Hello Friends,

I've been slowly plugging along the last few days. Waiting for putty to dry, and I spent all of yesterday afternoon trying to save the canopy... You may remember that I wasn't happy with my masking and painting job.

I tried to do a bit of cleaning with a little turpentine. In seconds, we had major fogging. My memories of being a kid came flooding back. Is there any solvent that won't ruin a canopy when you are trying to remove oils?

I did a little research and found that some guy had done a little salvaging using toothpaste. I tried that alone and with baking powder and saw that I was very slowly making headway. So, I realized that abrasion was the key.

I set to first with 1200 grit sandpaper, then baking soda on a q-tip, and finally grabbing the Dremel when my patience began to wane. BTW, I ordered a Vacu-formed canopy set by Falcon from Modelcrafts and Hobbies in New Zealand... Thanks Magnus!

I tried various buffing and polishing attachments that came with the Dremel that I hadn't until now an occasion to use.

and came to an 'almost' condition.

After doing major damage (I was experimenting after all) with a couple of buffing heads, I determined that one made of layers of soft cloth to be most effective. Dipping the canopy in thinned Future actually made some pieces of the canopy completely transparent and shiny.

But the canopy has some molding flaws, and a small crack from before I ever laid my hands on it. I reckon if I were to sand away all of the details and bring the lowered panels flush with the raised panels, I might have a chance with anything but the crack. So, it's toast.

Today I added the tail control surfaces. Just like the intakes placed above the engine I used pieces of brass rod to make alignment pins and drilled holes to make it all fit together.

All three pieces required sanding to get the trailing edges to feather sharpness. You can see by the thin lines of primer on the rudders that all three pieces seem to have slipped in the mold. ...or something like that.

I have a problem with both ailerons. There is a gap at the top which I don't want to fill with putty, but cannot leave open.

I have thought about drilling holes in each of the four blisters on either side and inserting brass rod to simulate moving parts within the structure.

Or, I can try to add some sheet material and hope that I don't ruin the blisters while I try to make the sheet look exactly like the blisters. I've never had a model plane take so much effort.

Any advice?

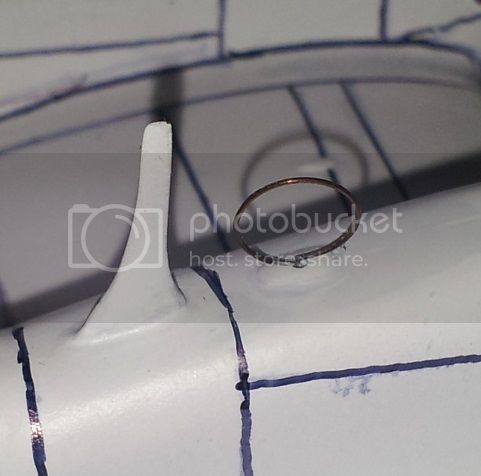

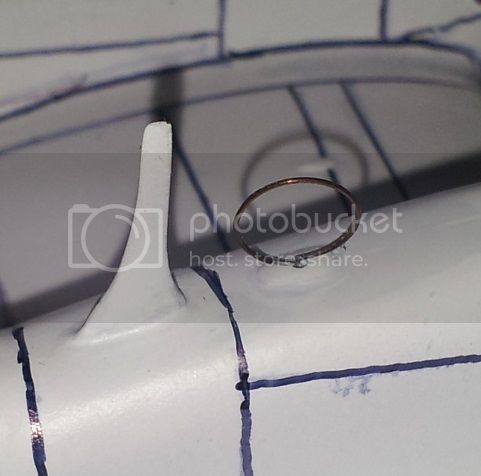

I thought I'd add a shot of my home-made blister, aerial mast, and dry-fitted DF loop just to show some progress.

...I gotta quit taking pictures in macro-vision...otherwise I'll never finish this thing.

Thank you for reading!

Gary

Edit: Spelling