I'll quote myself from the campaign thread for starters.

//START QUOTE//

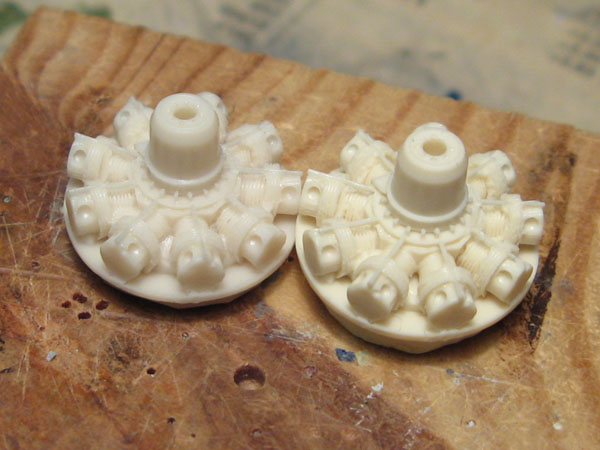

There's not so much flash to take care of, but the old-school style sprue containing smaller parts suffers from some mold mismatch, and of course, according to Murphy's laws, the parts most affected are the landing gears, which should be round even after cleaning... (fortunately, they're not that complicated, even making new ones from scratch doesn't look impossible)

More time will probably go to working with panel lines than flash, on many parts the recessed lines are either very delicate or partially filled with excess plastic (probably caused by worn moulds)

The focal point of the whole plane is the glasshouse canopy, and now I didn't take any chances on it when separating from the sprue.

I don't know if it's the clear part or the fuselage (or a bit of both), but there's somehing wrong with the fit here...

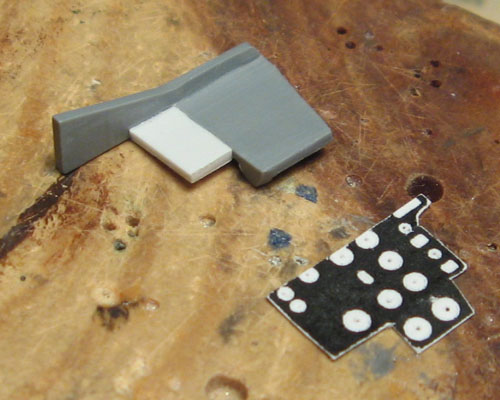

The shorter cockpit floor on mk.I is offered as a resin part, and in addition to the increased difficulty of attaching such a part, it was slightly warped. Comparing the original plastic part and the shorter resin one revealed that the latter is actually a modified copy of the longer mk.IV floor, so I'll be just cutting the styrene part to the proper lenght and using that instead.

//END QUOTE//

Taking off from that, it really looks like I'll either have to take the landing gear from the mk.IV in my stash (that has cleaner mouldings on the gear parts), or scratch-build new ones.

Misaligned moulds are the worst....

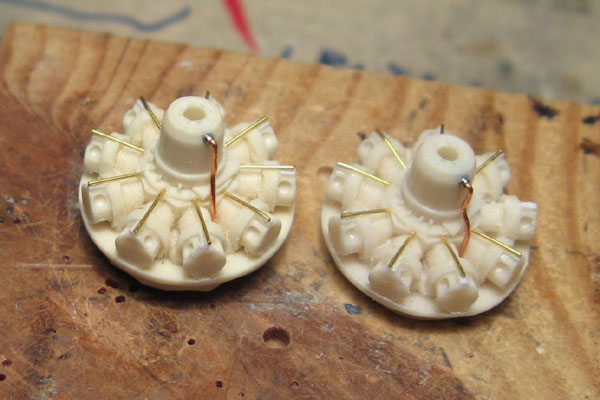

When you got that scraped and filed off, the parts are not that round anymore. Either way, I think I'll have to make new landing gear for either this or the other blenheim.

Why did the misalignment have be on the landing gear, instead of the prop blabes which I'll be replacing. Just my luck I guess...

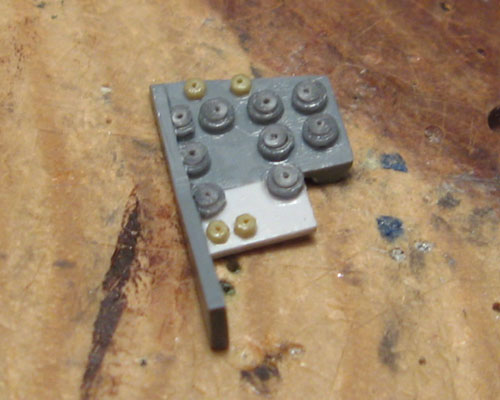

Cockpit components have been going together nicely.

It seem like the resin series II bomb bay from Galdecal will require some quite drastic surgery to enable the cockpit to fit, but that's still looming ahead.

In addition to flash removal, there seems to be a bunch of parts to sand down in this kit.

Quite a difference, the landing gear door on the right has been thinned already.

The engine cowling edges supposed to represent cooling flaps are as thick as the rest of the part. Quite a visible part, that has to be fixed. What's your opinion, should I try to sand the inside of the cowling (the outside details are quite nice), or just grind off the whole edges and make new flaps?

Doing that, I'll have to mount the cowlings some other way too, as out of the box, the cowling attaches to the engine mount on the wing by the flaps, it's all empty inside. Holes drilled to the wing and to backsides of the engines with wire in between should do the trick.