I found no picture or information about the installation of Vickers machine guns. I chose to install two guns Fiat.

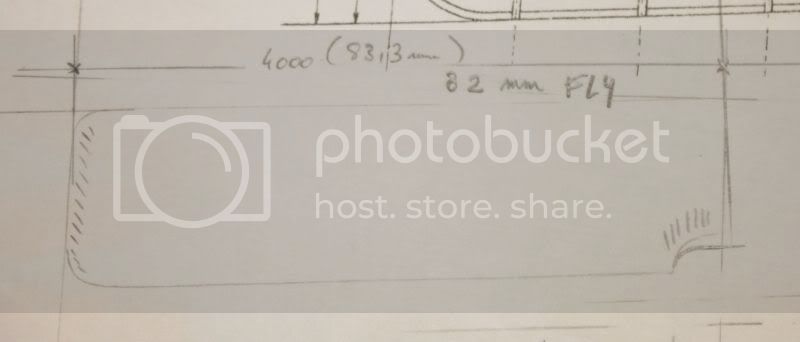

I used the design of the cockpit appeared in the Windsock datafile and the following documents:

A pdf document on the gun "Fiat Revelli model 1914" in English:

http://www.smallarmsreview.com/pdf/Fiat.pdfAnother Italian with technical drawings of the weapon:

http://www.armigeridelpiave.it/SELEZIONI/La%20mitragliatrice%20FIAT%20da%20aviazione.pdfThe weapons are installed with the left side up to be able to recharge. I am well used to detail the right side ... before I realized my mistake.

All lengths are in mm

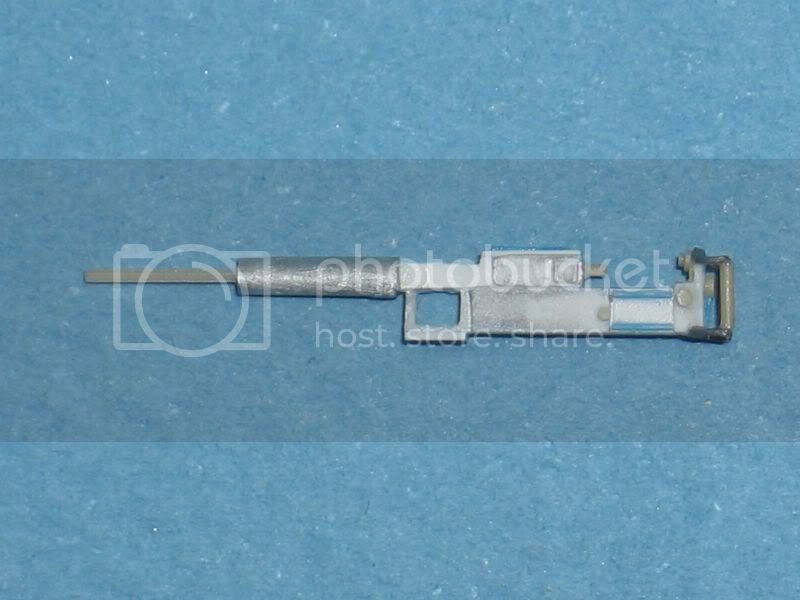

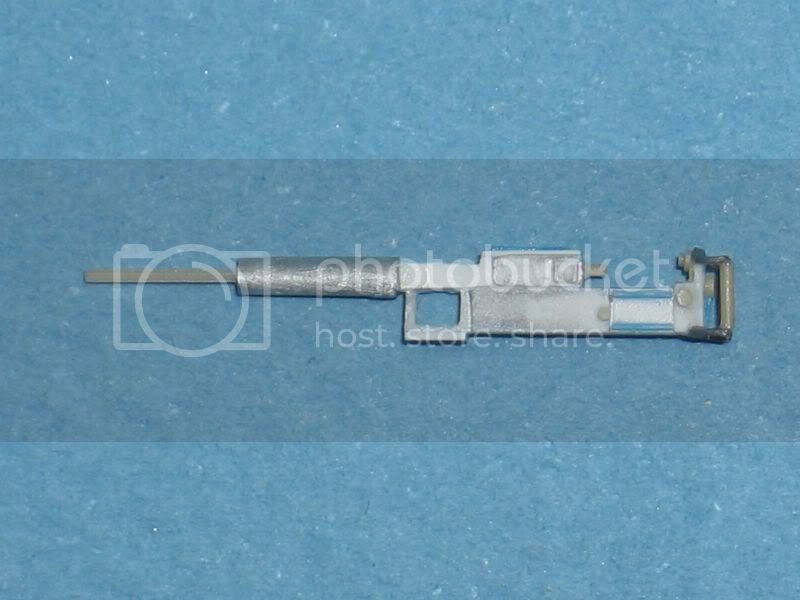

Stage 1: 3 parts : (1,5 X 0,25) X 93 shorten it to 2mm. Drill the hole

for cartridge clip. (red parts)

Stage 2: 2parts: (1,5 X 0,25) X 4,56 (green parts)

Stage 3: 1part: (1 X 1) X 3,35

Stage 4: 1part: (0,75 X 0,75) X 2,4 or (1x0.75) add 1mm to fix the sheath of the

barrel of the weapon

Stage 5: 3parts: 0,7 X 1,65 (?) X 0,25

Stage 6: Length 5mm. Diameter: 1,5mm « flan dish aluminium »

Stage7+8: 0,75X0,75 0,5X0,5 a thin slice....

Stage9: 1part: 0,25 X 2,3 X 1,8

Stage10: 13,5 and remove the added length to the fourth stage (1mm).

diameter: 0,4 ?

Stage11: Build black part, 0,1mm x 1 x 2

Stage12: Build orange part 0,1x 1,3 (?) x 3,35 the orange cover is a bit wider

than the part 3

Blue: Plastic (square section) stretched

1,5x0,25 1x1 0,75x0,75 0,5x0,5 come from evergreen's references.

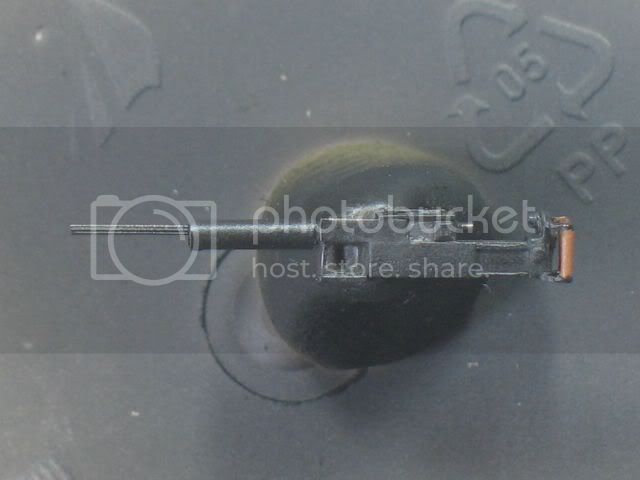

Only the rear will be visible. The cooling jacket and the gun will be hidden in the cabin.

The rest of the handle are made with a tin wire formatted by wrapping around a rod and flat on a glass plate with a steel ruler. It's fragile but quickly made.

The support handle is made with a tin wire formatted by wrapping around a rod and then flattened on a glass plate with a steel ruler. It's fragile but quickly made.

The barrel is made of plastic stretched. The piece is striated with very deep stria before being stretched. We find the stria after the plastic stretched. you dont see on the pictures because too thin.

before:

other files on other weapons:

http://www.smallarmsreview.com/Sample_Articles.htmA +

Best regards