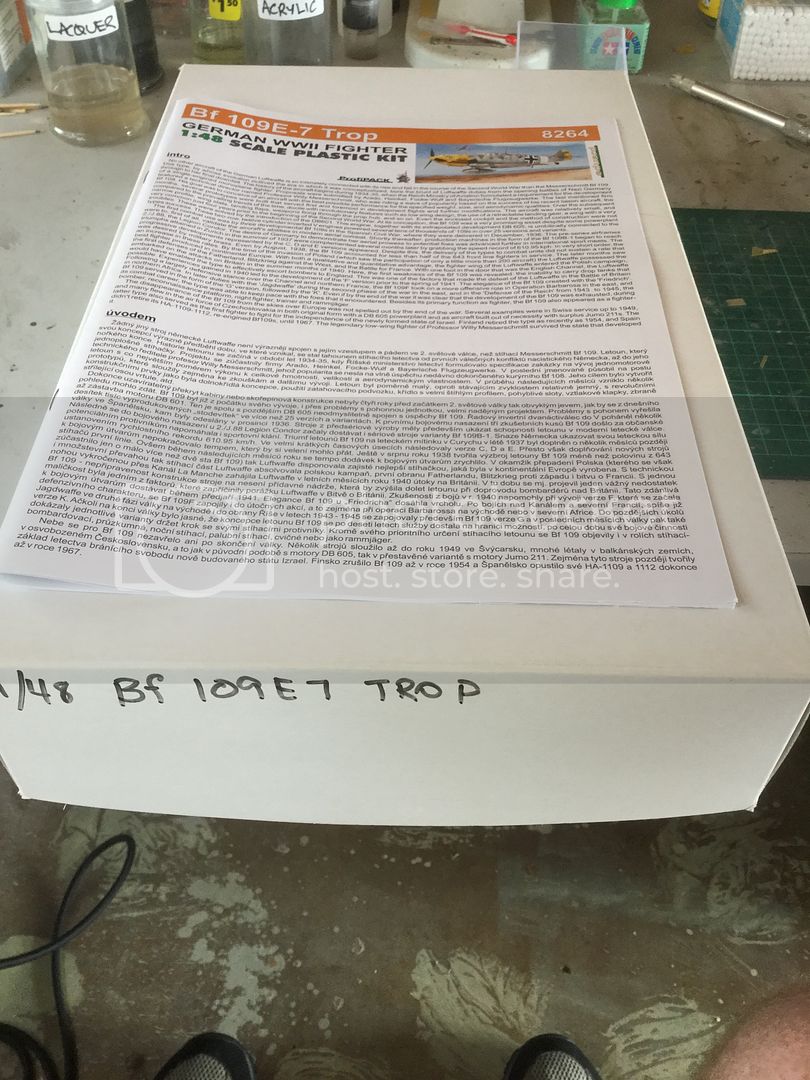

I was sitting there looking through the stash and contemplating my next project, the re-released Eduard Bf 109G-6, when I had one of those "Eureka" moments. The G went back into the shelf and out came an overtrees Bf 109E-7 Trop. Now as those of you familiar with the overtrees concept are aware, you get the bare bones plastic in a plain box. No PE, no decals, no masks, not even a set of instructions. It is designed to be used after you build up a Profipack kit and have some of those pesky decals left over:

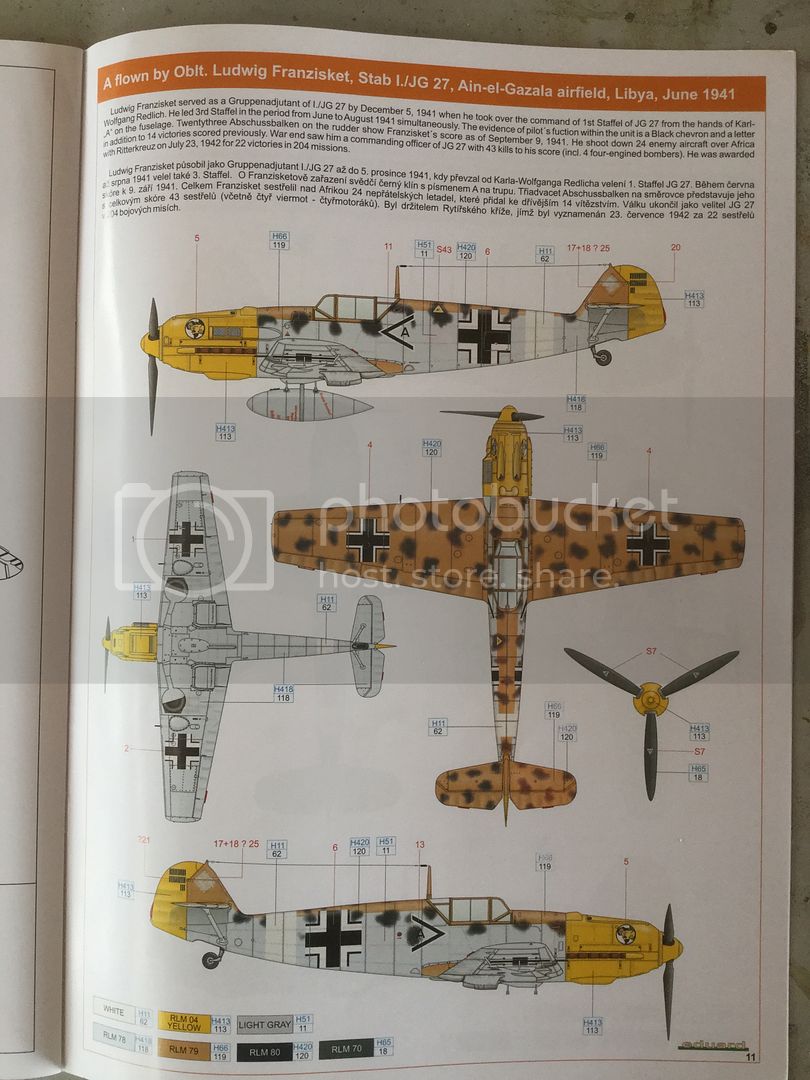

So I went to the stash and dug the instructions, decals and mask out of my Profipack kit and decided upon this scheme:

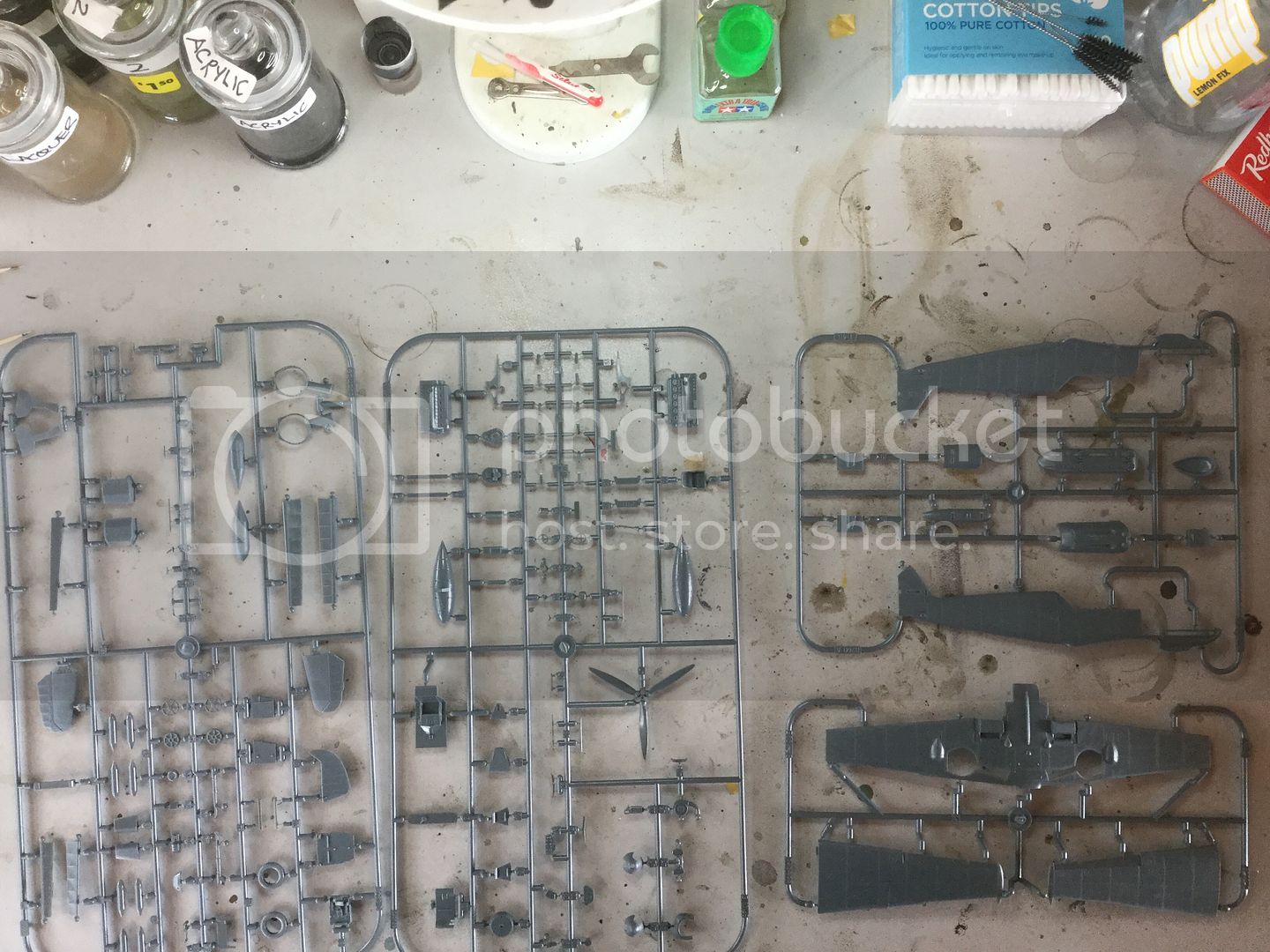

Here is the sprue shot:

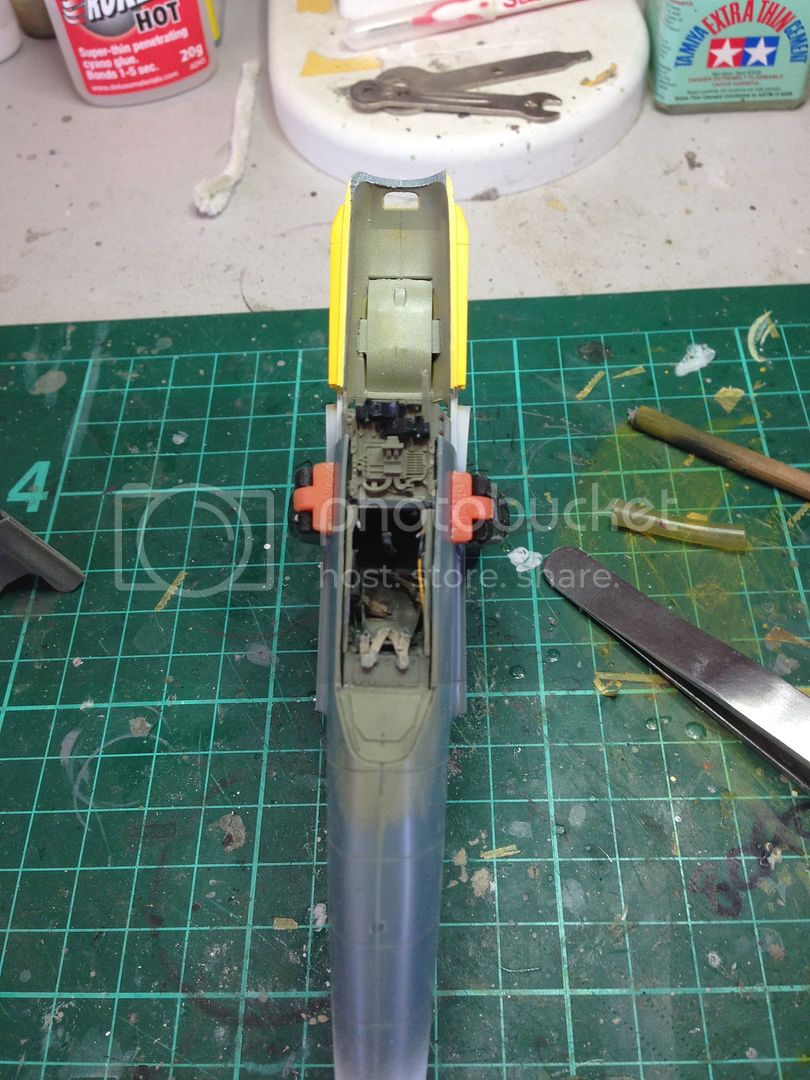

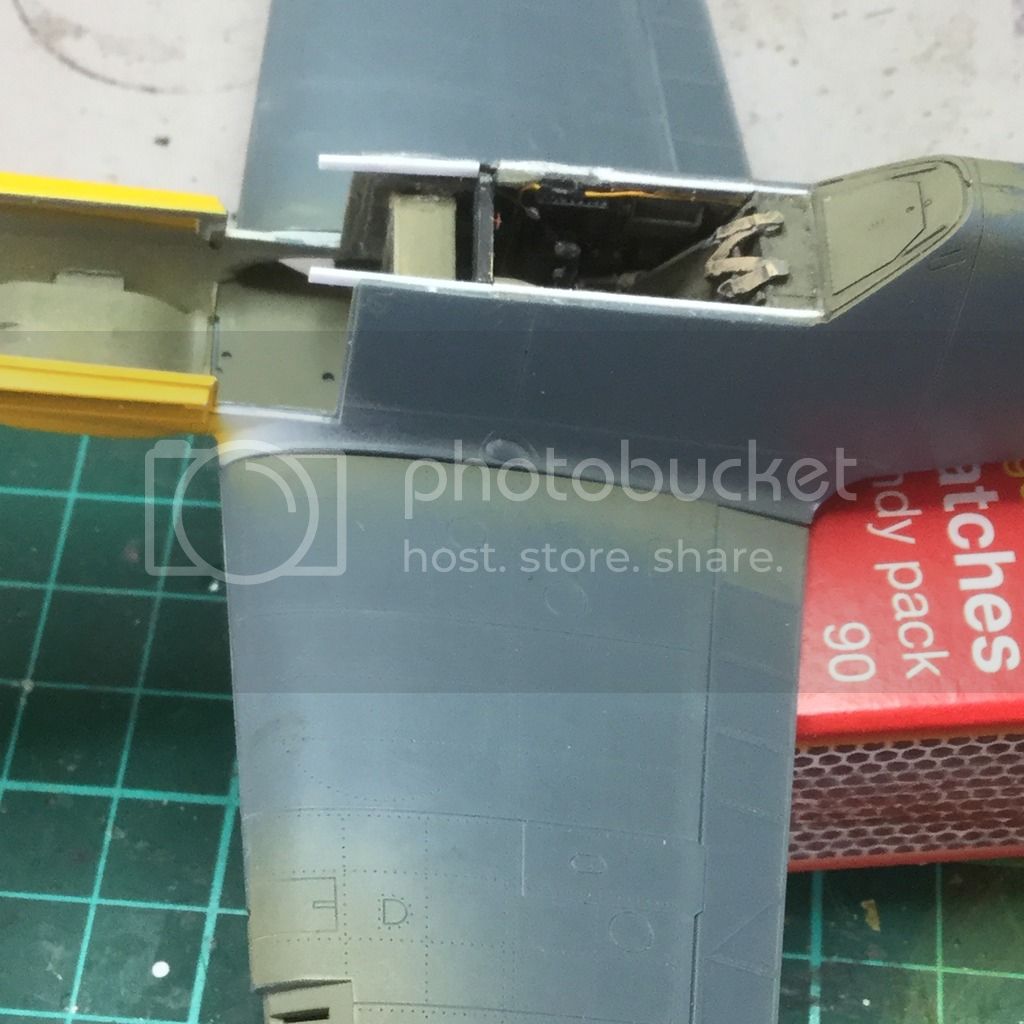

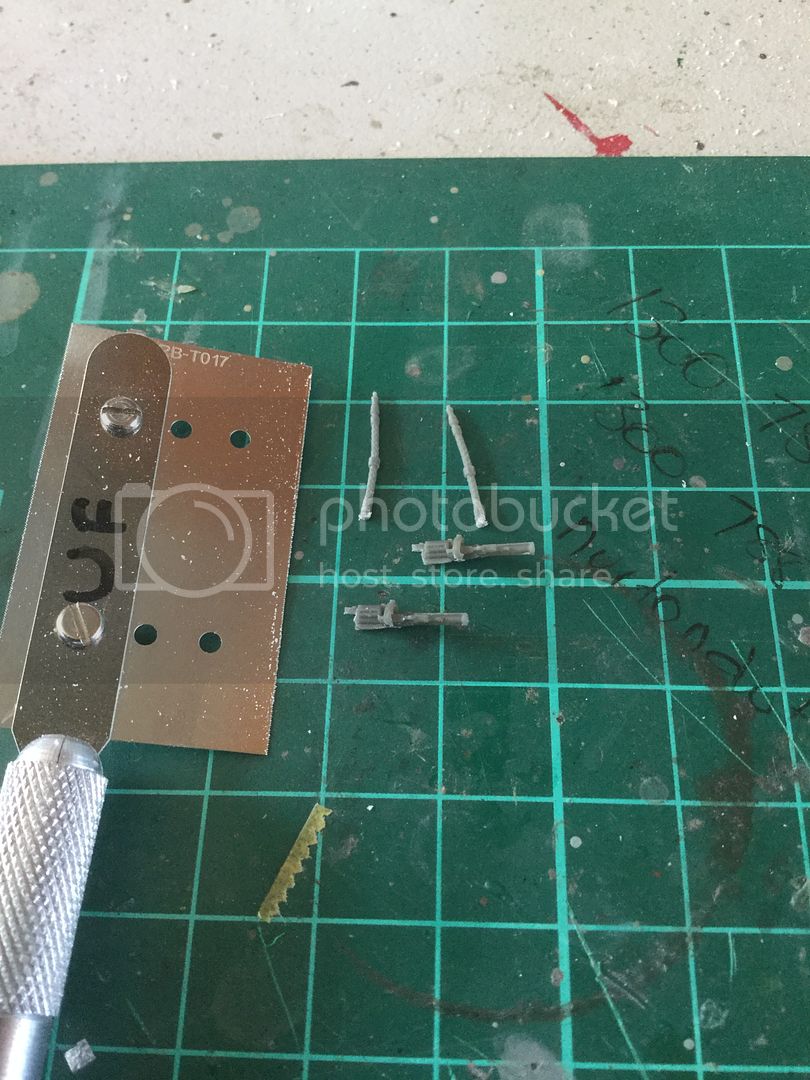

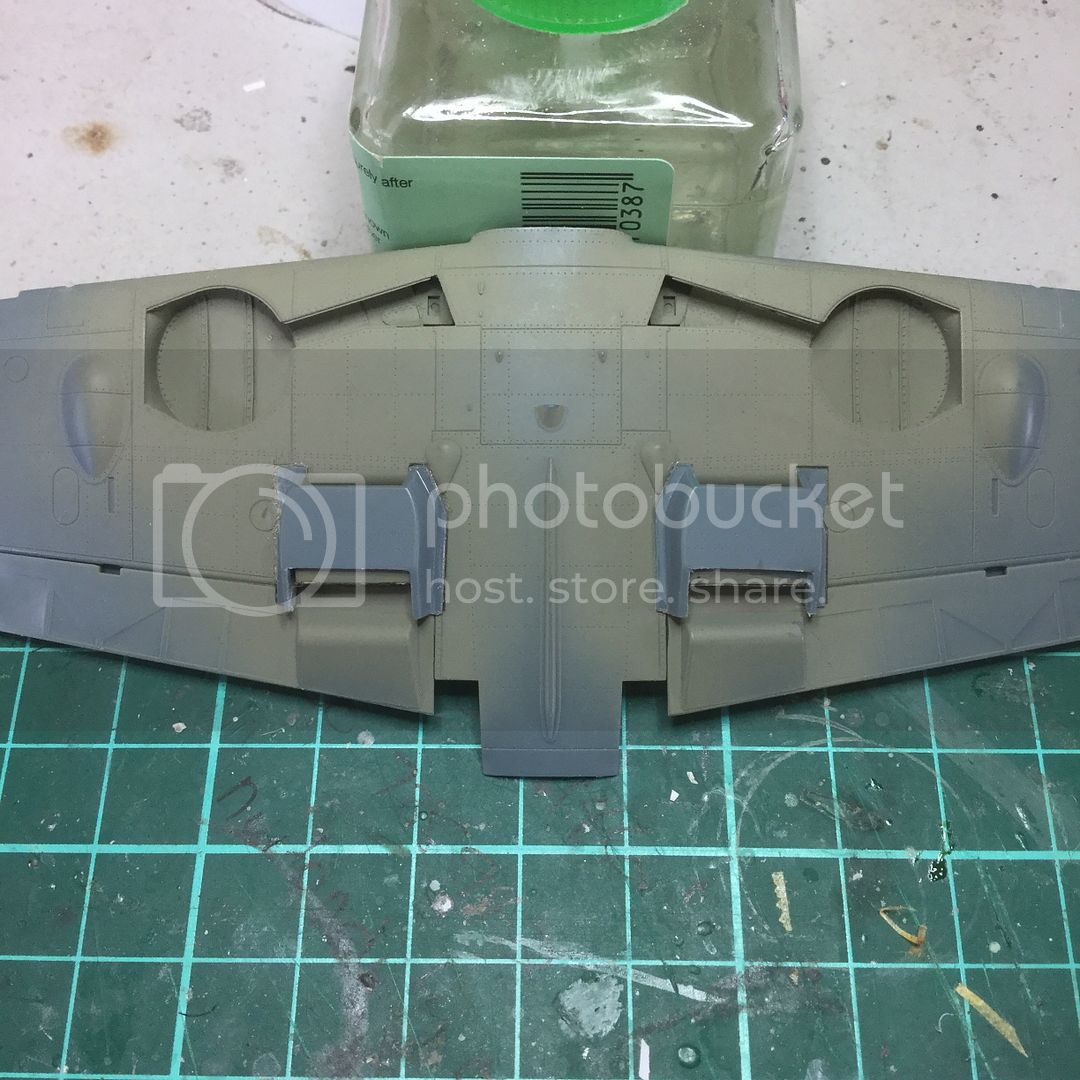

Very basic and probably stress free. But I ask where is the fun there? So I also dragged out the Bf 109E "Bigsin" box which contains almost absolutely everything in resin you could want to add to a basic build: cockpit, engine and radio, guns and wheels! Now we are talking! Throw in some extra Eduard PE, Master Barrels MG 17 and MGFF Barrels, Airscale LW cockpit placards and a set of Finemolds "Nano aviation" German aircraft seatbelts and we have a staggering amount of AM to test our mettle and frustration levels:

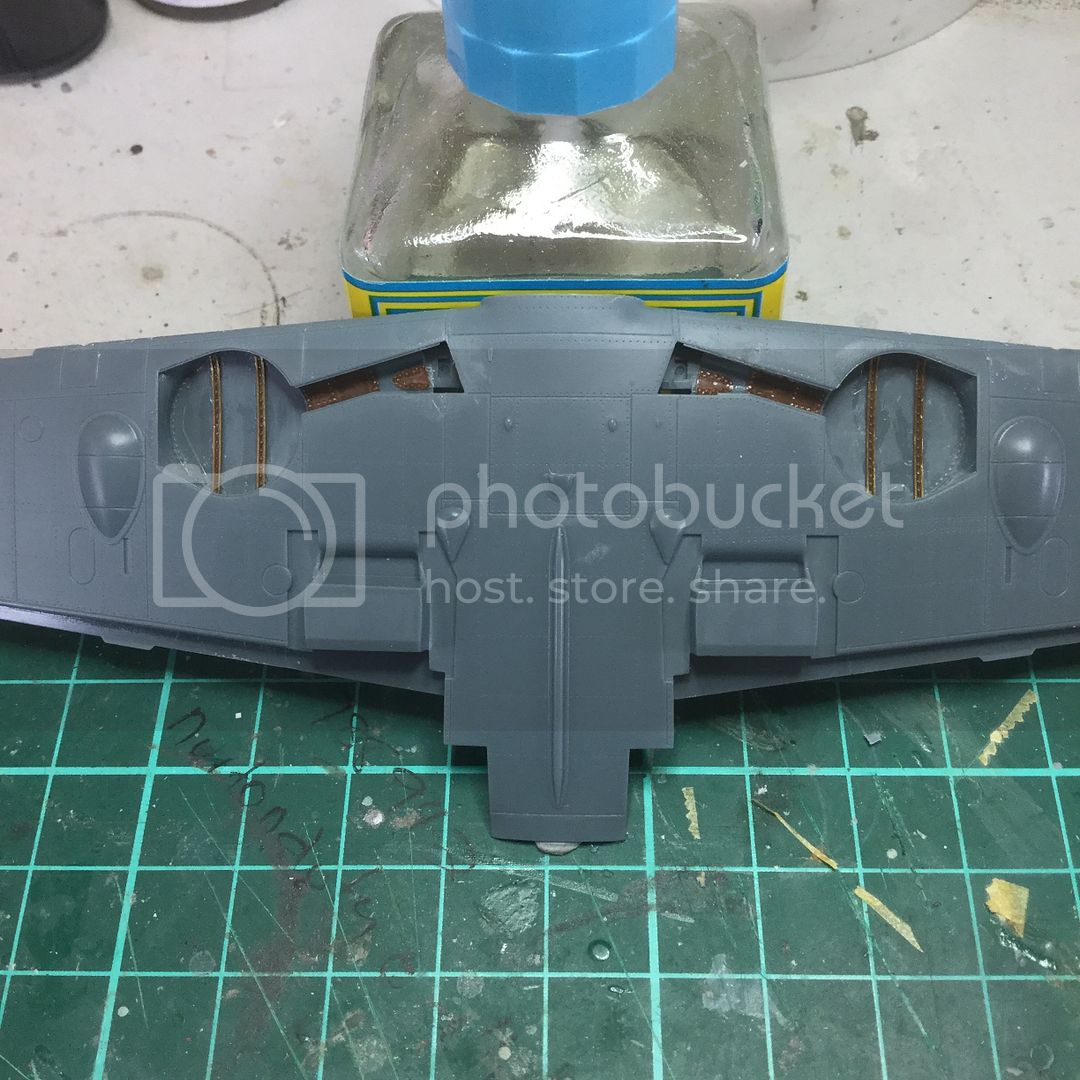

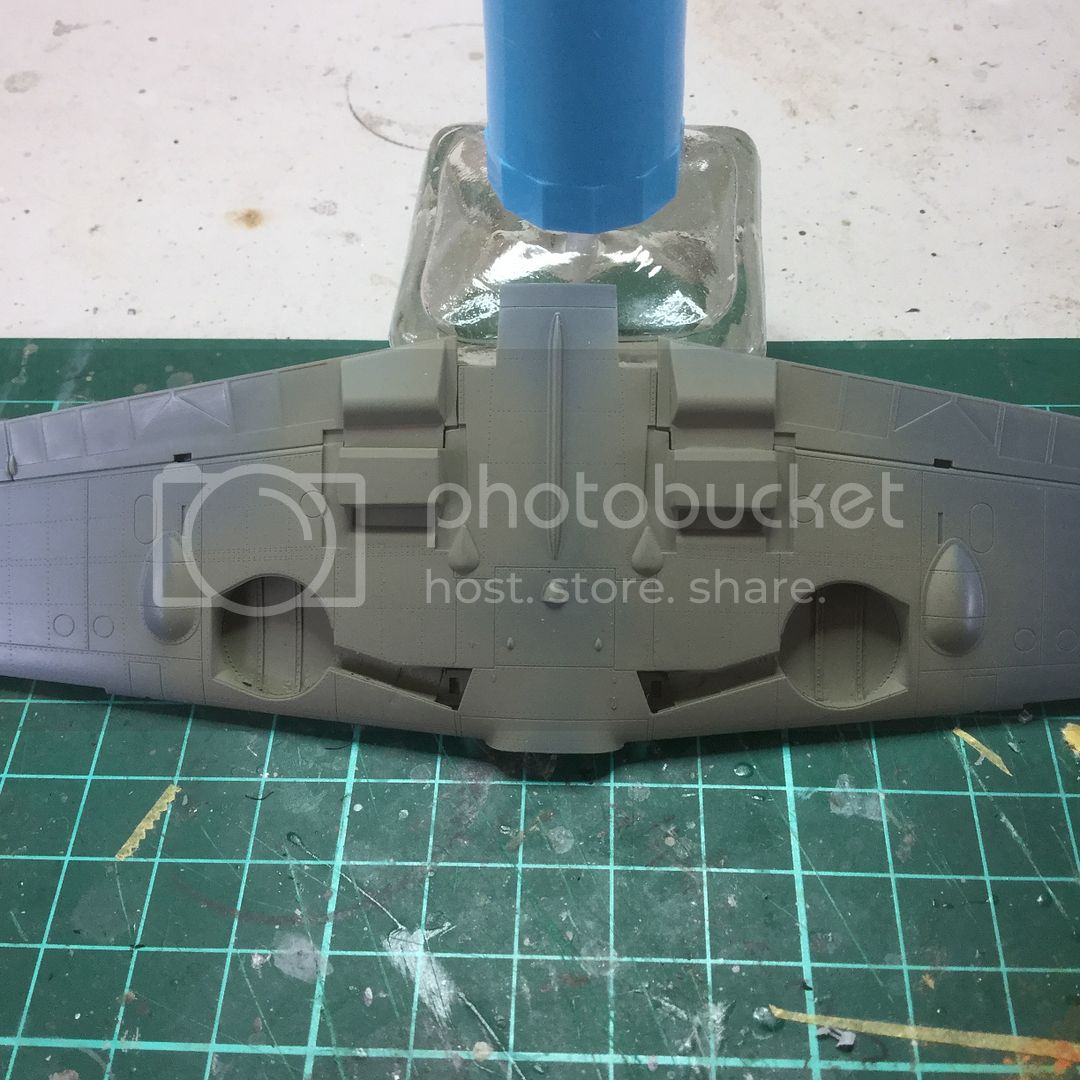

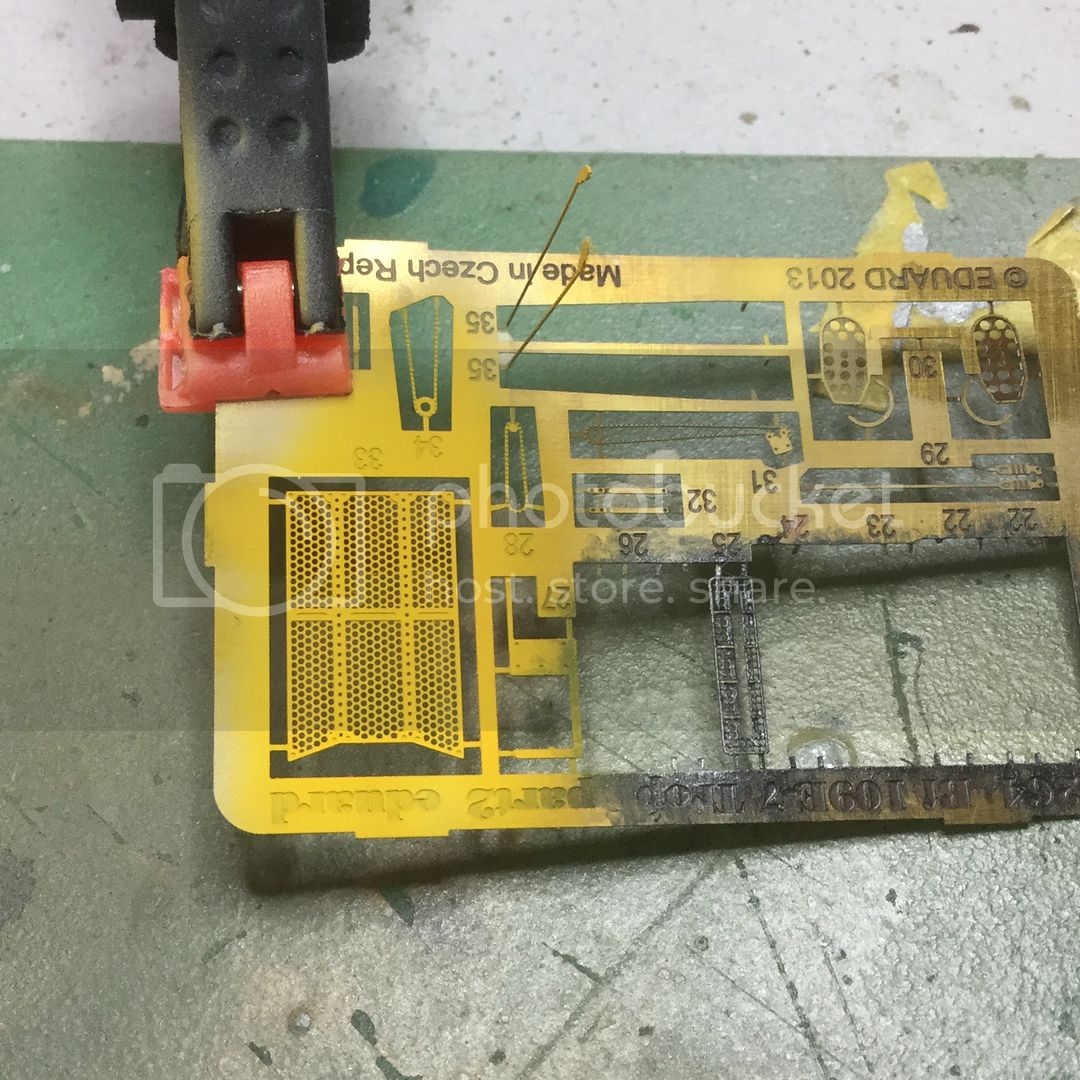

Let the games begin! I started by getting all the PE frets out and coating them with Tamiya Metal primer. I do this now so it is done and I don't forget a fret later on:

Regards,

[/url]

[/url]