General Aircraft

This forum is for general aircraft modelling discussions.

This forum is for general aircraft modelling discussions.

Hosted by Jim Starkweather

3DPrinting & Aeroscale

Posted: Tuesday, March 25, 2014 - 10:26 AM UTC

Hi Adam, those sound like very good prices to me. You'd need accurate plans and photo's etc for Depth Charges to do a good job of them. I'm not entirely sure what the rear end of the weapon looked like. Is it open or blanked off? I believe IWM Duxford has some on display. If anyone here has good photo's and measurements I'm sure they would be glad to help.

drabslab

Joined: September 28, 2004

KitMaker: 2,186 posts

AeroScale: 1,587 posts

Posted: Tuesday, March 25, 2014 - 10:32 AM UTC

Quoted Text

Quoted TextBristol bloodhound missile isn't available...

Ok we will build this for 1/72 scale and 1/48 scale and let you know when its available (in the next two days). Just to clafify, the missile will be able to be separated from the launch platform. What RRP do you think this should be? We will be limited to what it costs to print but its worth knowing what other mainstream models go for at this scale.

You will model a bloodhound and launchplatform in 1/48 scale in a few days???

Careful what you promise, most of us here are devoted rivet counters, not to mention screws and bolts, and we are very quality minded, if not spoilt completely by the high Tamiya/Eduard/Hasegawa ... standards.

If you can pull something like that of, then I expect you will find a good market for any niche product.

I think that anybody here can wait weeks or months for a niche product if this leads to better quality.

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Tuesday, March 25, 2014 - 10:40 AM UTC

Quoted Text

Quoted TextQuoted TextBristol bloodhound missile isn't available...

Ok we will build this for 1/72 scale and 1/48 scale and let you know when its available (in the next two days). Just to clafify, the missile will be able to be separated from the launch platform. What RRP do you think this should be? We will be limited to what it costs to print but its worth knowing what other mainstream models go for at this scale.

You will model a bloodhound and launchplatform in 1/48 scale in a few days???

Careful what you promise, most of us here are devoted rivet counters, not to mention screws and bolts, and we are very quality minded, if not spoilt completely by the high Tamiya/Eduard/Hasegawa ... standards.

If you can pull something like that of, then I expect you will find a good market for any niche product.

I think that anybody here can wait weeks or months for a niche product if this leads to better quality.

We will do our best to get it as high quality as possible, here is a Batman Tumbler we made to give you an idea of our high detail skill level at 1/48 scales:

http://www.flickr.com/photos/innerleaf/sets/72157632472205922/

Or check out our high detail Rifle designed for 1:1 scale and for printing for movie prop use:

http://www.flickr.com/photos/innerleaf/sets/72157642528300945/

We will do our best with this but if anyone can give us some high res blueprints and images? Can you email them through to [email protected] please?

raypalmer

Joined: March 29, 2010

KitMaker: 1,151 posts

AeroScale: 985 posts

Posted: Tuesday, March 25, 2014 - 10:40 AM UTC

OK I like your gumption. I will buy a bloodhound when you're ready. Don't rush now

Any other takers? I say we encourage this. Entrepreneurship and all that.

Come on guys he's on here taking requests!

It is a particularly beautiful missile...

Any other takers? I say we encourage this. Entrepreneurship and all that.

Come on guys he's on here taking requests!

It is a particularly beautiful missile...

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Tuesday, March 25, 2014 - 11:14 AM UTC

Quoted Text

OK I like your gumption. I will buy a bloodhound when you're ready. Don't rush now

Any other takers? I say we encourage this. Entrepreneurship and all that.

Come on guys he's on here taking requests!

It is a particularly beautiful missile...

Ok great, can you send me a link to some other similar models that are commercially available to buy please just so I can see what is being offered.

drabslab

Joined: September 28, 2004

KitMaker: 2,186 posts

AeroScale: 1,587 posts

Posted: Tuesday, March 25, 2014 - 11:55 PM UTC

Quoted Text

OK I like your gumption. I will buy a bloodhound when you're ready. Don't rush now

Any other takers? I say we encourage this. Entrepreneurship and all that.

Come on guys he's on here taking requests!

It is a particularly beautiful missile...

Well, if all seems right, I can use one as well.

and to the 3dprint modellers, don't try to make everything in one part, a logical breakdown of parts is better because it facilitates sanding/polishing in case that the surface is not perfectly smooth, and it makes it easier to airbrush. Making assembly instructions available on the web is good enough, there is no need to print any instruction sheets.

drabslab

Joined: September 28, 2004

KitMaker: 2,186 posts

AeroScale: 1,587 posts

Posted: Wednesday, March 26, 2014 - 12:19 AM UTC

@Adam,

I sent you a few emails with a few suggestions.

What would also be useful in 1/48 is a forklift used on military airfields (just google and you will find plenty of models.)

Usually these forklift are just standard forklifts painted green so I guess you may find a scale 1:1 object in your neighbourhood

I sent you a few emails with a few suggestions.

What would also be useful in 1/48 is a forklift used on military airfields (just google and you will find plenty of models.)

Usually these forklift are just standard forklifts painted green so I guess you may find a scale 1:1 object in your neighbourhood

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Wednesday, March 26, 2014 - 12:32 PM UTC

WWII Depth Charge:

Hi Everyone,

We have completed the model of the WWII Depth Charge at your request and its now uploading to our Online Shop which is located here:

http://printedplanes.moonfruit.com/

Hi Everyone,

We have completed the model of the WWII Depth Charge at your request and its now uploading to our Online Shop which is located here:

http://printedplanes.moonfruit.com/

Removed by original poster on 03/28/14 - 01:42:40 (GMT).

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Thursday, March 27, 2014 - 01:45 PM UTC

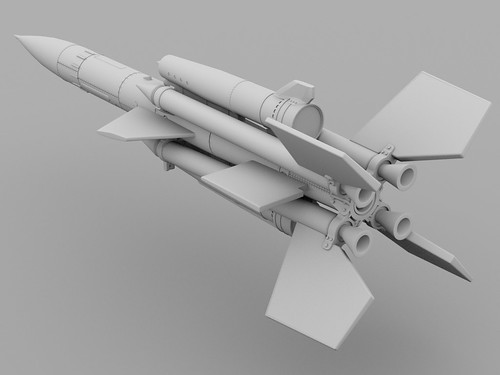

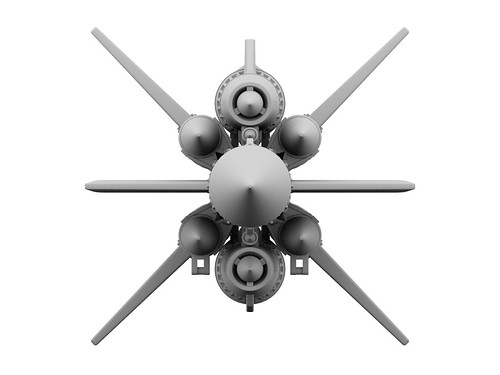

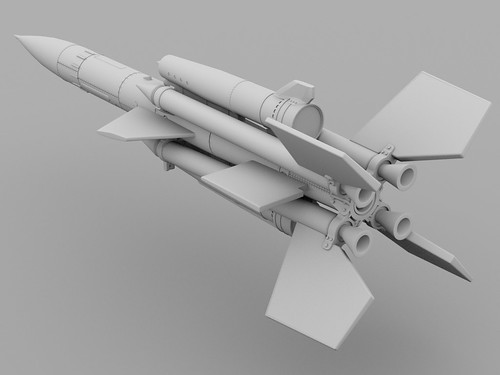

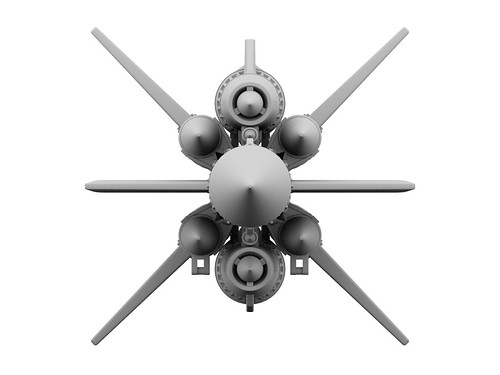

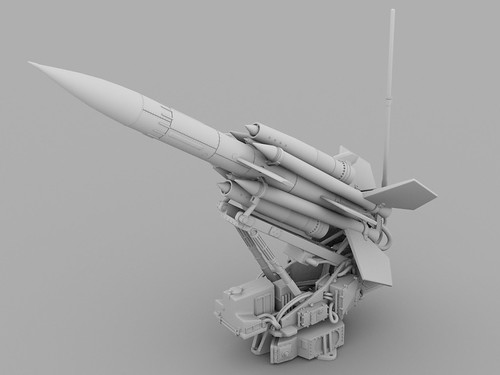

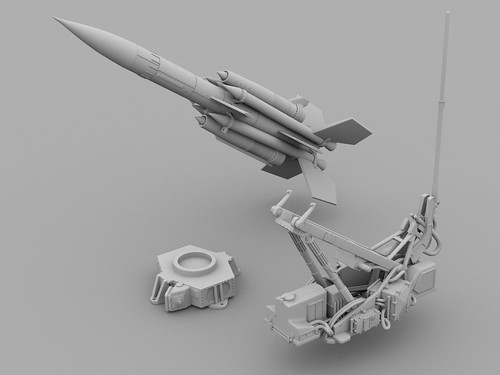

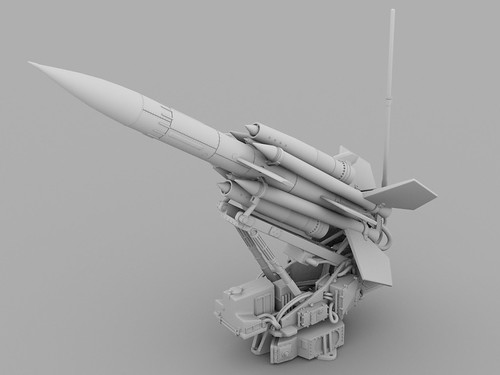

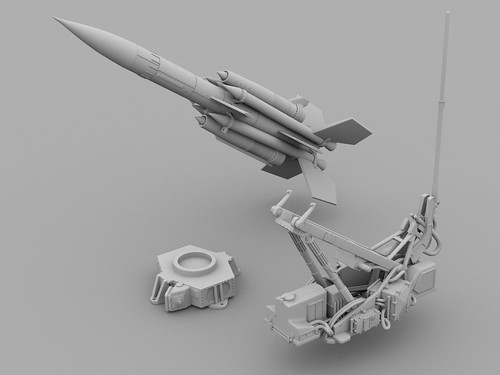

Bristol Blood Hound - Work in Progress

Posted: Friday, March 28, 2014 - 11:01 AM UTC

That looks nice!

Adam, did you get my message about the Depth Charges?

Adam, did you get my message about the Depth Charges?

raypalmer

Joined: March 29, 2010

KitMaker: 1,151 posts

AeroScale: 985 posts

Posted: Friday, March 28, 2014 - 11:19 AM UTC

God's teeth you're quick! Looks amazing!

That HAS to sell well. Look at that gorgeous piece of British engineering.

Next suggestion:

De Havilland Goblin turbojet! Unless I'm mistaken this doesn't exist in resin. If it does, what about RR Derwent, or Avon??

That HAS to sell well. Look at that gorgeous piece of British engineering.

Next suggestion:

De Havilland Goblin turbojet! Unless I'm mistaken this doesn't exist in resin. If it does, what about RR Derwent, or Avon??

Posted: Friday, March 28, 2014 - 07:36 PM UTC

Hi Adam

Very nice! My only suggestion would be to try to make the fins and the walls of the exhausts a lot thinner if you can.

All the best

Rowan

Very nice! My only suggestion would be to try to make the fins and the walls of the exhausts a lot thinner if you can.

All the best

Rowan

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Monday, March 31, 2014 - 10:27 AM UTC

Bloodhound: Not bad eh

For all of the images check out this photo album:

Bristol Bloodhound SAM https://flic.kr/s/aHsjVCTHnR

For all of the images check out this photo album:

Bristol Bloodhound SAM https://flic.kr/s/aHsjVCTHnR

Posted: Monday, March 31, 2014 - 11:02 AM UTC

Looks very nice! Knocks the socks off the old Airfix kit.

Did you get my message about the Depth Charge dimensions? Felt it important I passed on my findings about the dimensions. Again apologies for my earlier mistake.

Stephen

Did you get my message about the Depth Charge dimensions? Felt it important I passed on my findings about the dimensions. Again apologies for my earlier mistake.

Stephen

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Monday, March 31, 2014 - 11:14 AM UTC

Quoted Text

Hi Adam

Very nice! My only suggestion would be to try to make the fins and the walls of the exhausts a lot thinner if you can.

All the best

Rowan

Hi Rowan,

We are going to print this in a polished material which, through the polishing process, does slim parts down a little.

raypalmer

Joined: March 29, 2010

KitMaker: 1,151 posts

AeroScale: 985 posts

Posted: Monday, March 31, 2014 - 12:12 PM UTC

I'm looking forward to this! http://youtu.be/1F9mS1fNXVs

Posted: Monday, March 31, 2014 - 03:43 PM UTC

Intriguing!

robot_

Joined: March 08, 2009

KitMaker: 719 posts

AeroScale: 691 posts

Posted: Monday, March 31, 2014 - 06:47 PM UTC

My humble advice: remember to break down the parts far enough- printing in one or two pieces may be possible, but modellers would prefer more, as has been said- for sanding, modification or painting reasons (as well as the fun of assembly).

Your renders look good. You are using the polished white rather than the ultra detailed clear for price reasons, I think. In my opinion, if you are serious about this, you should stop giving away a big chunk of potential profit to Shapeways. Have one super-detailed master printed, polish and prep it, the send it to someone who specialises in resin casting. E.g http://www.cmamoldformltd.co.uk or Czech Master Resin. The cost per item would then be in equal competition with other companies, rather than the position you have now with your high costs and low profits.

Your renders look good. You are using the polished white rather than the ultra detailed clear for price reasons, I think. In my opinion, if you are serious about this, you should stop giving away a big chunk of potential profit to Shapeways. Have one super-detailed master printed, polish and prep it, the send it to someone who specialises in resin casting. E.g http://www.cmamoldformltd.co.uk or Czech Master Resin. The cost per item would then be in equal competition with other companies, rather than the position you have now with your high costs and low profits.

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Monday, March 31, 2014 - 06:57 PM UTC

Quoted Text

My humble advice: remember to break down the parts far enough- printing in one or two pieces may be possible, but modellers would prefer more, as has been said- for sanding, modification or painting reasons (as well as the fun of assembly).

Your renders look good. You are using the polished white rather than the ultra detailed clear for price reasons, I think. In my opinion, if you are serious about this, you should stop giving away a big chunk of potential profit to Shapeways. Have one super-detailed master printed, polish and prep it, the send it to someone who specialises in resin casting. E.g http://www.cmamoldformltd.co.uk or Czech Master Resin. The cost per item would then be in equal competition with other companies, rather than the position you have now with your high costs and low profits.

Hi,

This is a route we do often take with a mould makers in the UK but only if there is sufficient interest in a model. For us to create a model that is 3D Printed with less profit per model is a more suitable business model than invest in moulded models that sell only a few. It would bring the cost per model down yes but only on larger order runs of 100+. Its a risk and as we are building over 50 models at the minute for aircraft collectors and military forum members we are taking it step by step so as not to over extend our risk factor. Thanks for the link to that company though as I will ask them about their rates as I do need a metal casting company at the moment.

Posted: Monday, March 31, 2014 - 08:08 PM UTC

Aeroclub swung a very keen bat for quite a long time making pot metal propellers and engine fronts. He's gone off now, and someone is really needed to step into that place.

I personally have need of various propeller sets in 1/144 scale, there are many kits on the market with only very rude approximations of props. The grosser scales, 1:72 and larger, I expect have the same needs, and will pay more by the pound.

I personally have need of various propeller sets in 1/144 scale, there are many kits on the market with only very rude approximations of props. The grosser scales, 1:72 and larger, I expect have the same needs, and will pay more by the pound.

Jessie_C

Joined: September 03, 2009

KitMaker: 6,965 posts

AeroScale: 6,247 posts

Posted: Tuesday, April 01, 2014 - 12:44 AM UTC

Aeroclub is still operating, just not as visibly as before. Contact him through the Britmodeller forum via private message to John Aero.

robot_

Joined: March 08, 2009

KitMaker: 719 posts

AeroScale: 691 posts

Posted: Tuesday, April 01, 2014 - 03:27 AM UTC

Quoted Text

Hi,

This is a route we do often take with a mould makers in the UK but only if there is sufficient interest in a model. For us to create a model that is 3D Printed with less profit per model is a more suitable business model than invest in moulded models that sell only a few. It would bring the cost per model down yes but only on larger order runs of 100+. Its a risk and as we are building over 50 models at the minute for aircraft collectors and military forum members we are taking it step by step so as not to over extend our risk factor. Thanks for the link to that company though as I will ask them about their rates as I do need a metal casting company at the moment.

I think orders well under 100 are still more feasible from silicone moulds than 3d printing. A silicone mould only lasts 30 casts or so, so there are no economies of scale over 30 items. If your ~15cm long Bloodhound in 1/48 costs around (let's guess) £40, and you sell 10 of them, is that much return for your time? I don't know how fast you are at modelling, but I guess with overheads, etc. you would like to be earning £100+ an hour. I guess (again), that Shapeways would charge at least £25 to print the bloodhound, so only £15 profit per model sold. A resin model that cost £40, but was more detailed, and widely marketed could sell 50+ quite easily, I would think.

Anyway, I'm just expressing my (unprofessional) opinion on this. The 3D printed master and resin production business is being used by the big players in aftermarket items (Eduard, MPM), and small companies (e.g. http://www.videoaviation.com/), and their quality is incredibly high. E.g. Eduard's Merlin in 1/48.

I think using lower than the very best fidelity materials to print down to a cost (i.e. what you think the market can bear- comparison with resin cast products from other companies) will lead to fewer sales in this very specialist and discerning marketplace.

Anyway, to keep on-topic, I would love a model to be made of PDU 1 in 1/72 https://aeroscale.kitmaker.net//features/2823&page=1.

As it was never built, the accuracy is not important, just something that looks like the plan views and the pencil sketches, and was made with the opening for the glass floor, and the fuselage would need to be made in two halves for painting the insides.

If you could supply with it male moulds for crash-moulding transparencies for bubble hood and the floor windows, I would be prepared to pay £35 for a model of it. Not sure you'd find many other people interested, but you never know (Britmodeller and the WHIF forum would be good places to drum-up interest in it).

PS: I have Illustrator vector files of the 3-view.

drabslab

Joined: September 28, 2004

KitMaker: 2,186 posts

AeroScale: 1,587 posts

Posted: Tuesday, April 01, 2014 - 05:03 AM UTC

Quoted Text

Quoted Text

Hi,

This is a route we do often take with a mould makers in the UK but only if there is sufficient interest in a model. For us to create a model that is 3D Printed with less profit per model is a more suitable business model than invest in moulded models that sell only a few. It would bring the cost per model down yes but only on larger order runs of 100+. Its a risk and as we are building over 50 models at the minute for aircraft collectors and military forum members we are taking it step by step so as not to over extend our risk factor. Thanks for the link to that company though as I will ask them about their rates as I do need a metal casting company at the moment.

I think orders well under 100 are still more feasible from silicone moulds than 3d printing. A silicone mould only lasts 30 casts or so, so there are no economies of scale over 30 items. If your ~15cm long Bloodhound in 1/48 costs around (let's guess) £40, and you sell 10 of them, is that much return for your time? I don't know how fast you are at modelling, but I guess with overheads, etc. you would like to be earning £100+ an hour. I guess (again), that Shapeways would charge at least £25 to print the bloodhound, so only £15 profit per model sold. A resin model that cost £40, but was more detailed, and widely marketed could sell 50+ quite easily, I would think.

Anyway, I'm just expressing my (unprofessional) opinion on this. The 3D printed master and resin production business is being used by the big players in aftermarket items (Eduard, MPM), and small companies (e.g. http://www.videoaviation.com/), and their quality is incredibly high. E.g. Eduard's Merlin in 1/48.

I think using lower than the very best fidelity materials to print down to a cost (i.e. what you think the market can bear- comparison with resin cast products from other companies) will lead to fewer sales in this very specialist and discerning marketplace.

Anyway, to keep on-topic, I would love a model to be made of PDU 1 in 1/72 https://aeroscale.kitmaker.net//features/2823&page=1.

As it was never built, the accuracy is not important, just something that looks like the plan views and the pencil sketches, and was made with the opening for the glass floor, and the fuselage would need to be made in two halves for painting the insides.

If you could supply with it male moulds for crash-moulding transparencies for bubble hood and the floor windows, I would be prepared to pay £35 for a model of it. Not sure you'd find many other people interested, but you never know (Britmodeller and the WHIF forum would be good places to drum-up interest in it).

PS: I have Illustrator vector files of the 3-view.

Maybe you could work with a sign up approach at model launch? It would give you an idea of the market size, and then you could adapt the production method to that.

3DPrinting

Joined: March 21, 2014

KitMaker: 31 posts

AeroScale: 28 posts

Posted: Tuesday, April 01, 2014 - 09:10 AM UTC

By 'Sign up' approach I presume you mean to get people to sign up if they would want to buy the model if we can get it made in a strong Resin material? We followed this approach in other forums and ran a poll for aircraft people wanted. As you may imagine the sales never matched the interest so I think realistically the only true way to get a feel for peoples interest in asking them to contribute financially, like a kickstarter project, because in that way you can filter out those who like to talk and those who are actually interested.

|