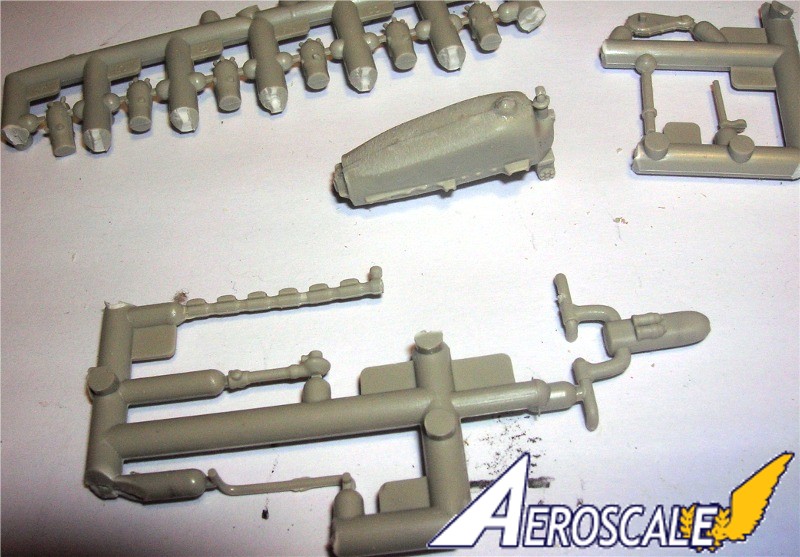

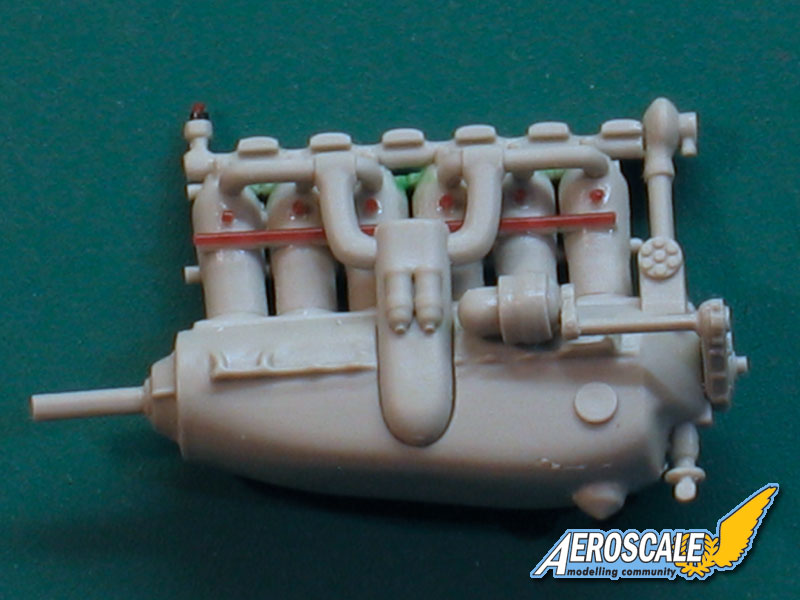

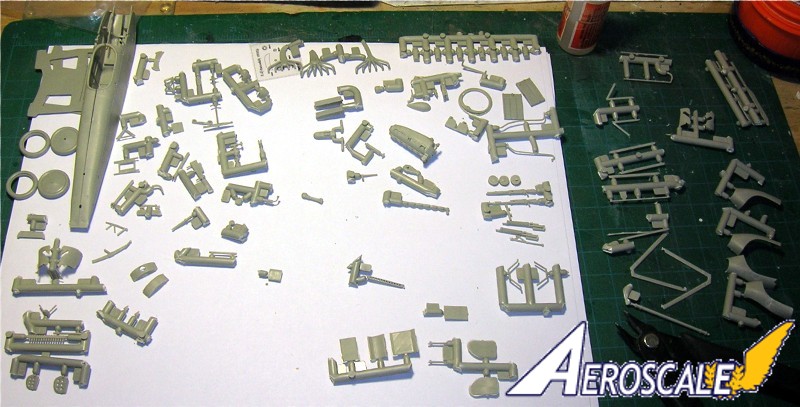

As mentioned earlier the preparation has taken about 4 hours. I can usually gauge how long a build will go after the preparation time. There are a lot of parts (141 @ grey styrene parts w/16 not needed) and I had my hands on all of them at one time or another this evening.

For me prepping is one of the most critical events of a build. The plastic sprue attachment points that have been previously noted are not bad to deal with at all. I will begin my build blog in a separate thread later this next week. The underside of wings stabilizers and elevator did get a quick base coat and will be left to dry for a couple of days.

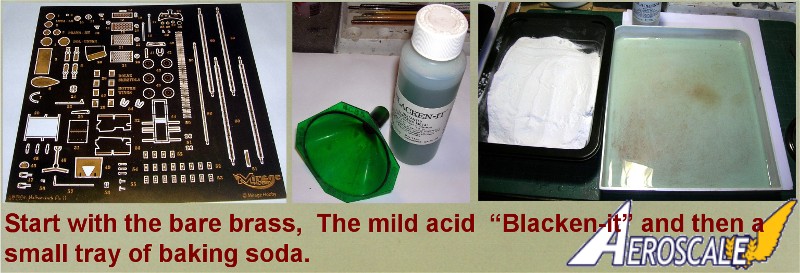

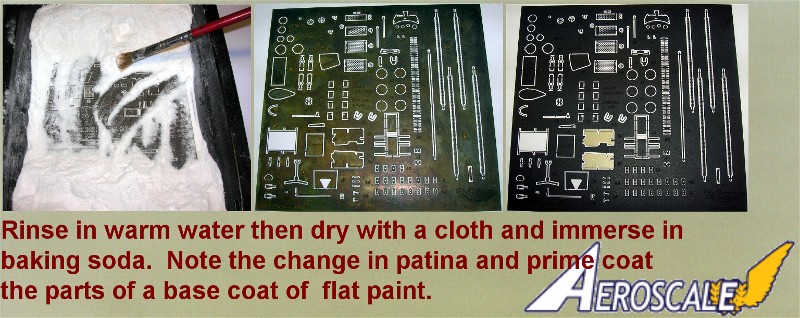

The following is provided to help anyone looking for a good method to prep.

1. Read and re-read the instructions.

2. Sand smooth all edges of the wing panels, ailerons, stabilizers, elevator & rudder.

3. Sand smooth most sprue attachment points for other parts.

4. Separate parts into fabric covered, metal and wood areas.

5. Inventory required paints for the build.

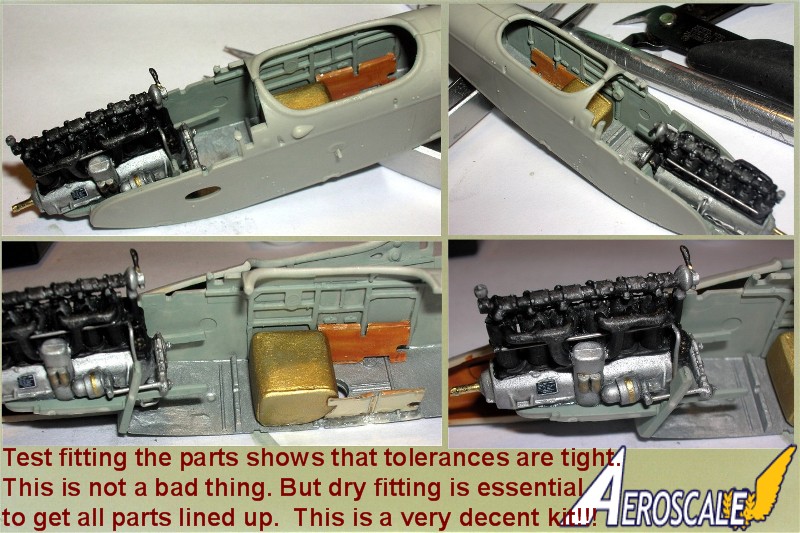

6. Test fit basic components.

7. Identify areas that will need "extra" work or detailing from your spares or aftermarket sets