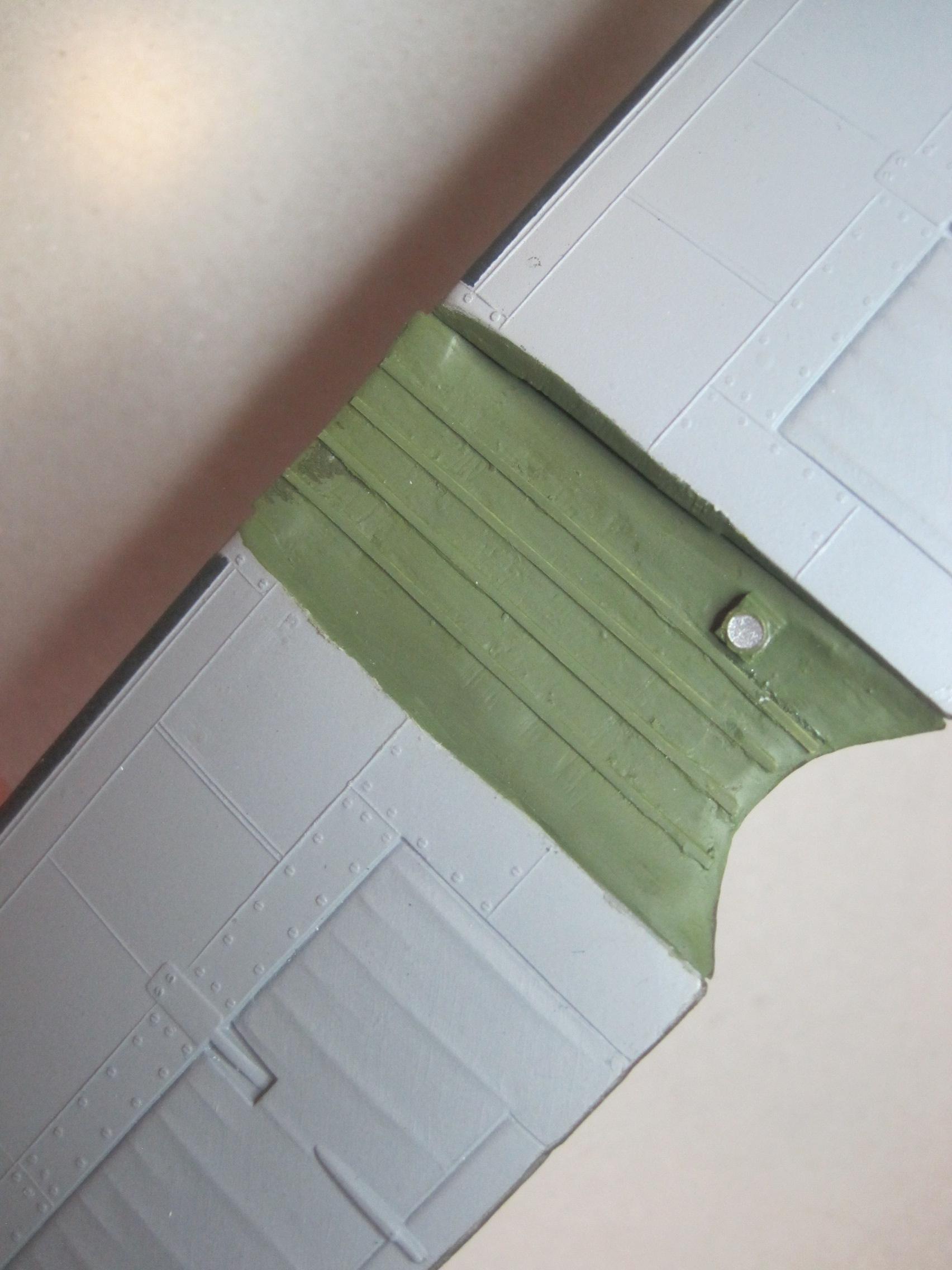

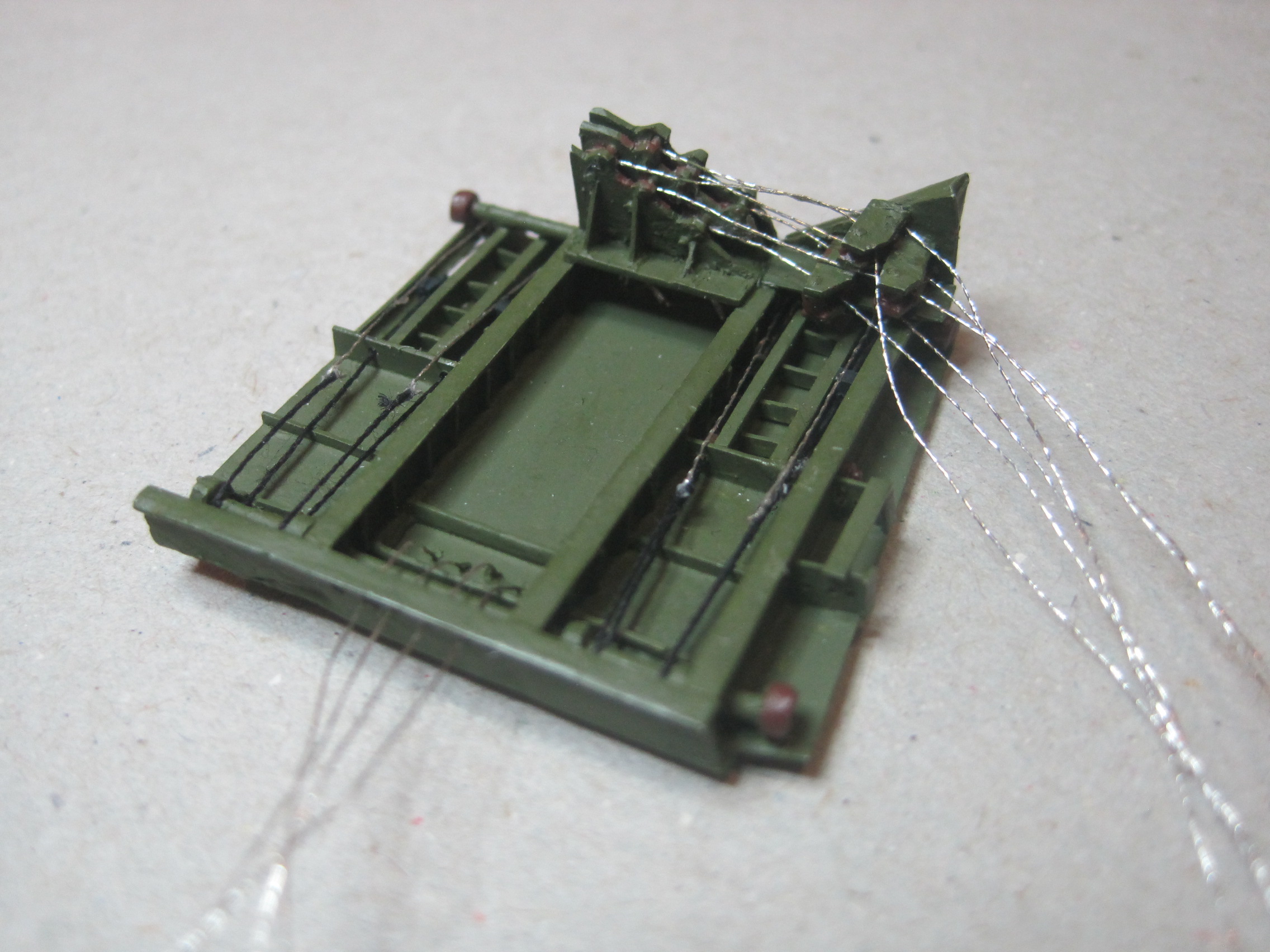

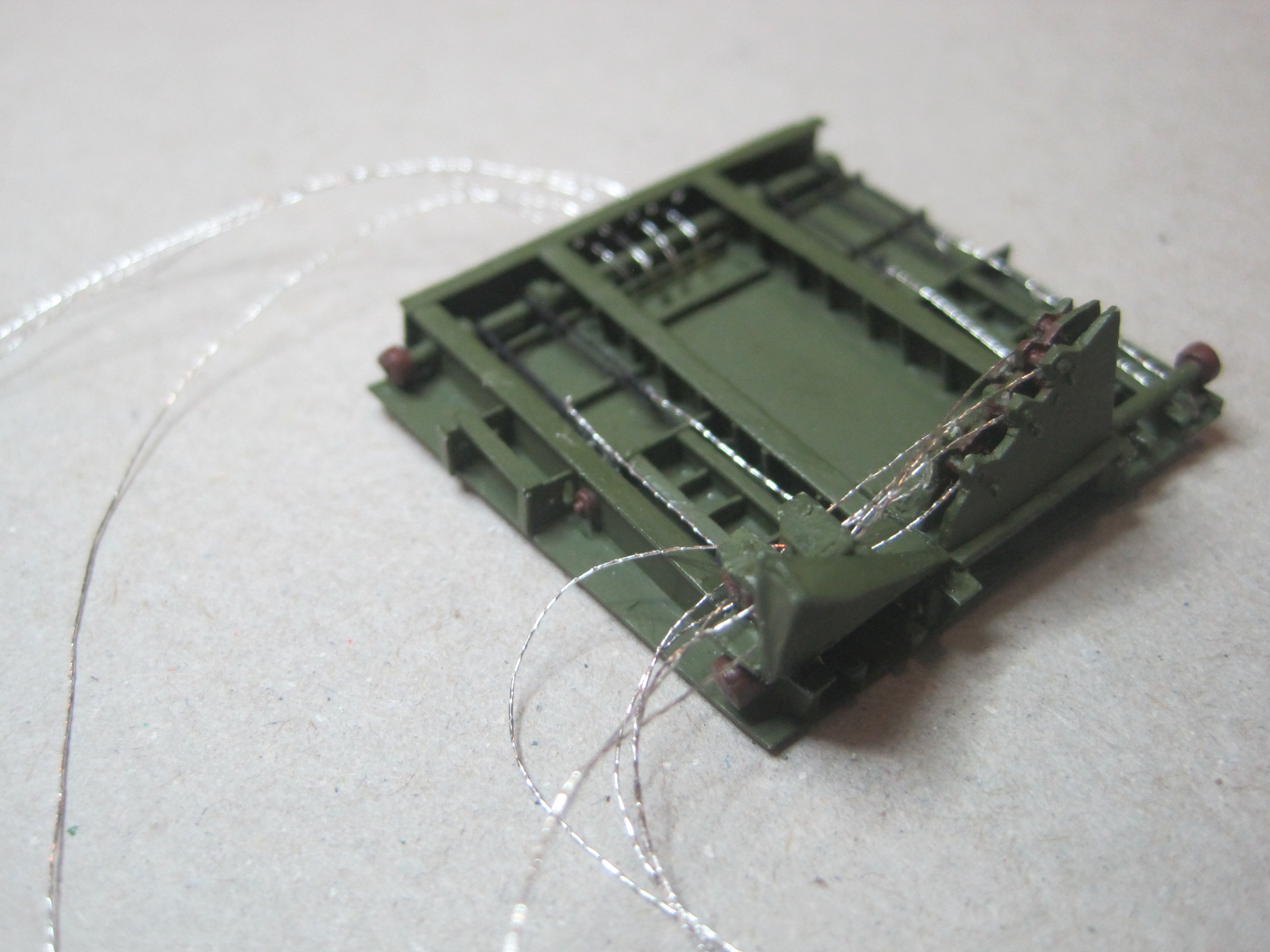

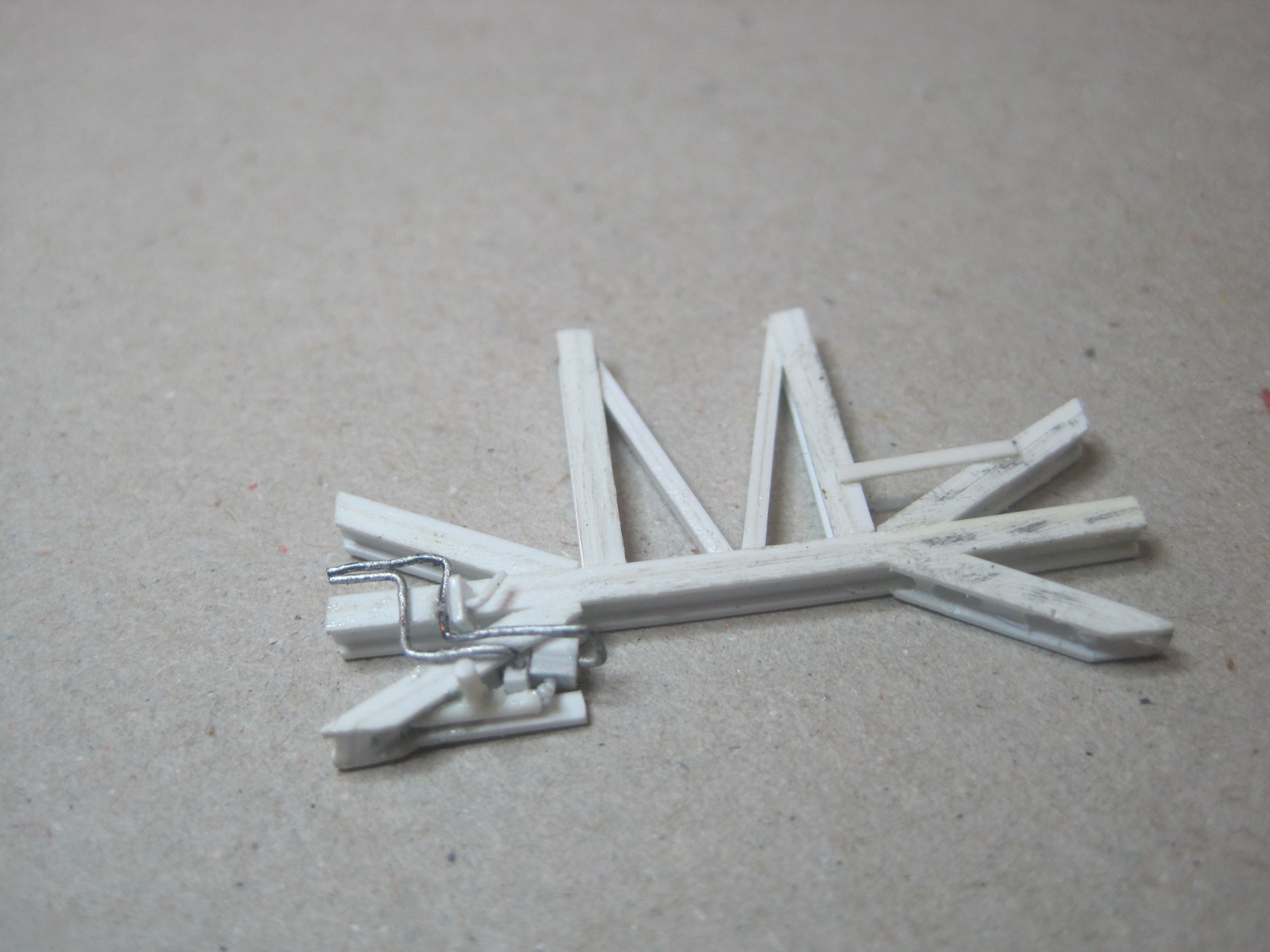

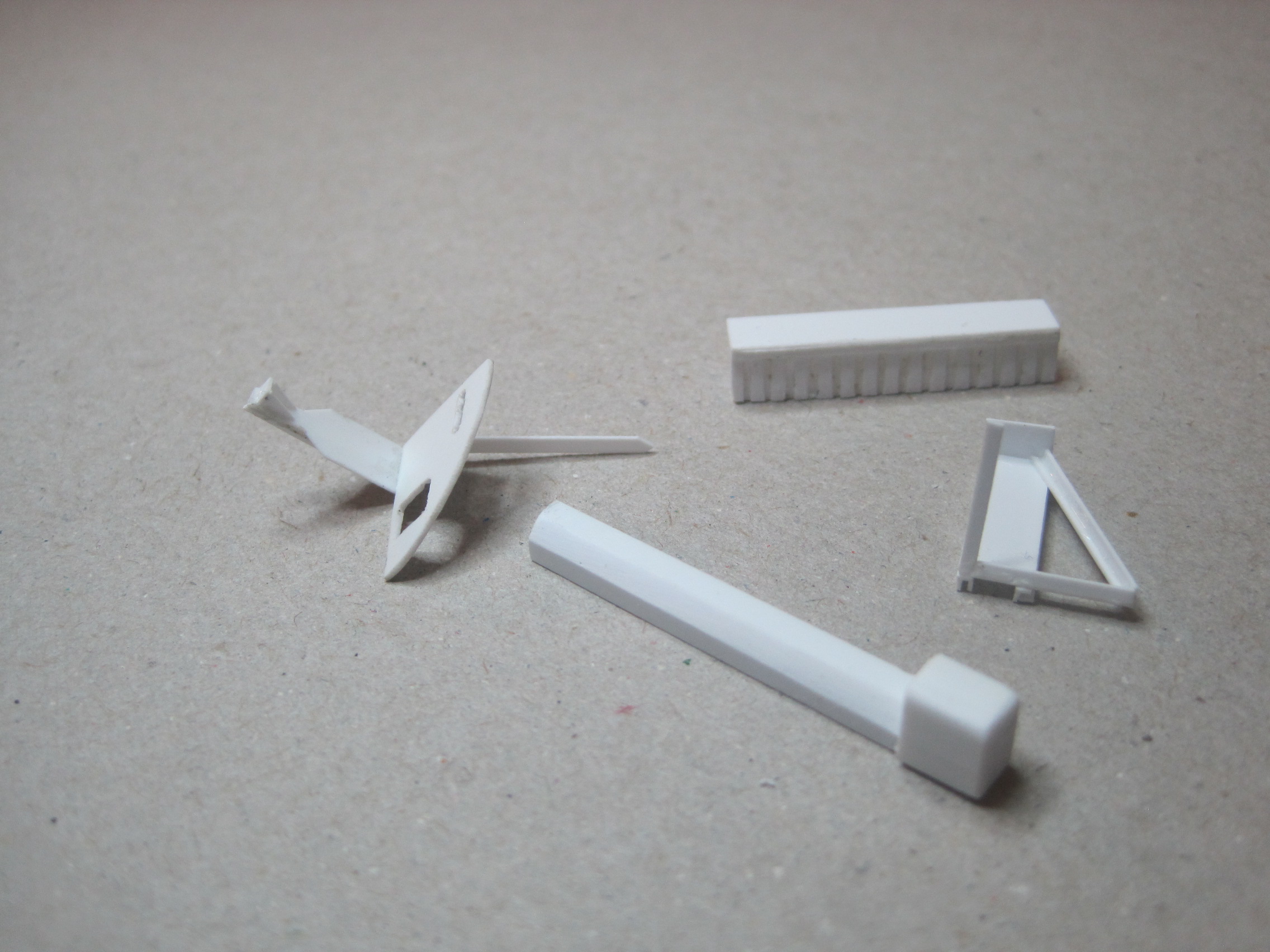

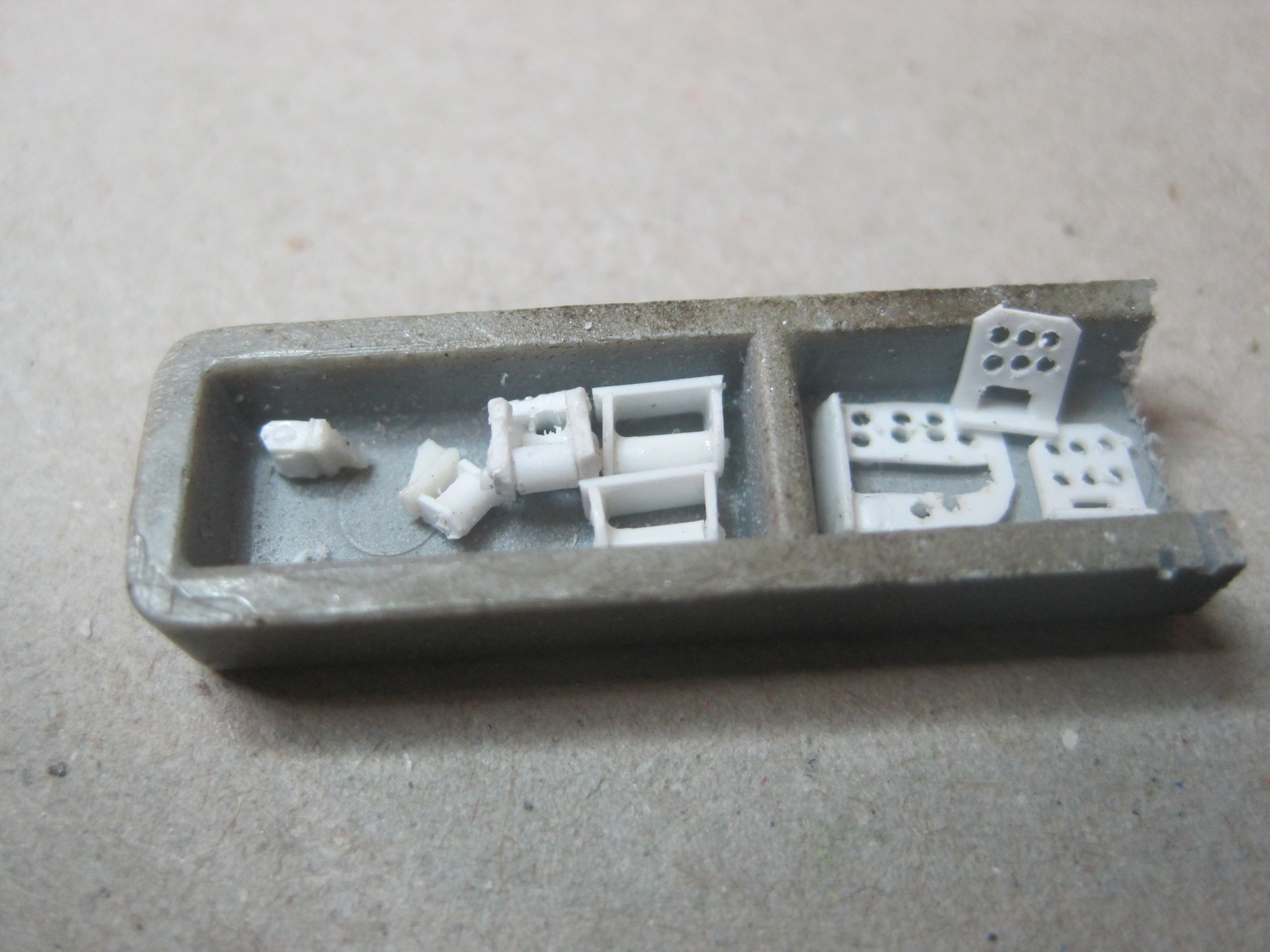

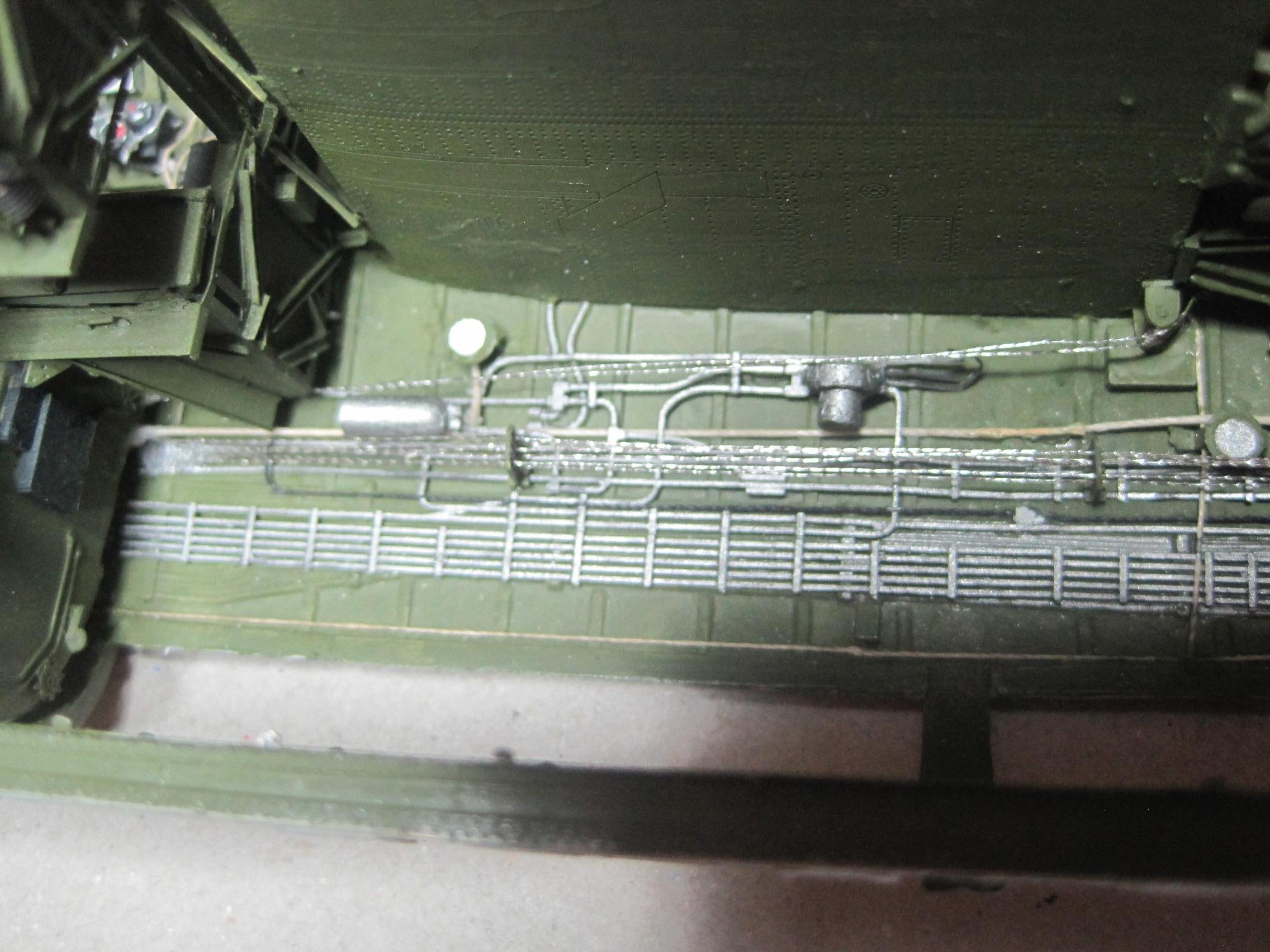

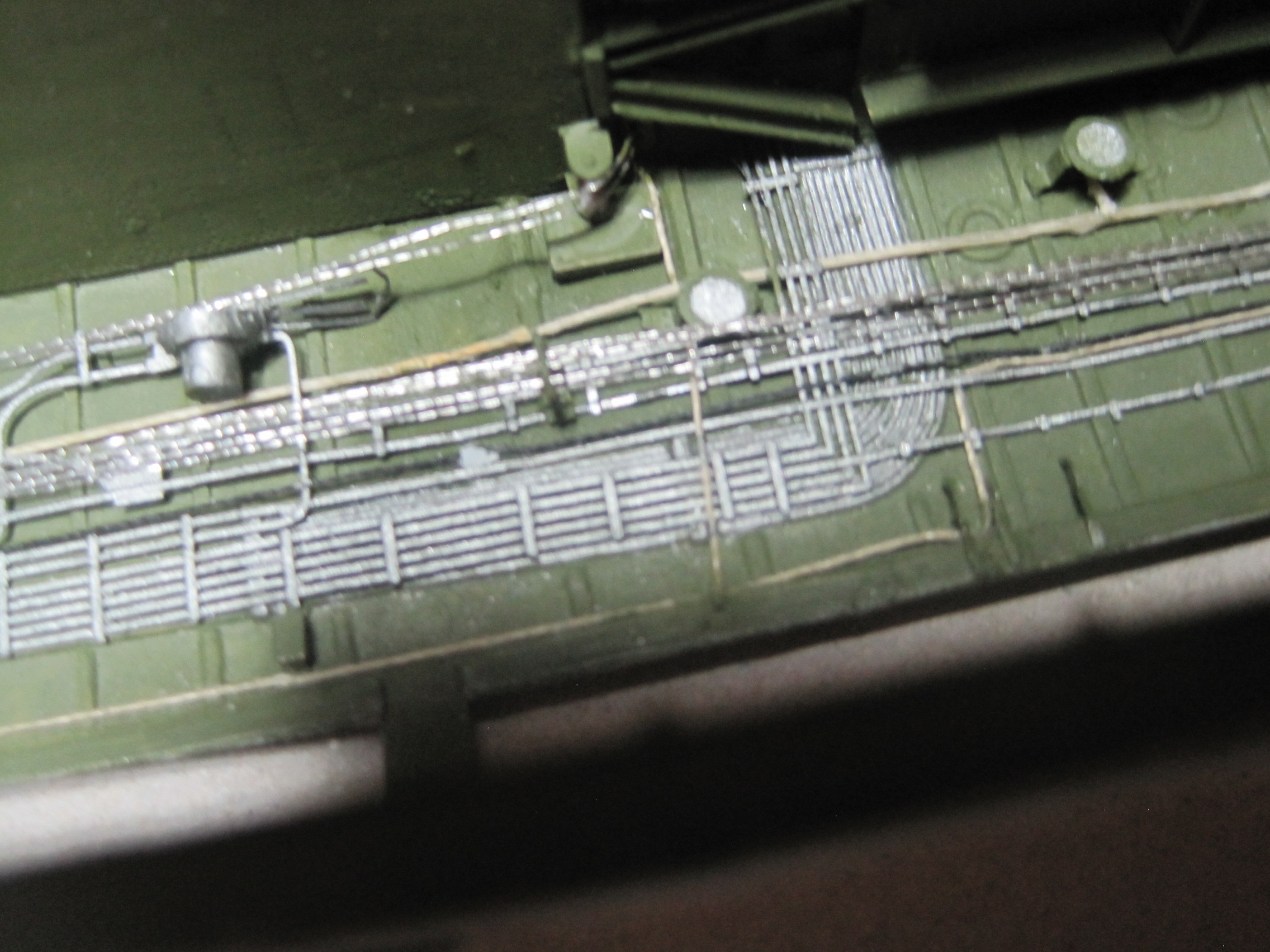

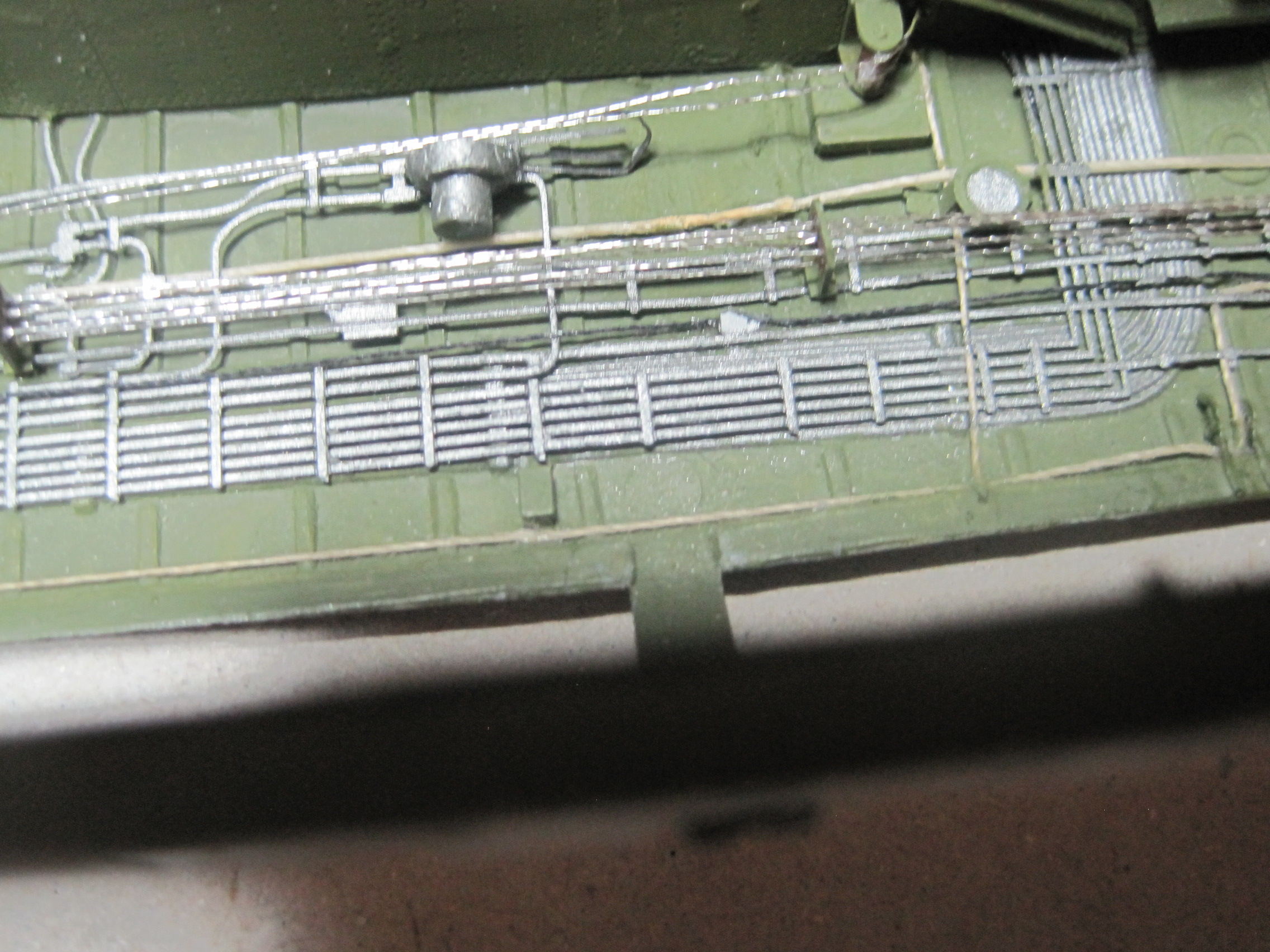

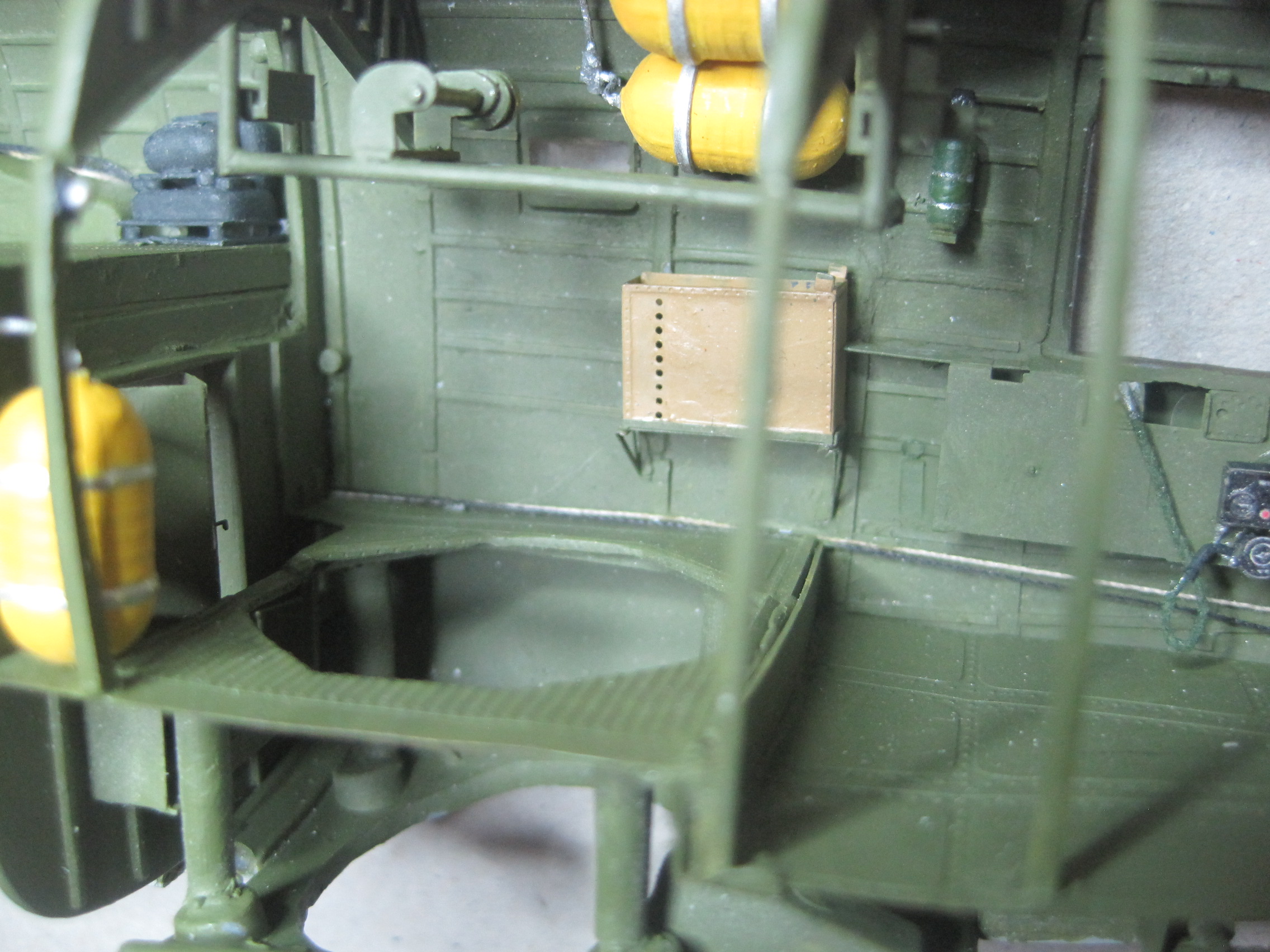

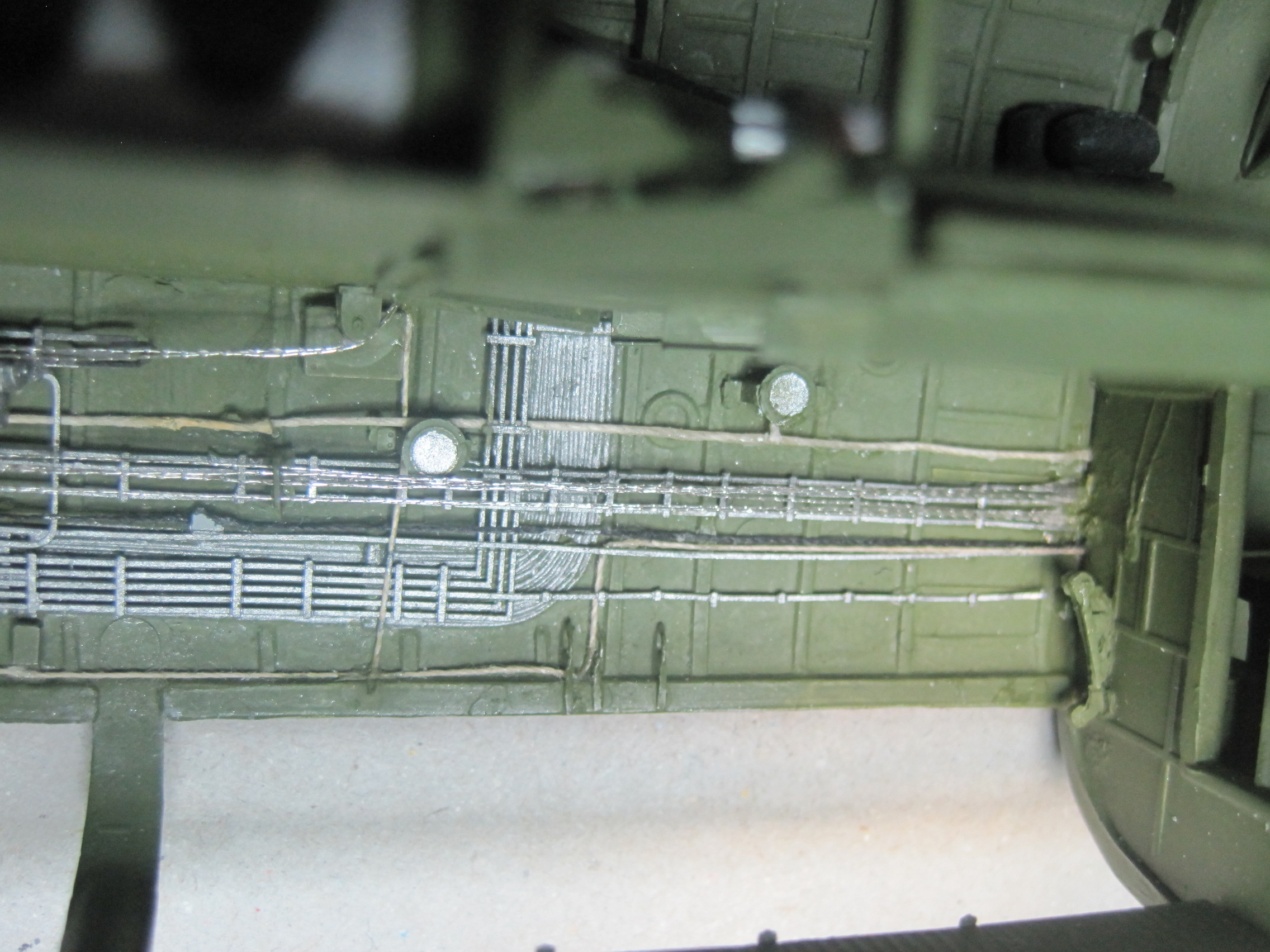

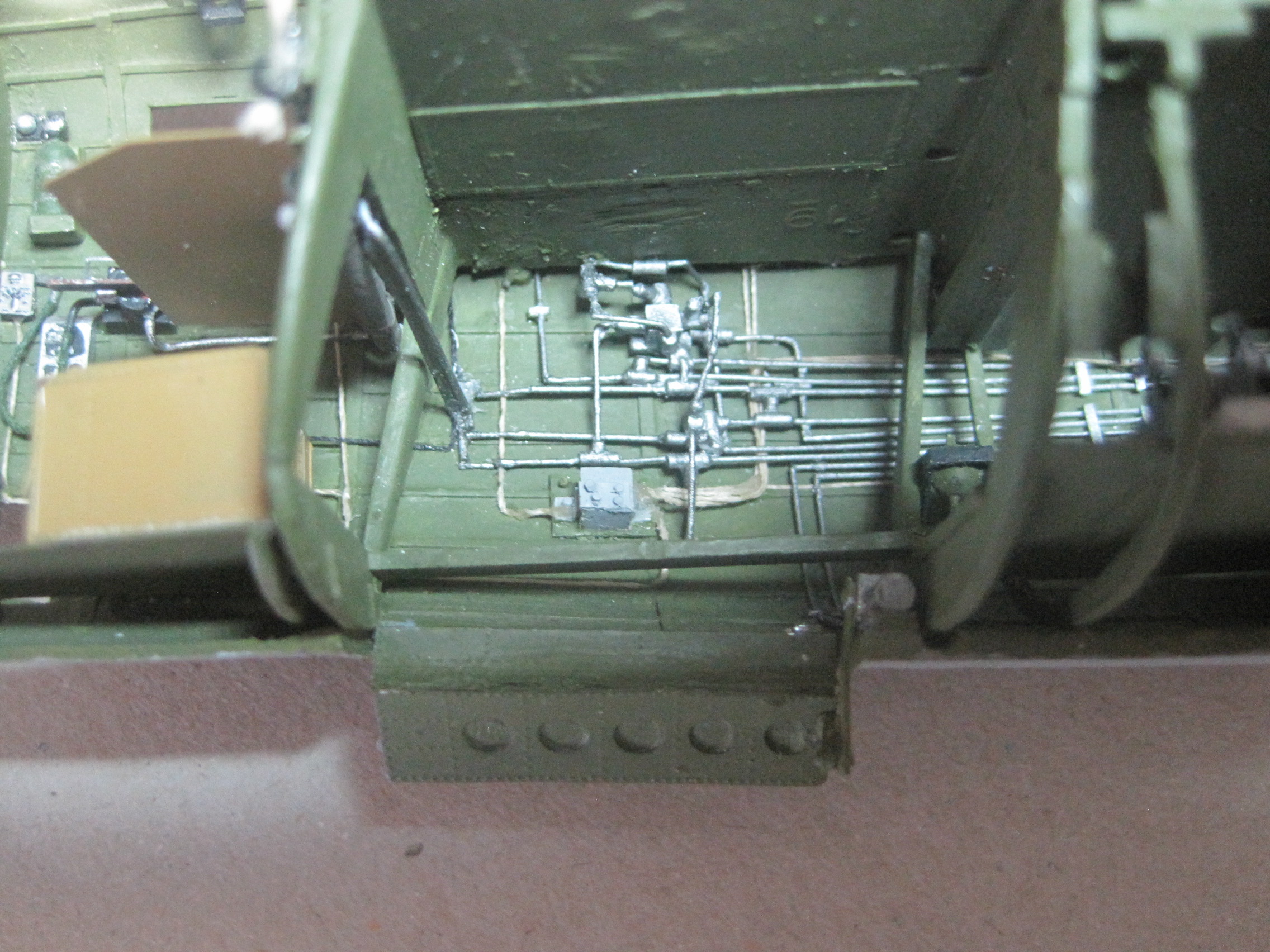

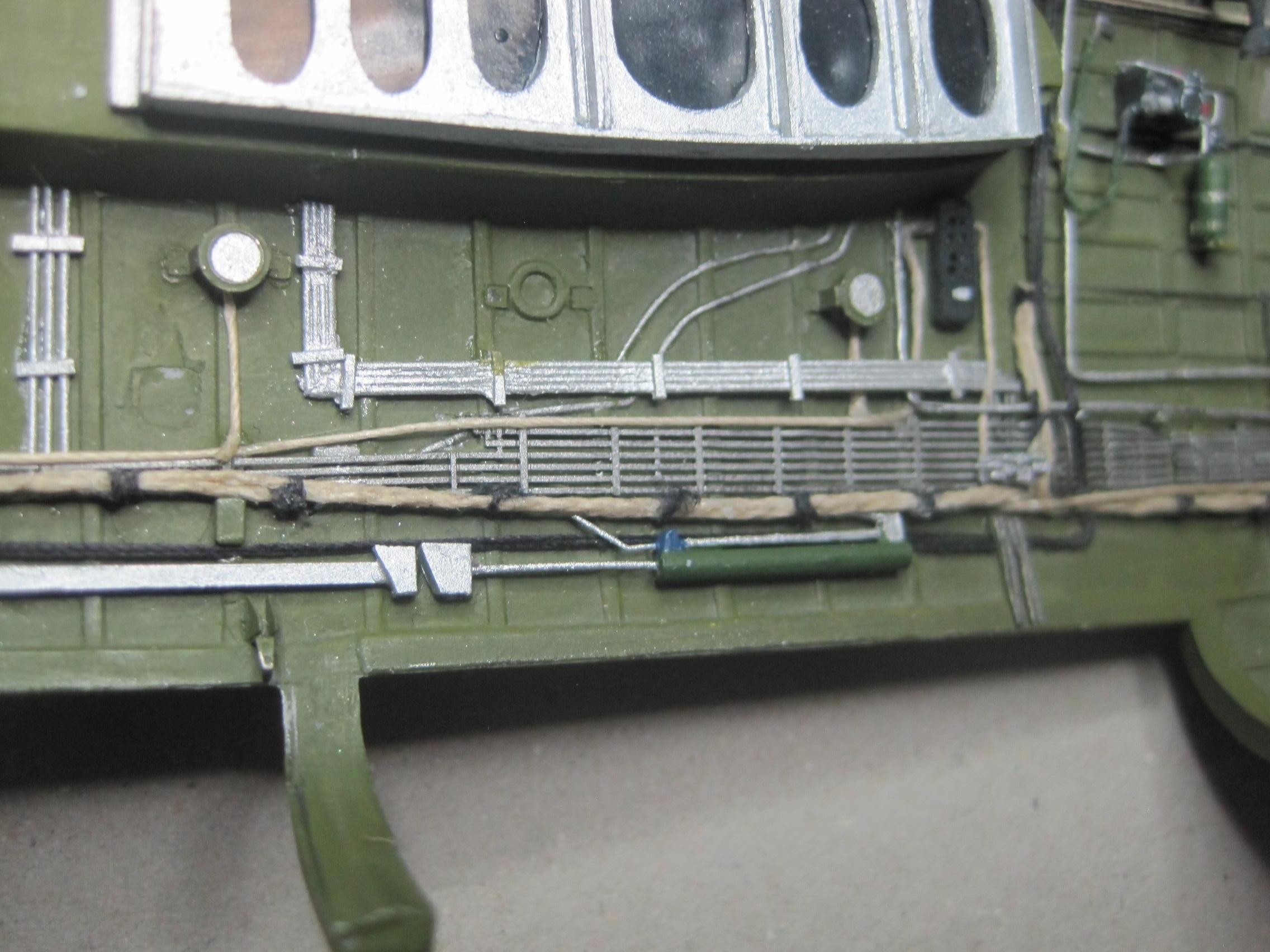

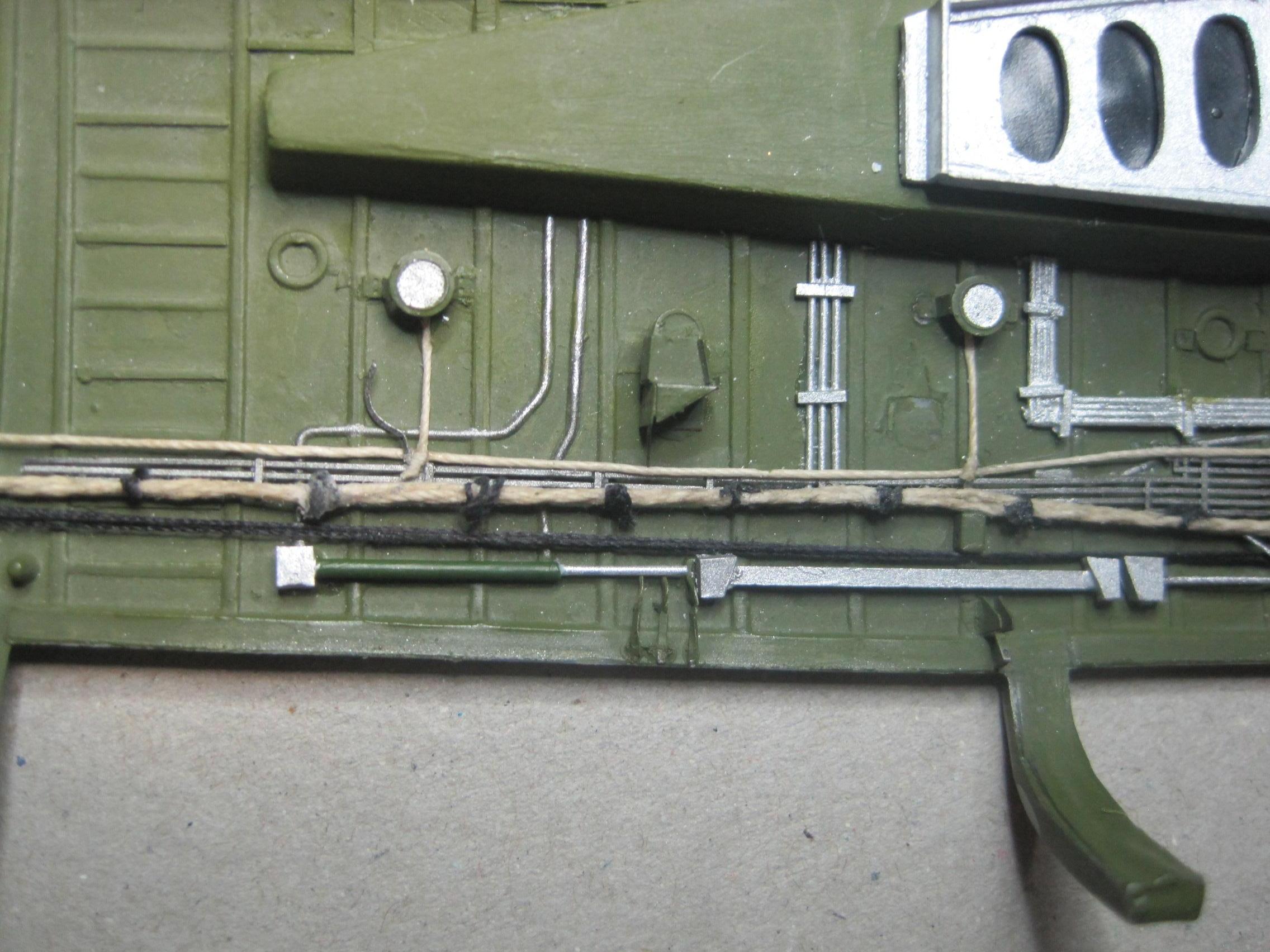

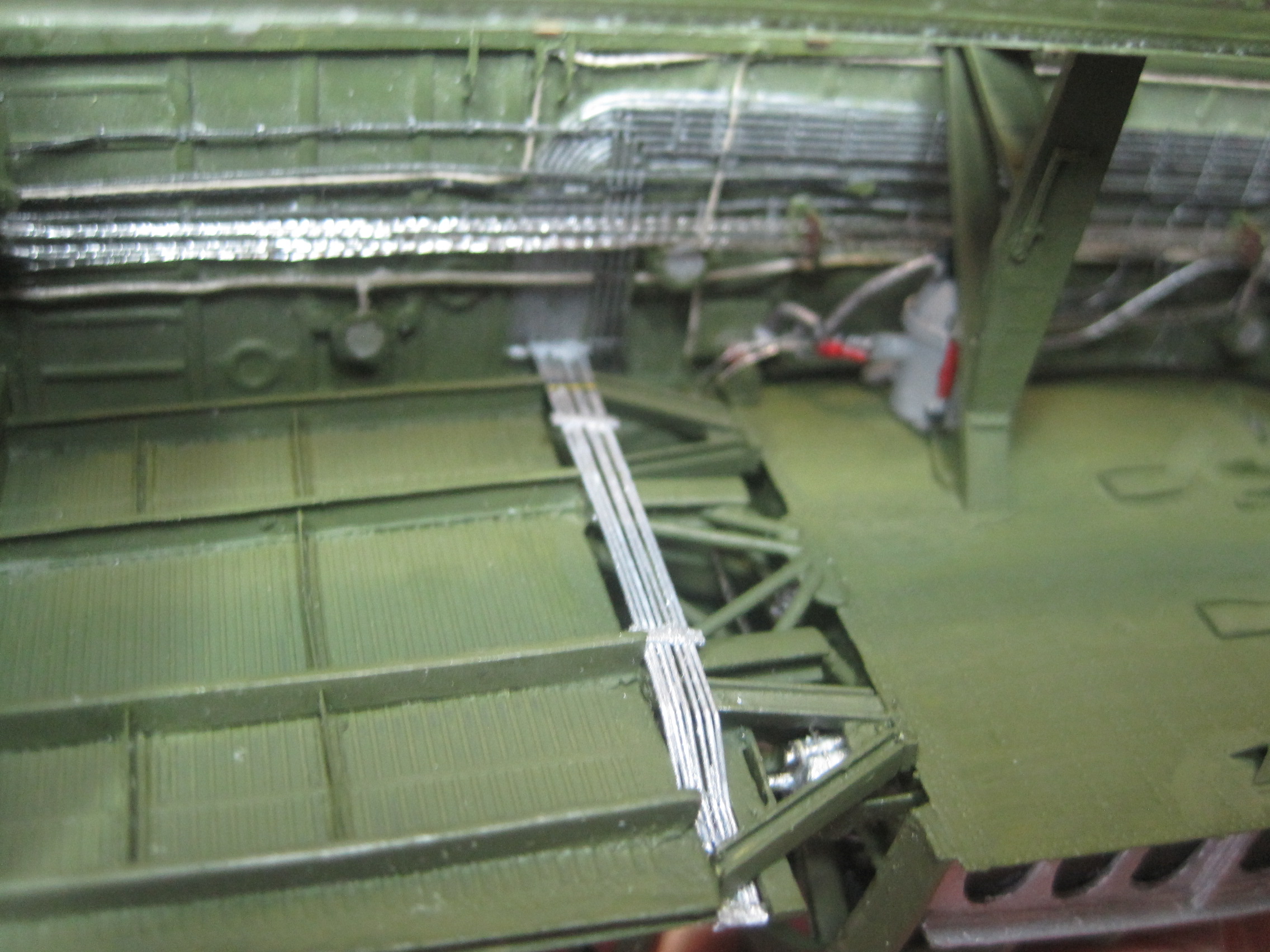

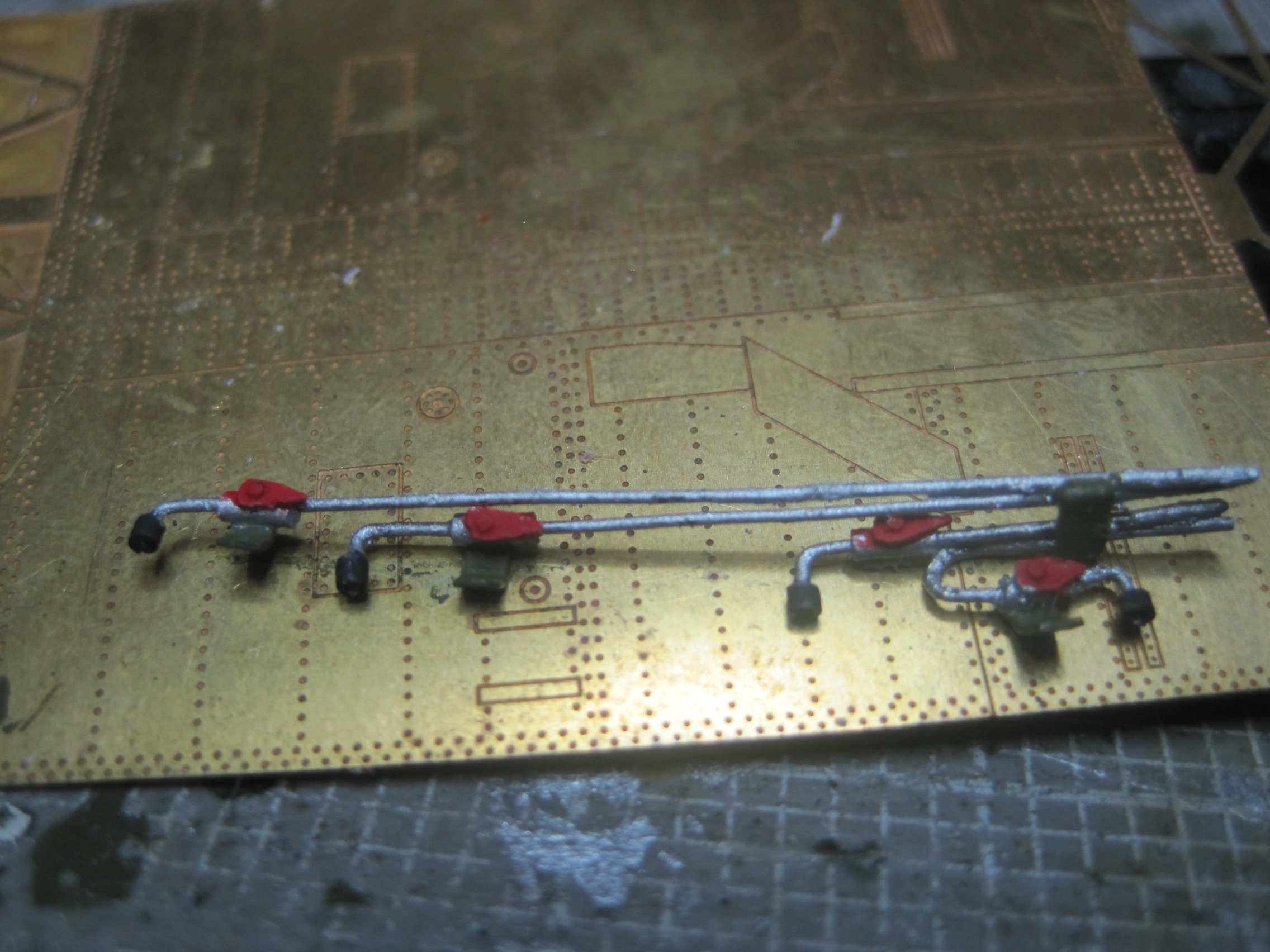

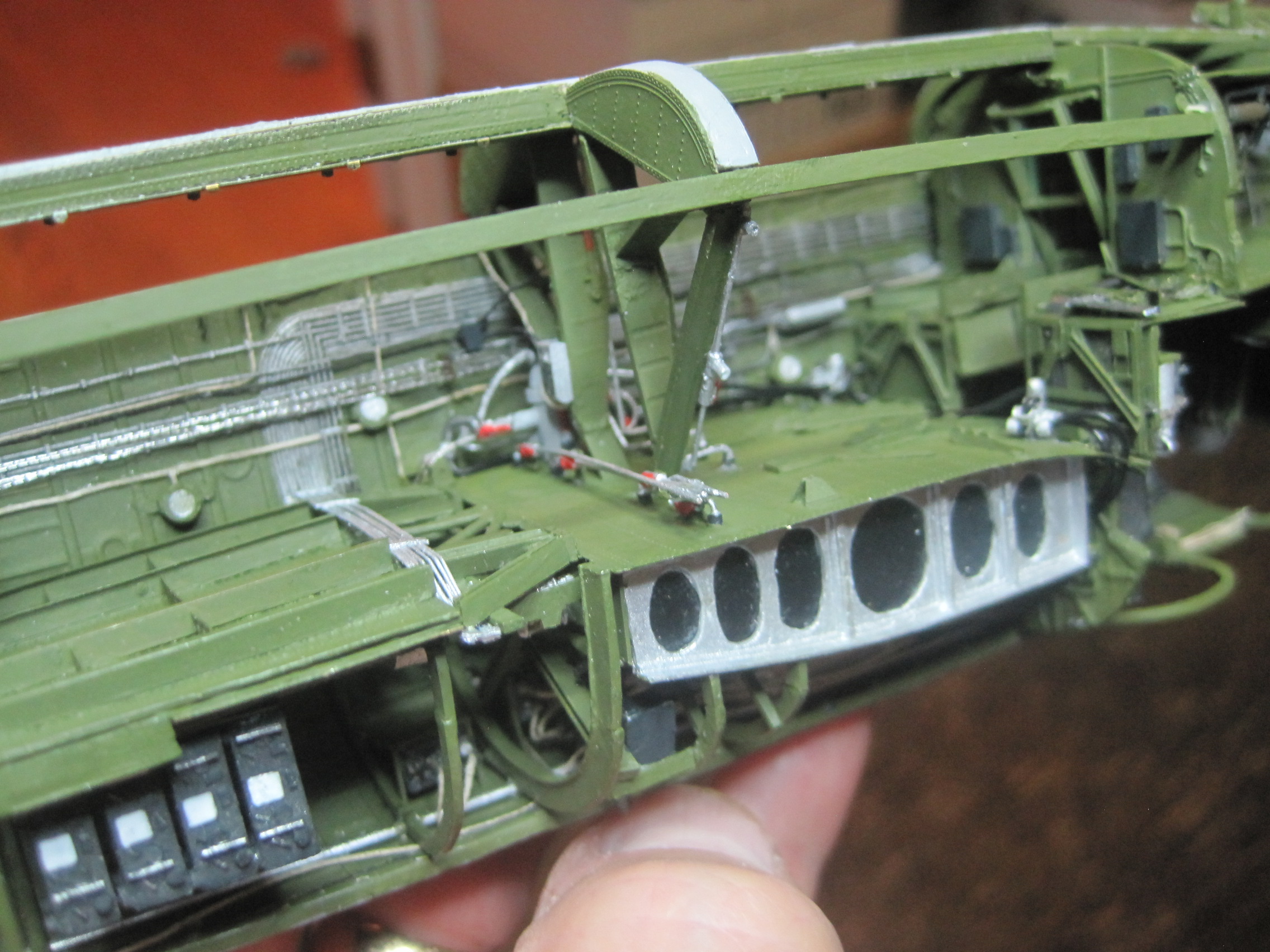

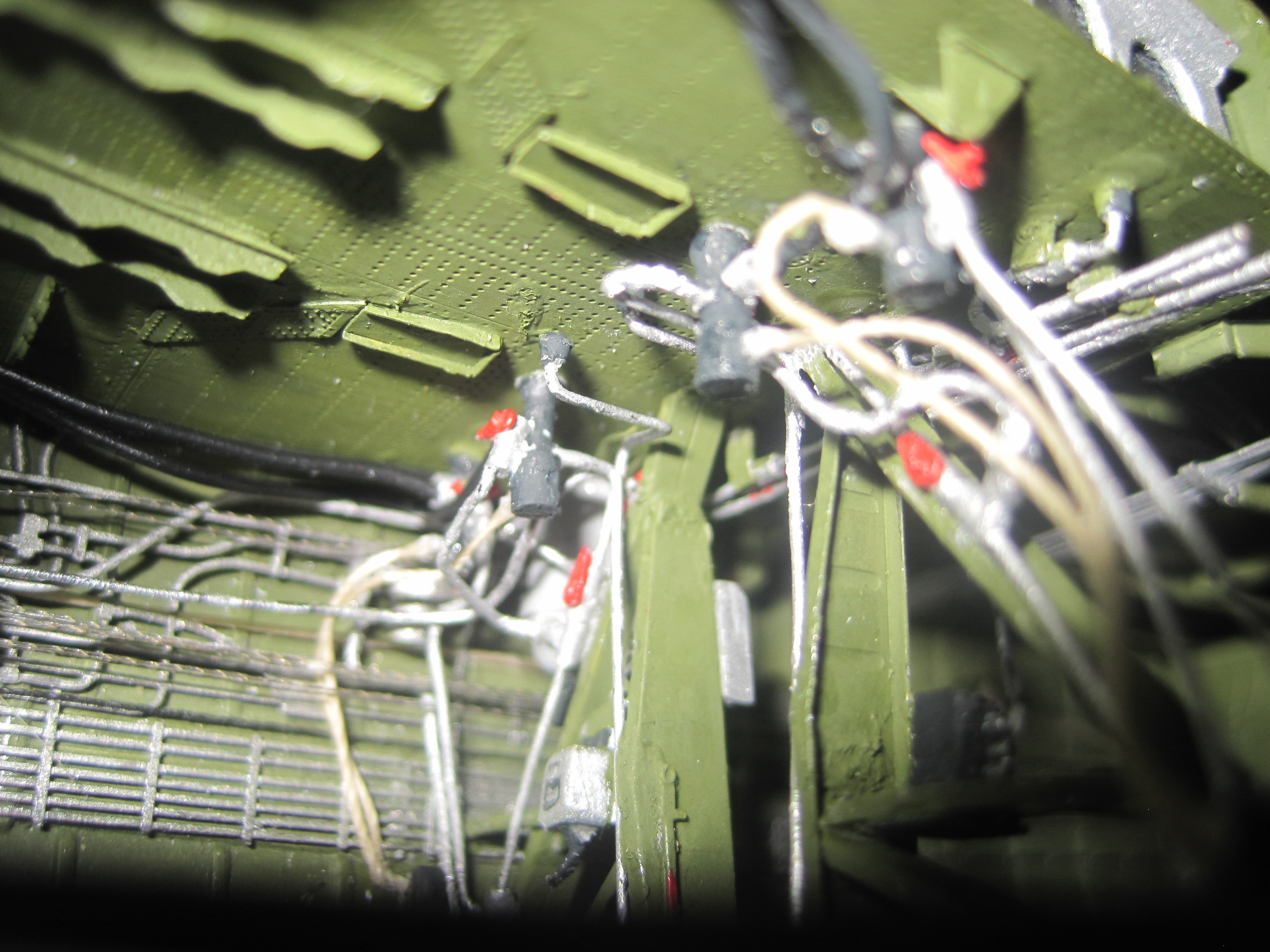

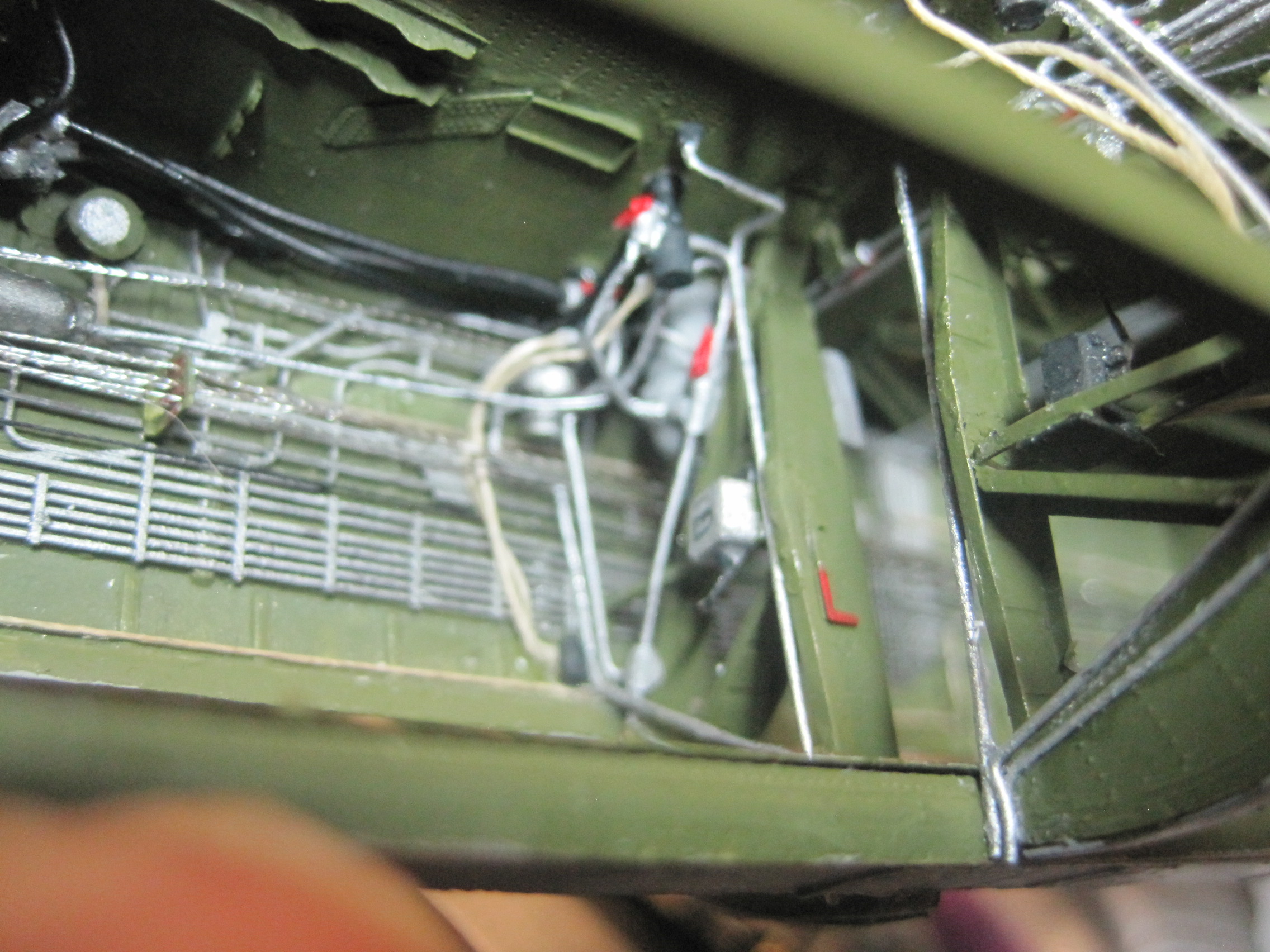

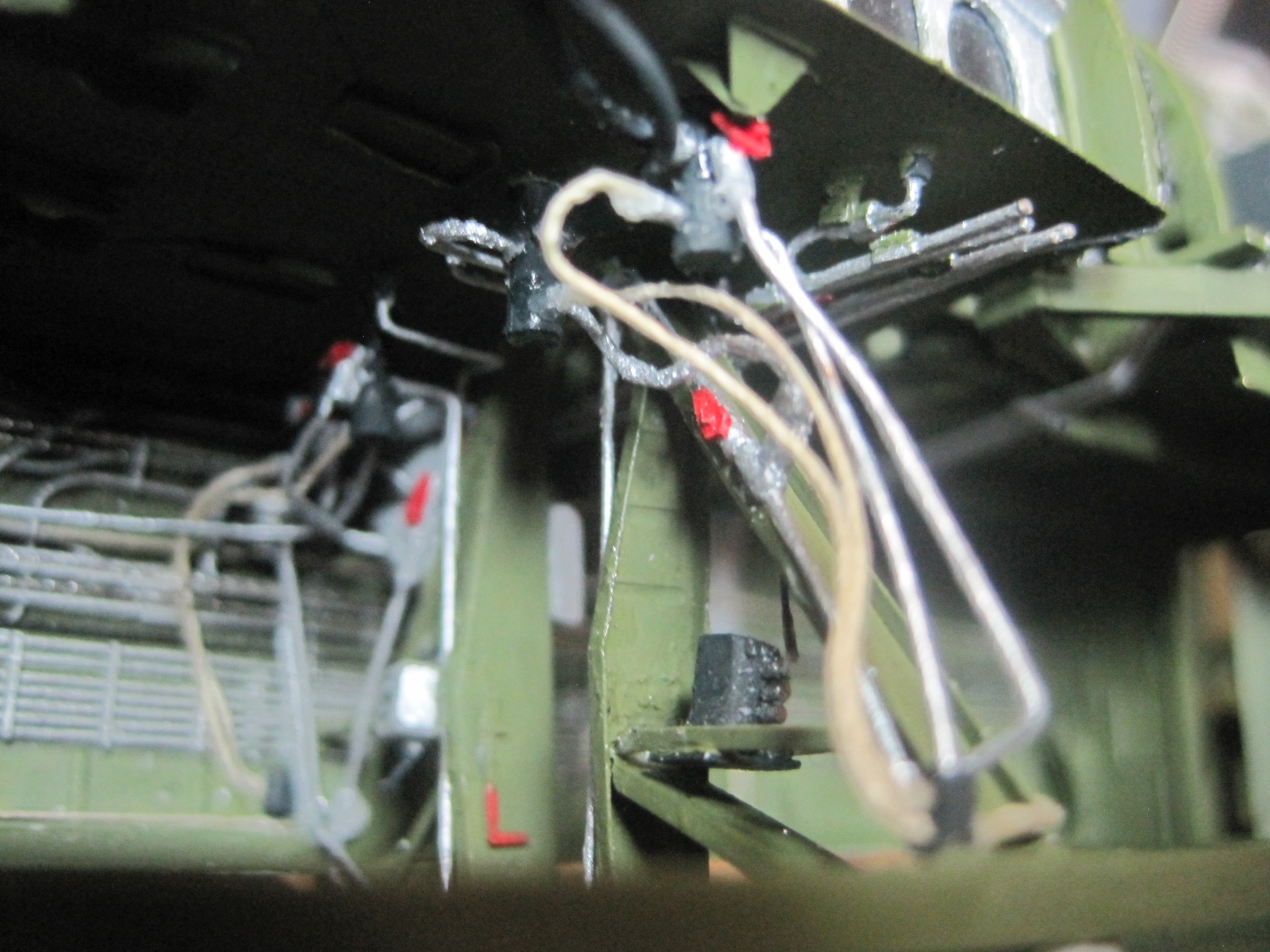

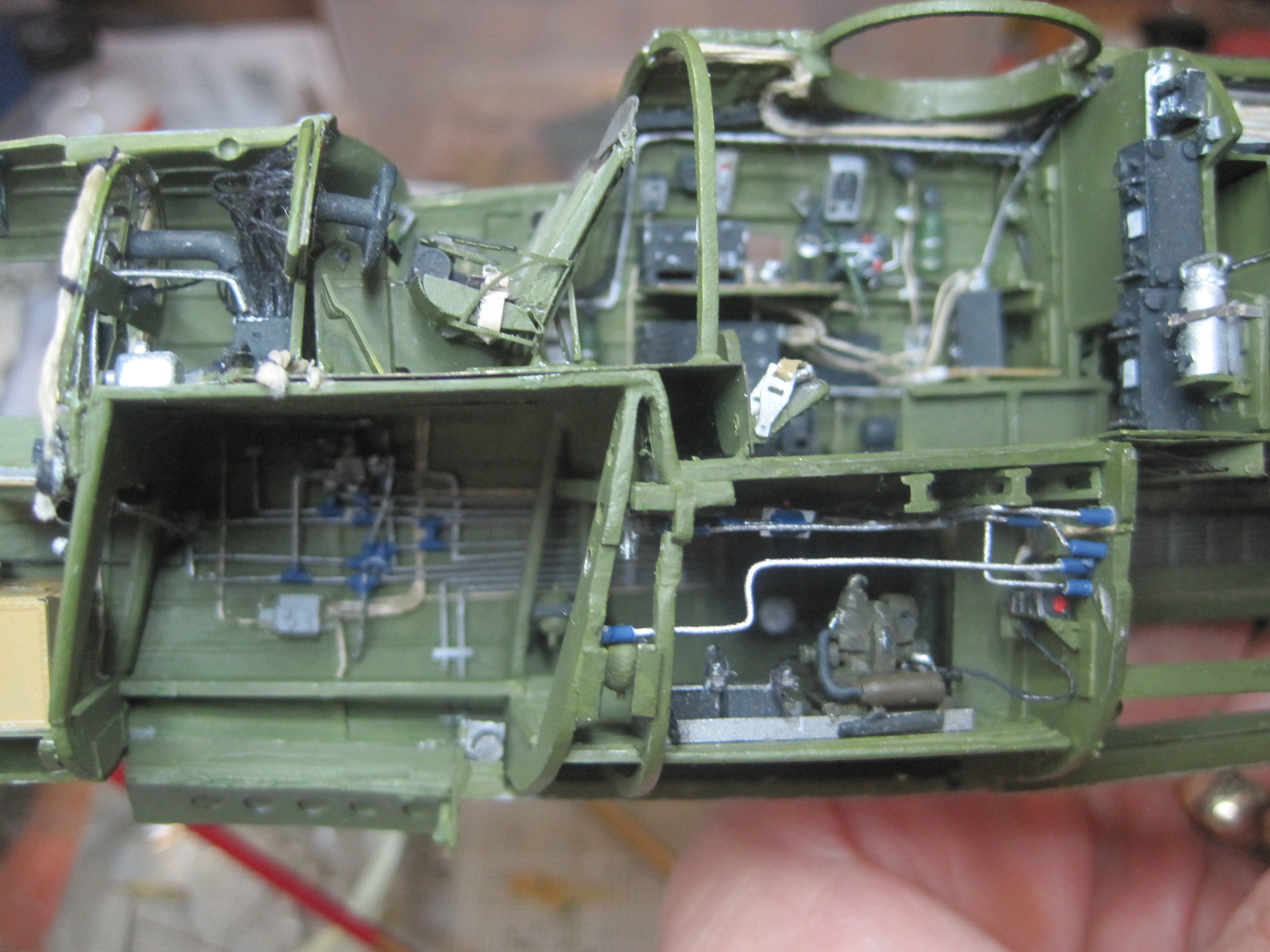

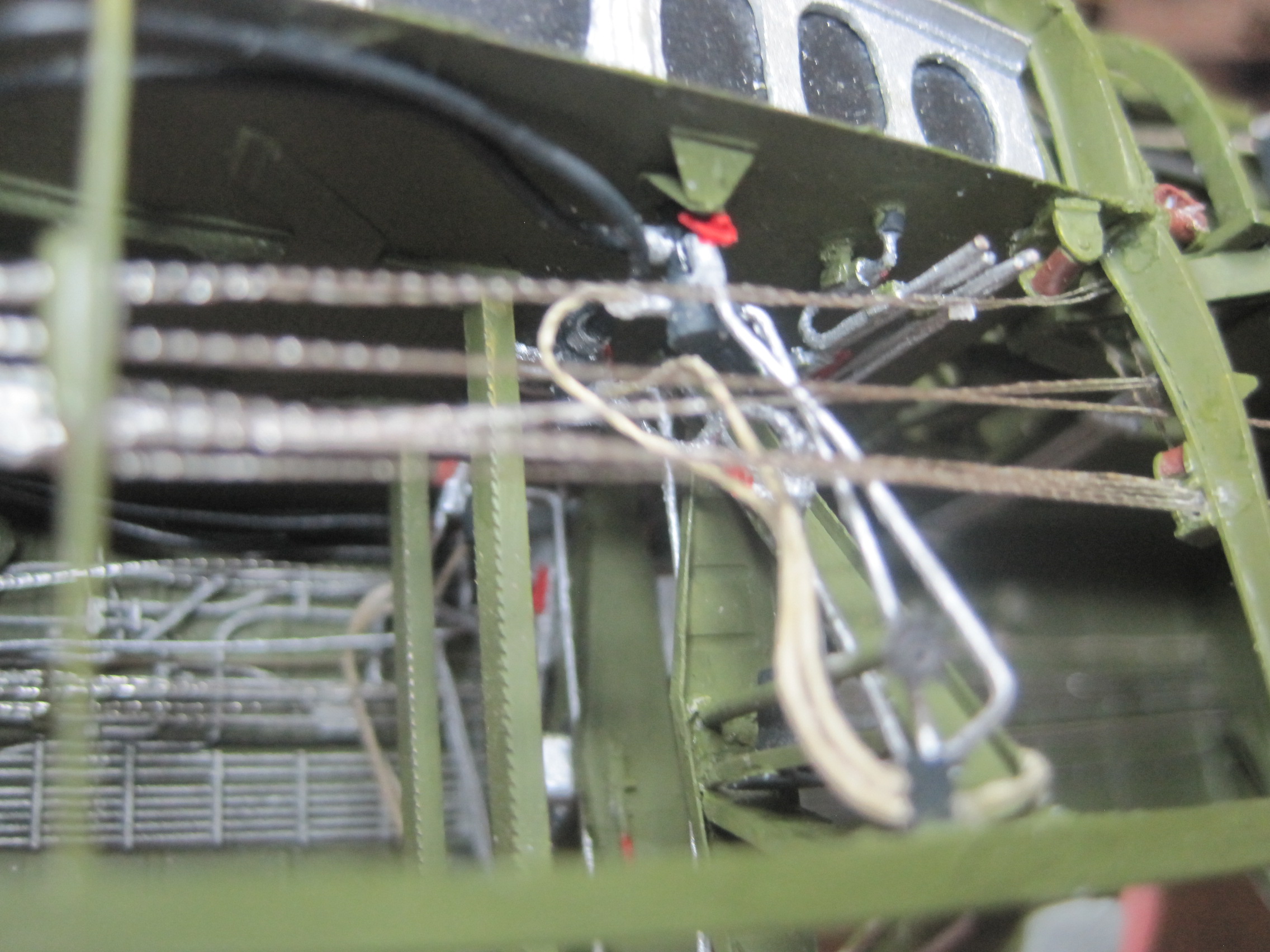

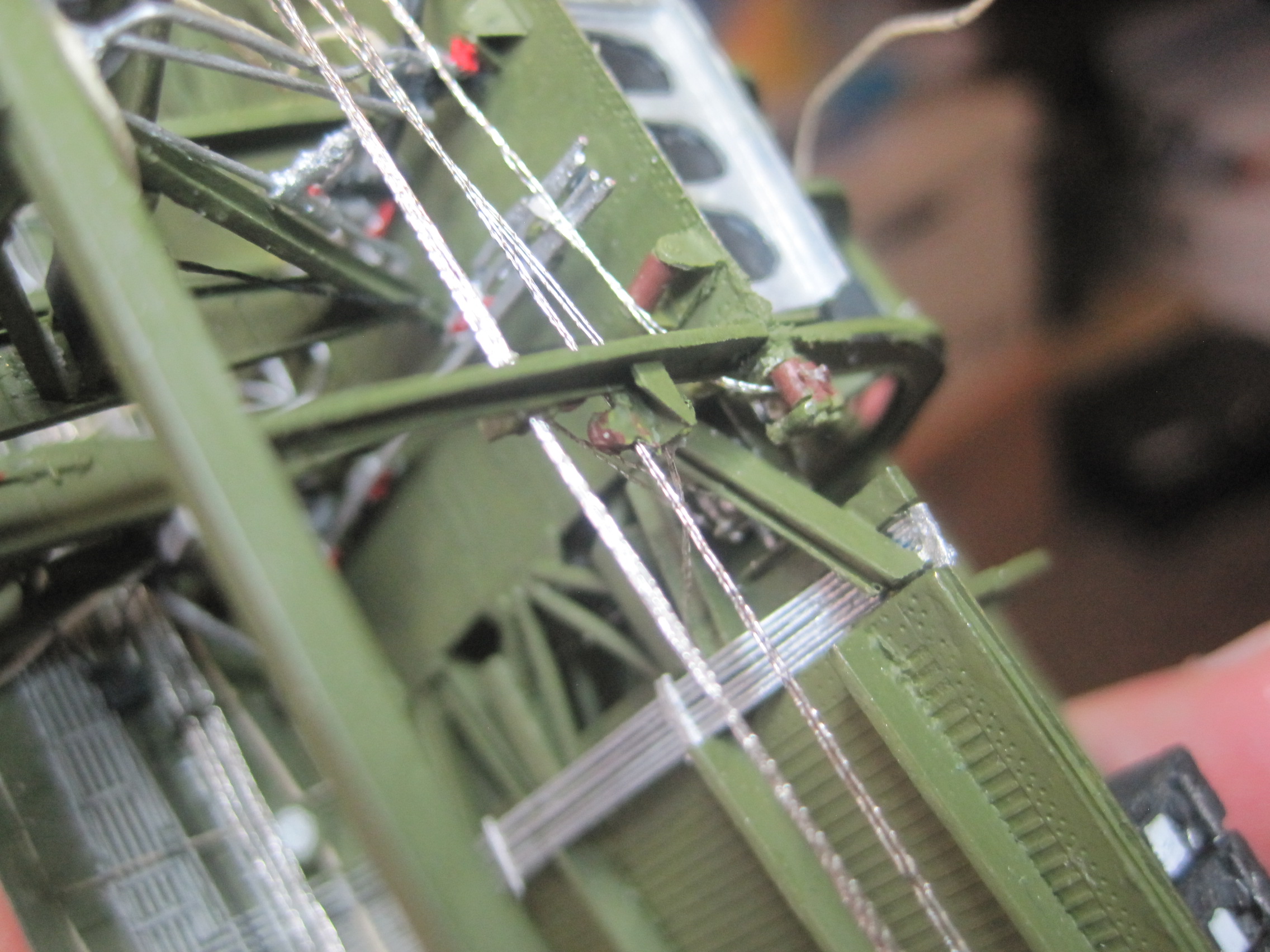

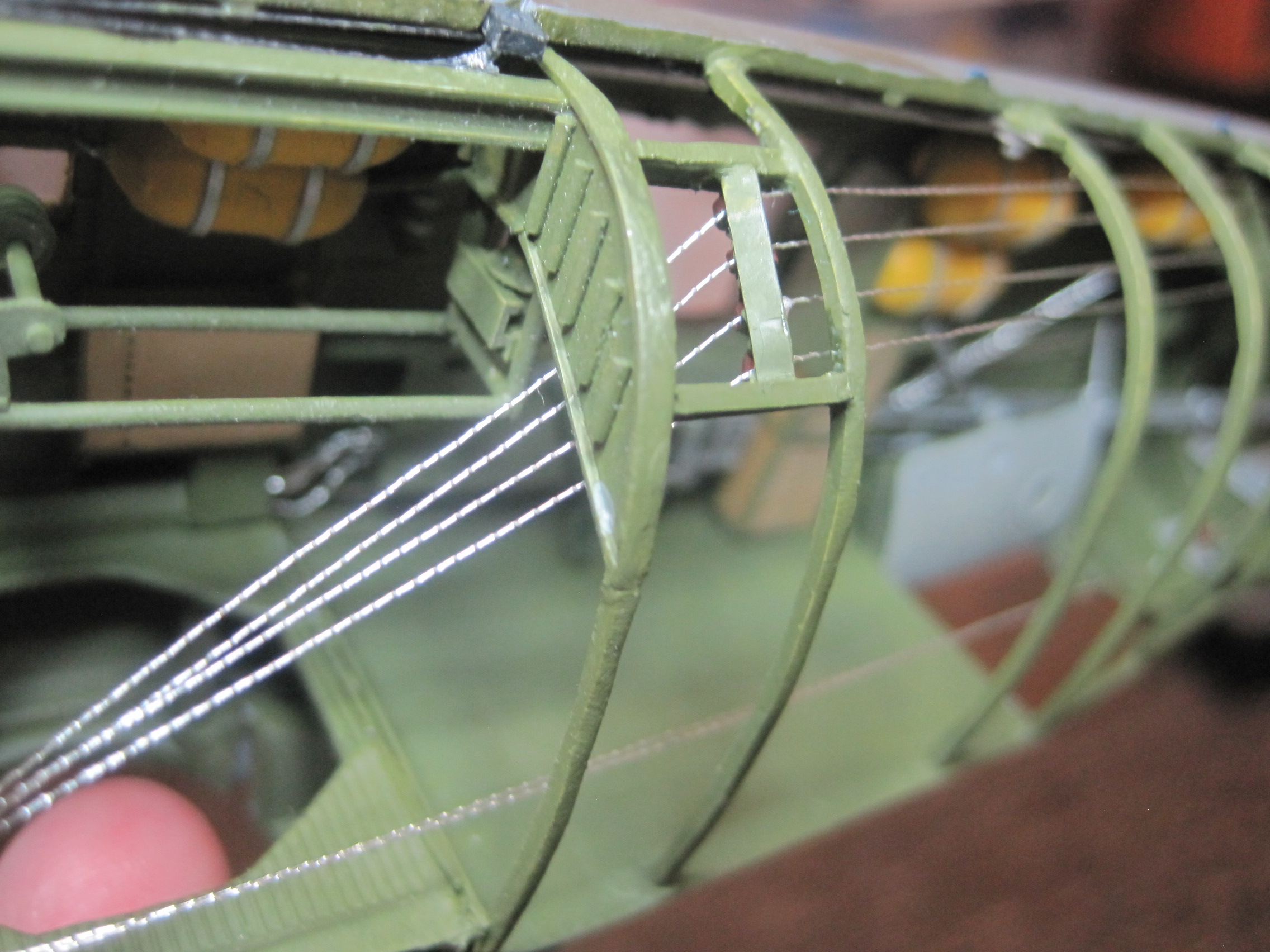

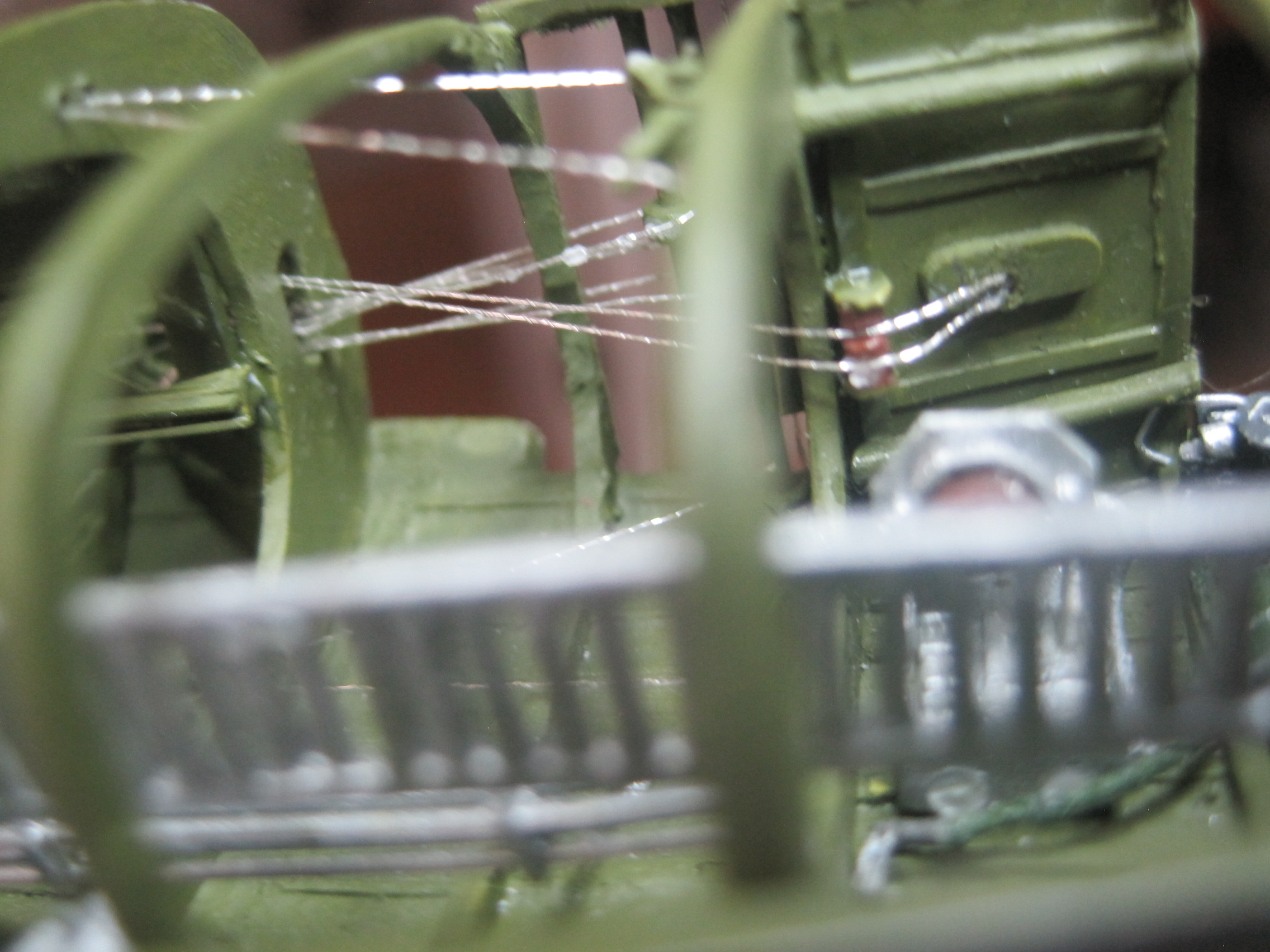

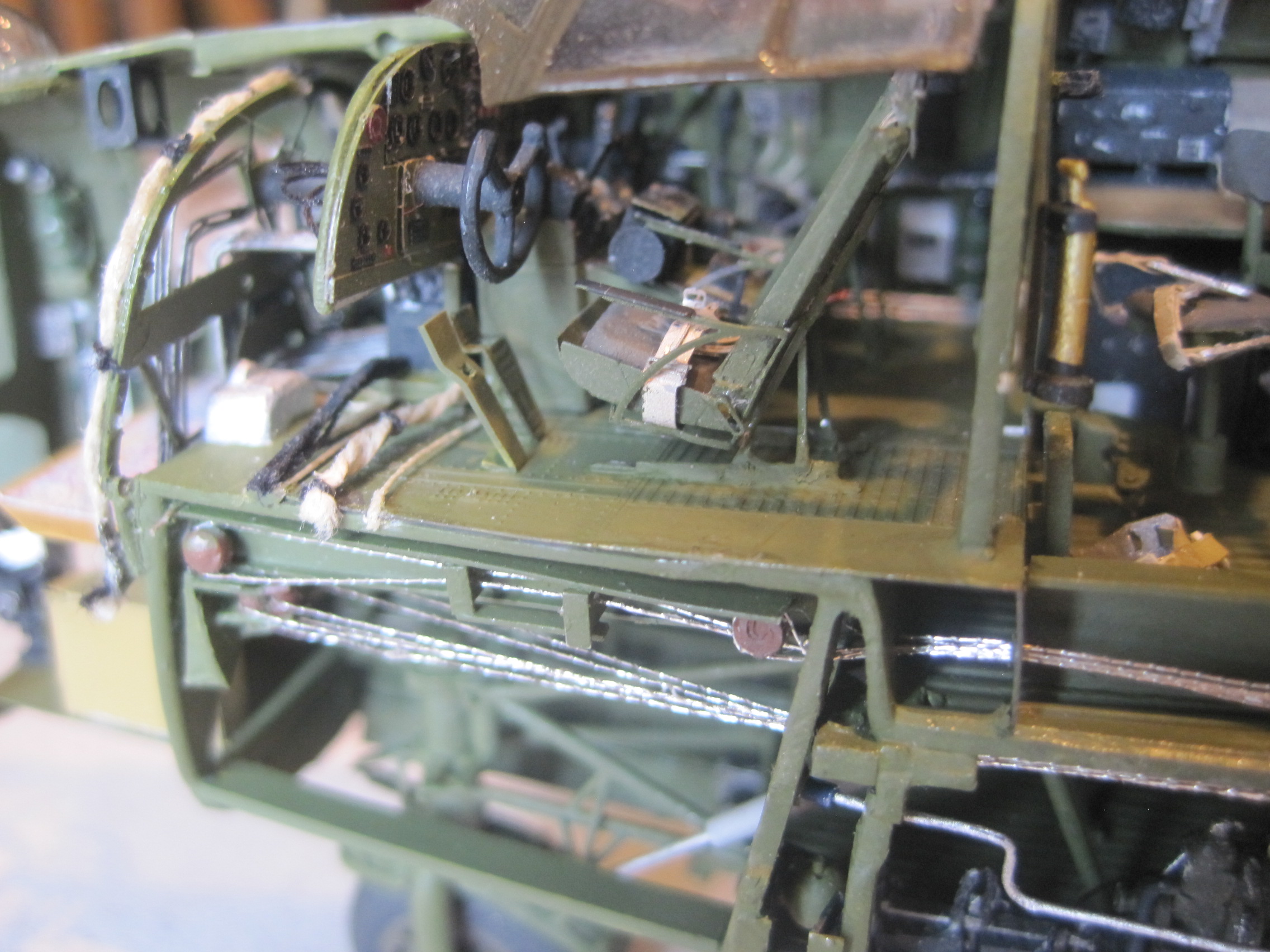

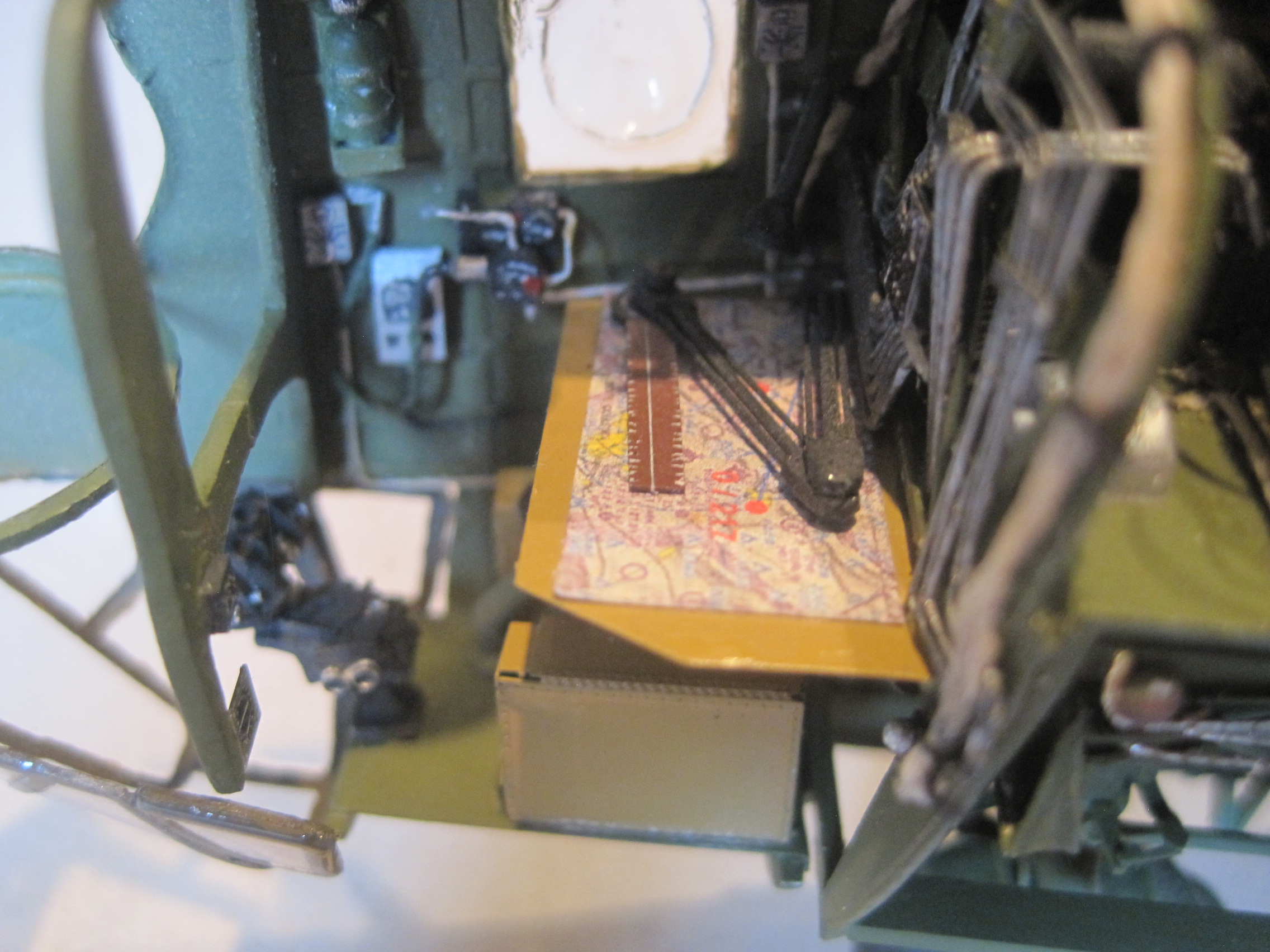

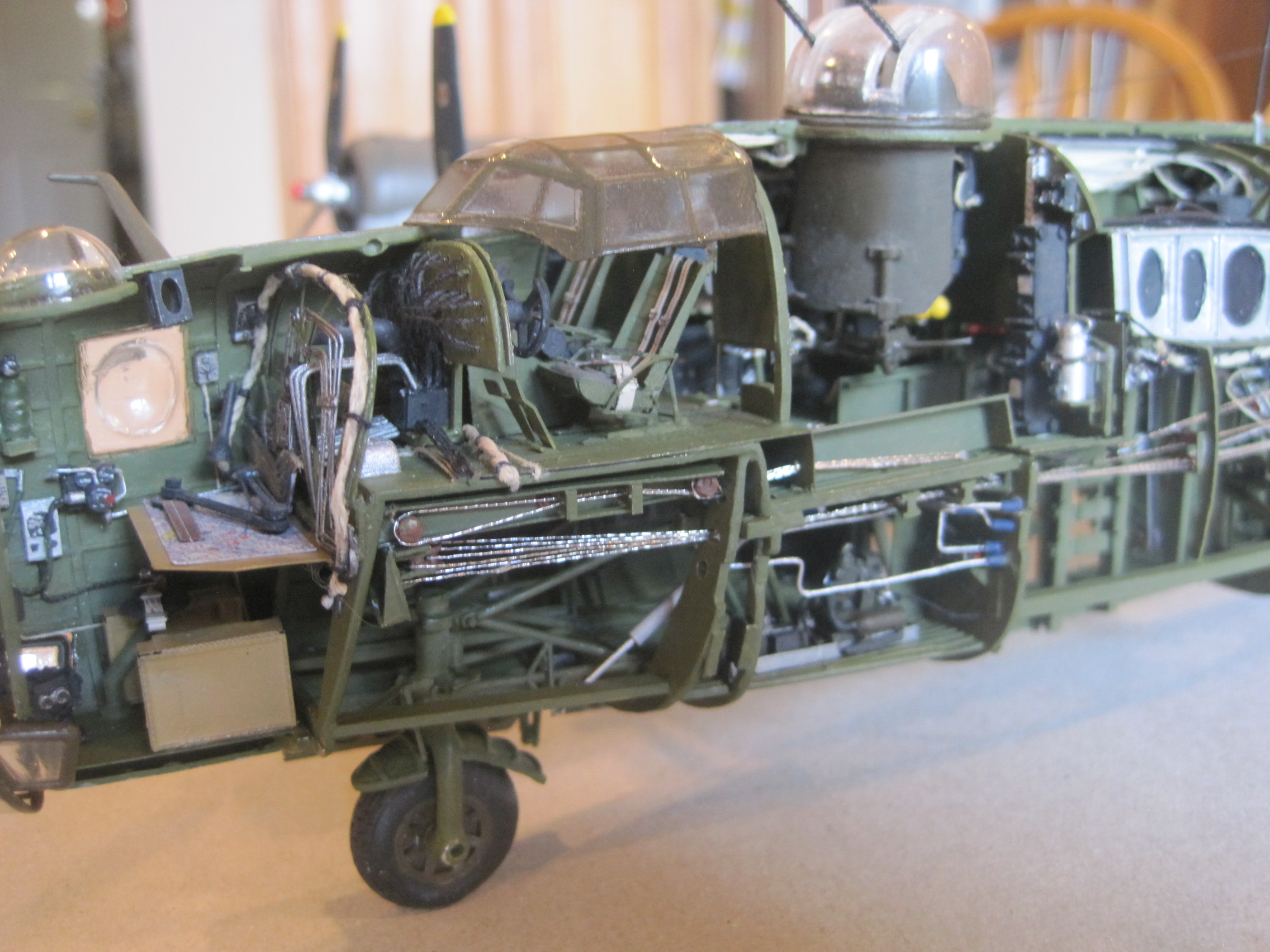

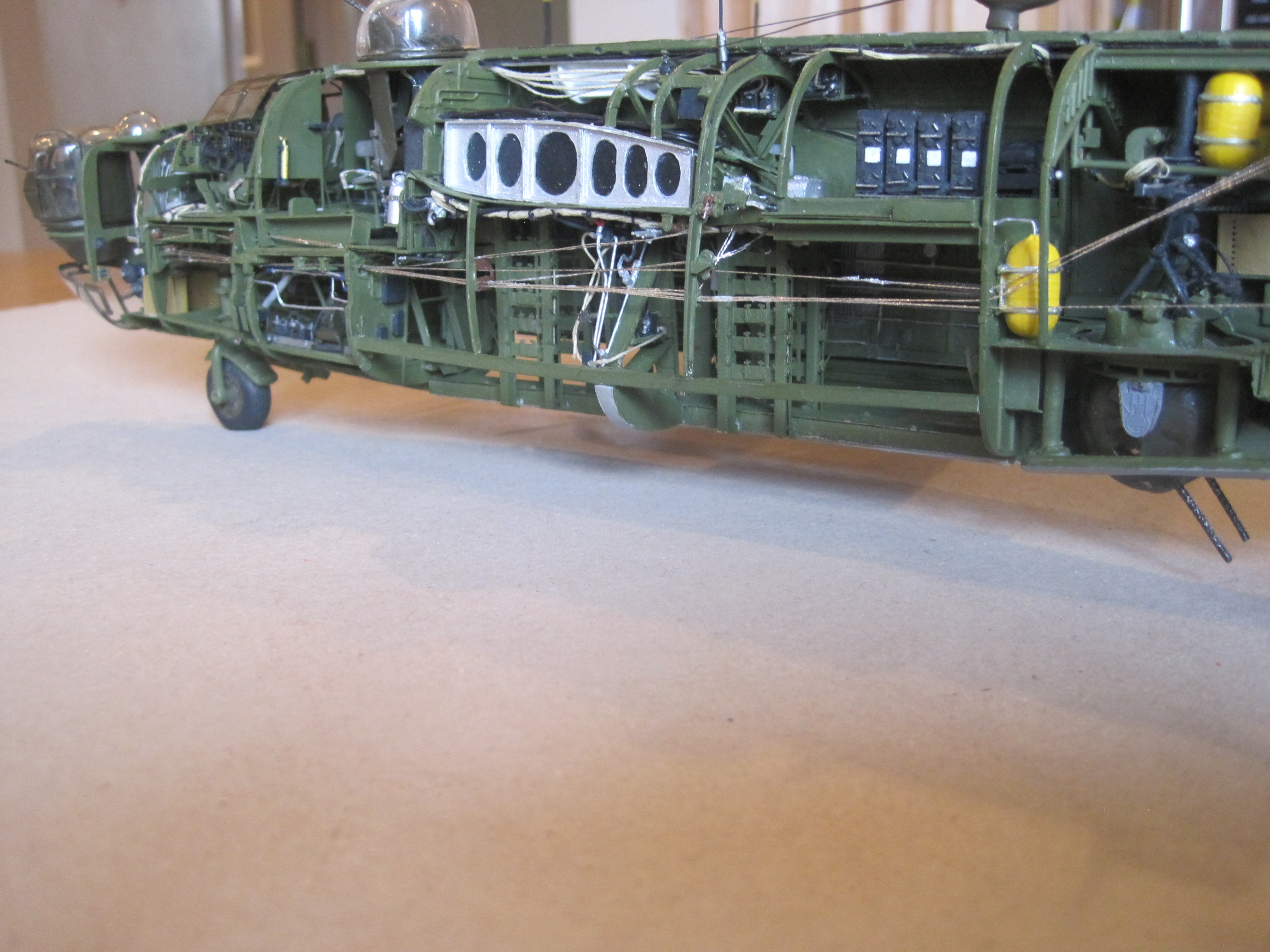

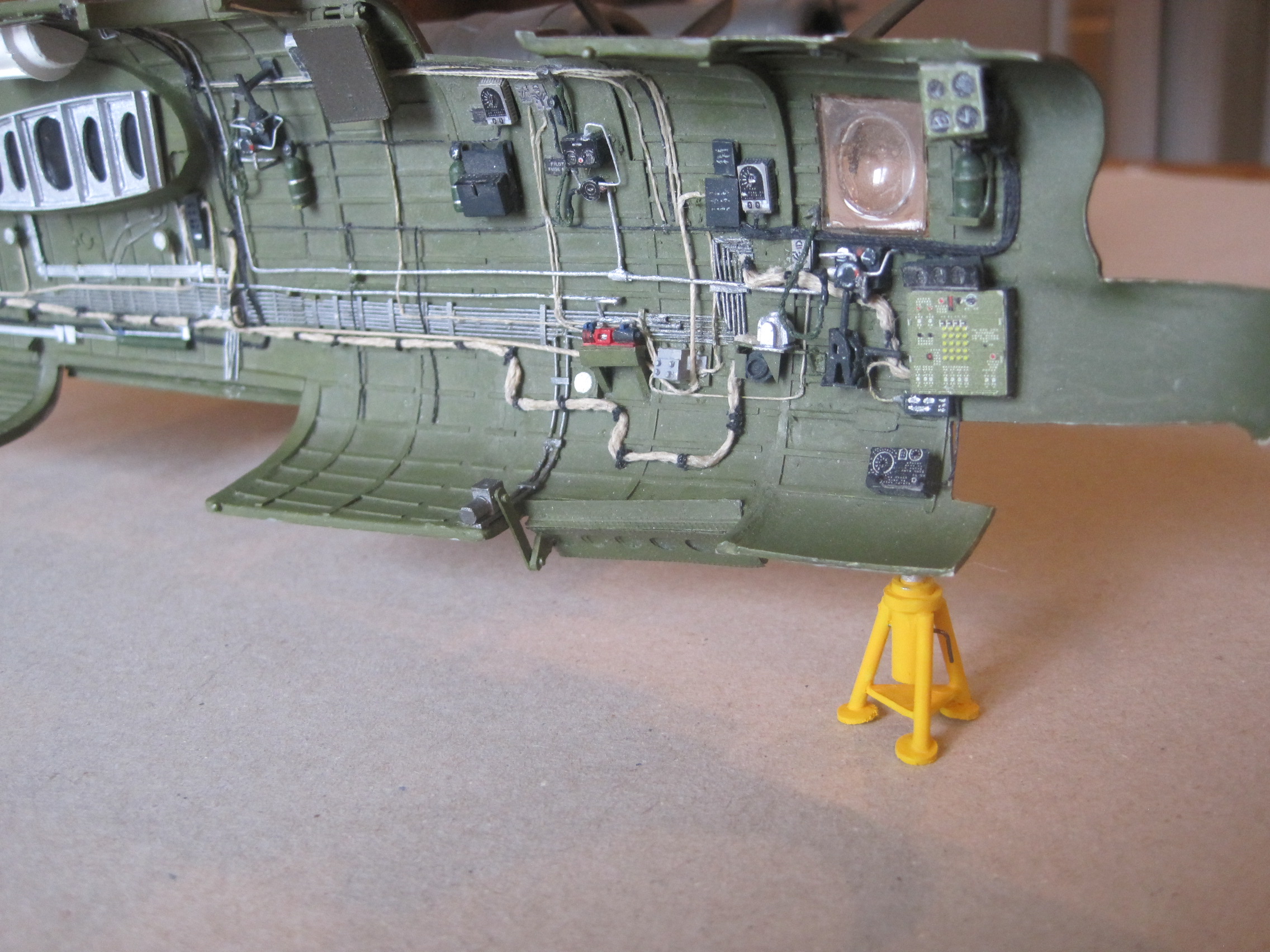

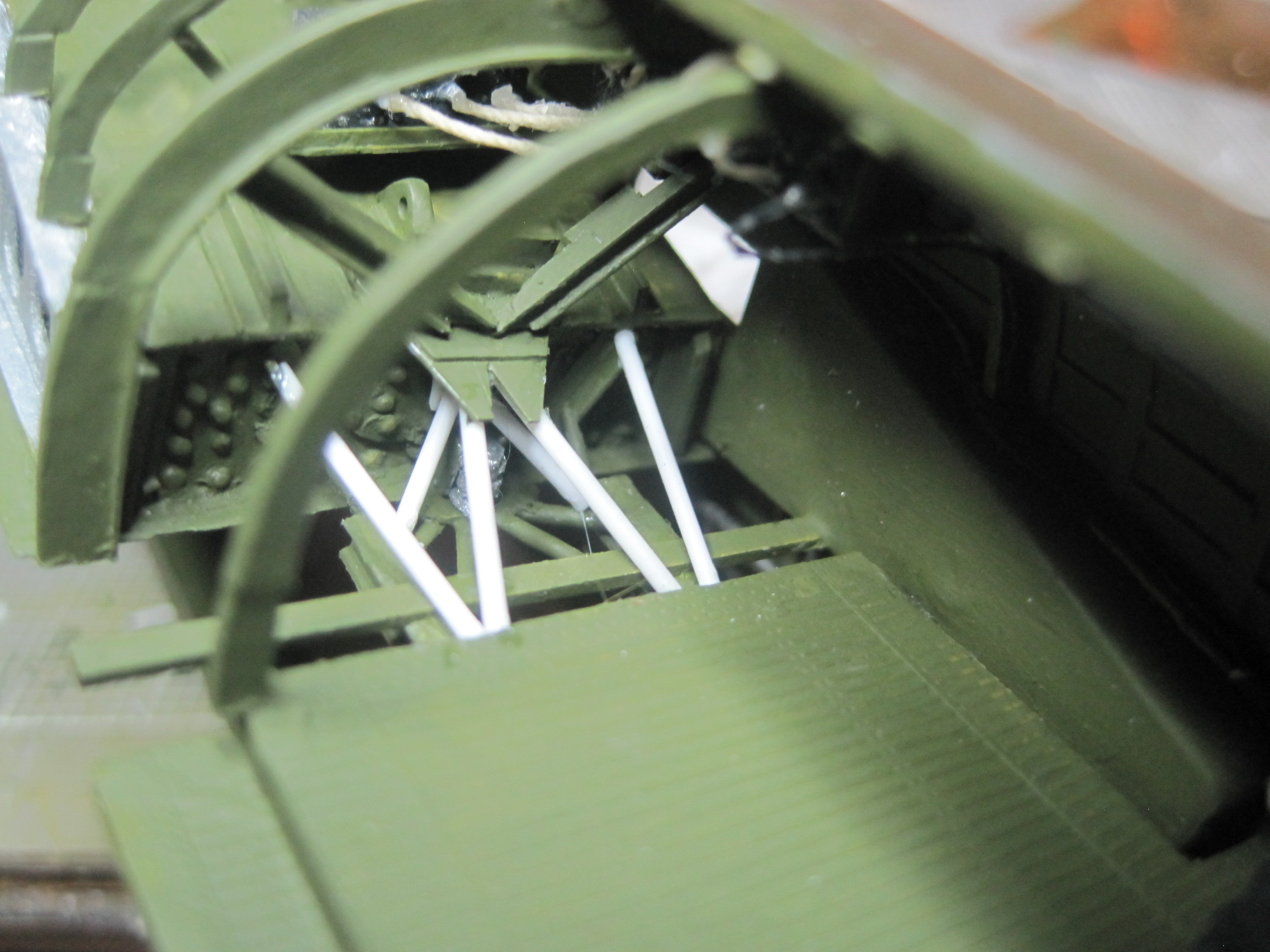

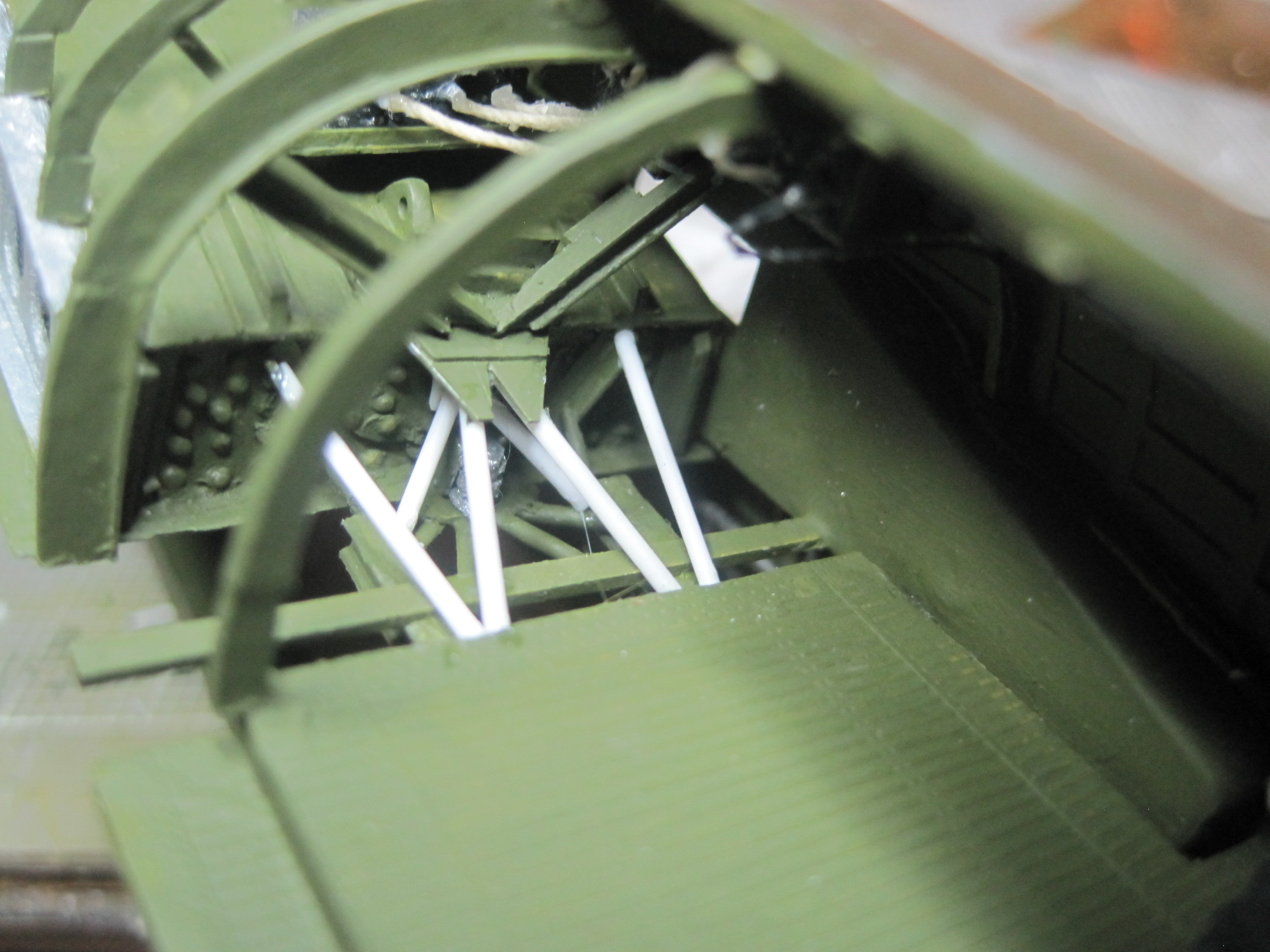

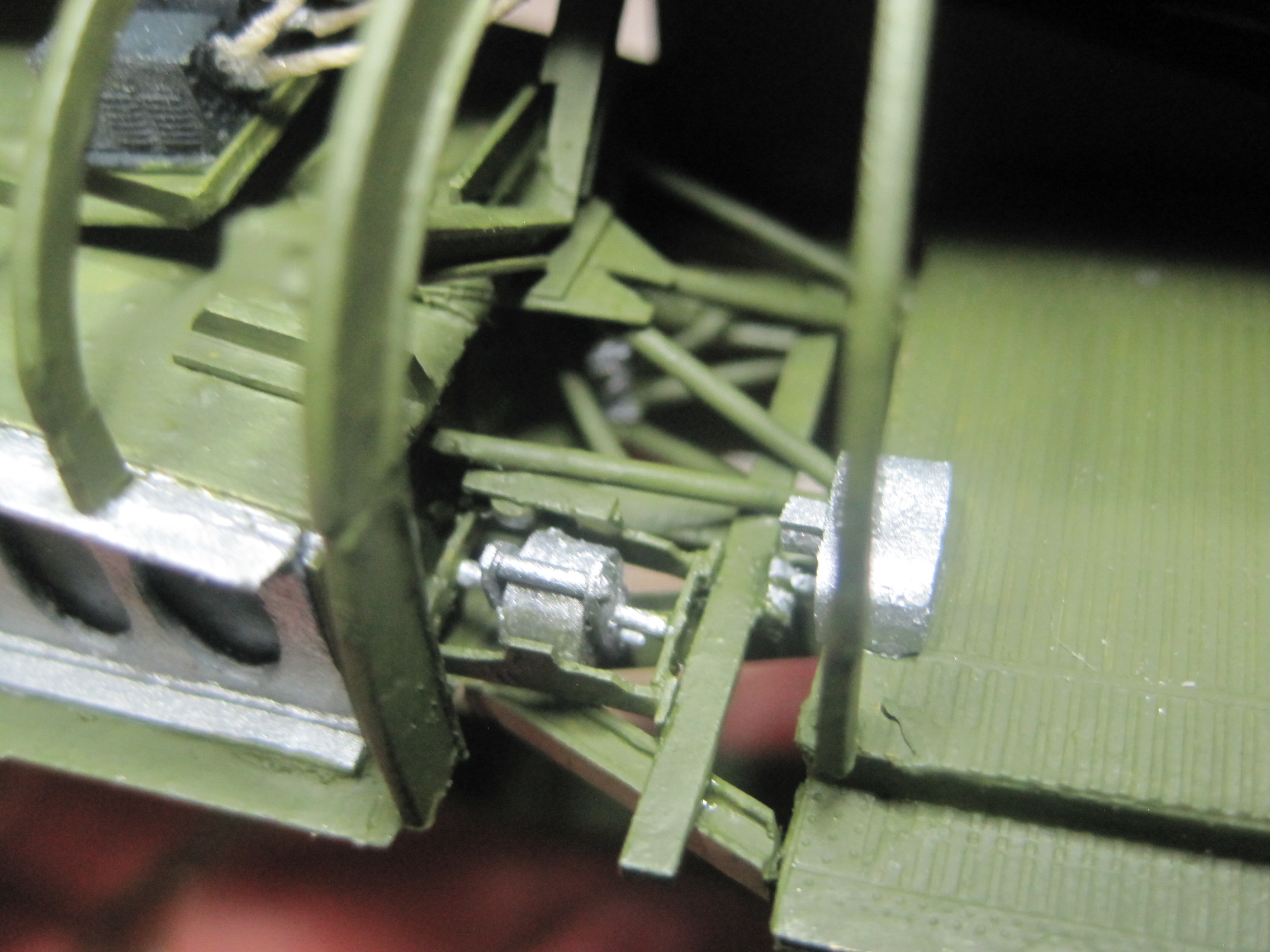

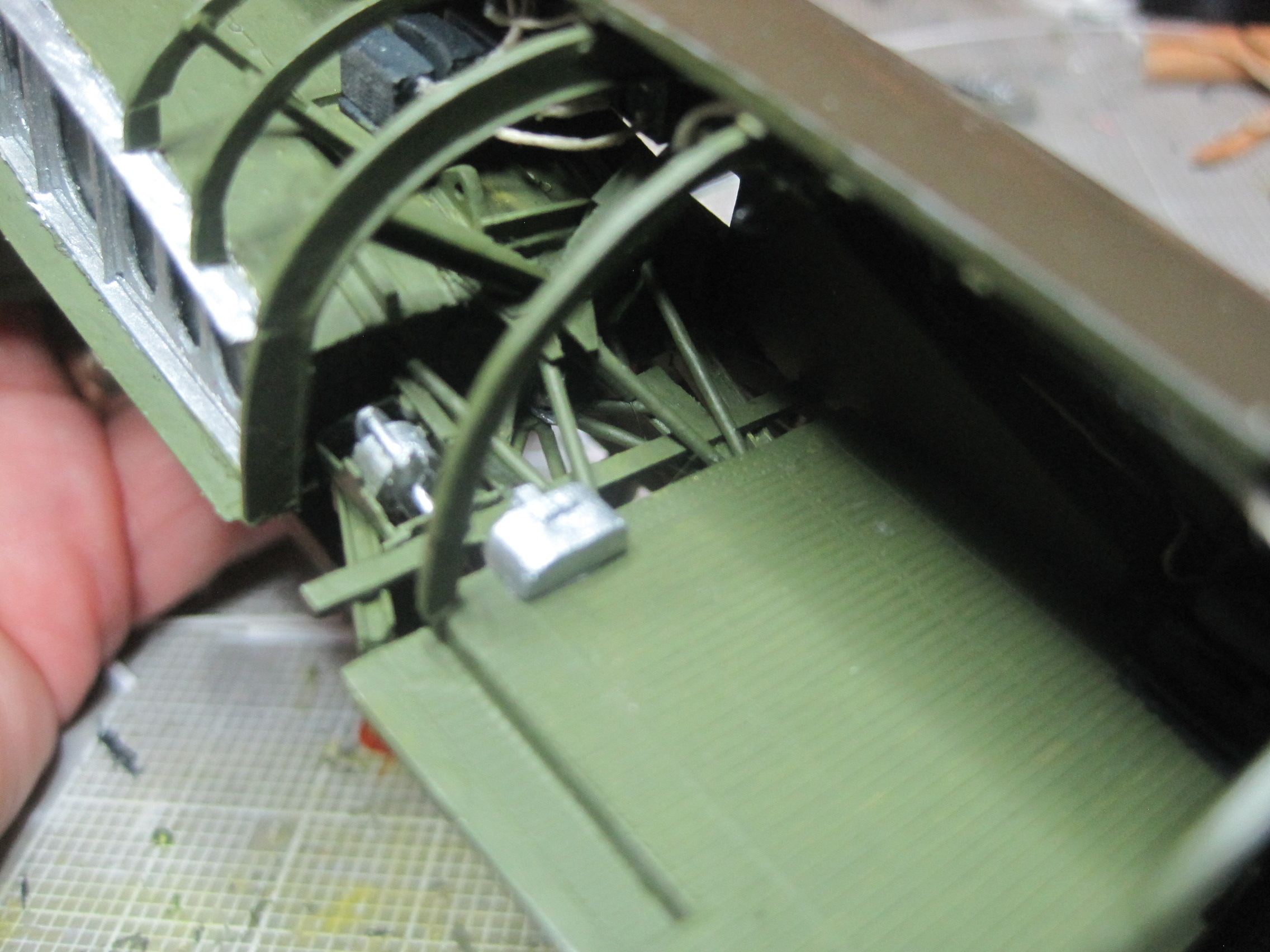

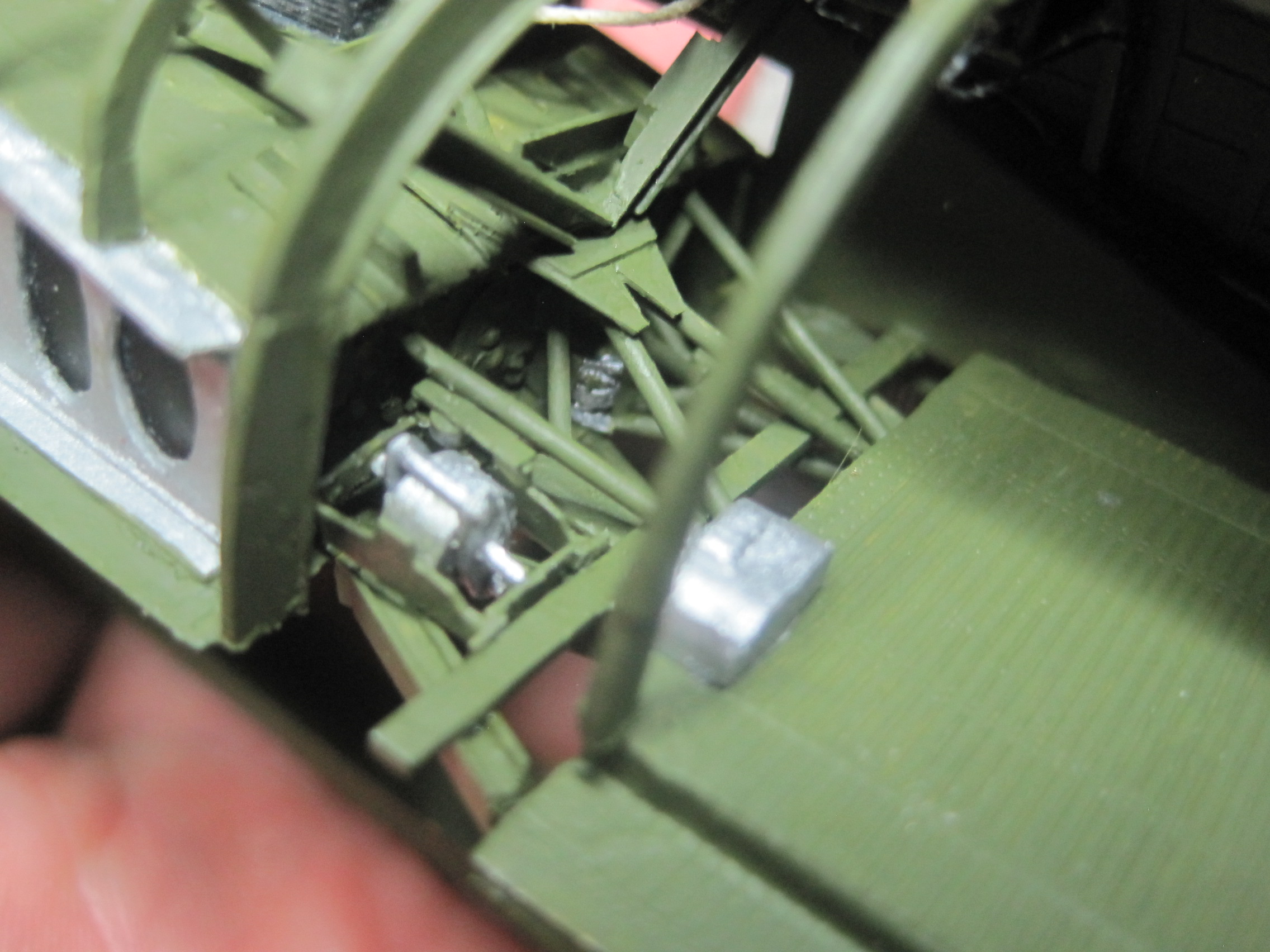

Part of what helped me is that I spent 30 years as an automotive product design engineer. The experience helped in understanding the most likely function and operation of a lot of the things you can see in the photo, i.e. "what does this thing do and how does it work". And having to come up with a way to "create" something to perform a certain task helps out. Another helpful thing is to be able to "visualize" the likely entire shape of some item you can only partially see in a photo, and then be able to reduce that item into basic "shapes" and scratch build it.

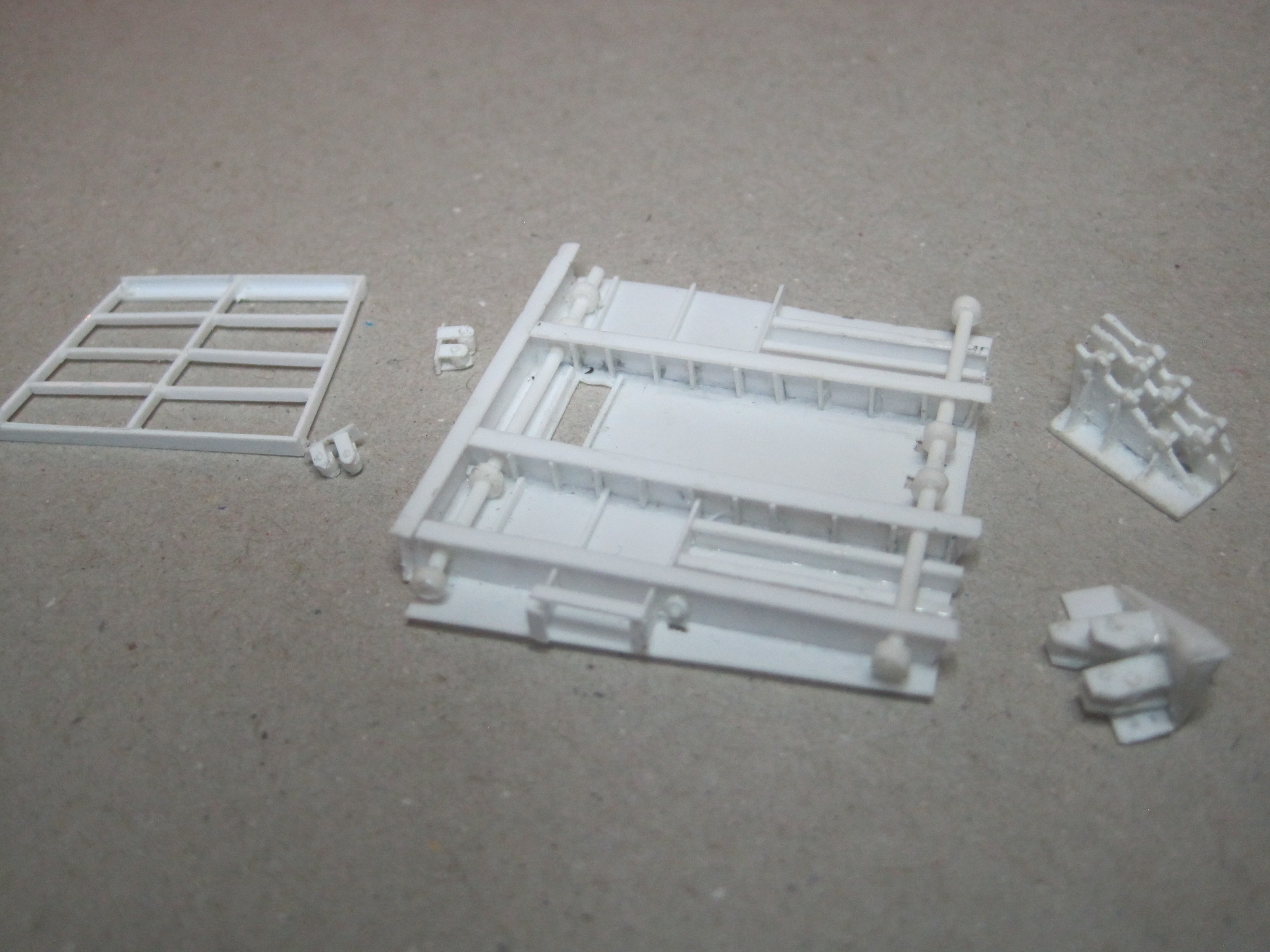

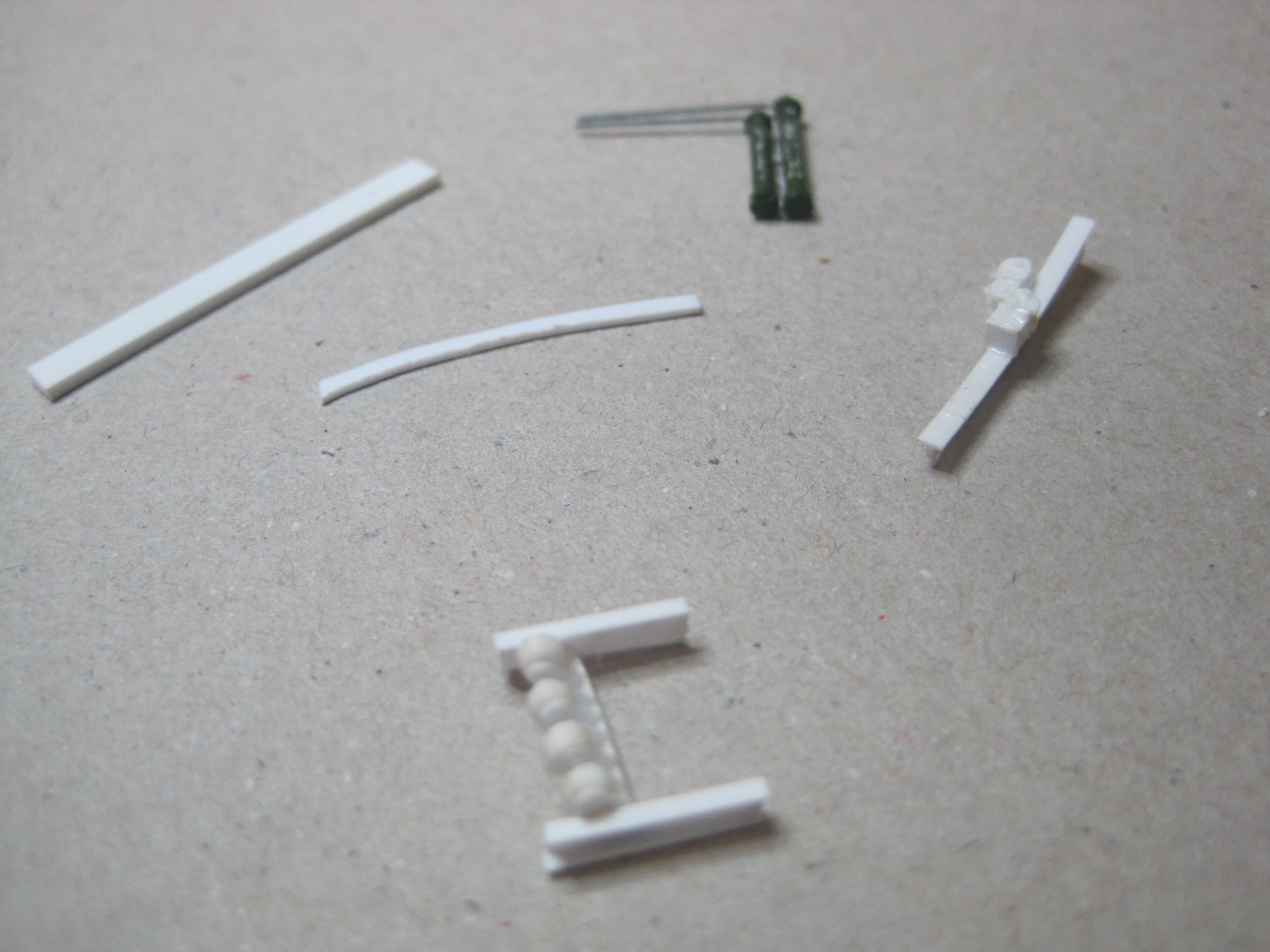

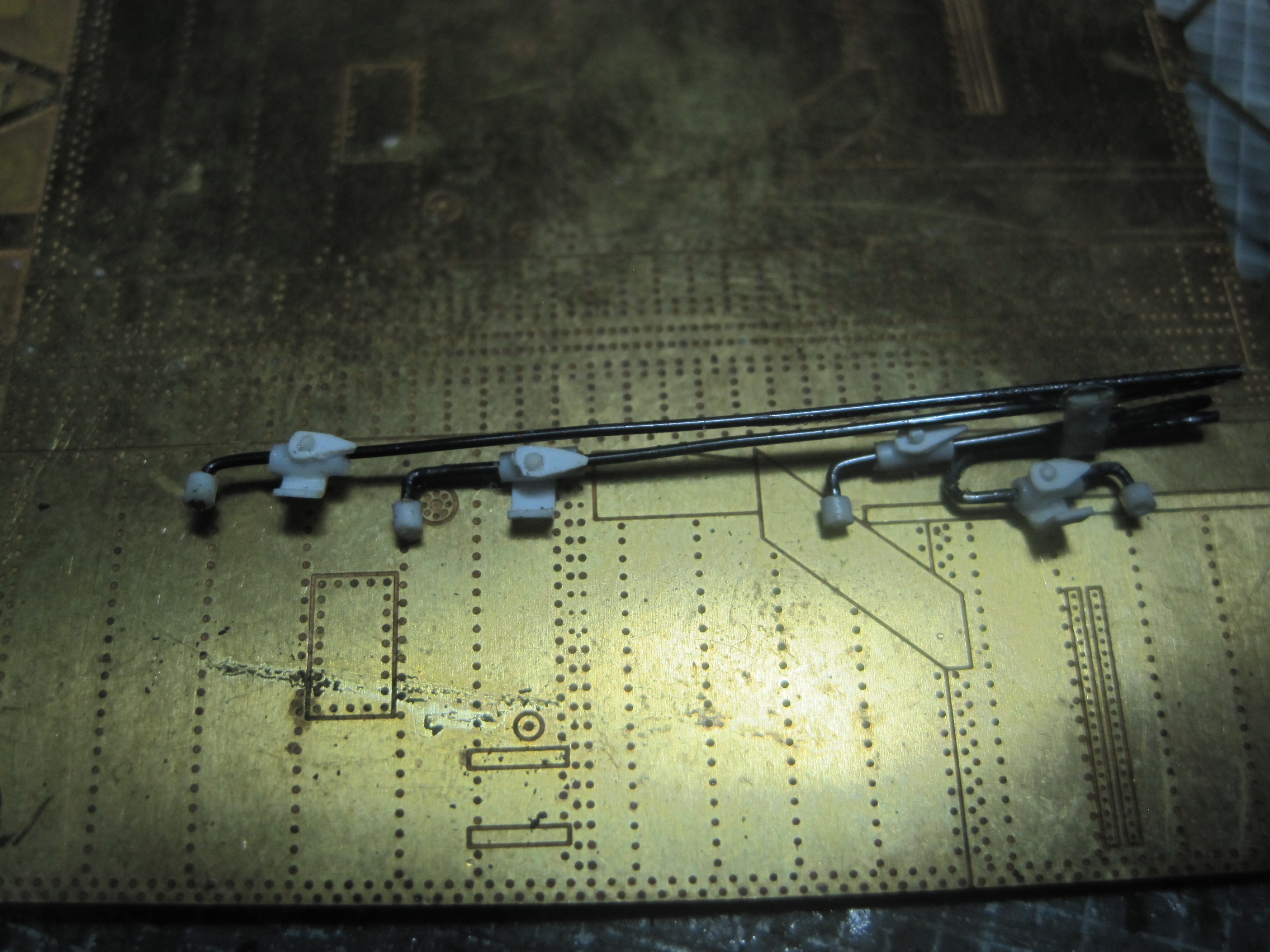

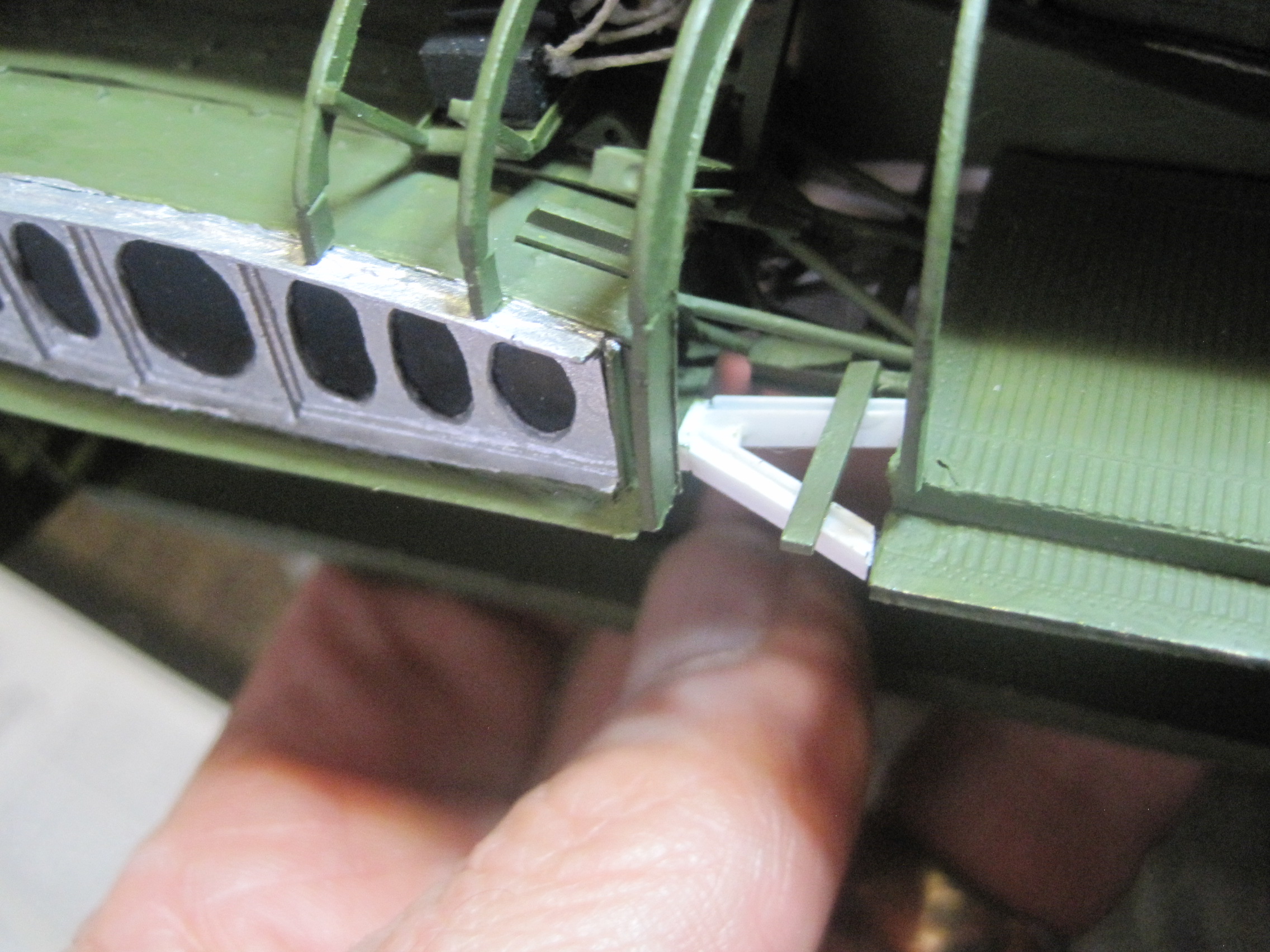

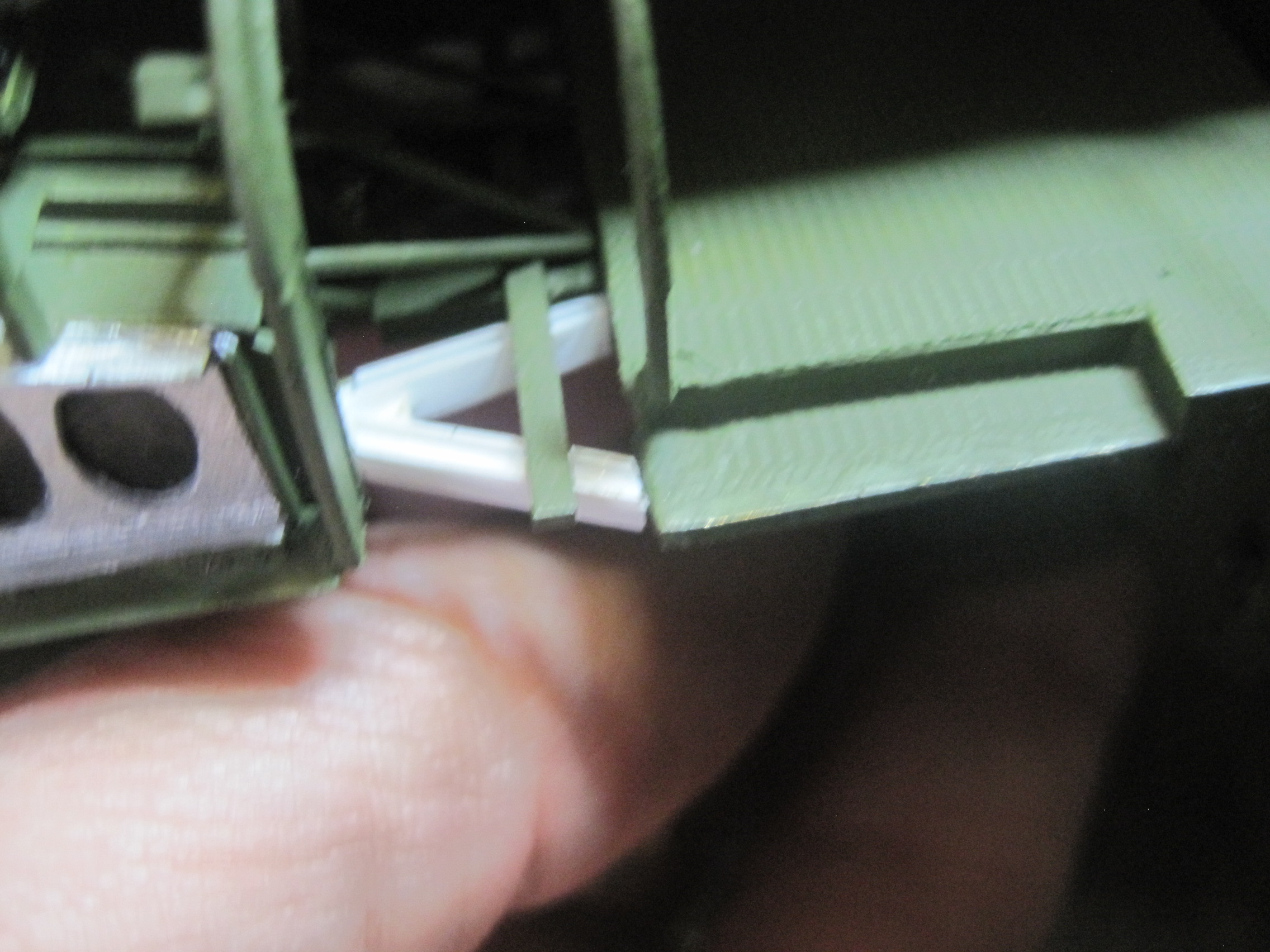

Because I do a lot of scratch building and I'm not very "patient", I have over time built up a VERY large collection of the Evergreen styrene in the rod, tube, strip and sheet with pretty much every thickness, width, and diameter they make. That allows me to grab the size I need right away and have lots of options to choose from.

I have, in the past, scaled the dimensions from a photo, especially if there is something in there I can use as a fixed reference. More often I will just visualize the difference in size the item I'm trying to make compared with the other parts I already have. It doesn't always work out exactly, and I find that when I make a mistake, I've usually scratch made my part too big. And sometimes simply in order to actually MAKE something (especially hinges) they inevitably wind up being out of scale on the large side.

But I've learned to live with the fact that it is impossible to replicate everything you can see in a photo of the real item in a kit.

Even if you tried in a 1/1 scale.

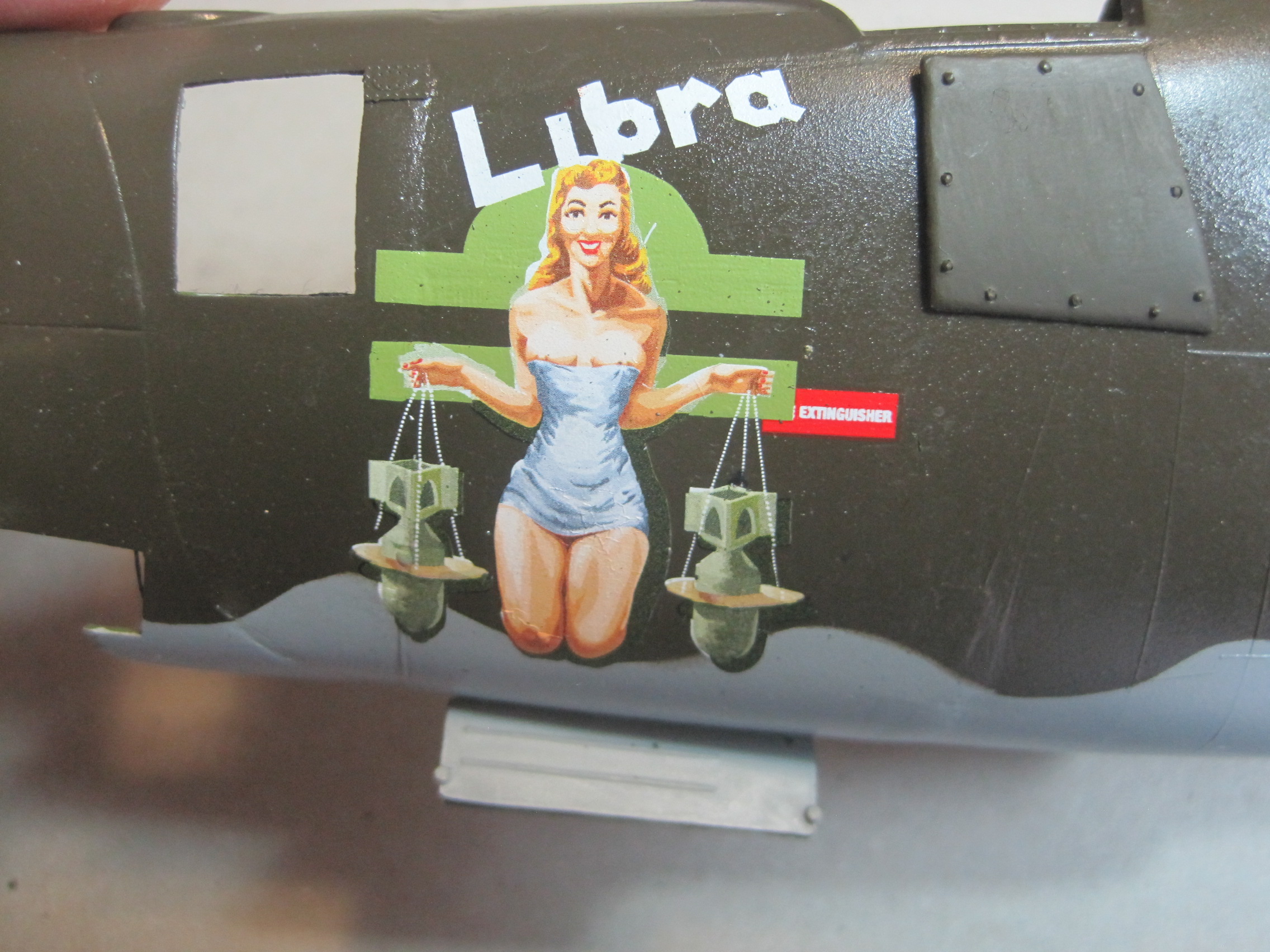

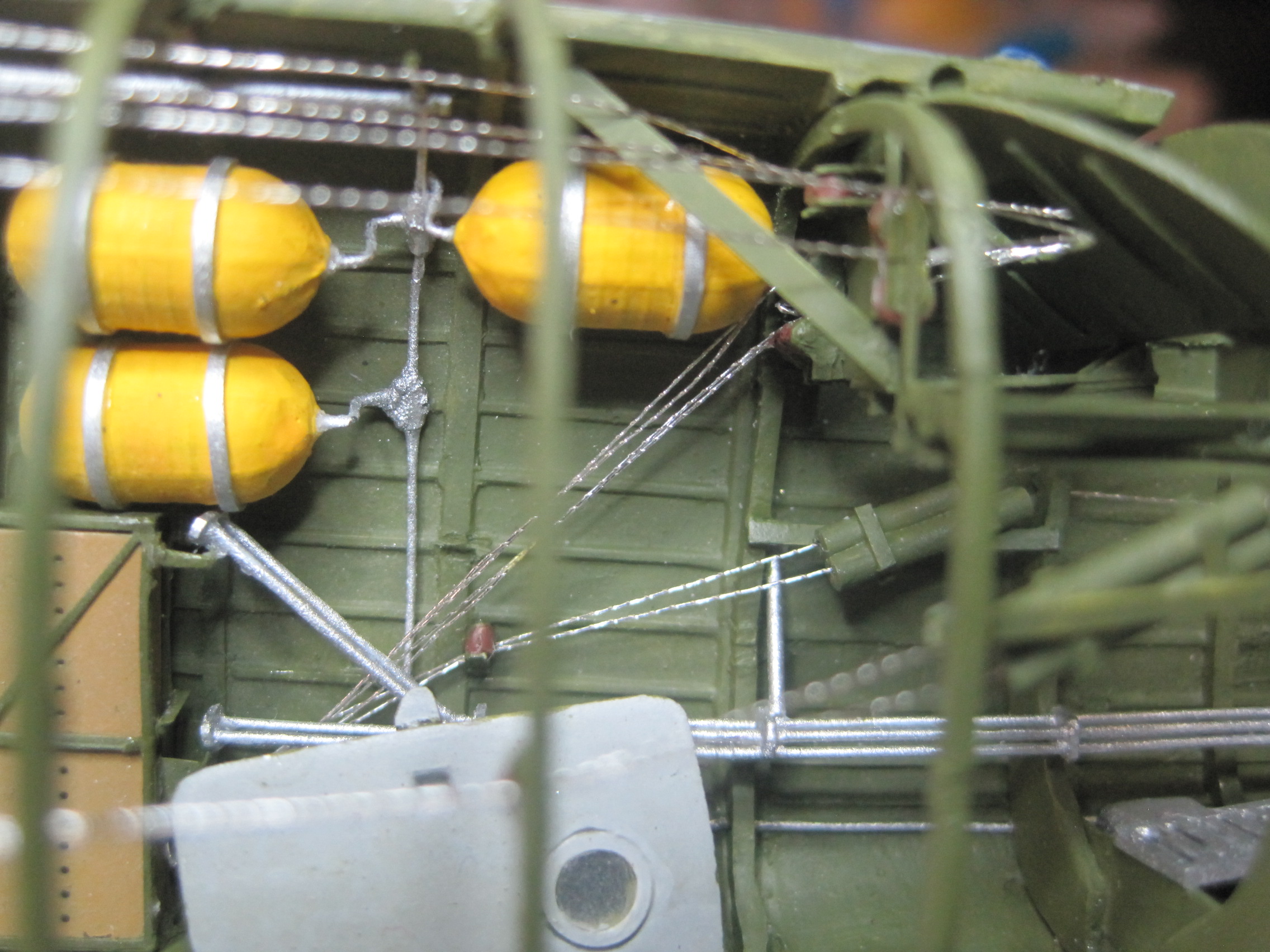

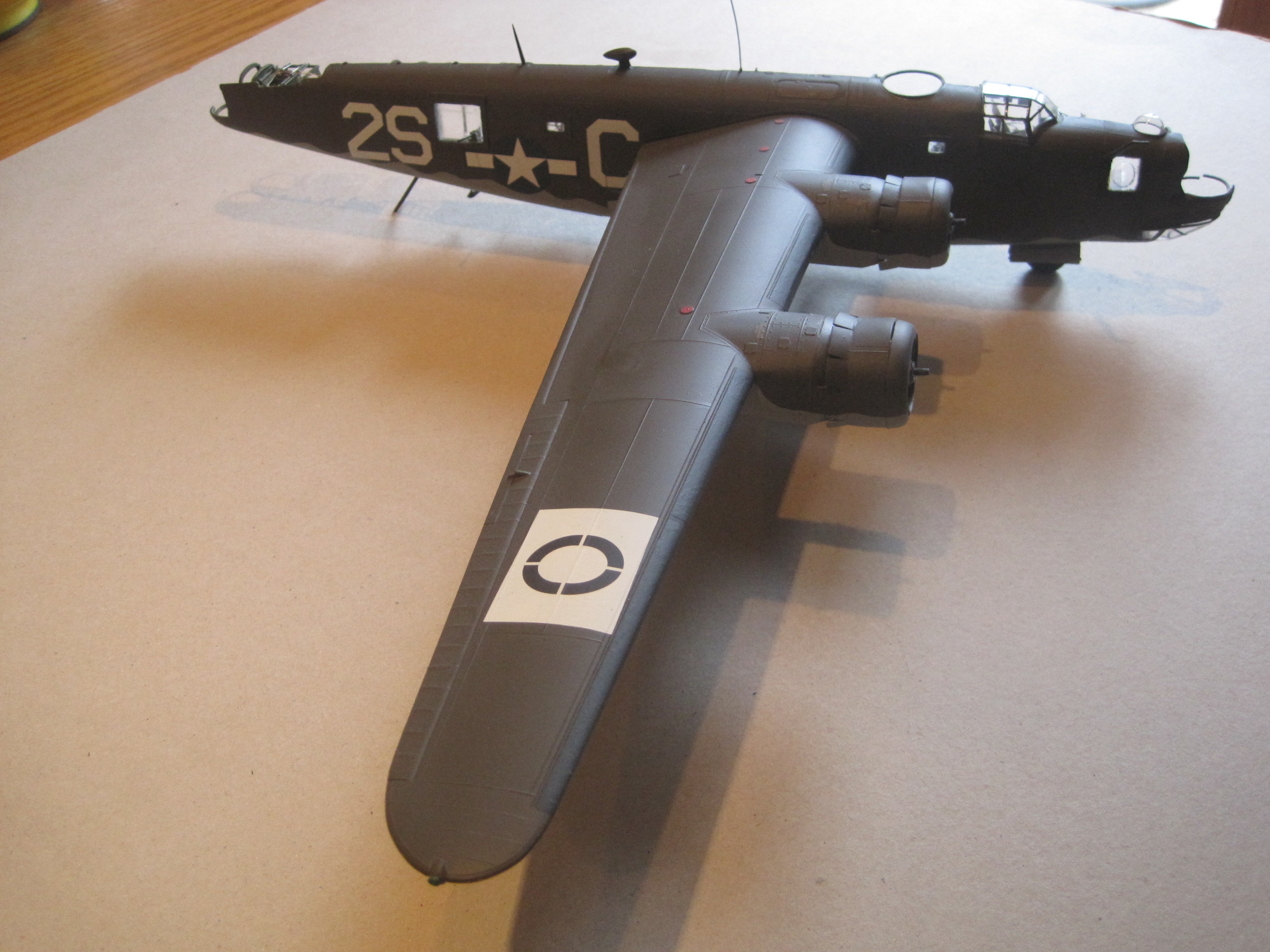

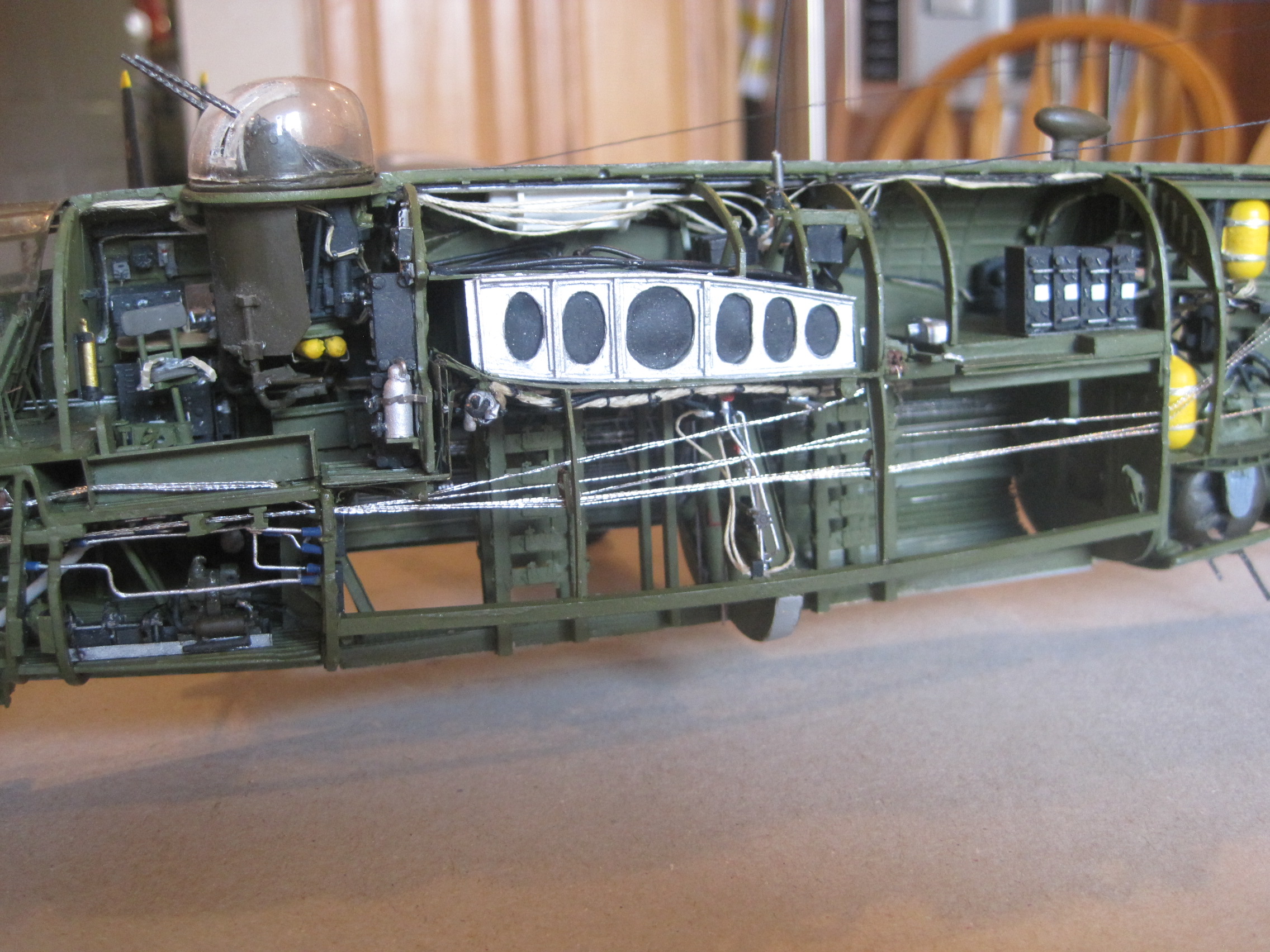

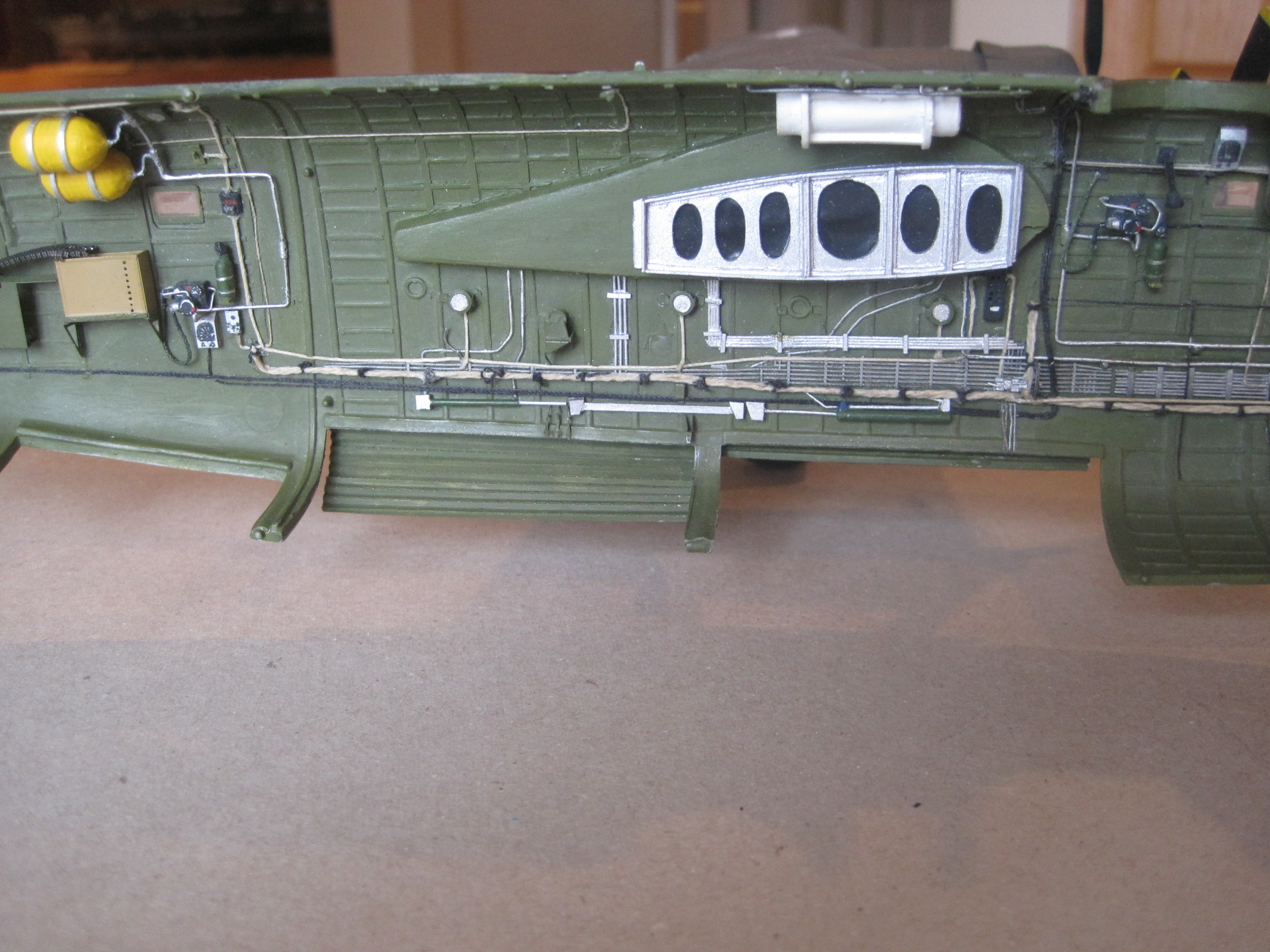

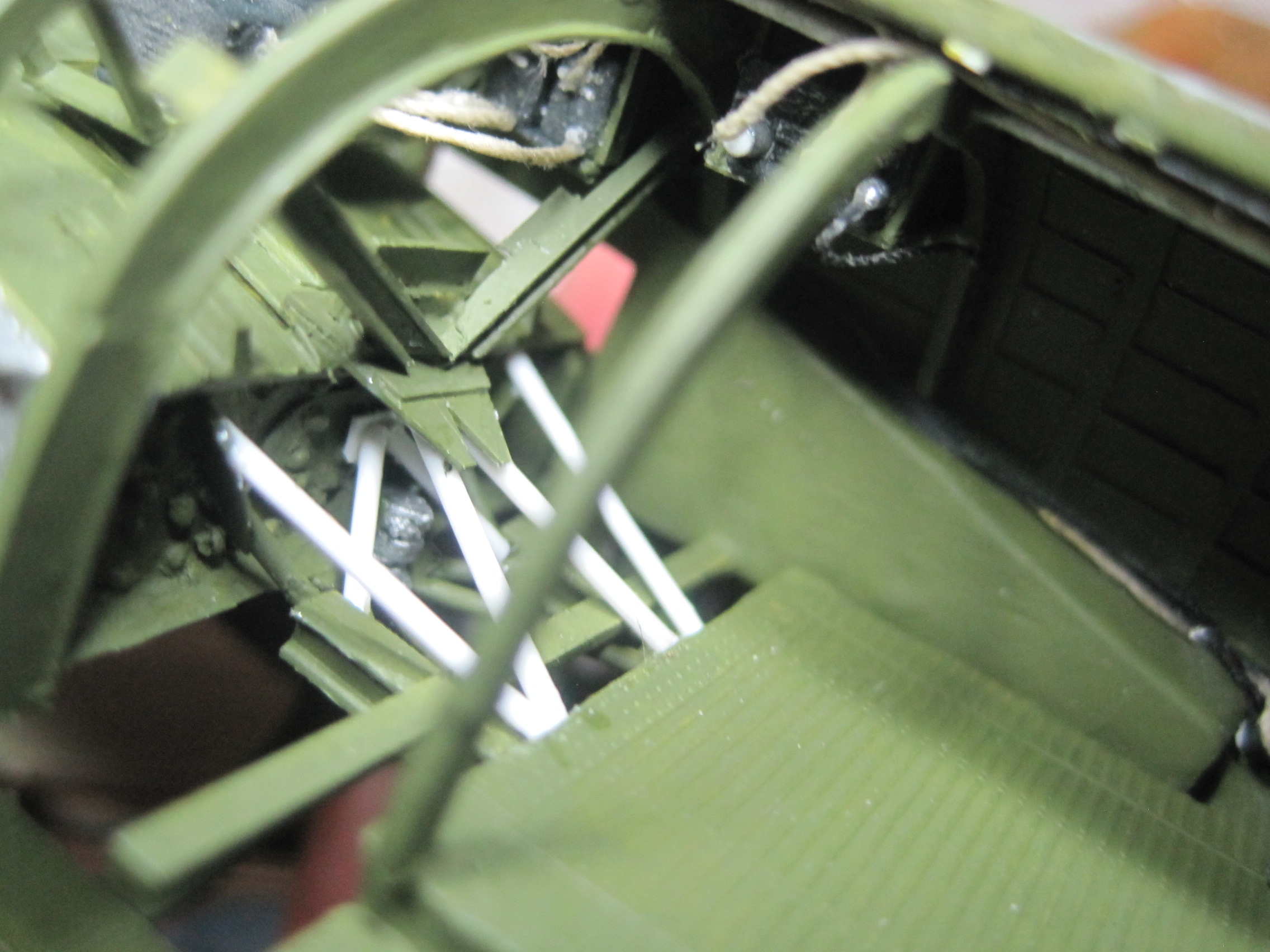

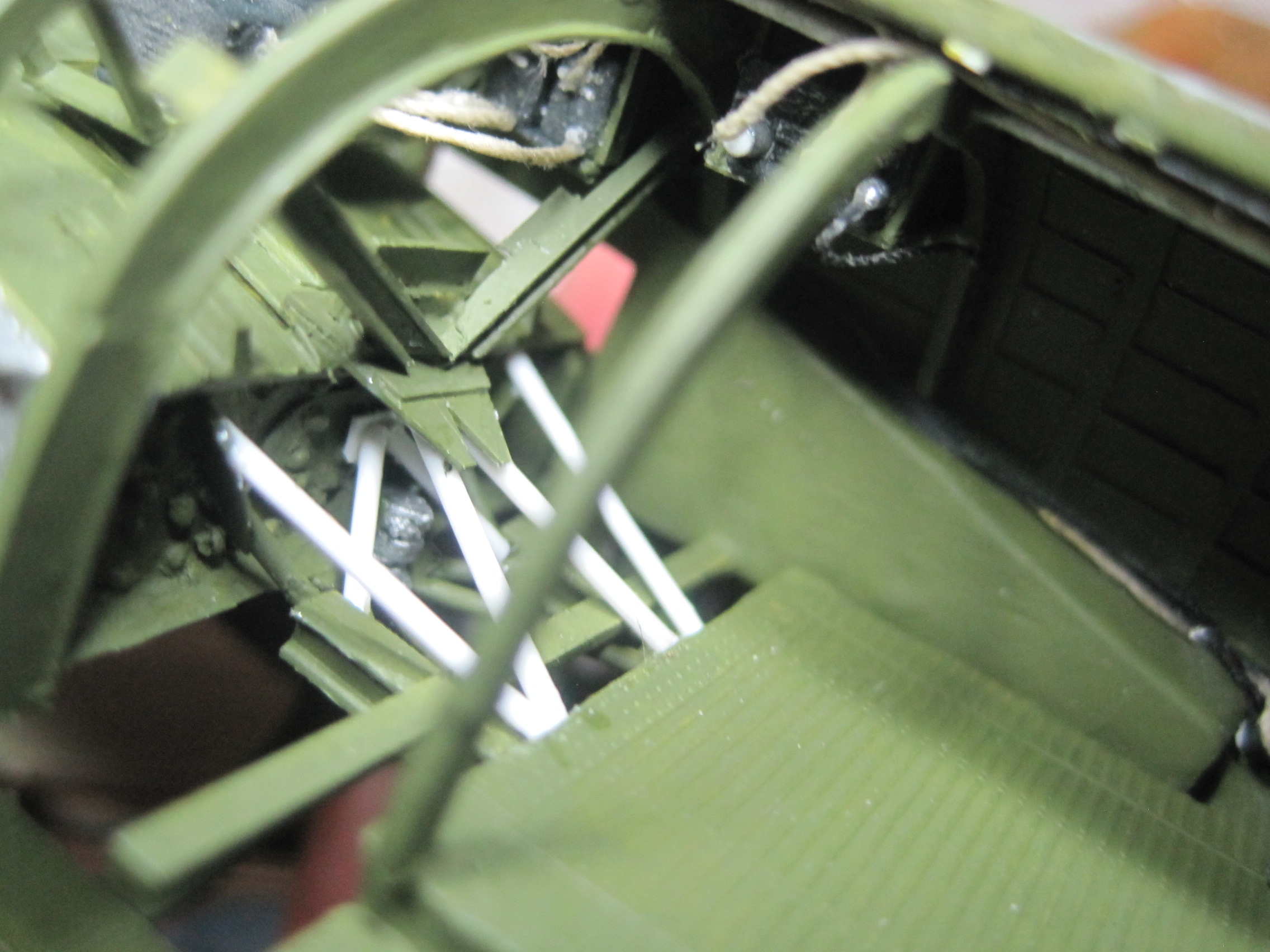

But finding the silver lining, the stay at home/quarantine which has cancelled the end of my grandkids hockey season and the start of spring hockey, has suddenly provided me with a whole lot more time at home, so I've been putting it to good use. I've made quite a bit of progress, and I'm now feeling a lot more confident that I'll be able to either finish or at least ALMOST finish by the mid-May deadline for the 75th Anniversary of VE Day toward which I've been working. But who knows with everything that's going on (and NOT going on) whether those sorts of events will still be scheduled two months from now.

But finding the silver lining, the stay at home/quarantine which has cancelled the end of my grandkids hockey season and the start of spring hockey, has suddenly provided me with a whole lot more time at home, so I've been putting it to good use. I've made quite a bit of progress, and I'm now feeling a lot more confident that I'll be able to either finish or at least ALMOST finish by the mid-May deadline for the 75th Anniversary of VE Day toward which I've been working. But who knows with everything that's going on (and NOT going on) whether those sorts of events will still be scheduled two months from now.