Quoted Text

This absolutely fantastic work that your doing Stephen! Before these "evening classes", the Lozenge just looked like another camouflage which didn't make any sense whatsoever to me. But thanks to you all make perfect sense now, I see the angles and all that.....

I have two questions though to you.

1: In the case that you did repairs out at the front units, how was the fabric delivered to you? In rolls or were they delivered as pre-cut units for you to just put in place?

2: Was there ever a winter version tested or planned of the Lozenge?

Looking forward to more matey!

Greetings Jan;

Thanks for the support. I had hoped to be able to give everyone a good basic understanding.

1.The repair stores had to be delivered in small rolls. Every wing configuration had differing areas. Precut sections would have proved useless.

2. There was not a winter scheme of lozenge.

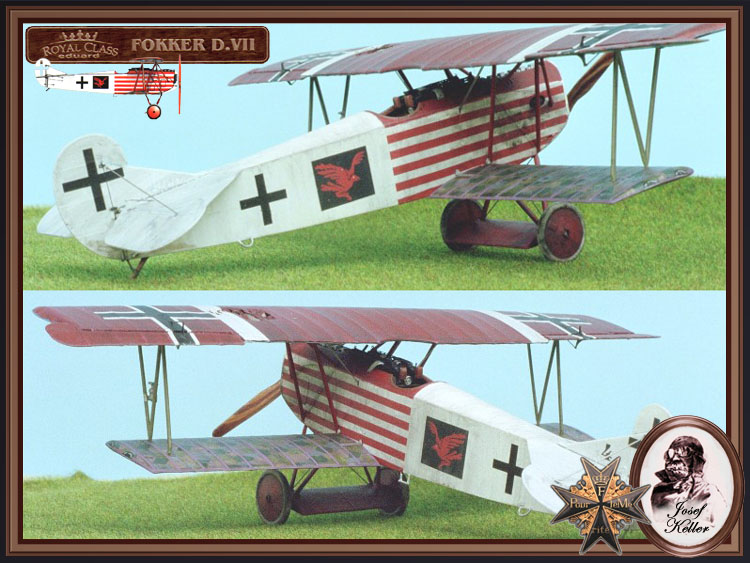

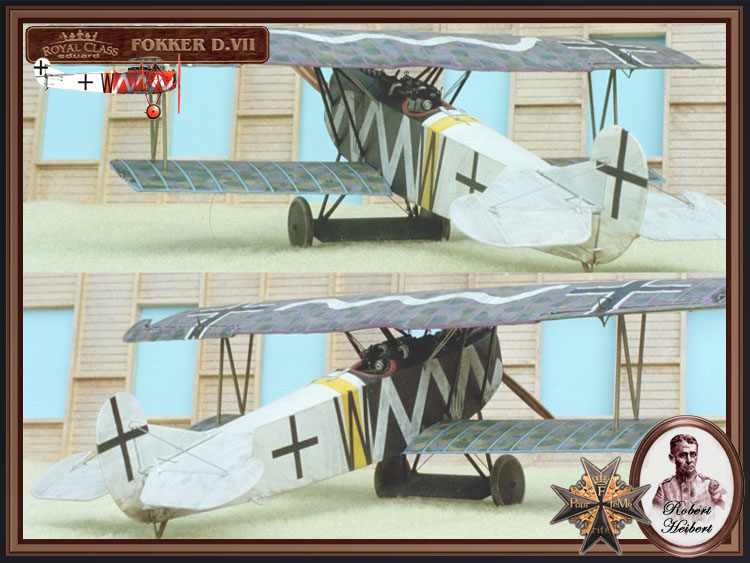

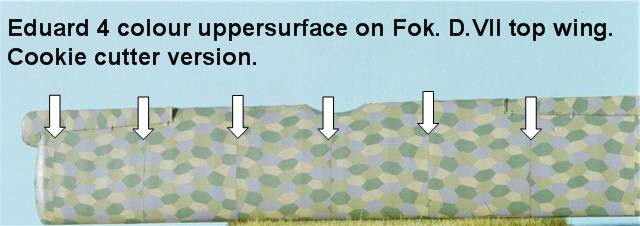

From the venerable Dan San Abbott, here is a bit more on the specific factories that used what appications. Note the term bias is meant to decribe the factory edge to factory edge unions of fabric bolts layed out at the 45 degree angle.

"...Almost all German aircraft factories used the chordwise method of covering wings. The Halberstadt, DFW and Siemens Schuckert used the bias (angled) covering method with the warp yarns (seams) at 45 degrees to the leading edge.

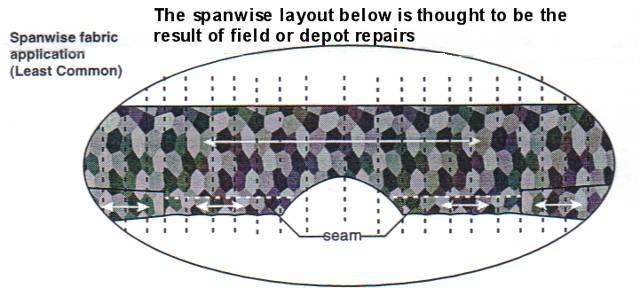

Some used the spanwise wing covering were used by Alb.D.Va on one production batch which included Alb.D.Va5390/17. Siemens-Schuckert used bias(angled) covering on the upper wing and spanwise on the lower wings on the SSW D.III fighter. (Remember my build of the SSW D.III?)

DFW built DFW C.V were bias (angled) covered on all their orders except Aviatik built, serial numbers DFW C.V (Av) 5825/16 to 5974/16 and all subsequent Aviatik built machines through serial DFW C.V(Av) 8249/18.

It is my understanding that bias (angled) wing covering were used on wings where wing warping was used for (lateral) roll control..."