H.G.'s work on the wheel wells continues unabated. I'll take you through it as I discovered the details.

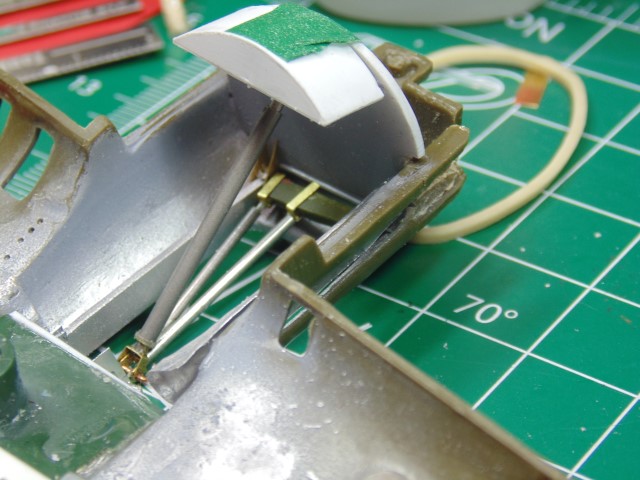

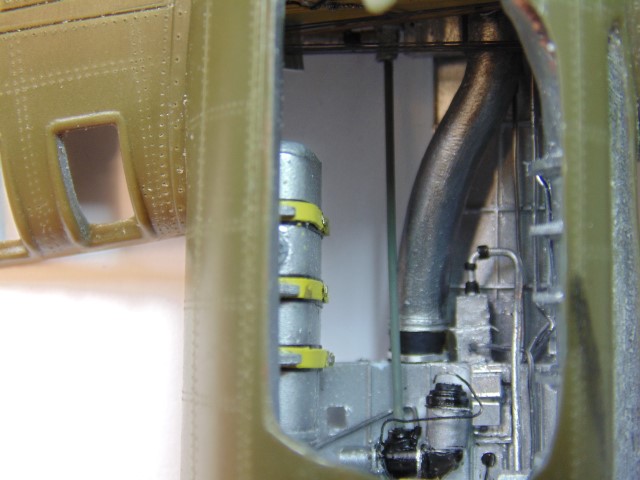

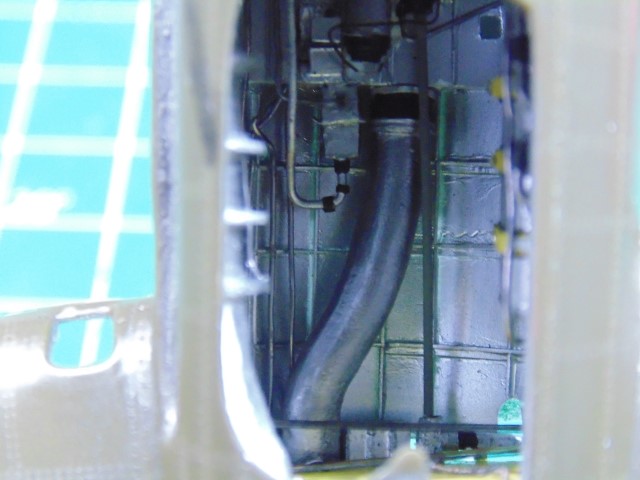

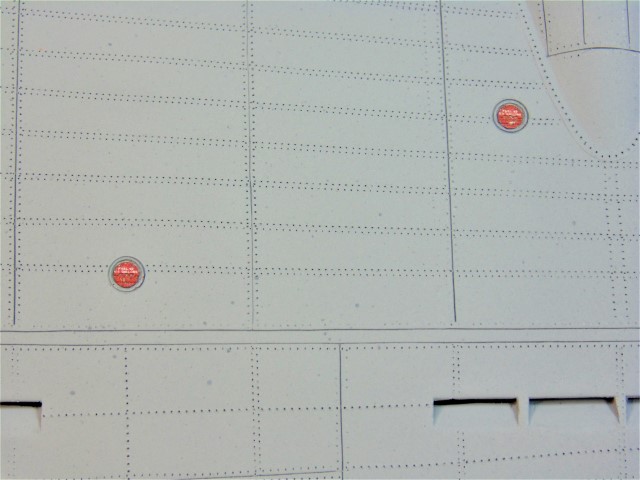

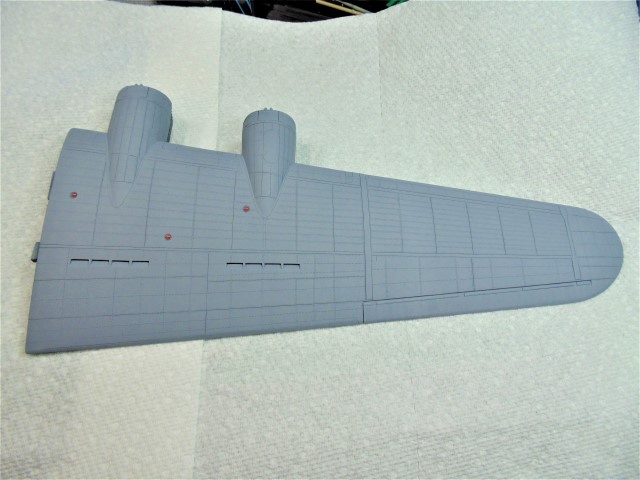

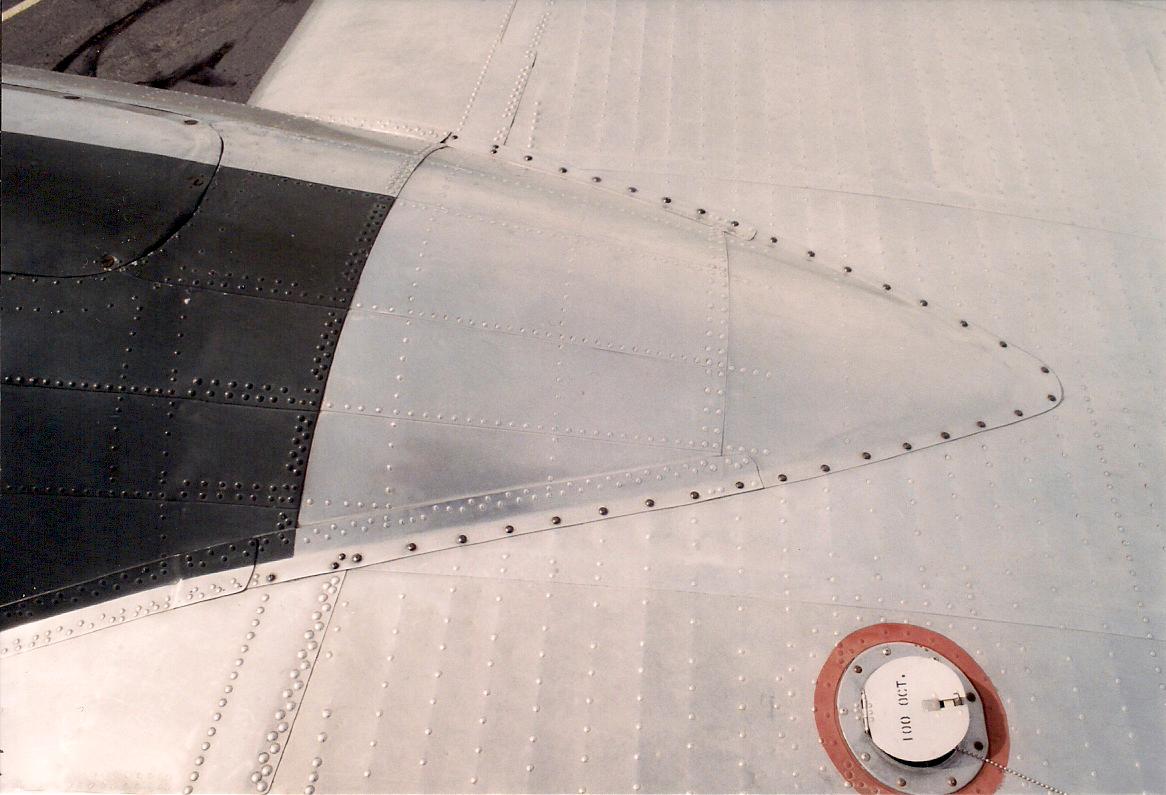

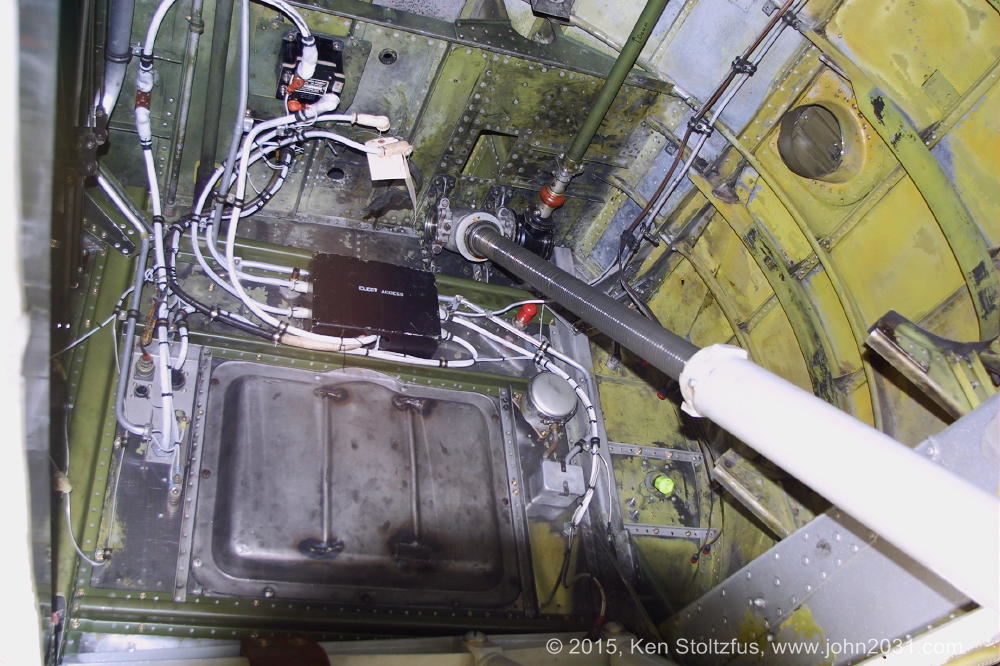

First, a refresher on what the engine oil tank looks like.

And, BTW, don't forget that large landing strut in the foreground cutting diagonally across the tank. I will return to that later.

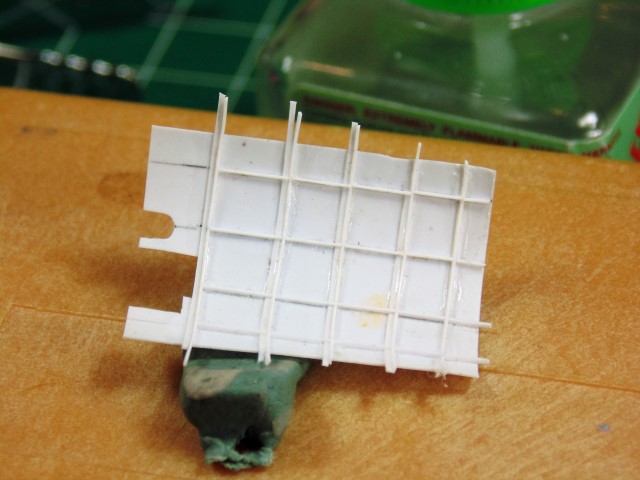

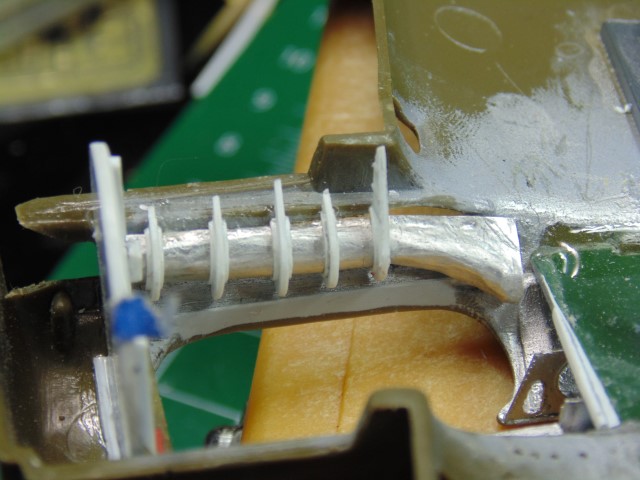

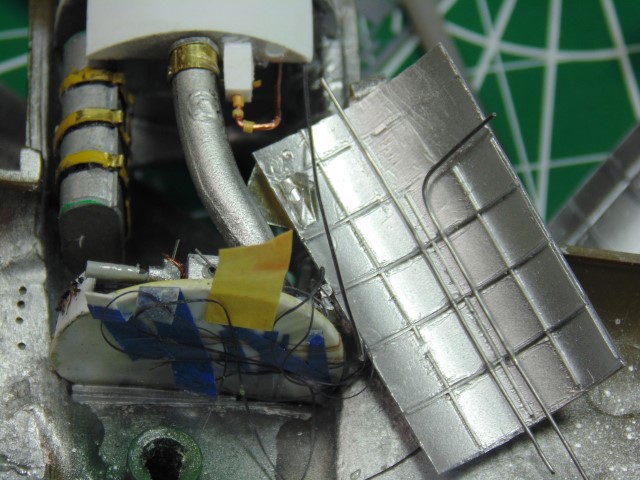

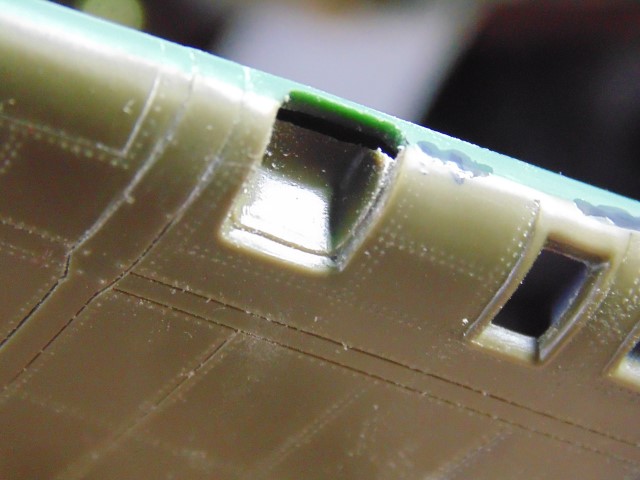

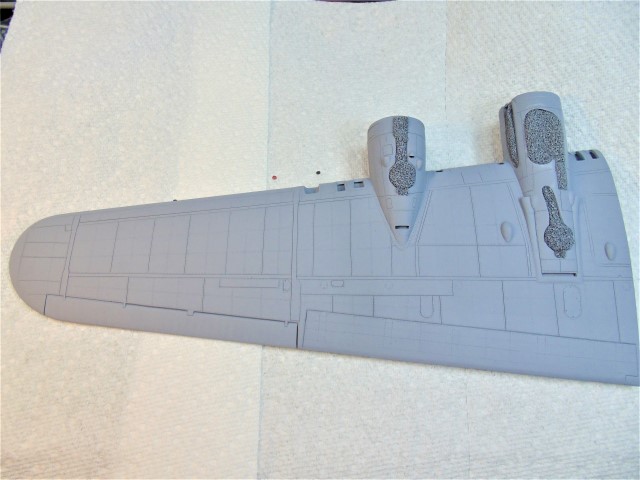

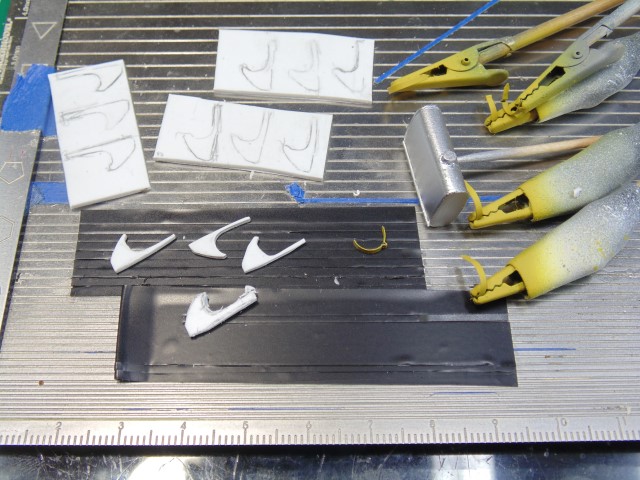

What are these styrene cut-outs, you might ask? I did.

Why, the "J" shaped brackets to hold the oil tanks in place, of course!

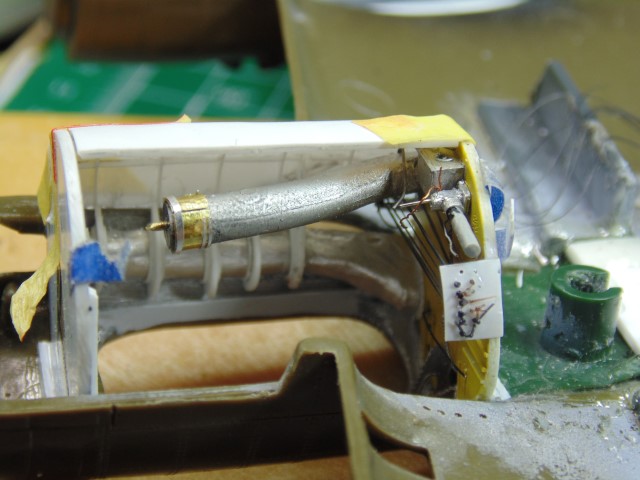

Look to the right.

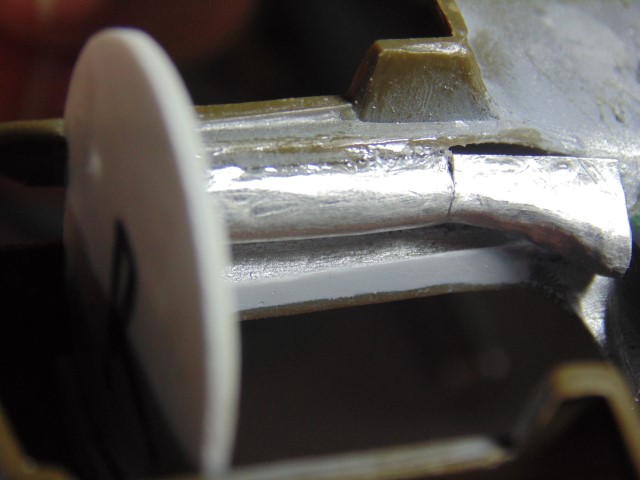

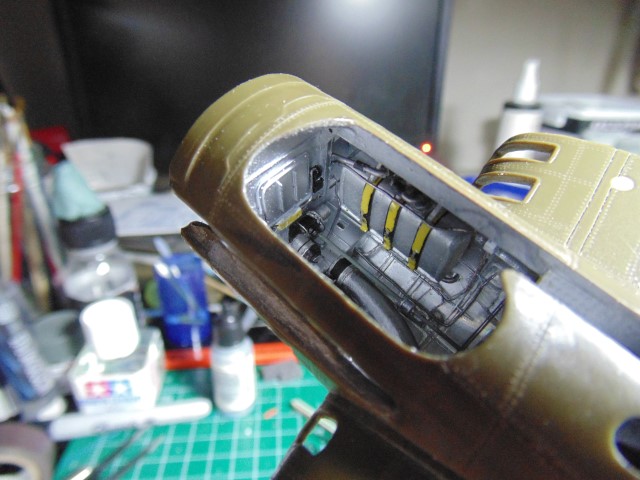

This picture is also interesting because the upper part of the long retracting strut is unsheathed. Compare it with the preceding real-thing photo.

Earlier I had asked, rhetorically, if this section of the landing gear mechanism was a "ballscrew." Here we can see that the answer is plainly "yes." From the prior real-thing photo, we can see that the ballscrew is covered by a two-part sheath or cover and that the lower part of the retracting strut goes inside the sheath when the gear is raised. (I think, I mean it has to, no??) More on this later.

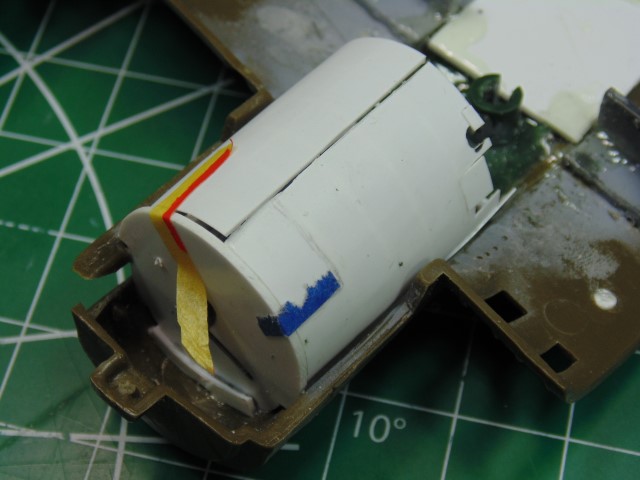

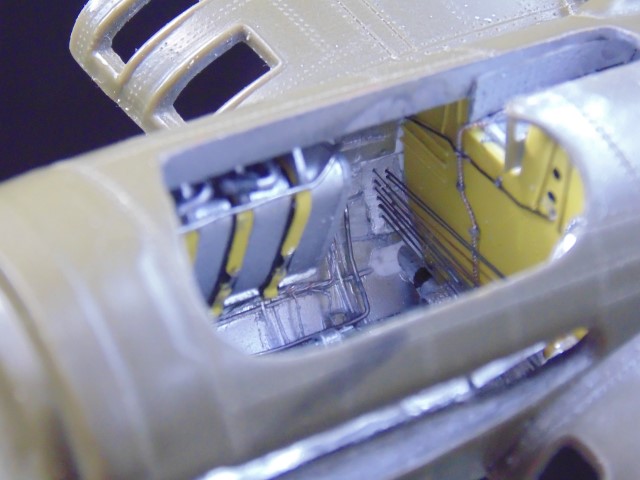

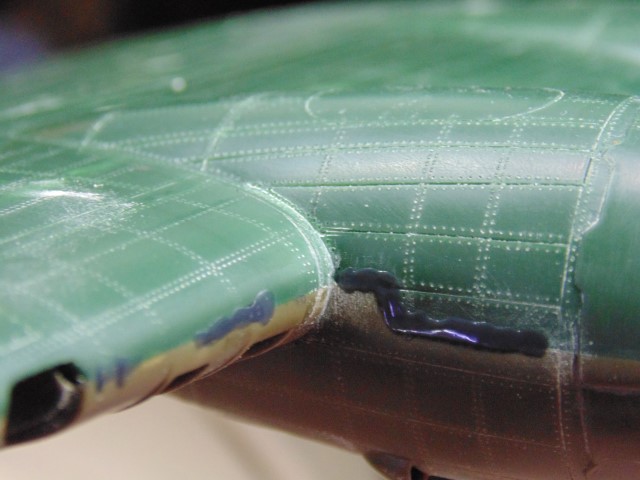

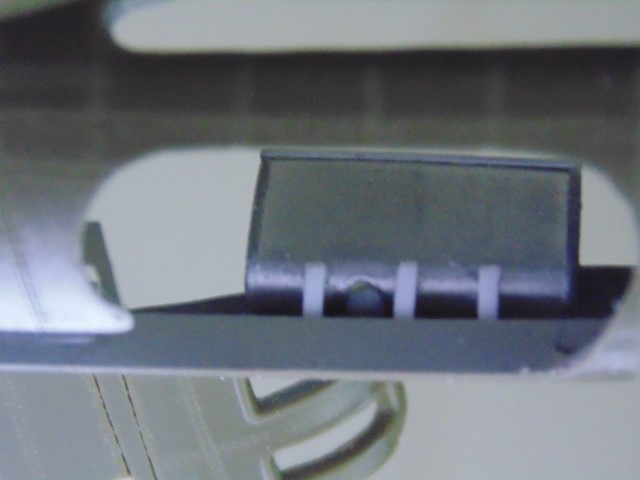

Let's return to the oil tank. Here you can see the "J" brackets fitted to it -- they are NOT finished or fully shaped yet. This is just to provide "a look."

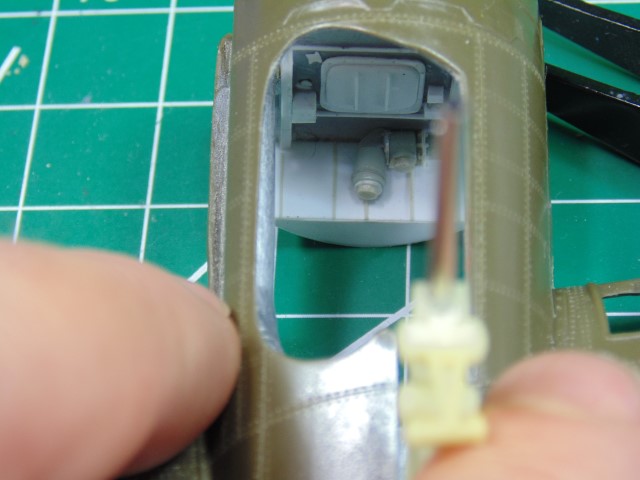

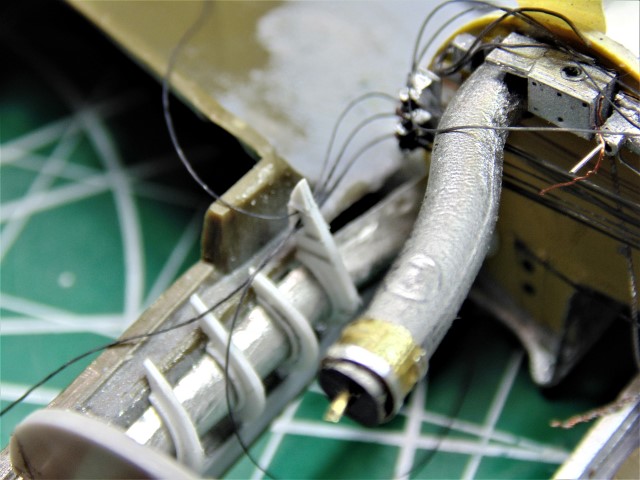

Here are two shots of the tank seated on the "J" brackets inside the nacelle.

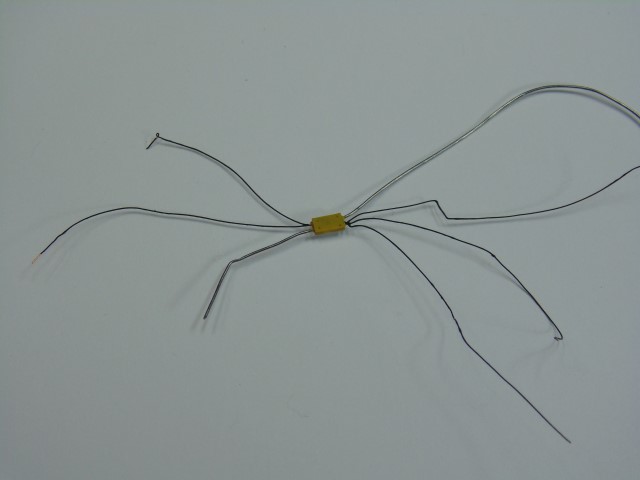

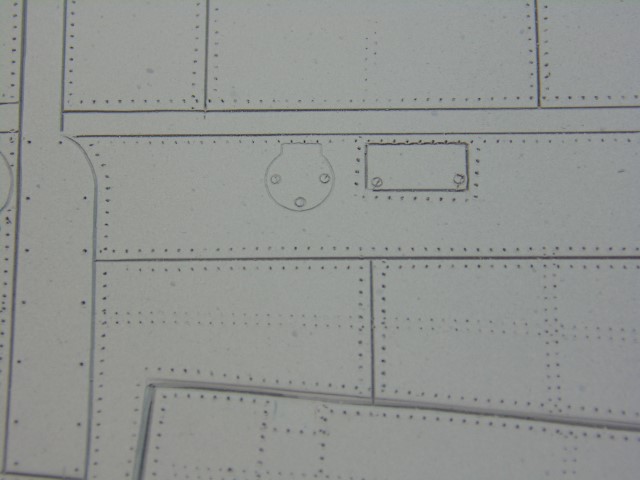

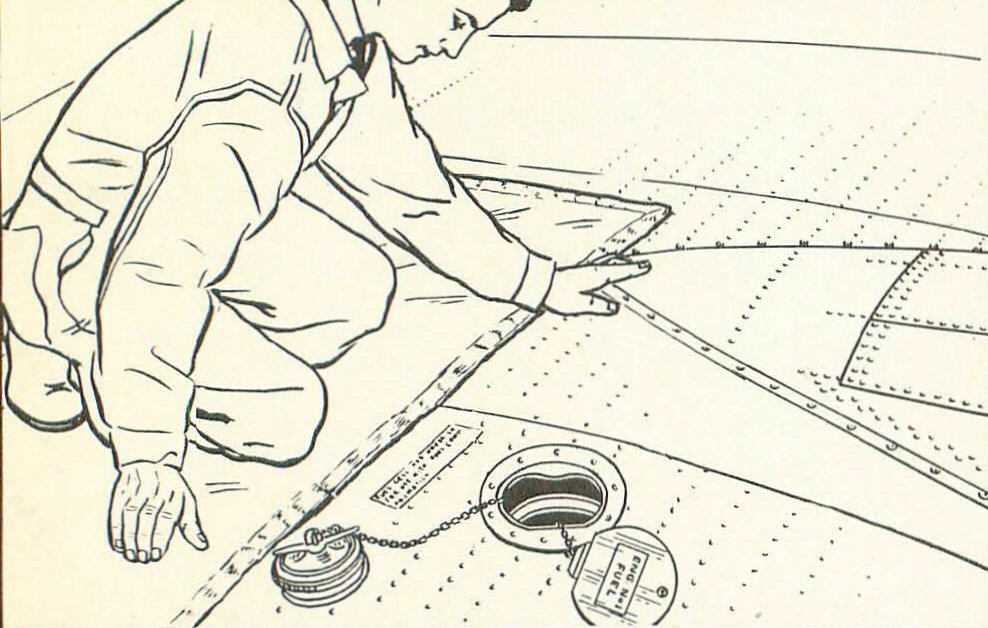

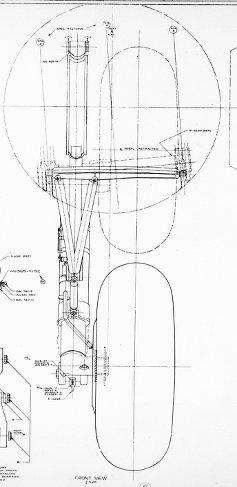

And now back to the landing gear retracting shafts. This diagram is courtesy of Karl (of course):

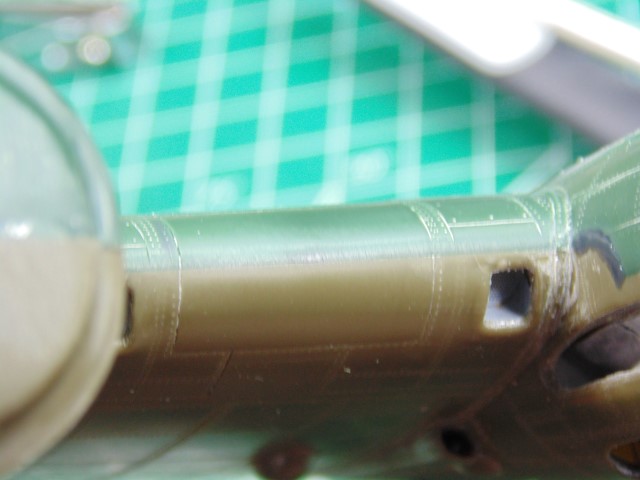

It took me a while to figure out where the three metal legs that H.G. scratch-built were going to interface with the kit parts.

A picture is worth a thousand words.

Man, oh man!

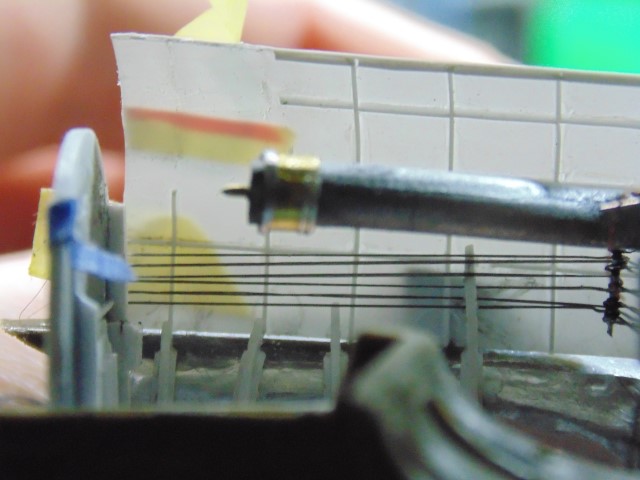

You see that H.G. is also thinning the plastic piece.

What a great way to start U.S. Labor Day Weekend!