MORE LANDING GEAR AND WHEEL WELL PREP WORK

H.G. is grinding it out, doing work to position the landing gear in the nacelles, and getting both the gear and the wells set up for later detailing.

So far as I am concerned, this is the most technically challenging part of the build, given the detail and the kit part configuration. Not to mention that the landing gear must be firmly fixed in the nacelles because they hold the whole model up!

It's clear the designers of the kit engineered it with no regard for the wheel well details, but rather as a platform to hold and position the kit landing gears, which are cut off at the insertion points where the ends fit into the flat kit parts. The only concession to "realism" is the oval openings in the parts to "make space" for the tires themselves, because even with a passing glance inside the nacelles it would look flawed and strange for there to be no space for the wheels to "fit" when "retracted."

I'm not really criticizing this kit design decision. It was the "state of the art" and detail at the time, and besides, "Who's going to really pick up the model and look inside the wheel wells?" From a functional display standpoint, the wheel wells were "invisible."

As a refresher, let's look at the kit parts again to see what I'm trying to describe.

Now

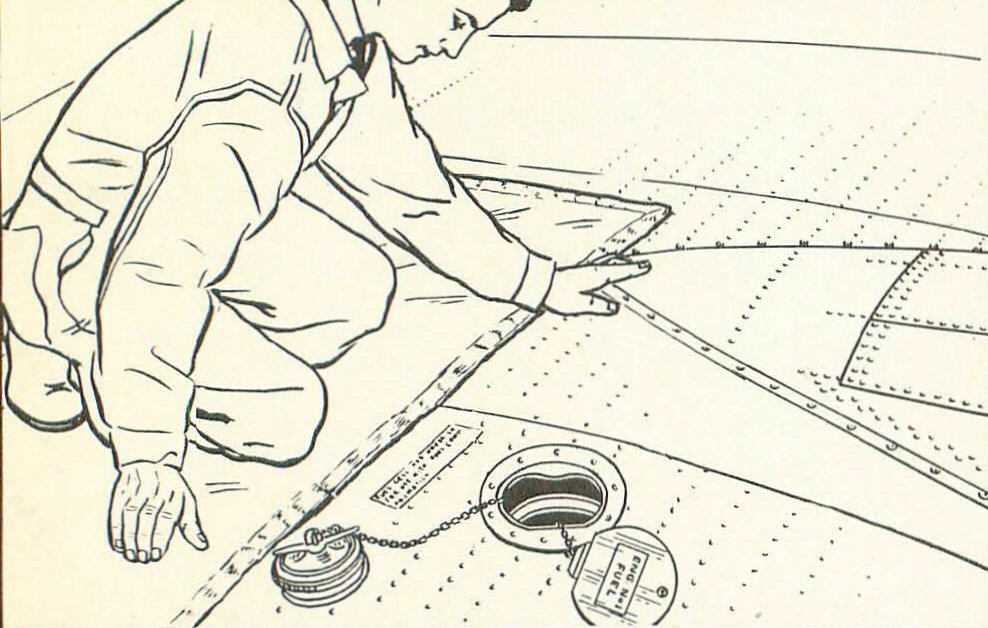

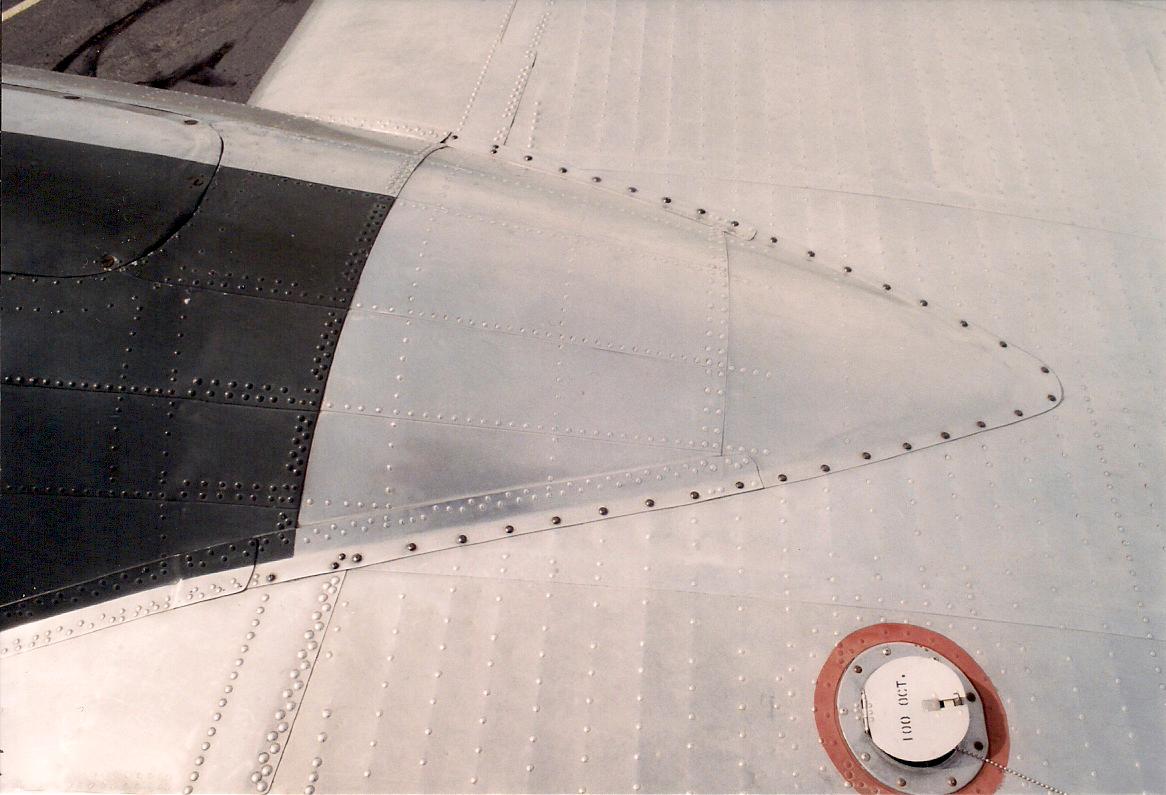

let's look at a real wheel well. The below pictures come from the site at the link.

It's fair to say these show just how wide open the wheel well is, and how much detail is missing from the kit configuration. I particularly like the last one, showing what I think is the black hydraulic pump and gearbox that drives the

ball screw actuator, which in turn raises and lowers the landing gear.

My understanding is that H.G. is going to use the flat kit parts as a locator for the landing gear,

but that he is then going to cut away most of it so that the whole well is visible.

Here's some of the prep work:

The supercharger location detail in the above picture is to highlight an additional mod H.G. is going to make: widening the channel forward to replicate the "Y" shaped exhaust piping at the front underneath the cowl flaps. See below.

Finally, a teaser. To ensure a level fit, H.G. is hand-manufacturing a jig on which to place the taped-together model with gear installed

In the world of real aerospace component manufacturing, which I lived in during the first 20 years of my legal career at Curtiss-Wright, such things are called "tooling" and "fixtures." They are essential components of the manufacturing process.

The below picture,

"Huge drop hammers day and night forming sheet metal parts for B-25s and P-51s built at the North American Aviation Inc. plant in Inglewood in October 1942. Alfred T. Palmer / U.S. Office of War Information." illustrates "tooling" if yuz asks me.

This one, from a picture captioned, "Mounting motor on a B-25 bomber at North American Aviation Inc. plant in Inglewood in 1942. Alfred T. Palmer / U.S. Office of War Information," at the same site shows a "fixture" IMHO. I refer to the "L" shaped brown piping used to hold the front of the engine up during installation on the aircraft.

As I have said before, all this is waaaaaay above my labor grade.

QUESTION FOR KARL: What color were the wheel well interiors painted, or were they left bare metal at the factory or sprayed with some kind of clear primer? Also, did we make any mistakes technically?

Karl, I also have some questions about exterior detailing on the supercharger piping leading from the cowling. Is there an exterior difference in the parts based on the fact that the F model had hydraulic controls for the superchargers, but the G model had an improved electronic control system. The guy who makes the "Resin2Detail" parts has a pair of outer nacelle pipes that I think were intended just for the G model.

http://resin2detail.com/product/ac48005/

I don't know. I do have a set of these. Thanks.