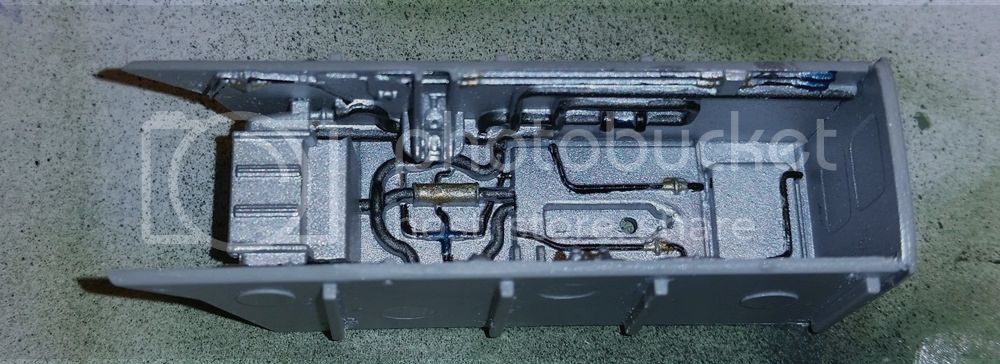

Of course, the problem here is not the model. It is my assumption that they should align at all. How mad was that assumption! That would make things so easy, simple and dull. After half an hour of fiddling and test fitting I discovered that the correct option appears to be as shown in the photo below.

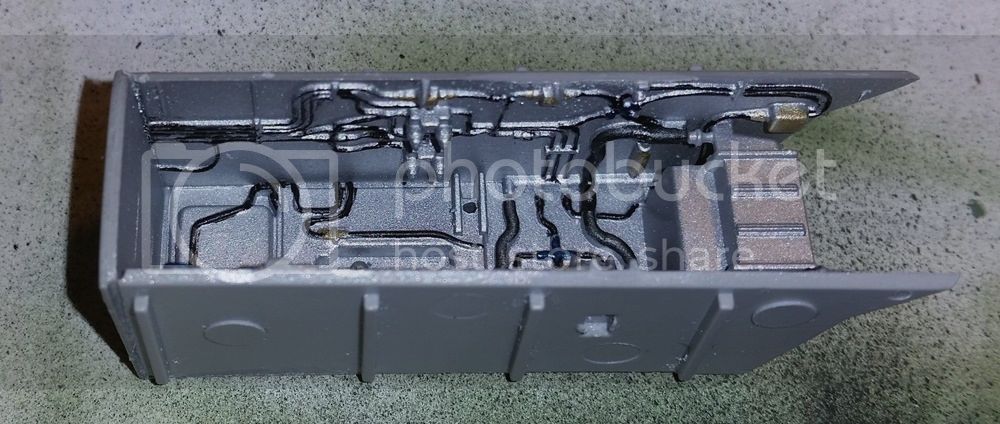

The side parts sit just under the lip at the edge of the top of the wheel bay. This leaves a gap between the rear and top part, and it also leaves moulded hoses in the interior do not meet.

However it does mean that the lower edges sit snuggly inside the guides on the lower fuselage half, and it looks right when viewed from underneath.

As you can see, the parts aren't glued yet. They are held together with tape. I don't fully trust I have this right, so Iím going to work on the cockpit tub which attaches to the front landing gear bay, and then do a second test fit with it in a more complete state.

Wow, all this from one simple illustration in the instructions. Is that what they call value for money?

I wonder how the cockpit tub will fit and if it will in turn fit snuggly to the upper fuselage halves. Shall we take a bet?