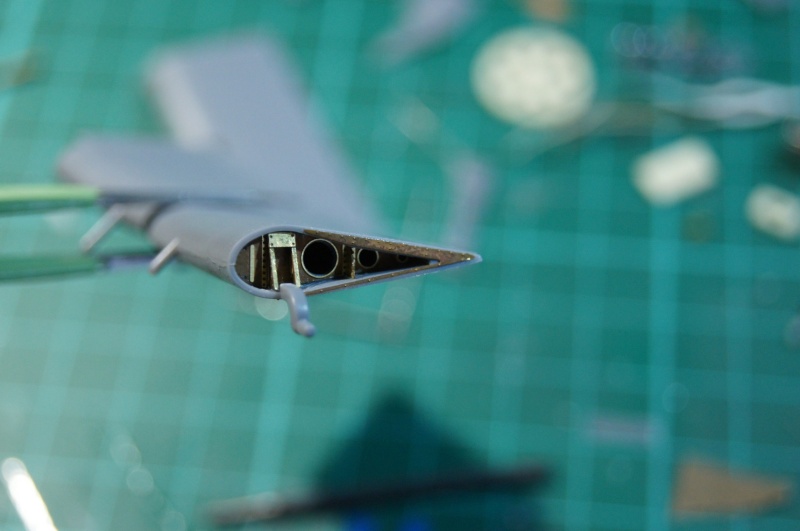

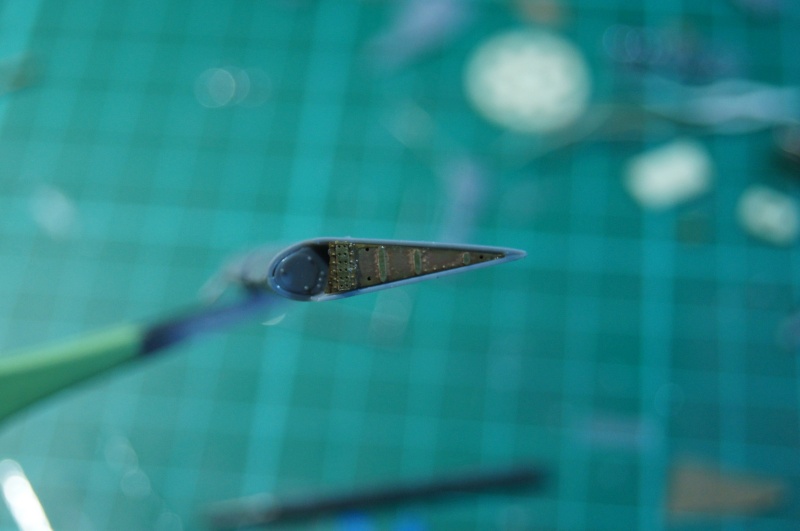

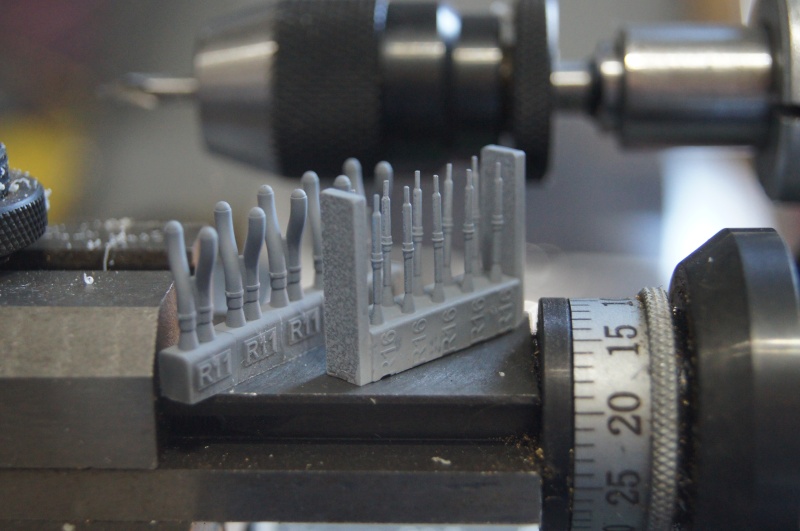

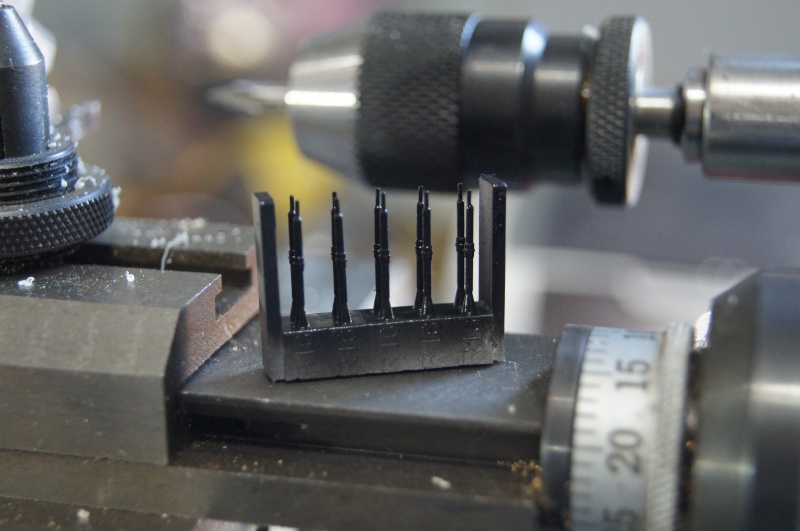

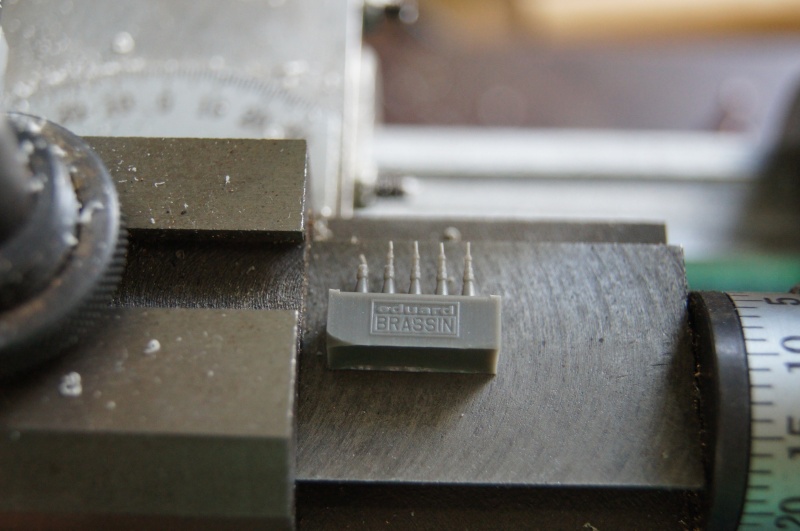

Spark plugs shortened and drilled:

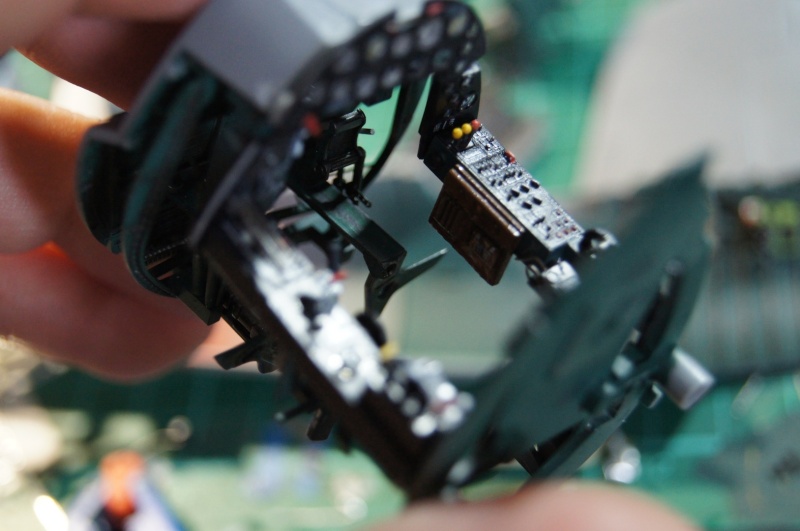

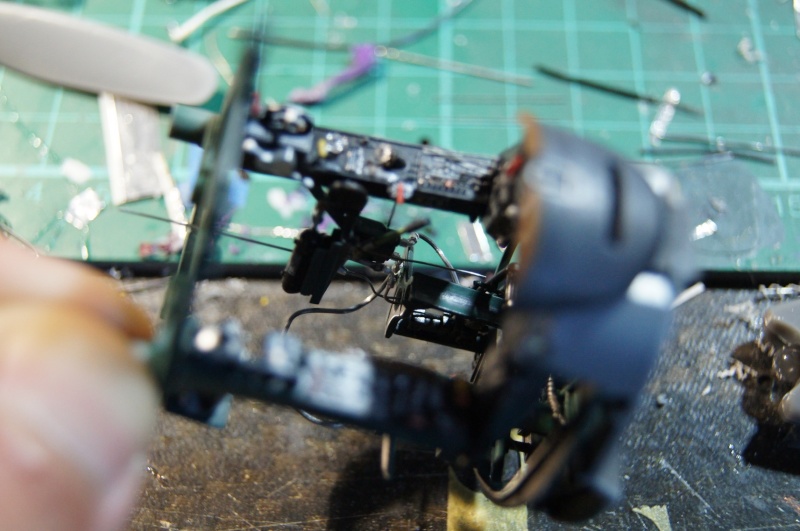

Magnetos ready and installed with the center part of the ignition crown:

Cables ready to be connected:

First step to give life; Olive Green, W&N.

...then second layer with Raw Umber, Burnt Umber and a bit of Black, oil from W&N and Rembrandt.

Still wet and waiting for the next step:

Same for the ignition, with Smoke and still wet:

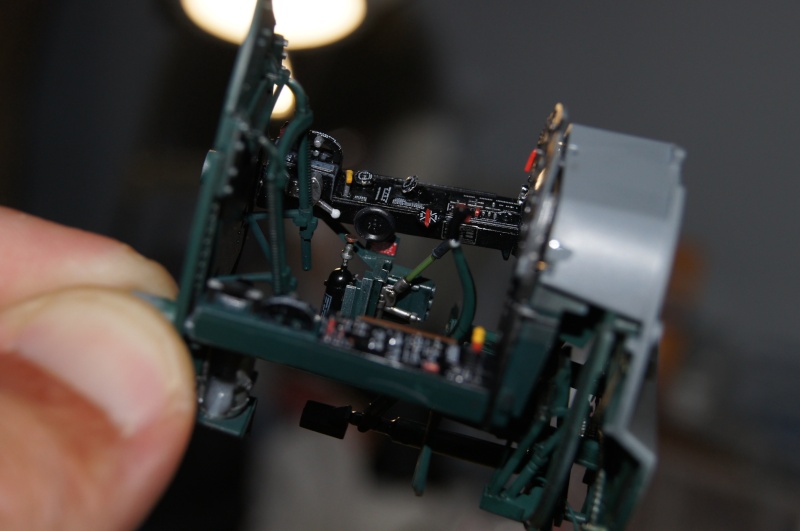

Now just need to put it on the aircraft:

Joke... this one is the wrong scale!

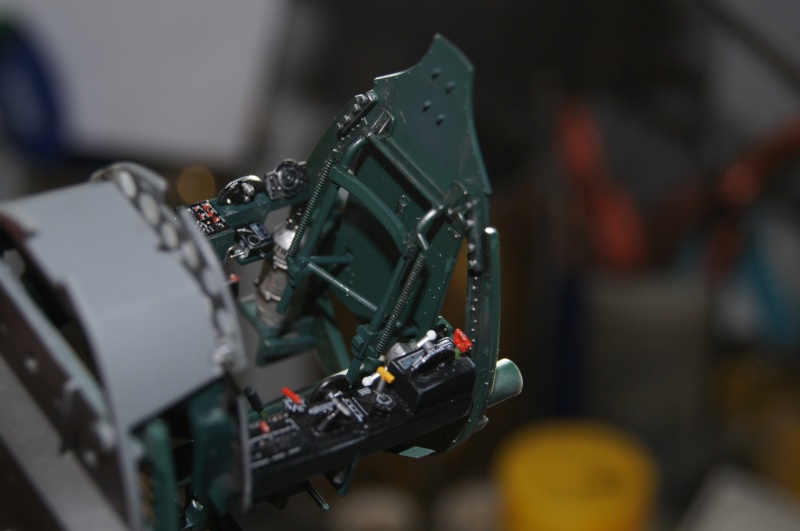

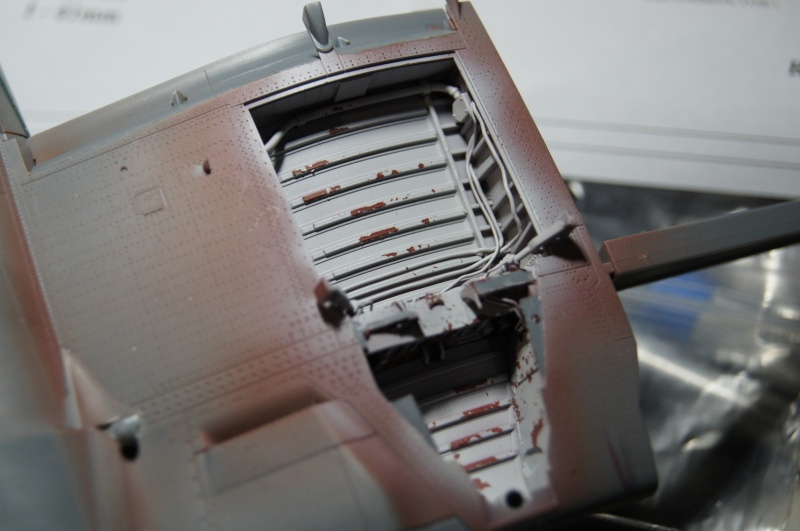

The Corsair EMM says that internal parts of the cowlings should be Light Grey-Non Specular.

But I love Zinc Chromate...

After a "long" reflection, I've decided to keep the covers painted ZC. I will use those in the second Brassin kit I have to paint them NS Light Grey and consider that the ones I've already done are a "field mod" ...

So I continued to work on the internal aspect of the cowl to mitigate (or tone down) the first step.

Done on the right side, still first step on the left...

Weathering is still progressing. Oils.

One done, the other just in first step.

Sorry for the poor quality pics...

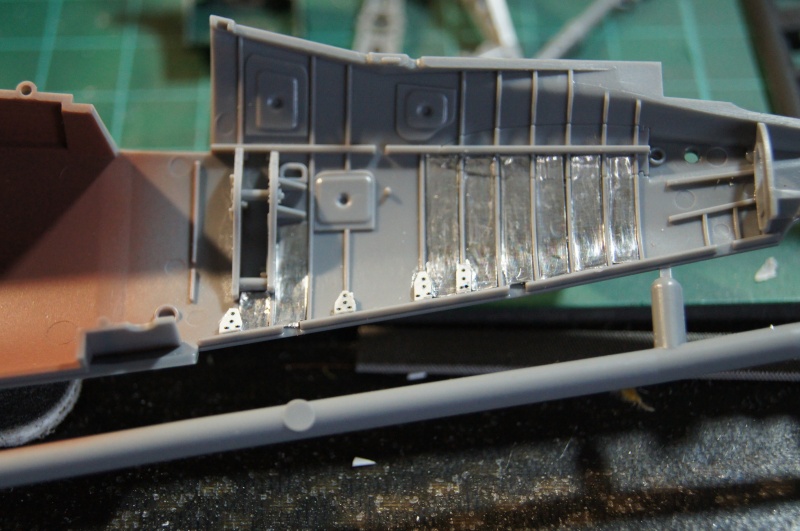

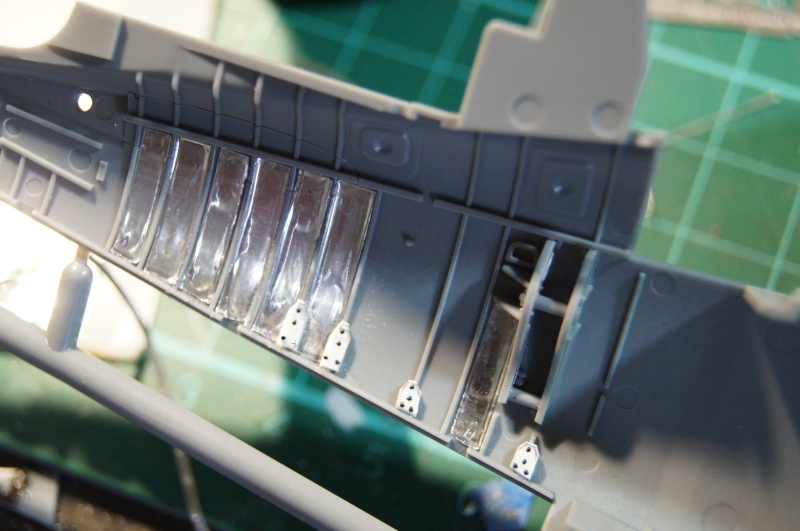

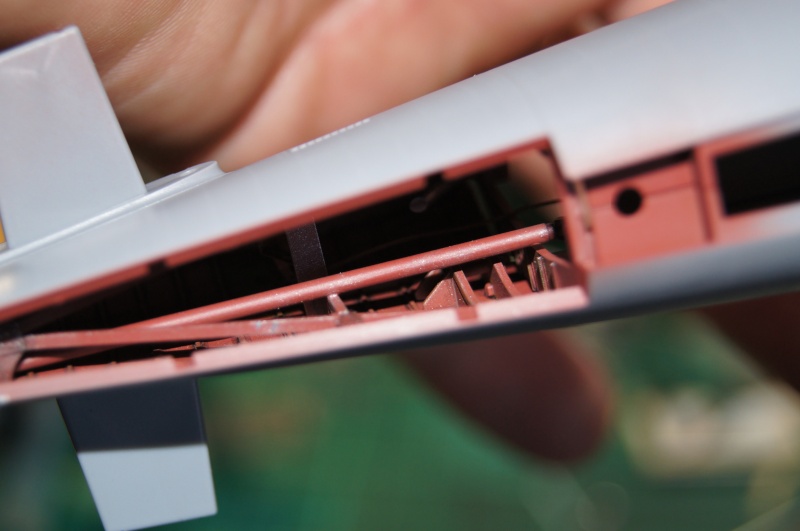

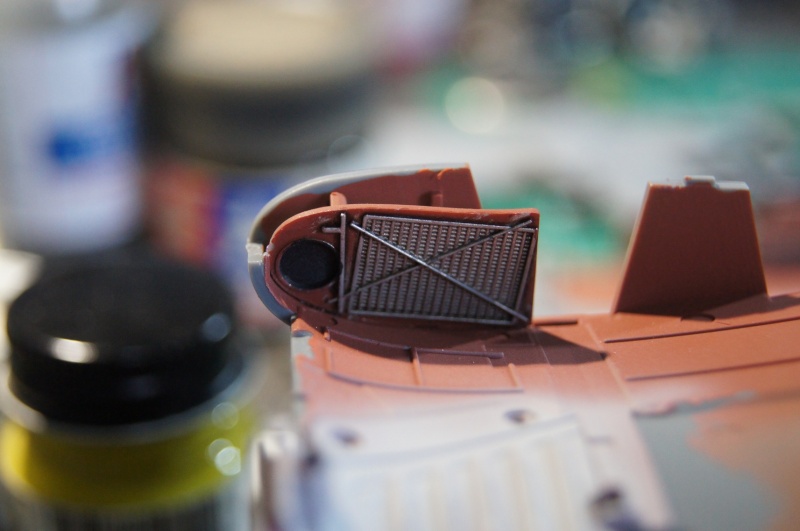

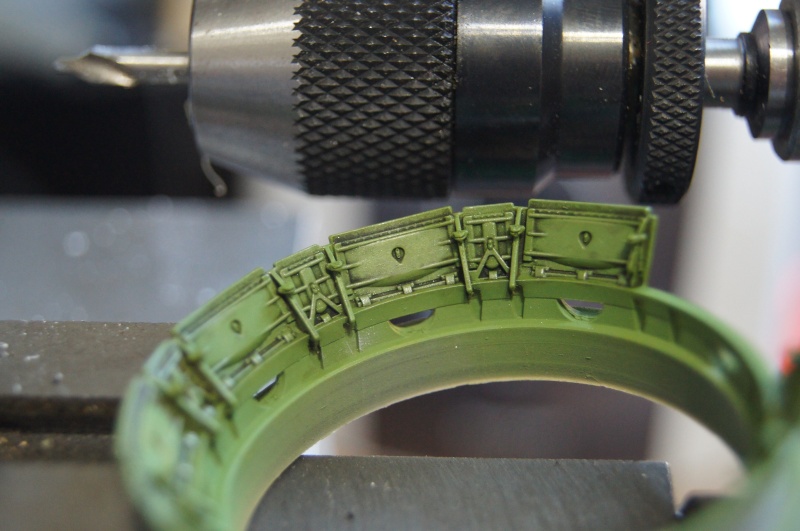

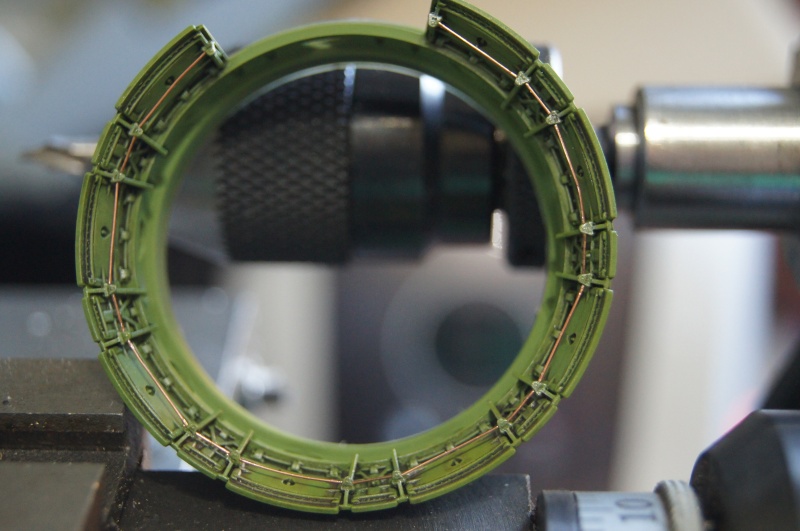

"Cable" of the cowl flaps installed:

Need to be painted!

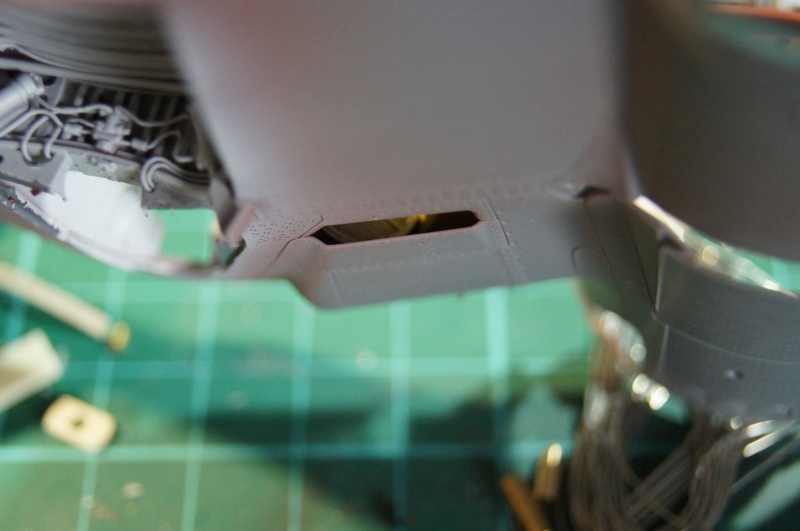

Small work to adjust the front cowl to the cylinders head:

Ignition ring glued on the magnetos:

Spark plugs wiring on the way:

Nothing extraordinary... but needed!!

Very small progress once again.

But the weather was so nice that it was really better to be ... "cruising" at few thousand feet than breathing resin down on the floor!

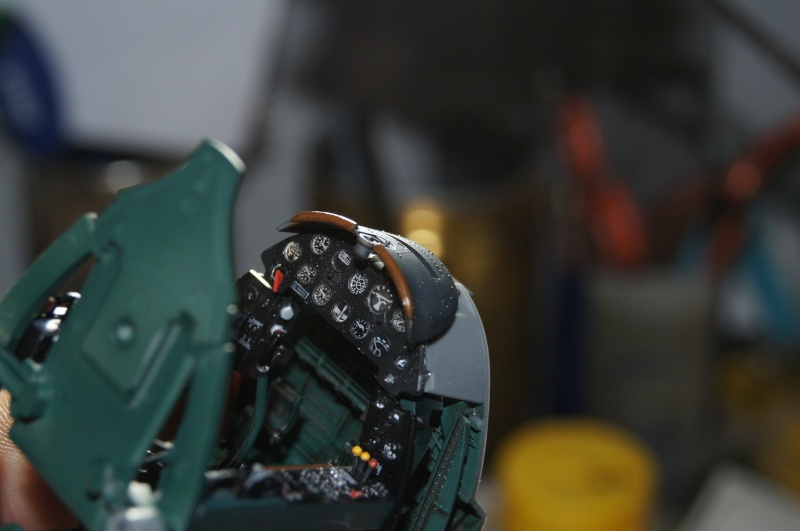

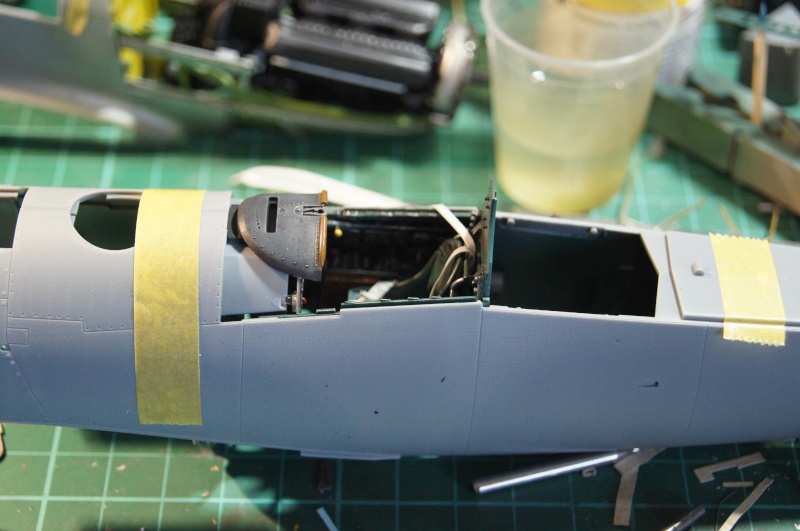

Firewall painted using Dull alu, Airframe et Pale Burnt Metal here and there.

... and ZC Acryl from Model Master (Top paint!) applied few minutes after the quick drying Alclad.

Admission plate is painted grey using a mix of FS 36118 and FS 35237 Grayish Blue from Gunze.

Inlet pipes installed on the front row

"Spark plugs" put on the rear cylinders

... and a quick test fit to see if it's OK.

Well , this is my interpretation of the Monster...

Questions and comments are welcome.

I hope you like it.

More to come soon.

Pascal